Introduction: Navigating the Global Market for cnc mini wood lathe

In an increasingly competitive global market, sourcing a CNC mini wood lathe that meets both quality and cost-effectiveness is a significant challenge for B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe. As the demand for precision woodworking rises, businesses are tasked with finding reliable suppliers who can deliver machines that not only enhance productivity but also ensure the highest standards of craftsmanship. This comprehensive guide addresses these concerns by exploring the various types of CNC mini wood lathes available, their specific applications across different industries, and essential criteria for vetting suppliers.

From understanding the technical specifications to evaluating the cost implications, this guide empowers international buyers with the knowledge they need to make informed purchasing decisions. We delve into the intricacies of different models, including benchtop options suited for small workshops and larger, more advanced systems designed for commercial use. Additionally, we provide insights into the sourcing process, including tips on negotiating terms, assessing warranty offers, and ensuring compliance with international safety standards.

By the end of this guide, B2B buyers will be equipped with actionable insights that facilitate not only effective sourcing but also strategic investments in CNC technology that can drive growth and innovation in their respective markets.

Understanding cnc mini wood lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mini Benchtop Wood Lathe | Compact, entry-level, computer-controlled, suitable for small crafts | Arts and crafts, small-scale woodworking | Pros: Affordable, easy to use, versatile. Cons: Limited to small projects, lower durability. |

| CNC Wood Lathe | Advanced CNC capabilities, suitable for both round and square wood | Furniture making, stair parts fabrication | Pros: High precision, suitable for mass production. Cons: Higher initial investment, requires technical knowledge. |

| CNC Tabletop Lathe | Compact design, suitable for small workshops, versatile for various projects | Hobbyist crafts, small furniture items | Pros: Space-saving, user-friendly software. Cons: Limited power for heavy-duty tasks. |

| Multi-Function CNC Wood Lathe | Capable of turning, milling, and drilling operations | Custom woodworking, intricate designs | Pros: Multifunctional, enhances productivity. Cons: More complex setup, higher maintenance. |

| High-Speed CNC Wood Lathe | Fast processing speeds, designed for high-volume production | Industrial furniture manufacturing, mass production | Pros: Increased efficiency, cost-effective for large runs. Cons: Requires significant investment, larger footprint. |

What Are the Characteristics of a Mini Benchtop Wood Lathe?

Mini benchtop wood lathes are ideal for beginners and hobbyists, offering a compact design that fits easily on a tabletop. They are primarily used for crafting small items such as bowls, beads, and decorative pieces. B2B buyers should consider their ease of use and affordability, making them perfect for small businesses and artisans. However, their limitations in size and power may not suit larger production needs.

How Does a CNC Wood Lathe Stand Out in the Market?

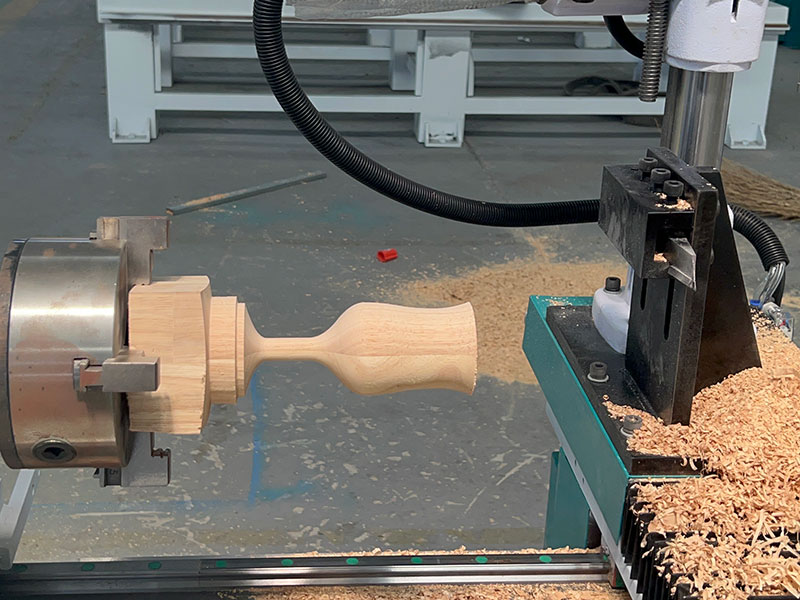

CNC wood lathes offer advanced capabilities for precision machining, making them suitable for industries like furniture making and stair parts fabrication. These machines can handle both round and square wood, allowing for diverse applications. B2B buyers should evaluate the investment against the potential for high-volume production and the need for skilled operators to maximize their functionality.

Why Choose a CNC Tabletop Lathe for Small Workshops?

CNC tabletop lathes are designed for small workshops and hobbyists, providing an excellent balance between size and functionality. They are user-friendly and can perform a variety of tasks, making them suitable for crafting small furniture items and artistic projects. Buyers should consider their space constraints and the versatility of these machines, although they may lack the power for more extensive operations.

What Are the Benefits of a Multi-Function CNC Wood Lathe?

Multi-function CNC wood lathes combine various machining capabilities, including turning, milling, and drilling. This versatility is particularly beneficial for custom woodworking and intricate designs. B2B buyers should assess their production needs, as these machines can significantly enhance productivity, though they may require a more complex setup and maintenance.

When Is a High-Speed CNC Wood Lathe the Right Choice?

High-speed CNC wood lathes are engineered for efficiency and high-volume production, making them ideal for industrial applications like furniture manufacturing. They provide rapid processing speeds that can reduce lead times. However, buyers must consider the substantial investment required and the larger footprint these machines occupy in a production facility.

