Introduction: Navigating the Global Market for cnc milling software

Navigating the intricate landscape of CNC milling software can be a daunting challenge for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. With varying levels of technological maturity and industrial needs, sourcing the right CNC milling software that aligns with specific operational requirements is crucial for enhancing manufacturing efficiency and precision. This guide is designed to equip international buyers with comprehensive insights into the various types of CNC milling software available, their applications across different industries, and essential factors to consider when vetting suppliers.

From understanding the distinctions between CAD and CAM functionalities to exploring cost structures and licensing models, this guide empowers decision-makers to make informed purchasing choices. We delve into the latest innovations, highlight key players in the market, and provide actionable advice on integration and support services. By addressing common pain points and equipping buyers with the knowledge to navigate the complexities of sourcing CNC milling software, we aim to facilitate smoother procurement processes and foster long-term partnerships. Whether you are in Saudi Arabia, Brazil, or beyond, this guide serves as a valuable resource in your journey toward optimizing manufacturing operations through advanced CNC technology.

Understanding cnc milling software Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CAD/CAM Software | Integrates design and manufacturing processes; supports G-code. | Product design, prototyping, manufacturing. | Pros: Streamlined workflow, high precision. Cons: Can be costly and complex to learn. |

| Standalone CAM Software | Focused solely on toolpath generation; often less expensive. | Small-scale manufacturing, hobbyist projects. | Pros: Lower cost, easier to learn. Cons: Limited features compared to full suites. |

| Open-source Software | Free to use with community support; customizable. | Educational institutions, startups. | Pros: Cost-effective, flexible. Cons: Variable support quality, potential compatibility issues. |

| Specialized CNC Software | Tailored for specific industries or machine types (e.g., wood, metal). | Niche manufacturing sectors. | Pros: Optimized for specific tasks. Cons: May lack versatility for broader applications. |

| Cloud-based Solutions | Accessible from any device with internet; often subscription-based. | Remote teams, collaborative projects. | Pros: Easy access, collaborative features. Cons: Ongoing costs, dependent on internet connectivity. |

What Are the Characteristics of CAD/CAM Software?

CAD/CAM software serves as a comprehensive solution that combines computer-aided design (CAD) with computer-aided manufacturing (CAM). This type of software allows engineers to create intricate designs and directly translate them into machine instructions. It is particularly suited for industries requiring high precision and efficiency in production, such as aerospace and automotive. B2B buyers should consider the software’s compatibility with existing machinery, support for various file formats, and the learning curve associated with its use.

How Does Standalone CAM Software Differ?

Standalone CAM software focuses primarily on generating toolpaths and G-code from existing designs created in CAD software. It is often more affordable and easier to use, making it ideal for small manufacturers or hobbyists. While it provides essential functionality, buyers should evaluate whether the limited features will meet their operational needs, especially if they require advanced capabilities like simulation or integrated design.

Why Choose Open-source Software for CNC Milling?

Open-source CNC software is an attractive option for educational institutions and startups due to its zero-cost entry and community-driven support. These platforms allow users to customize the software to fit specific needs, fostering innovation. However, B2B buyers must weigh the potential for variable support quality and compatibility challenges, especially when scaling operations or integrating with other systems.

What Are the Benefits of Specialized CNC Software?

Specialized CNC software targets specific sectors, such as woodworking or metal fabrication, optimizing processes for those industries. These tools can enhance productivity and precision for niche applications. When considering a purchase, businesses should assess whether the software’s tailored features align with their production goals and whether it can adapt to changing industry demands.

How Do Cloud-based Solutions Enhance Collaboration?

Cloud-based CNC software allows teams to access design and manufacturing tools from any location, fostering collaboration among remote teams. This flexibility is especially beneficial for companies with multiple sites or those engaging in joint ventures. Buyers should consider the ongoing subscription costs and ensure that their internet infrastructure can support the software’s demands to avoid disruptions in workflow.

Key Industrial Applications of cnc milling software

| Industry/Sector | Specific Application of CNC Milling Software | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision Component Manufacturing | Enhanced accuracy and reduced waste in part production | Compatibility with high-precision CNC machines, software support for complex geometries |

| Automotive | Prototype Development for New Models | Faster time-to-market for new vehicle designs | Integration with CAD systems, ability to handle diverse materials |

| Medical Devices | Custom Surgical Instrument Fabrication | Tailored solutions leading to improved patient outcomes | Regulatory compliance features, material compatibility for sterilization |

| Electronics | PCB and Enclosure Production | Streamlined production processes and reduced lead times | Support for intricate designs, software adaptability for various CNC setups |

| Furniture Manufacturing | Custom Furniture Design and Production | Unique offerings leading to competitive advantage | Flexibility in design capabilities, cost-effectiveness of software options |

How is CNC Milling Software Used in the Aerospace Industry?

In the aerospace sector, CNC milling software is vital for manufacturing precision components such as turbine blades and fuselage parts. This software allows engineers to create intricate designs that meet stringent safety and performance standards. The primary challenge is ensuring that the software can effectively communicate with high-precision CNC machines, which often require specific configurations. International buyers should prioritize software that offers robust technical support and compatibility with various CNC controllers to ensure seamless integration into their manufacturing processes.

What Role Does CNC Milling Software Play in Automotive Prototype Development?

CNC milling software is instrumental in the automotive industry for developing prototypes of new vehicle models. By converting CAD designs into precise toolpaths, manufacturers can create components quickly and accurately, significantly reducing the time-to-market. The challenge lies in selecting software that can handle diverse materials and complex geometries, which are common in modern automotive design. Buyers should consider software that integrates well with existing CAD systems and offers flexibility in design modifications to adapt to evolving market demands.

