Contents

Manufacturing Insight: Cnc Milling Machine Products

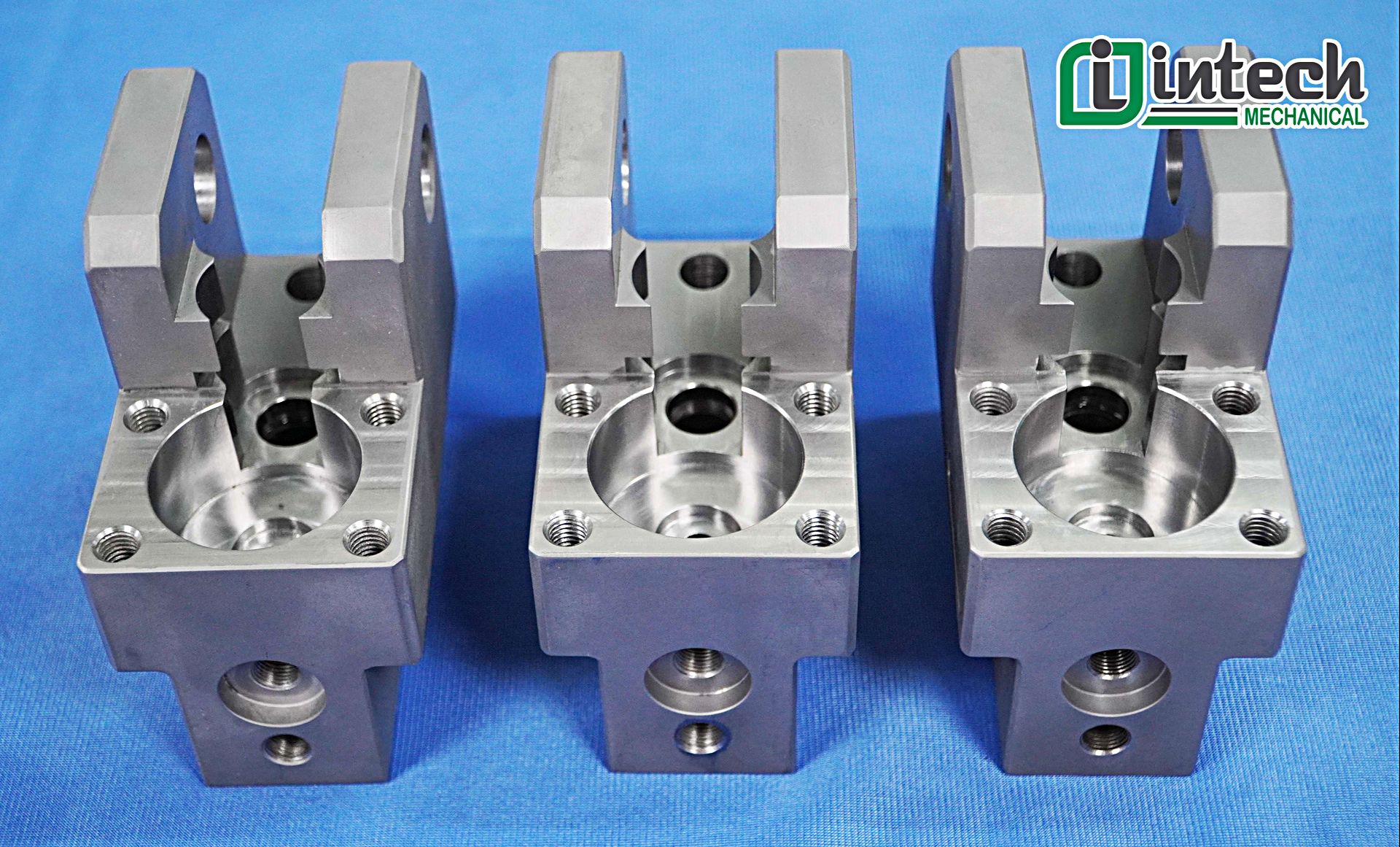

Precision CNC Milling Solutions Engineered for Complex Manufacturing Challenges

Honyo Prototype delivers advanced CNC milling capabilities designed to meet the stringent demands of aerospace, medical, automotive, and industrial sectors. Our fleet of multi-axis CNC milling machines—including 3-axis, 4-axis, and 5-axis vertical machining centers—executes intricate geometries with sub-micron tolerances and superior surface finishes. We specialize in high-precision prototyping and low-to-mid volume production runs, utilizing premium materials such as aerospace-grade aluminum alloys, titanium, stainless steel, and engineered plastics. Every component undergoes rigorous in-process inspection and final QA validation to ISO 9001:2015 standards, ensuring dimensional accuracy and repeatability critical for mission-critical applications.