Key Industrial Applications of cnc mini wood lathe

| Industry/Sector | Specific Application of cnc mini wood lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking Crafts | Production of intricate wooden crafts | High precision and customization capabilities | Ensure machine supports various wood types and designs |

| Furniture Manufacturing | Creating detailed furniture components | Enhanced production efficiency and quality control | Check for compatibility with specific wood materials |

| Jewelry and Accessories | Crafting wooden jewelry and decorative items | Ability to produce unique, high-value products | Sourcing for small-scale production requirements |

| Musical Instruments | Manufacturing wooden instrument parts | Precision in creating acoustically optimized parts | Verify material handling capabilities for specific woods |

| Home Décor and Gifts | Turning decorative items and personalized gifts | Increased market appeal through unique offerings | Focus on design flexibility and ease of operation |

How is CNC Mini Wood Lathe Used in Woodworking Crafts?

In the woodworking crafts sector, the CNC mini wood lathe is utilized to produce intricate wooden items such as bowls, vases, and decorative pieces. This application allows artisans to achieve high precision and repeatability, addressing common challenges like consistency in design and finish. Buyers from regions like Africa and South America may seek machines that can handle a variety of local hardwoods, ensuring that the lathe can accommodate diverse materials while providing the necessary technical support and warranty options.

What Role Does CNC Mini Wood Lathe Play in Furniture Manufacturing?

In furniture manufacturing, CNC mini wood lathes are employed to create detailed components like table legs and chair spindles. The precision of CNC technology allows manufacturers to streamline production processes, reducing waste and improving quality control. For international buyers, especially in Europe, it is crucial to source lathes that can work with specific materials and meet local safety standards, ensuring compliance with regulations while optimizing production efficiency.

How is CNC Mini Wood Lathe Beneficial for Jewelry and Accessories?

The jewelry and accessories industry leverages CNC mini wood lathes to craft unique wooden jewelry items, such as pendants and earrings. This application provides artisans with the ability to produce high-value, personalized products that appeal to niche markets. Buyers should consider sourcing lathes that offer customization capabilities and are compatible with various wood types, particularly those prized for their aesthetics and durability, to meet consumer demands effectively.

Why is CNC Mini Wood Lathe Essential for Musical Instruments?

In the musical instruments sector, CNC mini wood lathes are crucial for manufacturing components like wooden flutes and drum shells. The precision offered by these machines ensures that parts are acoustically optimized, which is vital for sound quality. International buyers should look for lathes that can handle specific types of hardwoods and provide reliable after-sales support, as the quality of materials directly affects the final product’s performance.

How Does CNC Mini Wood Lathe Enhance Home Décor and Gift Production?

CNC mini wood lathes are widely used in the production of decorative items and personalized gifts, such as custom wooden ornaments and home décor pieces. This application allows businesses to tap into the growing market for unique, handcrafted products. Buyers should focus on sourcing lathes that offer design flexibility and are user-friendly, enabling them to easily create a range of products that cater to diverse customer preferences.

3 Common User Pain Points for ‘cnc mini wood lathe’ & Their Solutions

Scenario 1: Navigating Sourcing Challenges for Quality CNC Mini Wood Lathes

The Problem: B2B buyers, especially in emerging markets like Africa and South America, often struggle with sourcing high-quality CNC mini wood lathes. There is a significant risk of encountering subpar machinery that does not meet production requirements, leading to increased downtime and financial losses. Buyers may find themselves overwhelmed by the myriad of suppliers, each claiming to offer the best products, making it difficult to discern which machines are truly reliable and cost-effective.

The Solution: To overcome sourcing challenges, B2B buyers should engage in thorough market research to identify reputable manufacturers and distributors. It is crucial to look for suppliers with a proven track record, positive customer testimonials, and certifications such as ISO or CE standards. Attending industry trade shows can provide direct access to manufacturers, allowing buyers to inspect machines firsthand and ask detailed questions about specifications and capabilities. Additionally, seeking out suppliers that offer extended warranties and comprehensive after-sales support can significantly mitigate the risks associated with purchasing. Buyers should also consider forming partnerships with local distributors who understand regional needs and can provide ongoing technical support.

Scenario 2: Difficulty in Understanding CNC Mini Wood Lathe Specifications

The Problem: Many B2B buyers lack the technical expertise to fully understand the specifications and functionalities of CNC mini wood lathes. This can lead to purchasing machines that do not fit their specific operational needs, whether it’s for crafting intricate wood pieces or producing larger batches of simpler items. Misunderstandings about capabilities such as turning diameter, processing precision, and compatible materials can result in costly mistakes and unsatisfactory production outcomes.

The Solution: To navigate this complexity, buyers should invest time in educating themselves about CNC technology and its applications in woodworking. Online resources, including webinars, tutorials, and manufacturer guides, can provide valuable insights into the specifications that matter most for their operations. Engaging with industry experts or consultants can also help clarify what features are essential based on specific production goals. When evaluating potential machines, buyers should create a checklist of critical specifications tailored to their needs, ensuring they prioritize factors like precision, motor power, and compatible materials. Furthermore, reaching out to suppliers for detailed demonstrations and obtaining machine samples can help in making informed decisions.

Scenario 3: Managing Operational Integration of CNC Mini Wood Lathes

The Problem: Integrating a new CNC mini wood lathe into existing production lines can pose significant challenges for B2B buyers. Issues such as compatibility with current software systems, training staff to operate new machinery, and ensuring that the lathe meets production demands can create friction during the transition phase. This can lead to reduced efficiency and output, as well as potential errors in production processes if not managed properly.