Why is CNC Milling Software Essential for Medical Device Fabrication?

In the medical device industry, CNC milling software is used to fabricate custom surgical instruments tailored to specific procedures. This capability leads to improved patient outcomes by ensuring that instruments are designed for optimal functionality. However, manufacturers must navigate regulatory compliance requirements, making it crucial to choose software that includes features for documentation and validation. Buyers in this sector should also prioritize material compatibility to ensure that the final products can withstand sterilization processes.

How Does CNC Milling Software Benefit Electronics Manufacturing?

CNC milling software is widely used in electronics manufacturing for producing printed circuit boards (PCBs) and protective enclosures. The software facilitates the creation of intricate designs that are essential for modern electronic devices, streamlining production processes and reducing lead times. A key consideration for buyers is the software’s ability to adapt to various CNC setups and its support for complex design features. Additionally, compatibility with existing manufacturing systems is vital to ensure a smooth transition and efficient production.

What Advantages Does CNC Milling Software Offer in Furniture Manufacturing?

In the furniture manufacturing sector, CNC milling software enables the design and production of custom furniture pieces that stand out in a competitive market. This software allows for unique designs that can be produced at scale, providing businesses with a significant competitive advantage. Buyers should look for software that offers flexibility in design capabilities and cost-effectiveness, particularly in regions where budget constraints may be a concern. Ensuring that the software can handle both traditional and modern materials will also enhance production versatility.

3 Common User Pain Points for ‘cnc milling software’ & Their Solutions

Scenario 1: Difficulty in Integrating CAD and CAM Systems

The Problem: Many B2B buyers struggle with the integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems. This often leads to inefficiencies in the workflow, where designs created in one software do not seamlessly transfer to the other, resulting in wasted time and increased costs. For instance, an engineering firm may find that the designs crafted in their preferred CAD software are not compatible with their milling machines, necessitating time-consuming adjustments and manual interventions that can compromise precision.

The Solution: To overcome this integration challenge, B2B buyers should prioritize CNC milling software that offers robust compatibility features. When selecting software, look for solutions that explicitly advertise their ability to integrate CAD and CAM functionalities. Programs like Autodesk Fusion 360, which combines both CAD and CAM capabilities, can streamline workflows by enabling users to design and manufacture within a single platform. Additionally, conducting thorough research on software reviews and seeking out user testimonials can provide insights into integration capabilities. A trial period of the software before committing can also help assess its compatibility with existing systems.

Scenario 2: High Software Costs and Ongoing Maintenance

The Problem: The financial burden of investing in CNC milling software can be daunting for companies, especially small to medium-sized enterprises. The initial purchase price is only one aspect; ongoing costs for maintenance, updates, and potential subscription fees can accumulate rapidly, putting a strain on budgets. This scenario is particularly prevalent in regions with limited access to affordable software solutions, such as parts of Africa and South America, where companies may need to balance quality with cost.

