Contents

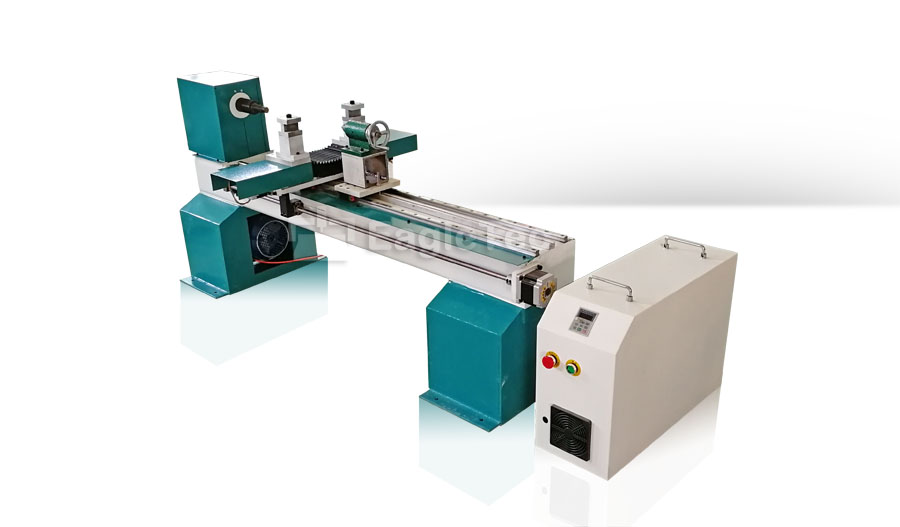

Manufacturing Insight: Cnc Mini Wood Lathe

Precision Wood Component Manufacturing with Honyo Prototype CNC Services

Honyo Prototype delivers advanced CNC machining solutions specifically engineered for high-fidelity wood components, leveraging specialized CNC mini wood lathes to achieve exceptional detail and repeatability. Our precision-focused approach transforms complex wood part designs—from intricate decorative elements to functional mechanical prototypes—into reality with consistent accuracy unattainable through manual methods. By integrating state-of-the-art CNC mini lathes with rigorous material science protocols, we ensure optimal toolpath strategies for delicate wood substrates, minimizing tear-out while maintaining sub-0.005mm tolerances critical for assembly-critical applications.

Our CNC mini wood lathe capabilities are supported by a comprehensive suite of complementary manufacturing services, enabling seamless production of multi-material assemblies. Whether producing small-batch artisan components or rapid functional prototypes, Honyo’s engineering team optimizes every parameter, including spindle speed, feed rate, and tool geometry, to preserve wood grain integrity and surface finish. Key technical specifications for our wood turning operations are summarized below:

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Max Workpiece Diameter | 150 mm | ±0.01 mm |

| Max Workpiece Length | 300 mm | ±0.02 mm |

| Material Compatibility | Hardwoods, Softwoods, Plywood, MDF | N/A |

| Typical Tolerance | ±0.005 mm | ISO 2768-m |

Beyond wood-specific machining, Honyo Prototype’s full-spectrum CNC services encompass multi-axis milling, turning, and finishing for metals, plastics, and composites, providing end-to-end manufacturing support for integrated assemblies. All processes are executed under ISO 9001-controlled workflows with real-time in-process inspection, ensuring dimensional compliance and material performance validation. For engineering teams requiring rapid validation of wood-turned concepts, our Online Instant Quote system delivers manufacturability feedback and competitive pricing within minutes—eliminating traditional quoting delays while maintaining technical rigor. Submit your STEP or IGES file today to accelerate prototyping cycles with Honyo’s precision wood machining expertise.

Technical Capabilities

Honyo Prototype provides advanced CNC mini wood lathes engineered for precision prototyping and small-part manufacturing. While primarily designed for wood, these machines are upgraded to support multi-axis milling and turning operations, enabling high-accuracy work on a range of engineering materials including aluminum, steel, ABS, and nylon. The integration of 3/4/5-axis control allows complex geometries with tight tolerances, making them suitable for both prototyping and low-volume production.

| Parameter | Specification |

|---|---|

| Machine Type | CNC Mini Wood Lathe with Multi-Axis Milling & Turning Capabilities |

| Axis Configuration | 3-Axis Standard, Optional 4-Axis Rotary Upgrade, 5-Axis Compatible Controller |

| Turning Diameter (Max) | 120 mm (4.7 in) |

| Turning Length (Max) | 300 mm (11.8 in) |

| Spindle Speed Range | 500 – 4,500 RPM (Variable Speed Control) |

| Milling Spindle Power | 800 W – 1.5 kW (ER20 Collet System) |

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Maximum Tolerance Achieved | ±0.01 mm (Tight Tolerance Applications) |

| Control System | CNC Controller with G-Code Support (LinuxCNC / Mach4 Compatible) |

| Tool Changing | Manual or Optional Automatic Tool Changer (ATC) for Milling Operations |