The Solution: To facilitate smooth operational integration, buyers should develop a comprehensive implementation plan before purchasing. This includes conducting a detailed analysis of existing workflows to identify how the new lathe will fit into the production process. Collaborating with suppliers who offer training programs can significantly help in upskilling staff and ensuring they are proficient in using the new machine. Additionally, investing in software that is compatible with both the lathe and existing systems can streamline operations and minimize disruptions. Regular feedback sessions with staff during the integration process can also help identify and resolve issues early, ensuring that the transition is as seamless as possible. By taking a proactive approach, businesses can maximize the potential of their new CNC mini wood lathe while maintaining high production standards.

Strategic Material Selection Guide for cnc mini wood lathe

What Are the Key Materials for CNC Mini Wood Lathes?

When selecting materials for CNC mini wood lathes, it’s crucial to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Below is an analysis of four common materials used in CNC mini wood lathes: aluminum, steel, cast iron, and composite materials.

How Does Aluminum Perform in CNC Mini Wood Lathes?

Aluminum is a lightweight and corrosion-resistant metal, making it a popular choice for CNC mini wood lathe components. Its excellent machinability allows for intricate designs and high-speed operations. The typical temperature rating for aluminum parts can withstand moderate heat, which is beneficial during prolonged use.

Pros: Aluminum is durable yet lightweight, which reduces overall machine weight and enhances portability. Its resistance to corrosion makes it ideal for humid environments, common in regions like the Middle East and parts of Africa.

Cons: While aluminum is generally cost-effective, high-grade alloys can be expensive. Additionally, it may not provide the same rigidity as heavier metals, which can impact precision in high-stress applications.

Impact on Application: Aluminum is suitable for crafting small, delicate items, such as jewelry or decorative pieces, where precision is paramount. However, it may not be the best choice for heavy-duty applications.

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM or DIN for aluminum quality. Preferences for specific aluminum alloys may vary by region, impacting procurement strategies.

What Role Does Steel Play in CNC Mini Wood Lathes?

Steel, particularly high-carbon steel, is renowned for its strength and durability. It can withstand high pressures and temperatures, making it suitable for heavy-duty applications. Steel components often have a longer lifespan compared to those made from softer metals.

Pros: Steel provides excellent rigidity and strength, essential for maintaining precision during machining. It is also relatively cost-effective compared to other high-strength materials.

Cons: The downside is that steel is heavier, which can affect the portability of CNC mini wood lathes. Additionally, it is susceptible to rust if not properly treated, necessitating regular maintenance.

Impact on Application: Steel is ideal for applications requiring high durability, such as furniture making or crafting sporting goods. Its strength allows for the machining of larger and more complex items.

Considerations for International Buyers: Buyers should ensure that steel components meet regional standards like JIS in Japan or EN in Europe. Availability may vary, affecting lead times and costs.

Why Choose Cast Iron for CNC Mini Wood Lathes?

Cast iron is often used for the base and frame of CNC mini wood lathes due to its inherent vibration-damping properties. This material can absorb vibrations during operation, ensuring smoother performance and improved accuracy.

Pros: The stability provided by cast iron enhances the precision of the lathe, making it suitable for intricate woodworking tasks. Its durability ensures long-term use without significant wear.

Cons: Cast iron is heavy, which can limit the portability of the lathe. It is also more brittle than other metals, making it susceptible to cracking under extreme stress.

Impact on Application: Cast iron is ideal for heavy-duty applications, such as turning large wooden pieces or producing furniture components. Its vibration-damping qualities make it particularly beneficial for precision work.

Considerations for International Buyers: Buyers should look for cast iron that complies with relevant standards, such as ASTM A48. The weight of cast iron may influence shipping costs, especially for international transactions.

How Do Composite Materials Enhance CNC Mini Wood Lathes?

Composite materials, such as fiberglass or carbon fiber, are increasingly used in CNC mini wood lathes for specific components. These materials offer a unique combination of strength, lightweight, and resistance to environmental factors.

Pros: Composites are highly resistant to corrosion and can be engineered for specific applications, providing flexibility in design. They also contribute to reduced weight, enhancing portability.

Cons: The manufacturing complexity of composites can lead to higher costs. Additionally, they may not be suitable for all applications, particularly where high temperatures are involved.

Impact on Application: Composites are ideal for crafting intricate designs and lightweight components, making them suitable for artistic woodworking projects. However, they may not replace metals in heavy-duty applications.

Considerations for International Buyers: Buyers should verify that composite materials meet industry standards for performance and safety. Understanding local preferences for materials is crucial for successful procurement.

Summary Table of Material Selection for CNC Mini Wood Lathes

| Material | Typical Use Case for cnc mini wood lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Jewelry, decorative items | Lightweight and corrosion-resistant | Less rigidity than heavier metals | Medium |

| Steel | Furniture making, sporting goods | High strength and durability | Heavier, rust-prone without treatment | Medium |

| Cast Iron | Heavy-duty applications, furniture parts | Excellent vibration damping | Heavy and brittle | Medium |

| Composite | Artistic projects, lightweight components | Corrosion-resistant and flexible | Higher manufacturing complexity | High |

This detailed analysis provides B2B buyers with essential insights into material selection for CNC mini wood lathes, enabling informed purchasing decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc mini wood lathe

What Are the Key Stages in the Manufacturing Process of CNC Mini Wood Lathes?

The manufacturing process of CNC mini wood lathes is a multi-faceted procedure involving several critical stages. Each stage contributes to the overall quality and performance of the lathe, ensuring it meets the specific needs of artisans, hobbyists, and small businesses.

Material Preparation: What Materials Are Used and How Are They Processed?

The foundation of any CNC mini wood lathe is its materials. Typically, high-quality steel and aluminum alloys are used for the frame and components to ensure durability and precision. The first step involves sourcing materials that meet international standards, which is crucial for ensuring that the finished product can withstand operational stresses.