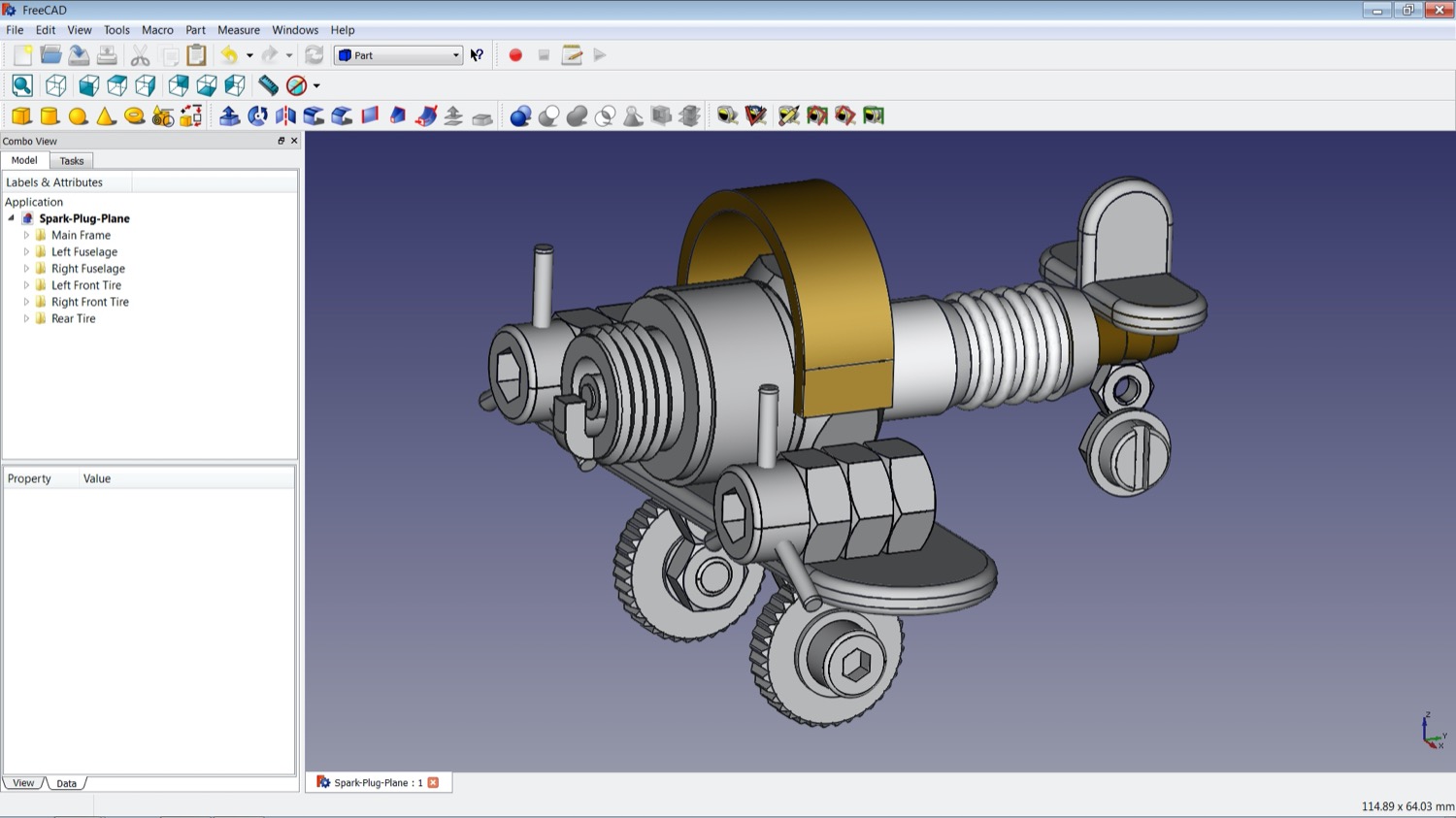

The Solution: To mitigate the financial impact, businesses should explore flexible pricing models and open-source software options. Some CNC milling software providers offer tiered pricing based on usage or company size, which can make budgeting more manageable. Additionally, leveraging open-source alternatives like FreeCAD can provide a cost-effective entry point into CNC milling without sacrificing essential features. Companies should also assess their long-term needs and consider investing in training for their staff to maximize the software’s potential, ensuring that they get the most value from their investment.

Scenario 3: Limited Technical Support and Training Resources

The Problem: A common pain point for B2B buyers is the lack of adequate technical support and training resources for CNC milling software. This is especially critical in regions where technical expertise is scarce, and the software’s complexity can be overwhelming for new users. For example, a manufacturing firm in the Middle East may invest in sophisticated milling software but struggle to find local training resources, leaving employees underprepared to utilize the software effectively.

The Solution: To address this issue, buyers should prioritize software vendors that offer comprehensive support and training options. Look for companies that provide extensive documentation, video tutorials, and live support channels. Many reputable vendors also offer training programs, either online or in-person, which can significantly enhance user competency. Additionally, joining user communities or forums can provide valuable peer support and insights. Engaging with local educational institutions to develop training workshops can also foster a skilled workforce capable of leveraging CNC milling software effectively.

Strategic Material Selection Guide for cnc milling software

What Are the Key Properties of Common Materials Used in CNC Milling Software?

When selecting materials for CNC milling applications, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials: Aluminum, Steel, Plastic, and Wood. Each material offers unique characteristics that can significantly impact the performance of CNC milling operations.

How Does Aluminum Perform in CNC Milling Applications?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It typically has a temperature rating of around 660°C and can withstand moderate pressure. The key advantage of aluminum is its durability and ability to be anodized for enhanced corrosion resistance, making it suitable for various applications, including automotive and aerospace components. However, its relatively higher cost compared to other materials can be a drawback, especially for large-scale projects.

From a B2B perspective, aluminum’s compatibility with common CNC milling software is beneficial for manufacturers aiming for precision in their designs. International buyers should consider compliance with standards such as ASTM B221 for aluminum extrusions, which is widely recognized in regions like Europe and North America.

What Are the Benefits and Limitations of Using Steel in CNC Milling?

Steel is renowned for its strength, durability, and versatility. It can handle high temperatures and pressures, making it suitable for heavy-duty applications. Steel’s key properties include high tensile strength and excellent wear resistance. While it is generally more affordable than aluminum, the complexity of machining steel can increase operational costs due to longer machining times and tool wear.

For international B2B buyers, the choice of steel grade is crucial. Standards such as ASTM A36 or DIN 17100 are commonly referenced. Buyers from regions like Saudi Arabia and Brazil should also be aware of local regulations regarding steel quality and sourcing.

How Do Plastics Compare in CNC Milling Applications?

Plastics, such as acrylic and polycarbonate, are increasingly popular for CNC milling due to their lightweight nature and ease of machining. They typically have lower temperature and pressure ratings than metals but offer excellent corrosion resistance. Plastics are generally less expensive, making them a cost-effective option for prototypes and low-volume production runs.

However, the primary limitation of plastics is their lower durability compared to metals, which can affect their suitability for high-stress applications. International buyers should consider compliance with standards like ASTM D638 for tensile properties, especially when sourcing materials from different regions.

What Role Does Wood Play in CNC Milling Software?

Wood is a traditional material used in CNC milling, particularly for furniture and decorative items. It is easy to machine and offers a unique aesthetic appeal. Wood’s properties vary significantly based on species, but it generally has a lower temperature and pressure rating compared to metals. While wood is often more affordable, its susceptibility to moisture and pests can limit its durability.

For B2B buyers, understanding local wood regulations and sustainability certifications is essential. Standards such as FSC (Forest Stewardship Council) certification are increasingly important in Europe and North America, reflecting a growing preference for sustainable sourcing.

Summary of Material Selection for CNC Milling Software

| Material | Typical Use Case for cnc milling software | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Higher cost compared to other materials | Medium |

| Steel | Heavy machinery, structural components | High strength and durability | Longer machining times increase costs | Medium |

| Plastic | Prototypes, low-volume production | Cost-effective and easy to machine | Lower durability than metals | Low |

| Wood | Furniture, decorative items | Aesthetic appeal and ease of machining | Susceptible to moisture and pests | Low |

This guide provides a strategic overview of material selection for CNC milling software, enabling international B2B buyers to make informed decisions based on their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc milling software

CNC milling software is crucial for modern manufacturing, enabling precision in the production of complex components. Understanding the manufacturing processes involved and the quality assurance (QA) measures in place can help B2B buyers make informed decisions. Below is an in-depth look at the stages of manufacturing and the critical quality assurance processes that should be considered.