| Workholding | 3-Jaw Chuck, Faceplate, Tailstock; Compatible with Vacuum Fixturing |

| Compatible Materials | Hardwood, Softwood, Aluminum (6061, 7075), Mild Steel, ABS, Nylon, Delrin |

| Coolant Support | Optional Mist Cooling System for Metal Machining |

| Software Interface | CAD/CAM Ready (Supports Fusion 360, SolidWorks, Mastercam via Post Processing) |

| Machine Frame | Cast Iron or Reinforced Aluminum Alloy for Vibration Damping |

| Dimensions (L×W×H) | Approx. 800 × 400 × 500 mm |

| Weight | 75 – 100 kg |

This machine is ideal for hybrid turning-milling workflows, particularly in educational, prototyping, and precision woodworking environments. With proper tooling and setup, it supports tight-tolerance machining of both thermoplastics (ABS, Nylon) and light metals (aluminum, steel), enabling versatile use across engineering and design disciplines.

From CAD to Part: The Process

Honyo Prototype CNC Mini Wood Lathe Manufacturing Process

Our end-to-end workflow for CNC mini wood lathe production begins with a standardized digital intake and concludes with validated delivery. This process ensures precision, material suitability, and adherence to functional requirements specific to woodworking applications.

Upload CAD

Clients submit detailed 3D CAD models (STEP, IGES, or native SOLIDWORKS formats) via our secure portal. For mini wood lathes, we require complete assemblies including spindle components, headstock/tailstock geometry, bed alignment features, and mounting interfaces. Geometric dimensioning and tolerancing (GD&T) must specify critical alignment tolerances (e.g., spindle runout ≤ 0.02mm) and surface finishes for wood-contact surfaces. Incomplete submissions trigger an automated request for supplemental documentation within 2 business hours.

AI-Assisted Quoting

Our proprietary AI engine analyzes the CAD file against 12,000+ historical wood lathe projects to generate a preliminary quote within 4 business hours. The system evaluates material utilization (accounting for wood grain directionality and waste factors), machine time based on feature complexity (e.g., curved bed profiles vs. flat), and secondary operations like threading or knurling. Crucially, it flags common wood lathe pitfalls: undersized spindle diameters for torque requirements, inadequate bed rigidity tolerances, or non-optimized chip clearance geometries. A senior engineer validates all AI outputs before client submission.

DFM Analysis

A dedicated manufacturing engineer conducts a formal Design for Manufacturability review within 72 hours of quote acceptance. For wood lathes, this phase emphasizes:

Material suitability: Confirming hardwood species (e.g., beech, maple) meet stress requirements for rotational forces

Tolerance stack-up: Verifying cumulative tolerances across spindle, tool rest, and tailstock interfaces

Machinability: Assessing feasibility of deep recesses or thin-walled sections prone to vibration during woodturning

Assembly validation: Ensuring modular components align without shimming

Clients receive a marked-up DFM report with actionable recommendations, such as increasing fillet radii at stress points or adjusting pocket depths to prevent tear-out.

Production Execution

Approved designs move to our climate-controlled wood machining cell. Key production stages include:

Material preparation: Kiln-dried hardwood stock acclimatized for 72 hours at 8–10% moisture content

Precision milling: 5-axis CNC machining of critical components (bed, headstock) using carbide tooling optimized for wood

Spindle assembly: Dynamic balancing to ≤ 0.5 g·mm unbalance tolerance at 3,000 RPM

Surface treatment: Food-safe oil finishing on work surfaces; powder coating for structural elements

All mini lathe components undergo in-process metrology checks per ASME B5.54 standards, with spindle concentricity verified using laser alignment systems.

Quality Control & Delivery

Final validation includes functional testing under simulated load:

| Test Parameter | Acceptance Criteria | Verification Method |

|————————–|——————————-|——————————|

| Spindle runout | ≤ 0.03mm at 150mm from nose | Dial indicator @ 600 RPM |

| Bed flatness | ≤ 0.05mm over 500mm length | Granite surface plate + gauge|

| Vibration amplitude | ≤ 1.5 mm/s RMS | Accelerometer @ max speed |

| Thread engagement | Full torque without binding | Torque wrench + visual check |

Upon passing QC, units are crated with custom foam inserts protecting spindle noses and tool rest components. Shipping documentation includes alignment calibration certificates and moisture content reports. Standard lead time from CAD approval to delivery is 18 business days for quantities ≤ 25 units, with real-time logistics tracking provided.

This integrated approach ensures mini wood lathes meet both dimensional precision requirements and the operational demands of woodturning applications, minimizing field failures related to material behavior or assembly tolerances.

Start Your Project

Explore our precision CNC mini wood lathe, ideal for detailed woodworking and prototyping applications. Engineered for accuracy and efficiency, this compact lathe delivers consistent performance for small-scale production and hobbyist projects alike.

For inquiries and pricing details, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality output with fast lead times.

Contact Information

Name: Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

Let us support your next project with reliable, factory-direct solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.