Once materials are acquired, they undergo cutting, machining, and surface treatment. For instance, steel components may be cut using laser or water jet technology to ensure precise dimensions. Aluminum parts are often extruded or cast, followed by CNC machining to achieve the required specifications. This stage is vital, as it sets the groundwork for the lathe’s performance.

Forming: How Are Components Shaped for Precision?

The forming stage involves shaping the components of the lathe. This includes processes such as turning, milling, and drilling to create the various parts that make up the lathe, such as the headstock, tailstock, and bed. Advanced CNC machining centers are often employed to ensure high precision during this stage.

The use of computer numerical control technology allows manufacturers to achieve tight tolerances, typically within 0.01 mm, which is essential for the lathe’s accuracy. Additionally, this stage may involve heat treatment to enhance the mechanical properties of the steel, ensuring that it can endure long-term use without deformation.

Assembly: What Steps Are Involved in Putting the Lathe Together?

The assembly stage is where all the prepared components come together. Skilled technicians or automated systems assemble the individual parts, ensuring that each component fits correctly and functions as intended. Key components such as the motor, transmission systems, and control panels are integrated during this phase.

Quality checks are typically performed after initial assembly to identify any issues early on. This may include aligning the spindle and tailstock and ensuring that the drive system operates smoothly. Proper assembly is crucial, as any misalignment can lead to significant operational issues during the lathe’s use.

Finishing: How Is the Final Product Enhanced for Aesthetic and Performance?

Finishing processes are applied to enhance both the aesthetics and functionality of the CNC mini wood lathe. This may include powder coating, anodizing, or other surface treatments that provide corrosion resistance and improve the overall appearance of the machine.

Additionally, final adjustments are made to ensure that the lathe operates smoothly. This includes calibrating the control software and performing test runs to verify that all functions are working correctly. The finishing stage is essential for ensuring that the lathe is ready for immediate use upon delivery.

What Quality Assurance Standards Are Relevant for CNC Mini Wood Lathes?

Quality assurance is a critical aspect of manufacturing CNC mini wood lathes, as it ensures the final product meets both international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

For CNC mini wood lathes, ISO 9001 is a primary international standard that signifies a commitment to quality management systems. Compliance with ISO 9001 ensures that manufacturers adhere to consistent quality practices throughout their processes, from material sourcing to delivery.

Additionally, CE marking is crucial for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. For buyers in regions like Africa and South America, understanding local compliance requirements is also essential, as these may differ significantly from European standards.

What Are the Key Quality Control Checkpoints in CNC Mini Wood Lathe Manufacturing?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This is the initial inspection stage where raw materials are verified against specifications. All materials must meet predetermined quality criteria before they can proceed to the forming stage.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are performed to ensure that components are being produced according to specifications. This includes checking dimensional tolerances and functional tests on critical components.

-

Final Quality Control (FQC): Once assembly is complete, the entire lathe undergoes a final inspection and testing phase. This includes functional tests, performance assessments, and safety checks to ensure the machine operates correctly and safely.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of suppliers. Here are several effective strategies:

-

Conduct Supplier Audits: Regular audits help assess the manufacturer’s adherence to quality standards. During these audits, buyers can evaluate the production processes, quality control measures, and compliance with international standards.

-

Request Quality Assurance Documentation: Buyers should request documentation, such as quality control reports, certificates of compliance (e.g., ISO, CE), and test results. This documentation provides transparency and assurance regarding the quality of the products.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These services can conduct inspections at various stages of production and provide detailed reports.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of several nuances related to quality control when sourcing CNC mini wood lathes:

-

Understanding Regional Standards: Different regions may have specific quality and safety standards that products must meet. Buyers should familiarize themselves with these regulations to ensure compliance and avoid potential legal issues.

-

Cultural and Communication Considerations: Effective communication is crucial in international transactions. Buyers should establish clear expectations regarding quality standards and inspections to prevent misunderstandings.

-

Logistics and Delivery Quality: The quality of logistics and transportation can also impact product integrity. Buyers should evaluate suppliers’ logistics capabilities to ensure that products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance protocols associated with CNC mini wood lathes, B2B buyers can make informed decisions that enhance their operational capabilities and ensure product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc mini wood lathe’

In the competitive landscape of woodworking, sourcing a CNC mini wood lathe involves careful consideration and strategic planning. This guide provides a structured checklist to assist international B2B buyers in making informed procurement decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your technical requirements. Consider the types of projects you’ll be undertaking, including the materials and dimensions you’ll be working with.

– Key specifications to determine:

– Maximum turning diameter and length.

– Precision requirements (e.g., tolerance levels).

– Type of wood to be processed (e.g., hardwood vs. softwood).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in CNC mini wood lathes. Use online directories, industry forums, and trade shows to compile a list of candidates.

– Important factors to investigate:

– Supplier reputation in the market.

– Years of experience and expertise in CNC machinery.

– Client testimonials and case studies.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you consider possess relevant certifications that confirm their adherence to quality and safety standards.

– Look for certifications such as:

– ISO 9001 for quality management systems.

– CE marking for compliance with European safety standards.

– Any specific industry certifications relevant to your region.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include all specifications, pricing, and terms of sale.

– What to include in your request:

– Breakdown of costs (machine price, shipping, duties).

– Warranty and after-sales service terms.

– Lead times for delivery and installation.

Step 5: Assess After-Sales Support and Warranty Terms

Evaluate the after-sales support offered by the suppliers. Reliable support can significantly impact your operational efficiency, especially if you encounter issues post-purchase.

– Key aspects to consider:

– Availability of technical support (e.g., on-site assistance or remote troubleshooting).

– Length and coverage of warranty (especially on critical components).

– Availability of spare parts and service plans.