What Are the Main Stages of Manufacturing for CNC Milling Software?

How Is Material Prepared for CNC Milling?

The manufacturing process begins with material preparation, which involves selecting the appropriate raw materials based on the specifications of the final product. Common materials used in CNC milling include metals such as aluminum, steel, and titanium, as well as plastics and composites. During this stage, materials are cut to size, and any necessary treatments (e.g., heat treatment) are applied to enhance their properties.

Proper material preparation is essential as it directly impacts the efficiency of the milling process and the quality of the final product. B2B buyers should ensure that suppliers provide detailed specifications and certifications for the materials used, verifying that they meet industry standards.

What Techniques Are Used in the Forming Stage?

The forming stage involves the actual CNC machining process, where the prepared materials are shaped into the desired components. This is achieved using various techniques, including:

- Milling: The primary technique for shaping materials through the rotation of cutting tools.

- Turning: Involves rotating the workpiece while a stationary cutting tool shapes it.

- Drilling: Creates holes in the material using rotating drill bits.

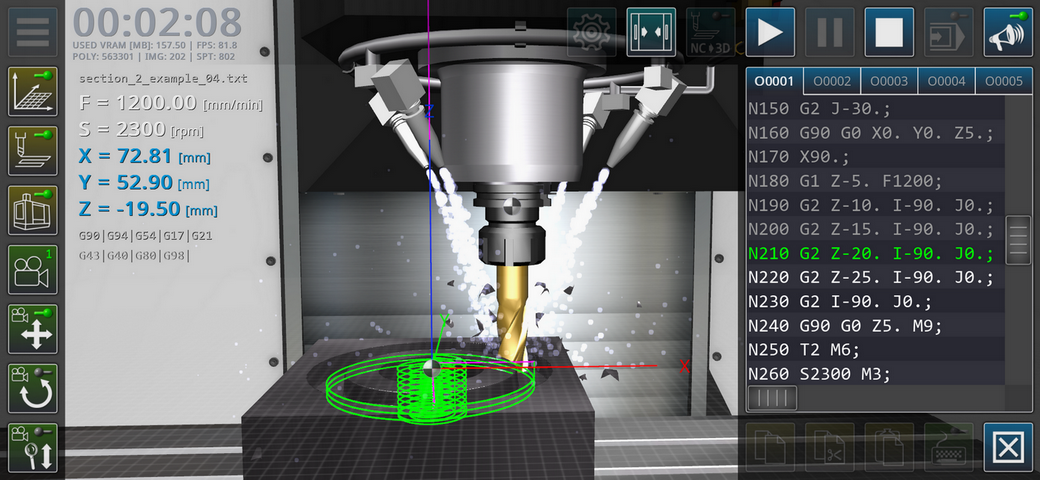

CNC milling software plays a critical role in generating the toolpaths that guide the CNC machines during this stage. Advanced software solutions integrate CAD and CAM capabilities, allowing for seamless transitions from design to machining.

How Does the Assembly Process Work?

Once the individual components are formed, they may need to be assembled into larger systems or products. This stage can involve manual assembly or the use of automated processes, depending on the complexity and scale of production. CNC milling software can assist in creating assembly instructions and simulations to ensure that components fit together correctly.

Effective communication between suppliers and buyers regarding assembly requirements is vital, especially for international transactions. Buyers should confirm that suppliers have the necessary capabilities to handle assembly and that they follow best practices in manufacturing.

What Finishing Techniques Are Commonly Employed?

Finishing is the final stage of the manufacturing process, where the components undergo treatments to improve their appearance and functionality. Common finishing techniques include:

- Deburring: Removing sharp edges and burrs from machined parts.

- Coating: Applying protective layers (e.g., anodizing, powder coating) to enhance corrosion resistance and aesthetics.

- Polishing: Improving surface finish for both functional and visual appeal.

The finishing process can significantly affect product quality, and buyers should ensure that suppliers can deliver the required finishing standards.

How Is Quality Assurance Implemented in CNC Milling Software Manufacturing?

What International Standards Should B2B Buyers Consider?

Quality assurance in CNC milling software manufacturing is often guided by international standards such as ISO 9001, which focuses on maintaining quality management systems across all stages of production. Compliance with these standards ensures that suppliers follow consistent processes that meet customer expectations.

Industry-specific certifications, such as CE marking for products sold in Europe or API standards for oil and gas equipment, may also apply. B2B buyers should inquire about these certifications to ensure compliance with relevant regulations in their regions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This is the initial inspection of raw materials and components to ensure they meet specified criteria before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify any deviations from the established standards.

- Final Quality Control (FQC): The final inspection occurs before products are shipped, ensuring that they meet quality and performance specifications.

B2B buyers should verify that suppliers implement these QC checkpoints as part of their quality management practices.

What Common Testing Methods Are Used?

Various testing methods are employed to assess the quality of CNC-milled components, including:

- Dimensional Inspection: Verifying that parts meet specified measurements using tools like calipers and micrometers.

- Material Testing: Ensuring that materials have the required properties through tensile, hardness, and fatigue tests.

- Functional Testing: Assessing whether the components perform as intended under real-world conditions.

Buyers should request detailed reports on testing methods and results to ensure the quality of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Can Be Taken to Assess Supplier Quality Assurance?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

- Conduct Audits: Regular audits of suppliers can provide insights into their quality management systems and manufacturing processes.

- Request Reports: Suppliers should provide documentation regarding their quality assurance processes, including certifications, inspection reports, and testing results.

- Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures.

What Nuances Should International Buyers Be Aware Of?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Buyers should ensure that their suppliers are not only compliant with international standards but also with any regional regulations that may apply to their products.

Moreover, communication is key. Buyers should establish clear expectations regarding quality standards and documentation requirements to avoid misunderstandings that could lead to delays or quality issues.

Conclusion

Understanding the manufacturing processes and quality assurance practices associated with CNC milling software is essential for B2B buyers. By being informed about material preparation, forming, assembly, and finishing techniques, as well as quality control measures, buyers can make more educated decisions when selecting suppliers. Implementing thorough verification processes will further ensure that the products meet the necessary standards, leading to successful international transactions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc milling software’

The following guide provides a structured approach for B2B buyers seeking to procure CNC milling software. This checklist will help ensure that you select a solution that meets your operational needs, budget, and future scalability.

Step 1: Define Your Technical Specifications

Before exploring software options, clearly define the technical requirements of your operations. Consider factors such as the types of CNC machines you use, the materials you work with, and the complexity of the parts you need to manufacture. This will guide your search and help you avoid software that lacks the necessary compatibility or features.

Step 2: Evaluate Software Capabilities

Assess the capabilities of potential CNC milling software. Look for features such as CAD/CAM integration, simulation capabilities, and support for multiple axis configurations (e.g., 3-axis, 4-axis, or 5-axis). Understanding these functionalities will help you determine which software aligns best with your production processes and efficiency goals.

Step 3: Consider User Experience and Support

The usability of the software is crucial for efficient operation. Investigate the user interface, ease of learning, and available training resources. Additionally, evaluate the level of customer support provided by the vendor, as this can significantly impact your team’s ability to resolve issues quickly and maintain productivity.

Step 4: Review Cost Structures and Licensing Options

Analyze the pricing models of different software solutions. Some may offer free versions with limited features, while others might require a significant investment. Understand any ongoing costs associated with support, updates, and subscriptions, as these can add up over time. Make sure the software’s pricing aligns with your budget while still meeting your needs.

Step 5: Request Demos and Trials

Before making a final decision, request demonstrations or trial versions of the software. This hands-on experience allows you to evaluate how well the software integrates with your existing systems and workflows. Pay attention to performance, ease of use, and whether it meets your specific operational requirements.

Step 6: Check for Compatibility with Existing Systems

Ensure that the CNC milling software can seamlessly integrate with your current CAD and CAM systems. Compatibility issues can lead to inefficiencies and increased costs. Look for software that supports common file formats and can communicate effectively with your CNC machines to streamline your operations.

Step 7: Gather Feedback from Current Users

Finally, seek feedback from current users of the software you are considering. Reach out to industry peers or consult online forums and reviews to gather insights on user experiences. Understanding how the software performs in real-world applications can provide valuable perspective and help mitigate risks associated with your purchase.

By following this checklist, B2B buyers can make informed decisions when sourcing CNC milling software, ensuring that their choice supports both immediate needs and long-term growth objectives.

Comprehensive Cost and Pricing Analysis for cnc milling software Sourcing

What Are the Key Cost Components in CNC Milling Software Pricing?

When sourcing CNC milling software, understanding the cost structure is crucial. The primary cost components include:

-

Materials: Software development involves various resources, including programming tools and platforms. The choice between commercial and open-source software can significantly impact costs, with proprietary solutions typically commanding higher prices due to development and support costs.

-

Labor: Development teams require skilled professionals, including software engineers and quality assurance testers. Labor costs vary widely depending on geographic location and expertise, with regions such as North America and Europe often facing higher labor costs compared to Africa and South America.

-

Manufacturing Overhead: This encompasses costs related to infrastructure, utilities, and administrative expenses. Established companies may have more efficient processes, potentially lowering overhead costs compared to startups.

-

Tooling: This refers to the tools and technology used to develop the software, including licenses for development environments, testing tools, and deployment frameworks. These costs can accumulate, especially for comprehensive solutions.

-

Quality Control (QC): Ensuring the software meets industry standards and user expectations requires rigorous testing. Companies may invest heavily in quality assurance processes to minimize bugs and enhance user experience.

-

Logistics: Although primarily a concern for physical products, logistics in software can relate to distribution channels and cloud hosting costs. The choice of deployment (cloud vs. on-premises) can influence the overall cost.

-

Margin: Software providers typically build a profit margin into their pricing. Understanding the market demand and competition will help buyers gauge whether the price reflects fair value.

How Do Price Influencers Affect CNC Milling Software Costs?

Several factors influence the pricing of CNC milling software, including:

-

Volume/MOQ: Purchasing software licenses in bulk can lead to significant discounts. Companies planning to scale operations should negotiate for volume pricing, especially if they foresee growth in their CNC capabilities.

-

Specifications/Customization: Custom features tailored to specific operations or industries often come at a premium. Buyers should assess whether the additional costs justify the potential efficiency gains.

-

Materials: The underlying technology stack can influence price. Software built on advanced, proprietary technologies may be costlier compared to those using open-source platforms.

-

Quality/Certifications: Software that complies with industry standards or possesses certifications may carry higher costs. However, such investments can lead to reduced long-term risks and enhanced reliability.

-

Supplier Factors: The reputation and reliability of the software provider can also affect pricing. Established brands might charge more due to their perceived value, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: For international transactions, understanding the agreed-upon Incoterms is crucial. They dictate who bears responsibility for costs and risks during shipping, which can indirectly impact overall software acquisition costs.

What Tips Can Buyers Utilize for Cost-Efficiency in CNC Milling Software Procurement?