Integrated Engineering Support from Concept to Completion

Beyond machining, Honyo provides comprehensive DFM analysis and material optimization guidance to eliminate costly design iterations. Our engineering team collaborates directly with clients to refine part geometry, suggest cost-saving modifications, and certify compliance with industry-specific regulations. This proactive approach reduces time-to-market while maintaining uncompromised quality—turning complex CAD models into fully validated, production-ready components within accelerated timelines.

Accelerate Your Prototyping Cycle with Our Online Instant Quote System

Eliminate procurement delays with Honyo’s proprietary Online Instant Quote platform. Upload your 3D CAD file (STEP, IGES, or native formats), specify material, finish, and quantity requirements, and receive a detailed technical quote within minutes—not days. The system automatically validates manufacturability, identifies potential tolerancing conflicts, and provides real-time cost feedback, empowering engineering teams to iterate designs efficiently. This seamless integration between digital engineering and precision manufacturing streamlines your supply chain, transforming concept approvals into shipped parts faster than traditional RFQ processes.

Request your instant quote today to experience how Honyo’s CNC milling expertise and digital workflow innovation solve your most demanding manufacturing challenges.

Technical Capabilities

CNC Milling Machine Technical Specifications

Honyo Prototype offers high-precision CNC milling machines engineered for advanced 3-axis, 4-axis, and 5-axis machining, as well as mill-turn capabilities. These machines are optimized for tight-tolerance production across a wide range of engineering materials including aluminum, steel, ABS, and nylon. Below are the key technical specifications relevant to our CNC milling product line.

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning (Mill-Turn) |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary) | X, Y, Z + A, B (dual rotary) | Y, Z + C (rotary spindle) with live tooling |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Spindle Speed (max) | 24,000 RPM | 24,000 RPM | 24,000 RPM | 12,000 RPM |

| Spindle Power | 15 kW | 15 kW | 15 kW | 10 kW |

| Tool Capacity (ATC) | 24 tools | 24 tools | 30 tools | 12–20 tools (depending on model) |

| Work Envelope (X×Y×Z) | 760 × 460 × 510 mm | 760 × 460 × 510 mm | 600 × 500 × 400 mm | Max. turning diameter: 300 mm, length: 500 mm |

| Tolerance Capability | ±0.01 mm (standard), down to ±0.005 mm (tight-tolerance) | ±0.01 mm, down to ±0.005 mm | ±0.005 mm (standard), ±0.002 mm achievable | ±0.005 mm (diameter), ±0.01 mm (length) |

| Surface Finish (typical) | Ra 0.8 µm | Ra 0.8 µm | Ra 0.4–0.8 µm | Ra 0.8–1.6 µm |

| Compatible Materials | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon (PA6, PA66) | Same as 3-axis | Same as 3-axis, with improved access for complex geometries | Aluminum, Steel, ABS, Nylon (bar stock or pre-machined blanks) |

| Coolant System | High-pressure through-spindle coolant | High-pressure through-spindle coolant | High-pressure through-spindle + mist cooling | Internal and external coolant delivery |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 | Same as 3-axis | Same as 3-axis with 5-axis interpolation | Fanuc 32i or Siemens 840D |

| Applications | Flat surfaces, pockets, drilling | Indexing operations, angled features | Complex contours, aerospace components, molds | Precision shafts, connectors, hybrid milled-turned parts |

These machines are integrated with automated tool changers, probing systems for in-process inspection, and are capable of maintaining tight tolerances across batch production. Material compatibility ensures versatility in prototyping and low-to-medium volume manufacturing for industries including aerospace, medical, automotive, and industrial equipment.