Step 6: Verify Logistics and Shipping Options

Understand the logistics involved in transporting the CNC mini wood lathe to your location. Efficient logistics can save time and reduce costs.

– Key considerations include:

– Shipping methods and associated costs.

– Import regulations and customs clearance procedures in your country.

– Insurance options for high-value machinery during transit.

Step 7: Conduct a Final Review and Make a Decision

Before finalizing your purchase, conduct a comprehensive review of all gathered information. Compare the suppliers based on quality, price, and service.

– Final checks should include:

– Confirming supplier contact details and responsiveness.

– Reviewing terms of payment and financing options.

– Trusting your instincts based on communication and overall professionalism.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing a CNC mini wood lathe, ensuring a wise investment that meets their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for cnc mini wood lathe Sourcing

What Are the Key Cost Components for Sourcing CNC Mini Wood Lathes?

When sourcing CNC mini wood lathes, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of wood and components used significantly impact the cost. High-quality alloys for cutting tools, durable electronic components, and robust frames can increase the overall expenditure. The choice between standard and premium materials can also affect the machine’s longevity and performance.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembly, and quality control. In regions with higher labor rates, such as Europe, this can be a significant portion of the total cost.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, equipment maintenance, and other indirect costs. Efficient production processes can help minimize these overhead costs.

-

Tooling: The initial investment in tools and dies necessary for production can vary widely. Custom tooling for specialized features or designs will add to the upfront cost.

-

Quality Control (QC): Implementing rigorous QC processes ensures the final product meets specifications. This involves testing and inspection, which can incur additional costs but is essential for maintaining product quality.

-

Logistics: Shipping costs, customs duties, and insurance can significantly impact the final price. Factors such as distance from the supplier and shipping method (air vs. sea) play a crucial role.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary based on market demand and competition, influencing the final price offered to buyers.

What Influences the Pricing of CNC Mini Wood Lathes?

Several factors can influence the pricing of CNC mini wood lathes:

-

Volume/MOQ: Larger orders often attract discounts due to economies of scale. Minimum order quantities (MOQ) can also affect pricing, with lower MOQs typically resulting in higher per-unit costs.

-

Specifications and Customization: Custom features or specifications can lead to higher costs. Buyers should evaluate whether the added features justify the price increase.

-

Materials: The choice of materials significantly impacts cost. Opting for premium materials can enhance performance but will increase the upfront investment.

-

Quality and Certifications: Products that meet international quality standards and certifications (like CE or ISO) may command higher prices due to perceived reliability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record may charge more for their products due to their proven quality and service.

-

Incoterms: The chosen shipping terms (e.g., FOB, CIF) can affect the total landed cost, impacting the final pricing structure for buyers.

How Can B2B Buyers Effectively Negotiate Prices for CNC Mini Wood Lathes?

Effective negotiation strategies can help B2B buyers secure favorable pricing:

-

Conduct Market Research: Understanding the market and comparing prices from multiple suppliers can provide leverage during negotiations.

-

Highlight Long-term Relationships: Emphasizing the potential for repeat business may encourage suppliers to offer better pricing.

-

Be Clear on Specifications: Clearly defining requirements can help prevent misunderstandings that might lead to additional costs.

-

Explore Payment Terms: Negotiating favorable payment terms can improve cash flow and may result in discounts.

What Should International Buyers Consider in the Total Cost of Ownership?

For international buyers, particularly from regions like Africa and South America, the Total Cost of Ownership (TCO) encompasses more than just the purchase price. It includes:

-

Operational Costs: Consider ongoing costs related to maintenance, tooling, and consumables.

-

Training: Factor in the cost of training staff to operate the CNC mini wood lathe efficiently.

-

Downtime: Assess potential downtime costs during maintenance or repairs, especially if parts need to be imported.

-

Logistical Challenges: Consider customs delays and additional fees associated with international shipping.

What Pricing Nuances Should Buyers in Europe and Other Regions Be Aware Of?

Buyers from regions such as Europe may face different pricing dynamics:

-

Currency Fluctuations: Be aware of how exchange rates can affect pricing when sourcing from countries with different currencies.

-

Regulatory Compliance: European buyers may need to ensure that products meet specific regulations, which could add to costs.

-

Cultural Considerations: Understanding local business practices and negotiation styles can facilitate smoother transactions.

Disclaimer on Indicative Prices

Prices for CNC mini wood lathes can vary widely based on the factors discussed. It’s essential for buyers to seek quotes tailored to their specific needs and to remain flexible in negotiations to achieve the best deal.

Alternatives Analysis: Comparing cnc mini wood lathe With Other Solutions

Exploring Alternatives to CNC Mini Wood Lathes for Woodworking Applications

When considering woodworking solutions, it’s essential to evaluate various options that can fulfill similar purposes as the CNC mini wood lathe. This analysis will compare the CNC mini wood lathe with two viable alternatives: traditional wood lathes and CNC routers. Each solution has its unique features, advantages, and limitations that may appeal to different segments of the B2B market.

| Comparison Aspect | CNC Mini Wood Lathe | Traditional Wood Lathe | CNC Router |

|---|---|---|---|

| Performance | High precision (0.01mm), ideal for intricate designs | Moderate precision, more manual control required | Versatile for various materials, not limited to wood |

| Cost | $2,800 – $3,100 | $1,000 – $2,500 | $2,000 – $5,000 |

| Ease of Implementation | User-friendly software, minimal setup | Requires skilled operator for manual setups | Requires software knowledge, more complex setup |

| Maintenance | Low, with lifetime support options | Moderate, dependent on use | Moderate to high, software updates required |

| Best Use Case | Small wood crafts, detailed work | Larger projects, artistic pieces | Large-scale production and complex designs |

What Are the Advantages and Disadvantages of Traditional Wood Lathes?