To maximize value and minimize costs, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if planning a long-term partnership. Leverage potential future orders to negotiate better terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes initial software costs, maintenance, training, and potential downtime. This holistic view aids in making informed decisions.

-

International Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing strategies. Currency fluctuations, import tariffs, and local market conditions can significantly affect software prices.

-

Trial and Evaluation: Many software providers offer free trials. Taking advantage of these opportunities allows buyers to assess functionality and fit before committing financially.

-

Assessing Support and Upgrades: Determine if the pricing includes ongoing support and future upgrades. A slightly higher upfront cost may be justified if it includes comprehensive support services.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on numerous factors, including market conditions, software complexity, and geographical location. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing cnc milling software With Other Solutions

Introduction to Alternatives in CNC Milling Solutions

When evaluating CNC milling software, it’s crucial for B2B buyers to consider alternative solutions that may offer similar or complementary functionalities. These alternatives can provide different levels of performance, cost-effectiveness, and ease of integration into existing operations. Understanding the various options available allows businesses to make informed decisions that align with their specific manufacturing needs and capabilities.

Comparison Table

| Comparison Aspect | CNC Milling Software | Free CAD/CAM Software | Manual CNC Programming |

|---|---|---|---|

| Performance | High precision and automation | Varies; generally lower | High precision but time-consuming |

| Cost | $500 – $5,000+ (licensing) | Free to low-cost (e.g., $200) | Low (cost of labor only) |

| Ease of Implementation | Moderate; requires training | High; user-friendly for basic tasks | Low; requires skilled personnel |

| Maintenance | Regular updates and support | Community-driven support | Minimal, but skill-dependent |

| Best Use Case | Complex designs and mass production | Prototyping and small-scale production | One-off custom projects |

Detailed Breakdown of Alternatives

1. Free CAD/CAM Software

Free CAD/CAM software, such as FreeCAD or Carbide Create, presents a viable alternative for businesses looking to minimize costs. These tools often provide basic functionalities for design and toolpath generation without the financial burden of commercial software. While the performance can be adequate for less complex projects, users may encounter limitations in advanced features and support. Moreover, while ease of implementation is generally high, the learning curve may vary depending on the user’s technical expertise.

Pros: Cost-effective, accessible, suitable for prototyping.

Cons: Limited advanced features, variable performance, less comprehensive support.

2. Manual CNC Programming

Manual CNC programming involves writing the G-code by hand or using basic text editors to guide CNC machines. This method is often used for simple, one-off custom projects where the cost of software is not justified. While it allows for a high degree of control and precision, it is labor-intensive and requires skilled personnel familiar with CNC operations. Additionally, the time required to create and debug programs can delay production timelines.

Pros: Cost-effective for simple jobs, high control over processes.

Cons: Time-consuming, requires skilled labor, less efficient for mass production.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between CNC milling software and alternative solutions, B2B buyers should assess their specific production needs, budget constraints, and the complexity of their projects. For businesses focused on high-volume manufacturing with intricate designs, investing in robust CNC milling software may yield the best long-term benefits. Conversely, companies with simpler, low-volume requirements might find sufficient capabilities in free CAD/CAM software or manual programming. Ultimately, the choice should align with operational goals, available resources, and the desired level of precision and efficiency in the manufacturing process.

Essential Technical Properties and Trade Terminology for cnc milling software

What Are the Key Technical Properties of CNC Milling Software?

When evaluating CNC milling software, understanding specific technical properties is crucial for making informed purchasing decisions. Here are essential specifications to consider:

1. Material Compatibility

CNC milling software must support a range of materials, including metals, plastics, and composites. Each material has unique properties, such as hardness and thermal stability, which affect machining techniques and tool selection. For B2B buyers, selecting software that accommodates various materials ensures versatility and the ability to meet diverse client needs.

2. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. CNC milling software should enable precise control over tolerances, often expressed in micrometers. High tolerance levels are vital for industries like aerospace and medical devices, where even minor deviations can lead to product failure. Understanding tolerance capabilities helps buyers ensure their software can meet industry standards and customer expectations.

3. G-code Generation

G-code is the language used to control CNC machines. The software must efficiently generate G-code that matches the specific CNC machine’s requirements, including different configurations and control systems (e.g., Fanuc, Siemens). For B2B buyers, this ensures smooth communication between design and manufacturing processes, minimizing errors and downtime.

4. Post-Processing Capabilities

Post-processing refers to the software’s ability to adapt G-code for different machines and setups. A robust CNC milling software should offer configurable post-processors that can handle various machine types and tool setups. This flexibility is crucial for manufacturers who may operate multiple machines or need to switch between projects frequently.

5. Simulation Features

Advanced CNC milling software often includes simulation tools that allow users to visualize the machining process before execution. This feature helps identify potential issues, such as tool collisions or inefficient paths. For B2B buyers, simulation capabilities can significantly reduce material waste and operational costs by ensuring optimal machining strategies are employed.

What Are Common Trade Terms in CNC Milling Software?

Familiarity with industry terminology is essential for effective communication in the B2B landscape. Here are several key terms relevant to CNC milling software:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of CNC milling software, it indicates the source of the machine or software used in manufacturing processes. Understanding OEM relationships can help buyers gauge the reliability and support options available for their CNC systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For CNC milling software, knowing the MOQ can help buyers plan their budgets and production schedules effectively. This term is particularly relevant for businesses that may need to scale operations or invest in multiple licenses.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. In the CNC milling context, an RFQ can help businesses compare software options and negotiate better deals. Understanding the RFQ process can streamline procurement and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is crucial for B2B buyers in the CNC milling sector, as it clarifies shipping, risk management, and liability issues. This knowledge can lead to smoother transactions and fewer disputes.