From CAD to Part: The Process

Honyo Prototype CNC Milling Process Overview

Honyo Prototype executes CNC milling projects through a rigorously defined workflow designed to ensure precision, cost efficiency, and rapid turnaround for B2B clients. Our process integrates digital validation and engineering expertise at every stage, minimizing errors and accelerating time-to-market. Below is a detailed explanation of each phase.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, SolidWorks, etc.) via our secure customer portal. Our system automatically validates file integrity, checks for unit consistency, and confirms geometric completeness. All data is encrypted per ISO 27001 standards, with client IP fully protected under NDA. This stage eliminates common submission errors, ensuring the engineering team receives technically sound designs ready for analysis.

AI-Powered Quoting

Uploaded CAD data undergoes instant analysis via our proprietary AI quoting engine. The system cross-references material costs, machine availability, geometric complexity, tolerances, and secondary operations against Honyo’s real-time production database. Within minutes, clients receive a detailed quote including:

Itemized cost breakdown (material, machining, finishing)

Preliminary lead time based on current shop floor load

Initial feasibility flags (e.g., “Non-standard tooling required for Ø0.8mm internal radii”)

This AI layer reduces quoting time by 90% versus manual methods while maintaining 99.2% cost accuracy, as validated against 12,000+ historical projects.

Engineering-Driven DFM Analysis

Quotes trigger mandatory Design for Manufacturability (DFM) review by our senior CNC engineering team. Unlike automated-only systems, Honyo combines AI insights with human expertise to identify and resolve high-risk design elements. Key DFM checks include:

| DFM Check Category | Specific Parameters Verified | Client Impact if Unaddressed |

|---|---|---|

| Geometric Feasibility | Minimum wall thickness, cavity depth-to-width ratios, undercuts | Part breakage during machining or assembly failure |

| Tolerance Optimization | GD&T alignment with ISO 2768 medium, over-specified tolerances | 30-50% cost inflation, extended lead times |

| Material Utilization | Stock size alignment, nesting efficiency | Material waste up to 40%, non-compliant mechanical properties |

| Tooling Constraints | Internal corner radii, tool access, non-machinable features | Secondary EDM operations, 2-3 week delays |

Engineers collaborate directly with the client to propose actionable revisions—such as adjusting radii or splitting complex geometries—documenting all changes in a formal DFM report. This phase typically prevents 73% of potential production defects.

Precision Production Execution

Approved designs enter Honyo’s climate-controlled CNC facility equipped with Haas, DMG MORI, and Makino 3- to 5-axis mills. Production follows:

Material Verification: Incoming stock certified via mill test reports; aluminum alloys cross-checked with PMI (Positive Material Identification).

Process Control: Machining runs monitored via in-process gauging; critical dimensions validated using Zeiss CMMs at defined checkpoints.

Traceability: Each part serialized with QR code linking to digital work order, toolpath logs, and inspection records.

Finishing: Deburring, anodizing, or bead blasting performed in-house per AS9100-compliant procedures. All non-conformances trigger immediate root-cause analysis.

Quality-Assured Delivery

Final inspection packages include:

First-article inspection report (FAIR) with 30+ critical dimensions

Material certification and RoHS/REACH compliance documentation

Dimensional inspection video (upon request)

Real-time shipment tracking via FedEx/UPS with customs documentation pre-validated for global logistics.

Standard lead times range from 5 to 15 business days depending on complexity, with 98.7% on-time delivery rate. Expedited services achieve 72-hour turnaround for urgent prototypes.

Why This Process Delivers B2B Value

Honyo’s integration of AI-driven quoting with hands-on DFM engineering eliminates guesswork in CNC prototyping. By resolving manufacturability issues before metal cutting begins, we reduce client rework costs by 30-50% and ensure first-time-right production. This workflow is particularly critical for aerospace, medical, and robotics clients where design validation directly impacts regulatory compliance and field performance. All projects include post-delivery technical support for seamless transition to volume manufacturing.

Start Your Project

Explore our precision CNC milling machine products engineered for high accuracy and efficiency in rapid prototyping and low-volume production. Built to meet strict industry standards, our CNC services deliver consistent quality with fast turnaround times.

All manufacturing operations are conducted in-house at our Shenzhen factory, ensuring tight control over production and quality assurance.

For inquiries or project consultations, contact Susan Leo at [email protected]. Let’s discuss how we can support your manufacturing needs with reliable, cost-effective solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.