Traditional wood lathes offer a more hands-on approach, allowing skilled operators to create artistic pieces. The initial investment is typically lower than that of CNC mini wood lathes, making them accessible for smaller workshops or startups. However, they require a skilled operator to achieve precise results, which can limit efficiency and scalability. Moreover, manual operation can lead to inconsistencies, particularly in high-volume production scenarios.

How Do CNC Routers Compare to CNC Mini Wood Lathes?

CNC routers are versatile machines capable of handling various materials, including wood, plastics, and metals. They provide excellent flexibility for different types of designs and can perform multiple operations such as milling and engraving. However, they often come with a higher price tag and require more technical know-how for operation and software management. While they excel in larger-scale production and complex designs, they may not be as effective for intricate, small-scale woodwork that a CNC mini wood lathe specializes in.

Conclusion: Which Woodworking Solution is Right for Your Business?

Choosing the right woodworking solution hinges on understanding your specific business needs, including production volume, material types, and the level of craftsmanship required. For businesses focused on small, detailed wood crafts, a CNC mini wood lathe offers unmatched precision and ease of use. Conversely, if your operations require versatility across different materials and larger-scale production, investing in a CNC router may be more beneficial. Traditional wood lathes remain a viable option for artisan-level projects but may lack the efficiency needed for modern production demands. Ultimately, aligning your choice with your operational goals will ensure you invest wisely in the right technology.

Essential Technical Properties and Trade Terminology for cnc mini wood lathe

What Are the Key Technical Properties of CNC Mini Wood Lathes?

When considering a CNC mini wood lathe for your business, understanding its technical specifications is crucial for ensuring the machine meets your operational needs. Here are some essential properties:

1. Turning Diameter and Length

The turning diameter refers to the maximum diameter of the material that can be processed, while the turning length indicates the longest piece that can be accommodated. For instance, a lathe with a turning diameter of 100mm and a maximum turning length of 400mm is suitable for crafting a range of small items, such as vases or decorative pieces. This specification is vital for businesses that require versatility in their product offerings.

2. Processing Precision

Precision is a critical factor in woodworking, especially for intricate designs. A processing precision of 0.01mm ensures that the lathe can produce fine details and tight tolerances. This level of accuracy is essential for manufacturers aiming for high-quality finishes, which can significantly impact customer satisfaction and reduce material waste.

3. Motor Power and Whole Machine Power

The motor power, often measured in kilowatts (KW), directly influences the lathe’s performance and efficiency. For example, a CNC mini wood lathe with a motor power of 750W and a whole machine power of 1.5KW can handle various wood types and thicknesses effectively. Understanding these power ratings helps buyers select machines capable of sustaining their production demands without overheating or experiencing downtime.

4. Operating System and Software Compatibility

Most modern CNC lathes operate using specialized software, often compatible with formats like CAD and DXF. An efficient operating system allows for easy programming and design adjustments, which is essential for businesses that frequently modify designs or work on custom projects. This flexibility can lead to faster production times and improved adaptability to market demands.

5. Material Compatibility

CNC mini wood lathes are designed to work with various wood types, including hardwoods like mahogany and rosewood. Knowing the machine’s material compatibility helps businesses select the right lathe that aligns with their product line, ensuring optimal performance and output quality.

What Are Common Trade Terms Related to CNC Mini Wood Lathes?

Familiarizing yourself with industry terminology can enhance communication and decision-making processes. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC mini wood lathes, understanding OEM relationships can help buyers identify reliable suppliers and ensure they are purchasing high-quality machines and components.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is significant for businesses looking to manage inventory and costs effectively. Understanding MOQs can help buyers negotiate better terms and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific goods or services. For businesses purchasing CNC mini wood lathes, issuing an RFQ can ensure they receive competitive pricing and detailed information about machine specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in transactions. Familiarity with Incoterms helps businesses understand shipping arrangements, risk management, and cost allocation, which is crucial when sourcing equipment from international suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on timely production schedules, understanding lead times is essential for planning and inventory management.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting CNC mini wood lathes, ensuring they choose machines that meet their operational needs and align with industry standards.

Navigating Market Dynamics and Sourcing Trends in the cnc mini wood lathe Sector

What Are the Current Market Dynamics and Key Trends in the CNC Mini Wood Lathe Sector?

The CNC mini wood lathe market is experiencing robust growth driven by several global factors. Firstly, the increasing demand for personalized and custom-made wooden products in both consumer and industrial sectors is propelling manufacturers to adopt CNC technology for precision and efficiency. Regions like Africa, South America, the Middle East, and Europe are witnessing an upsurge in woodworking as a lucrative business opportunity. Particularly in countries such as Brazil and Germany, there is a significant push towards integrating advanced machinery to enhance production capabilities.

Emerging trends include a shift towards automation and smart manufacturing practices. The adoption of CNC technology not only improves production speed but also enhances product quality and consistency. International B2B buyers are increasingly seeking suppliers that offer machines with advanced features such as user-friendly interfaces, automated tool changers, and integrated CAD/CAM systems. Additionally, the rise of e-commerce platforms has made it easier for buyers to source CNC mini wood lathes from global suppliers, increasing competition and driving down prices.

Furthermore, the growing trend of DIY and artisanal crafts is fostering a market for smaller, more affordable CNC lathes that cater to hobbyists and small businesses. This trend is particularly pronounced in regions where craftsmanship and artisanal skills are valued, creating opportunities for suppliers to target niche markets.

How Is Sustainability Shaping Sourcing Practices for CNC Mini Wood Lathes?