5. CAM (Computer-Aided Manufacturing)

CAM software is used to automate the manufacturing process, generating toolpaths based on designs created in CAD software. Understanding the relationship between CAD and CAM is essential for buyers to ensure that their CNC milling software integrates seamlessly with design tools, optimizing the production workflow.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when selecting CNC milling software that aligns with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the cnc milling software Sector

What Are the Key Drivers Influencing the CNC Milling Software Market?

The CNC milling software market is experiencing robust growth, driven by the increasing demand for automation and precision in manufacturing processes. Global trends indicate a shift towards Industry 4.0, where interconnected machines and data analytics are becoming paramount. This evolution is particularly relevant for B2B buyers in regions like Africa, South America, the Middle East, and Europe, where advancements in manufacturing capabilities are essential for competitive positioning.

Moreover, the rise of additive manufacturing and the integration of CAD/CAM solutions are reshaping sourcing strategies. Buyers are increasingly looking for software that not only enhances operational efficiency but also integrates seamlessly with existing systems. As companies strive for flexibility in production, the demand for scalable and customizable CNC milling software is on the rise.

Emerging technologies such as artificial intelligence and machine learning are also influencing the market. These technologies enable predictive maintenance and optimize machining processes, which can significantly reduce downtime and operational costs. B2B buyers should consider software solutions that incorporate these technologies to stay competitive in an evolving marketplace.

How Is Sustainability Shaping the Sourcing of CNC Milling Software?

Sustainability is becoming an essential factor in the sourcing of CNC milling software and associated machinery. As environmental concerns grow, B2B buyers are increasingly prioritizing software solutions that facilitate eco-friendly manufacturing practices. This includes software that supports the use of recyclable materials and minimizes waste during the machining process.

The importance of ethical supply chains cannot be overstated, particularly in regions where regulatory frameworks are becoming stricter. Buyers are encouraged to seek software vendors who demonstrate a commitment to sustainability through certifications or initiatives that reduce their environmental impact. This could include the use of energy-efficient algorithms or software that optimizes toolpaths to reduce energy consumption.

Furthermore, as consumers globally become more environmentally conscious, businesses that adopt sustainable practices can enhance their brand reputation and gain a competitive advantage. Therefore, it’s imperative for international B2B buyers to not only consider the technical capabilities of CNC milling software but also its alignment with sustainability goals.

What Is the Evolution of CNC Milling Software?

The evolution of CNC milling software has been marked by significant technological advancements. Initially, CNC software was limited to basic command functions that operated machines with minimal automation. As manufacturing processes evolved, so did the software, leading to the development of sophisticated CAD/CAM solutions that integrate design and manufacturing workflows.

In the early 2000s, the advent of user-friendly interfaces and more powerful computing capabilities allowed for more complex designs and automated machining processes. Today, CNC milling software encompasses advanced features such as simulation, real-time monitoring, and data analytics, making it a critical component of modern manufacturing.

As we look to the future, the ongoing integration of artificial intelligence and machine learning will further revolutionize CNC milling software, enabling even greater efficiency and precision. For B2B buyers, understanding this evolution is crucial for making informed decisions on software investments that will drive their manufacturing capabilities forward.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc milling software

-

How do I solve compatibility issues between CNC milling software and my machines?

To address compatibility issues, first, identify the specific CNC machines and controllers you plan to use. Research the software’s compatibility with your machines, including the supported file formats (like G-code) and any necessary post-processors. If possible, consult with the software vendor for compatibility confirmations. Engaging in forums or user communities can also provide insights from other users who faced similar challenges. Finally, consider software that integrates CAD and CAM to streamline workflows and reduce compatibility issues. -

What is the best CNC milling software for small to medium-sized enterprises?

The ideal CNC milling software for small to medium-sized enterprises often combines affordability, ease of use, and robust features. Software like Autodesk Fusion 360 or FreeCAD can be excellent choices, as they offer comprehensive CAD/CAM capabilities at a relatively low cost. These platforms facilitate design, simulation, and toolpath generation, making them suitable for businesses looking to optimize their manufacturing processes without a significant upfront investment. Always consider trial versions to assess usability before committing. -

How can I ensure the software I choose meets my specific manufacturing needs?

To ensure the software meets your manufacturing needs, start by clearly defining your operational requirements, including the types of materials, CNC operations (milling, turning, etc.), and complexity of parts. Evaluate software features such as toolpath generation, simulation capabilities, and integration with existing CAD systems. Engage with vendors for demonstrations and ask for case studies relevant to your industry. Additionally, consider user reviews and feedback from similar businesses to gauge the software’s effectiveness in real-world applications. -

What factors should I consider when vetting CNC milling software suppliers?

When vetting suppliers, consider their industry reputation, customer service quality, and support offerings. Check for certifications, customer testimonials, and case studies that demonstrate successful deployments. Evaluate their responsiveness and willingness to provide training or technical assistance. Additionally, assess the availability of regular updates and upgrades to ensure long-term software viability. Lastly, inquire about their experience with international clients, particularly in your target regions, to gauge their understanding of local needs. -

What are the typical payment terms for CNC milling software purchases?

Payment terms can vary widely depending on the supplier and the software package. Most vendors offer options such as upfront payment, installment plans, or subscription models. It’s crucial to understand the total cost of ownership, which may include initial purchase, ongoing support, and upgrade fees. Negotiate terms that fit your budget, and inquire about discounts for long-term commitments or bulk purchases. Always review the terms carefully to avoid unexpected costs in the future. -

Are there minimum order quantities (MOQ) for CNC milling software licenses?

