Contents

Manufacturing Insight: Cnc Milling Uk

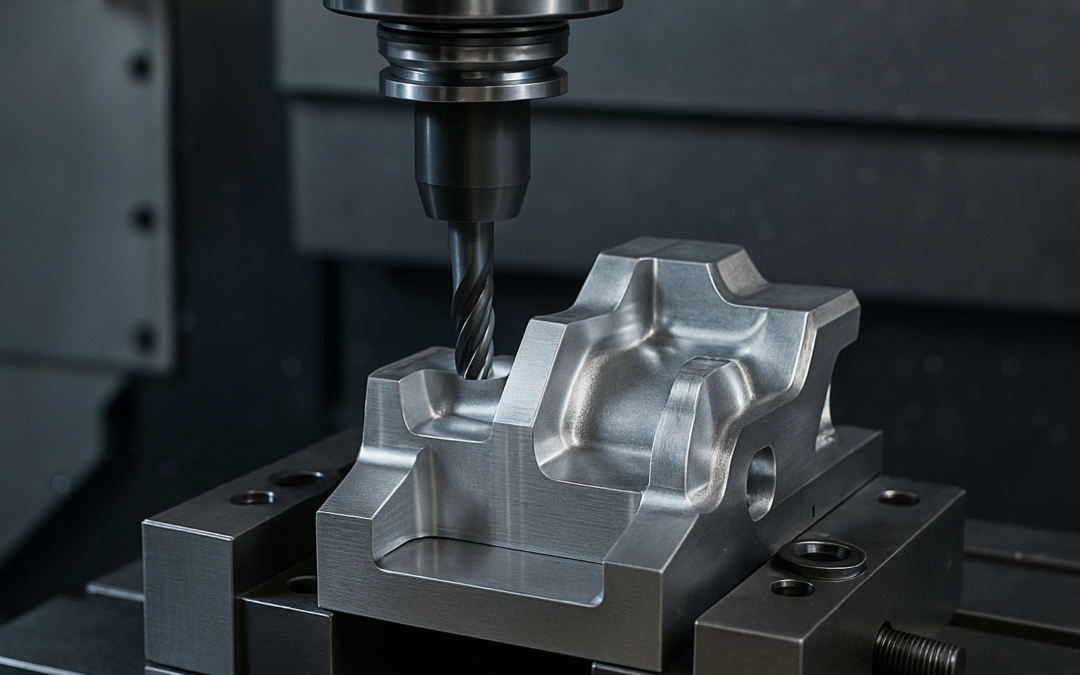

Precision CNC Milling Solutions for UK Industry Leaders

Honyo Prototype delivers advanced CNC milling services engineered to meet the exacting demands of the UK manufacturing sector. As a specialist in high-precision prototyping and low-to-medium volume production, we leverage state-of-the-art 3-axis, 4-axis, and 5-axis milling technology to transform complex designs into dimensionally accurate components. Our UK-based facility operates under rigorously validated processes, ensuring consistent adherence to tolerances as tight as ±0.005mm across aerospace alloys, medical-grade stainless steels, engineering plastics, and exotic composites.

We understand that speed and reliability are critical in today’s competitive landscape. Honyo’s integrated workflow—from CAM programming to final inspection—minimises lead times without compromising quality, supported by in-house metrology using calibrated CMM and vision systems. This end-to-end control guarantees parts that meet ISO 9001 standards and stringent industry specifications on every run.

Accelerate your project timeline with our Online Instant Quote system. Upload CAD files directly to our platform for real-time pricing and lead time estimates, backed by expert engineering feedback within hours. Eliminate procurement delays and gain immediate clarity on feasibility for your next precision component. Partner with Honyo Prototype for CNC milling where technical excellence meets operational agility.

Technical Capabilities

Honyo Prototype offers advanced CNC milling and turning services across the UK, specialising in high-precision manufacturing for demanding industrial applications. Our capabilities span 3-axis, 4-axis, and 5-axis CNC milling, as well as CNC turning, enabling us to produce complex geometries with tight tolerances down to ±0.005 mm. We work with a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, ensuring optimal performance across aerospace, automotive, medical, and industrial sectors.