Sustainability is becoming a critical consideration for B2B buyers in the CNC mini wood lathe sector. As environmental concerns rise globally, companies are increasingly prioritizing sustainable practices in their sourcing decisions. This shift is particularly relevant in regions like Europe, where stringent regulations and consumer preferences favor environmentally friendly products.

The environmental impact of sourcing materials for CNC wood lathes is significant. Buyers are encouraged to seek suppliers who utilize sustainably sourced wood and eco-friendly manufacturing processes. Certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are becoming essential for suppliers aiming to demonstrate their commitment to sustainability.

Moreover, the use of energy-efficient machinery and recyclable materials is gaining traction. Suppliers who can offer CNC mini wood lathes made from recycled components or those that incorporate energy-saving technologies are likely to appeal more to conscious buyers. This trend not only helps reduce the carbon footprint but also aligns with the growing consumer demand for ethical sourcing and corporate responsibility in the woodworking industry.

What Is the Evolution of CNC Mini Wood Lathes and Its Significance for Today’s Market?

The evolution of CNC mini wood lathes can be traced back to the early days of woodworking when manual lathes dominated the market. As technology progressed, the introduction of computer numerical control revolutionized the woodworking industry by enhancing precision and efficiency. Early CNC lathes were large, expensive, and primarily used in industrial settings. However, advancements in technology have led to the development of compact, affordable CNC mini wood lathes suitable for small workshops and individual artisans.

Today’s CNC mini wood lathes are equipped with sophisticated software that allows for intricate designs and complex operations, catering to both mass production and bespoke projects. This evolution not only democratizes access to advanced woodworking tools but also fosters creativity among artisans and hobbyists. As the market continues to expand, understanding this historical context can help B2B buyers appreciate the technological advancements and the potential applications of modern CNC mini wood lathes in various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc mini wood lathe

-

How do I choose the right CNC mini wood lathe for my business needs?

Selecting the appropriate CNC mini wood lathe involves assessing your specific woodworking projects, production volume, and budget. Consider the lathe’s specifications, such as turning diameter, length, and precision. Evaluate the materials you plan to work with, ensuring the lathe can accommodate them. Additionally, research suppliers’ reputation, warranty options, and after-sales support to ensure long-term reliability and service. -

What is the best CNC mini wood lathe for beginners?

For beginners, a mini benchtop CNC wood lathe with user-friendly controls and robust safety features is ideal. Look for models with comprehensive manuals and online support, like video tutorials. Brands that offer a one-year warranty and easy access to replacement parts are also preferable. Entry-level options like the STYLECNC STL0410 provide excellent features for hobbyists, including a compact design and versatile functionality for small projects. -

What are the minimum order quantities (MOQ) for CNC mini wood lathes?

MOQs for CNC mini wood lathes can vary significantly based on the supplier and region. Generally, manufacturers may set MOQs between 1 to 10 units for small-scale orders, while larger quantities can lead to discounts. It’s essential to discuss your specific requirements with potential suppliers to negotiate terms that suit your business needs, especially if you are looking to test the market with a smaller initial investment. -

What payment terms should I expect when purchasing CNC mini wood lathes?

Payment terms for CNC mini wood lathes typically include options such as a deposit upon order confirmation (often 30-50%) and the balance before shipment. Some suppliers may offer letters of credit or escrow services for added security. It’s advisable to clarify the payment methods accepted, including online options like PayPal or bank transfers, and ensure that they align with your financial processes. -

How can I ensure the quality of CNC mini wood lathes before purchase?

To ensure quality, request detailed product specifications, certifications (like CE), and samples if possible. Reviewing customer testimonials and case studies from previous buyers can provide insights into performance and reliability. Additionally, inquire about the supplier’s quality assurance processes, warranty terms, and after-sales service to ensure that you receive a machine that meets your operational standards. -

What are the shipping options for CNC mini wood lathes to international locations?

Shipping options for CNC mini wood lathes can vary, including air freight for faster delivery and sea freight for cost-effective bulk shipping. Discuss with suppliers about their logistics partners and delivery timelines. Ensure that they provide international shipping documentation, including customs clearance support and insurance options, to avoid delays and additional costs upon arrival in your country. -

Can I customize the features of a CNC mini wood lathe?

Many suppliers offer customization options to tailor CNC mini wood lathes to specific business needs. This may include modifications to size, motor power, or additional features like enhanced control systems or specialized tooling. Communicate your requirements clearly with potential manufacturers and request a detailed quote that reflects the customizations, including lead times and cost implications. -

What are the common applications of CNC mini wood lathes in various industries?

CNC mini wood lathes are versatile tools utilized across multiple industries, including crafts, furniture making, and jewelry design. They are ideal for producing intricate items such as decorative bowls, wooden toys, and custom furniture components. Understanding the applications relevant to your target market can help you leverage these machines effectively and cater to niche demands in woodworking and artisanal crafts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Cnc Mini Wood Lathe Manufacturers & Suppliers List

1. STYLECNC – Mini Benchtop Wood Lathe

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Mini Benchtop Wood Lathe for Small Wood Crafts & Arts

– Brand: STYLECNC

– Model: STL0410

– Price: $2,800 (Standard Edition) / $3,100 (Pro Edition)

– Stock: 360 Units available for sale every month

– Standards: CE Standards in terms of quality & safety

– Warranty: One-Year Limited Warranty for entire machine (Extended warranties available for major parts)