Typically, CNC milling software does not have a minimum order quantity like physical products do. However, some vendors may offer volume licensing discounts if you are purchasing multiple licenses for a larger team. It’s advisable to discuss your specific needs with the supplier to explore any available packages or discounts for bulk purchases. Additionally, inquire about any restrictions on license transferability, especially if your company scales or changes operations. -

What quality assurance processes should I implement when using CNC milling software?

Implementing quality assurance (QA) processes involves establishing a systematic approach to monitor and evaluate the output from your CNC operations. Start by developing standard operating procedures (SOPs) for design verification, toolpath simulation, and post-processing checks. Regularly calibrate your CNC machines and conduct routine maintenance to ensure precision. Utilize software features that allow for simulation and error checking before machining. Document all QA processes to facilitate continuous improvement and compliance with industry standards. -

How do logistics and support work for international buyers of CNC milling software?

Logistics for international buyers often involve digital delivery of software, minimizing shipping concerns. However, ensure the supplier offers robust technical support that can accommodate different time zones and languages. Investigate the availability of remote training sessions and online resources for troubleshooting. Additionally, confirm that the software complies with any local regulations or standards in your region. Establishing a clear line of communication with your supplier is essential for smooth operations and support.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Cnc Milling Software Manufacturers & Suppliers List

1. Autodesk – Fusion CNC Machining Software

Domain: autodesk.com

Registered: 1989 (36 years)

Introduction: CNC machining software from Autodesk, specifically Autodesk Fusion, integrates CAD and CAM functionalities to optimize manufacturing processes. It allows users to refine milling projects and generates toolpaths for CNC machines, controlling their motion and behavior. Key features include:

– Compatibility with various CNC machines and controllers (e.g., Heidenhain, Siemens, Fanuc).

– Support for di…

2. Fusion 360 – Recommended CAD/CAM Software

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Fusion 360 – Recommended CAD/CAM Software, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Vectric – Cut2D

Domain: vectric.com

Registered: 2005 (20 years)

Introduction: Vectric offers powerful and easy-to-use design software for CNC machining, including:

1. **Cut2D**:

– Easy to use vector drawing and editing software.

– Powerful 2D machining strategies for CNC routing, milling, or engraving.

– Available for a monthly subscription equivalent over 2 years.

2. **VCarve**:

– Built on the same interface as Cut2D.

– Adds 2.5D decorative carving strat…

4. Carbide 3D – Free CNC Software Options

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: Free CNC Software options include:

1. **FreeCAD**: A free 3D CAD parametric program suitable for complex designs. Outputs STL, STEP, SVG, or DXF. Runs on Mac, Windows, and Linux.

2. **Solvespace**: A freeware 3D CAD program better for mechanical parts. Exports STL or STEP files. Runs on Mac, Windows, and Linux.

3. **Inkscape**: A free 2D design software for CNC machining, exports SVG and DXF fi…

5. Easel – All-in-One CNC Software Solution

Domain: easel.com

Registered: 1997 (28 years)

Introduction: Easel is an all-in-one CNC software solution designed for design and CNC machining. Key features include:

1. **Design Tools**: Create stunning and functional designs with tools tailored for artisans and professionals. Access a design library with over 3 million designs and a customizable font library with 300+ fonts.

2. **Carving Capabilities**: Import STL files for 3D carving, achieve perfect cu…

6. Probotix – CNC Software Solutions

Domain: probotix.com

Registered: 2006 (19 years)

Introduction: CNC Software for Probotix CNC Routers includes features such as easy-to-use interface, compatibility with various file formats, and advanced control options. It supports G-code generation, toolpath simulation, and offers customization for specific machining needs. The software is designed to enhance productivity and precision in CNC operations.

7. SainSmart – CNC Routers and Laser Engravers

Domain: sainsmart.com

Registered: 2011 (14 years)

Introduction: CNC Software available at SainSmart.com includes various products related to CNC and engraving, such as CNC routers, laser engravers, and milling bits. The site features a range of CNC machines like the Cubiko 4040-PRO MAX and PROVerXL 4×4, along with laser engravers like Kiosk 2.5W~10W and Falcon A1 10W. Accessories include laser upgrade parts, spindle and stepper motors, extension kits, spoilboa…

8. MachSupport – Mach4-Industrial

Domain: machsupport.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”Mach4-Industrial”,”description”:”Completely new software with less than 1% of the programming code in common with Mach3. Written from the ground up to be expandable, flexible, and extremely responsive for use with very large files.”,”price”:”$1,400.00″},{“name”:”Mach4-Hobby”,”description”:”Completely new software with less than 1% of the programming code in common with Mach3….

Strategic Sourcing Conclusion and Outlook for cnc milling software

As the global landscape of CNC milling software continues to evolve, strategic sourcing emerges as a critical factor for B2B buyers aiming to enhance operational efficiency and competitiveness. By understanding the diverse software options available—from comprehensive CAD/CAM solutions like Autodesk Fusion to free alternatives—organizations can tailor their procurement strategies to meet specific manufacturing needs. Prioritizing compatibility, scalability, and support will empower buyers to optimize their workflows and maximize the return on investment.

In regions such as Africa, South America, the Middle East, and Europe, the demand for high-quality CNC milling software is on the rise. Buyers should leverage this opportunity to explore partnerships with reputable software providers that can deliver both technical expertise and customer support. Engaging in thorough market research and considering trial versions will facilitate informed decisions, ensuring that the chosen software aligns with business objectives.

Looking ahead, the future of CNC milling software is bright, with continuous advancements promising greater precision and integration. International B2B buyers are encouraged to take proactive steps today to secure the software solutions that will drive their manufacturing success tomorrow. Embrace innovation, invest strategically, and position your business for growth in the competitive manufacturing landscape.