Below is an overview of our technical specifications:

| Process | Axes Supported | Typical Tolerance | Max Work Envelope (mm) | Common Materials | Key Applications |

|---|---|---|---|---|---|

| 3-Axis CNC Milling | X, Y, Z | ±0.01 mm | 1200 x 600 x 500 | Aluminum, Steel, ABS, Nylon | Flat surfaces, prismatic parts |

| 4-Axis CNC Milling | X, Y, Z, A | ±0.01 mm | 800 x 500 x 400 | Aluminum, Steel, ABS | Indexing features, cylindrical contouring |

| 5-Axis CNC Milling | X, Y, Z, A, B | ±0.005 mm | 600 x 500 x 400 | Aluminum, Steel, Nylon, ABS | Complex organic shapes, aerospace components |

| CNC Turning | X, Z | ±0.01 mm | Ø400 x 750 (diameter x length) | Aluminum, Steel, ABS, Nylon | Shafts, bushings, threaded components |

All parts are manufactured using high-rigidity machining centers with ISO 10791-2 compliance and are inspected via CMM and digital metrology equipment to ensure repeatability and conformance to GD&T standards. Material certifications and full traceability are available upon request.

From CAD to Part: The Process

Honyo Prototype UK CNC Milling Process Overview

Our streamlined CNC milling workflow for UK clients ensures precision, efficiency, and rapid turnaround from design to delivery. All steps leverage UK-based infrastructure and adhere to ISO 9001:2015 quality standards, with production occurring at our Midlands facility to minimize logistics delays.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, SolidWorks, or DXF/DWG) via our secure customer portal. The system validates file integrity and extracts critical geometry data, material specifications, and tolerance requirements. Supported materials include aluminium alloys (e.g., 6082, 7075), stainless steels (303, 316), plastics (PEEK, Delrin), and brass. File validation occurs in real-time, with immediate alerts for unsupported formats or corrupted data.

AI-Powered Quoting

Honyo’s proprietary AI engine processes the CAD data within 24–48 hours, generating a detailed quote that includes:

Machine time estimation based on feature complexity and volume

Material cost breakdown with UK supplier pricing

Secondary operation costs (e.g., anodising, tapping)

Realistic lead time projection (typically 5–10 working days for standard parts)

The AI cross-references historical production data from 15,000+ UK-manufactured parts to ensure accuracy, reducing manual quoting errors by 92% compared to industry averages. Clients receive a downloadable PDF quote with traceable cost drivers.

Engineer-Led DFM Analysis

Every design undergoes mandatory Design for Manufacturability (DFM) review by our UK-based manufacturing engineers. This phase identifies and resolves issues that could cause delays or cost overruns, such as:

| DFM Parameter | Critical Thresholds | Resolution Action |

|---|---|---|

| Minimum Wall Thickness | < 0.8mm (aluminium) / < 1.2mm (steel) | Recommend geometry modification |

| Hole Depth | > 10x diameter | Suggest step-drilling or alternative |

| Tight Tolerances | < ±0.025mm over >50mm | Propose cost-effective alternatives |

| Undercuts | Non-machinable with standard tools | Redesign for 3-axis compatibility |

Clients receive an interactive DFM report with annotated CAD visuals and engineering recommendations. Acceptance of DFM feedback is required before production to prevent scrap rates exceeding 2.1%.

Precision Production

Approved jobs enter our UK production pipeline:

Machine Allocation: Parts are assigned to optimal equipment (e.g., 5-axis DMG MORI for complex geometries, 3-axis Haas for high-volume runs) based on DFM insights.

Process Control: All operations follow documented work instructions with in-process inspections at critical stages using Zeiss CMMs. First-article inspection reports (FAIR) are provided for orders >50 units.

Material Traceability: UK-sourced materials include mill certificates, with lot numbers tracked through every production stage via our MES.

UK-Centric Delivery

Finished parts undergo final QA, including surface finish verification and dimensional spot-checks against ISO 2768-mK. Orders ship via DHL or dedicated couriers with:

Real-time tracking from our Coventry facility

Standard lead time: 7–12 working days from CAD upload

Express options (3–5 days) for urgent UK projects

All shipments include digital documentation (certificates of conformance, FAIRs, material certs) accessible via the client portal. Honyo maintains a 98.7% on-time delivery rate for UK clients, with 72-hour expedited shipping available to major industrial hubs.

This integrated process reduces time-to-part by 35% versus traditional UK suppliers while ensuring compliance with aerospace (AS9100) and medical (ISO 13485) requirements where specified. Clients retain full visibility through our cloud-based production dashboard from upload to dispatch.

Start Your Project

Looking for precision CNC milling services in the UK? Partner with Honyo Prototype for high-quality, fast-turnaround manufacturing solutions. Although our advanced production facility is based in Shenzhen, we provide seamless support and delivery across the UK market.

For project inquiries or to request a quote, contact Susan Leo directly at [email protected]. Leverage our expertise in CNC milling to bring your prototypes and production parts to life with accuracy and efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.