– Money Back Guarantee: 30-Day

– Technical …

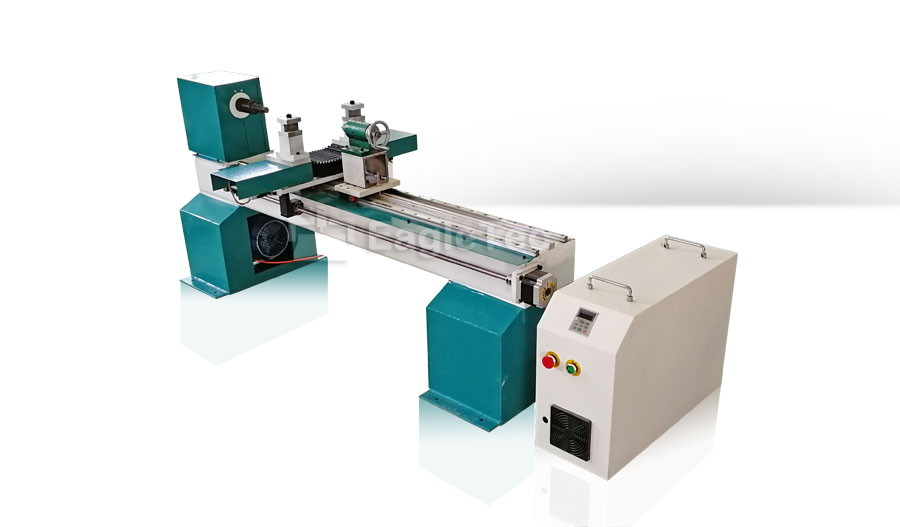

2. EagleTec – CNC Wood Lathes

Domain: eagletec-cnc.com

Registered: 2019 (6 years)

Introduction: CNC Wood Lathe for Sale with Affordable Price – EagleTec offers various models of CNC wood lathes including: 1. EA-TL1230SF – Fully Automatic Wood Lathe Machine with Auto Feed. 2. EA-TL1530T2 – Best CNC Lathe for Wood Balusters Fabrication, suitable for turning & fluting. 3. EA-T6015A – Mini Woodturning CNC for beads and furniture handles. 4. ET-TL1020PRO – Best CNC Wood Lathe for Baseball Bats. 5…

3. Sherline – 8 CNC Tabletop Lathe System

Domain: sherline.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “8” CNC Tabletop Lathe System”, “description”: “Perfect for customers looking for a mini CNC lathe to make small, precision parts. Made in the USA with high-quality precision capabilities for wood, plastic, aluminum, and steel.”, “included_components”: [“8″ tabletop lathe with two stepper motors”, “Computer with Ubuntu Linux-based OS and LinuxCNC 4-axis software”, “Keyboard and mo…

4. Woodcraft – Woodworking Lathes

Domain: woodcraft.com

Registered: 1995 (30 years)

Introduction: Woodworking Lathes – Benchtop Lathes – Mini Lathes

5. HITEC – Affordable CNC Wood Turning Lathe

Domain: hiteccnc.com

Registered: 2016 (9 years)

Introduction: Affordable CNC wood turning lathe machine for sale, HITEC HTL1530 CNC wood turning lathe with 4-axis slotting and carving, affordable mini CNC wood lathe machine with Jaw Chuck, suitable for making wood beads, wood bowls, wooden columns, affordable price CNC metal milling machine suitable for PCB, wood, Plexiglass, PVC, best 4-axis CNC wood turning lathe for engraving and carving on wood, affordab…

6. Catek – Cheap Mini CNC Wood Lathe

Domain: catekcnc.com

Registered: 2023 (2 years)

Introduction: Product Name: Cheap Mini CNC Wood Lathe – CK-0820

Maximum Processing Size: 800*200mm (length*diameter)

Price Range: $3,850.00 – $4,400.00

Key Features:

– Compact design suitable for users with limited space and budget.

– Reduces external dimensions while lowering the price by 20% compared to standard-sized lathes.

– Equipped with two symmetrical cutting tools for roughing and finishing in a singl…

7. Practical Machinist – Precision Wood Components

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 1. **Parts Specifications:**

– Peg: Diameter 0.540″, Length 1.157″, Quantity 500-1000 annually.

– Pin: Diameter 0.305″, Length 1.062″, Quantity 3000-6000 annually.

– Material: Hard heartwood (rosewood, ebony, cocobolo).

– Wood sourced from 3ft length boards, .100″ thicker than part diameter.

2. **Machine Options Considered:**

– Hobby lathes (Sherline / TAIG)

– Romi…

8. Tormach – 8L CNC Lathe

Domain: tormach.com

Registered: 2002 (23 years)

Introduction: Desktop/Tabletop CNC Lathes – Tormach

8L CNC Lathe: Perfect For Prototyping and Light Production

– Precision-crafted for prototyping and specialty manufacturing.

– Compact design with a footprint of 50in. x 26in.

– Operates on standard 120VAC 15A wall outlet.

Key Specs:

– Spindle Speed: 180 to 5,000 rpm

– Maximum Workpiece Length: 16 in.

– Maximum Swing Over Bed: 8 in. (200 mm)

– Maximum Swing O…

Strategic Sourcing Conclusion and Outlook for cnc mini wood lathe

In conclusion, strategic sourcing of CNC mini wood lathes presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the unique requirements of your target market—such as the demand for precision craftsmanship and the versatility of applications—can guide you in selecting the right equipment. By prioritizing quality, supplier reliability, and tailored solutions, businesses can enhance their operational efficiency and product offerings.

Investing in CNC mini wood lathes not only enables manufacturers to meet the growing consumer demand for custom wood products but also positions them competitively in the marketplace. With the ability to work with various materials and produce intricate designs, these machines serve as an invaluable asset for artisans, hobbyists, and small-scale manufacturers alike.

As you consider your sourcing strategy, remember to leverage global logistics and after-sales support to maximize your investment. Embrace the future of woodworking by exploring partnerships with reputable suppliers, ensuring your business remains at the forefront of innovation and quality in woodcraft. Take action now to equip your operations with the best CNC mini wood lathes available, paving the way for growth and success in your market.