Introduction: Navigating the Global Market for cnc milling machine for aluminium

In the competitive landscape of global manufacturing, sourcing the right CNC milling machine for aluminum can pose significant challenges for B2B buyers. With the increasing demand for precision and efficiency, international buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate an intricate web of supplier options and machine specifications. This guide aims to demystify the complexities involved in selecting aluminum CNC milling machines by covering essential aspects such as types of machines, their applications, and key factors in supplier vetting.

Throughout this comprehensive resource, we will explore the various categories of CNC milling machines tailored for aluminum, including desktop models ideal for prototyping and industrial-grade machines designed for high-volume production. We will also delve into the applications of these machines across diverse industries, from aerospace to automotive, highlighting how each sector can benefit from advanced machining capabilities. Furthermore, we will provide insights into the cost structures associated with these machines, allowing you to make informed financial decisions.

By equipping you with actionable knowledge and strategic insights, this guide empowers international B2B buyers to confidently assess their needs, evaluate potential suppliers, and ultimately invest in CNC milling machines that enhance operational efficiency and product quality in their manufacturing processes.

Understanding cnc milling machine for aluminium Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-Speed CNC Milling Machines | Up to 60,000 RPM spindles, optimized for aluminum machining | Aerospace, automotive, electronics | Pros: Fast cycle times, superior surface finishes. Cons: Higher initial investment. |

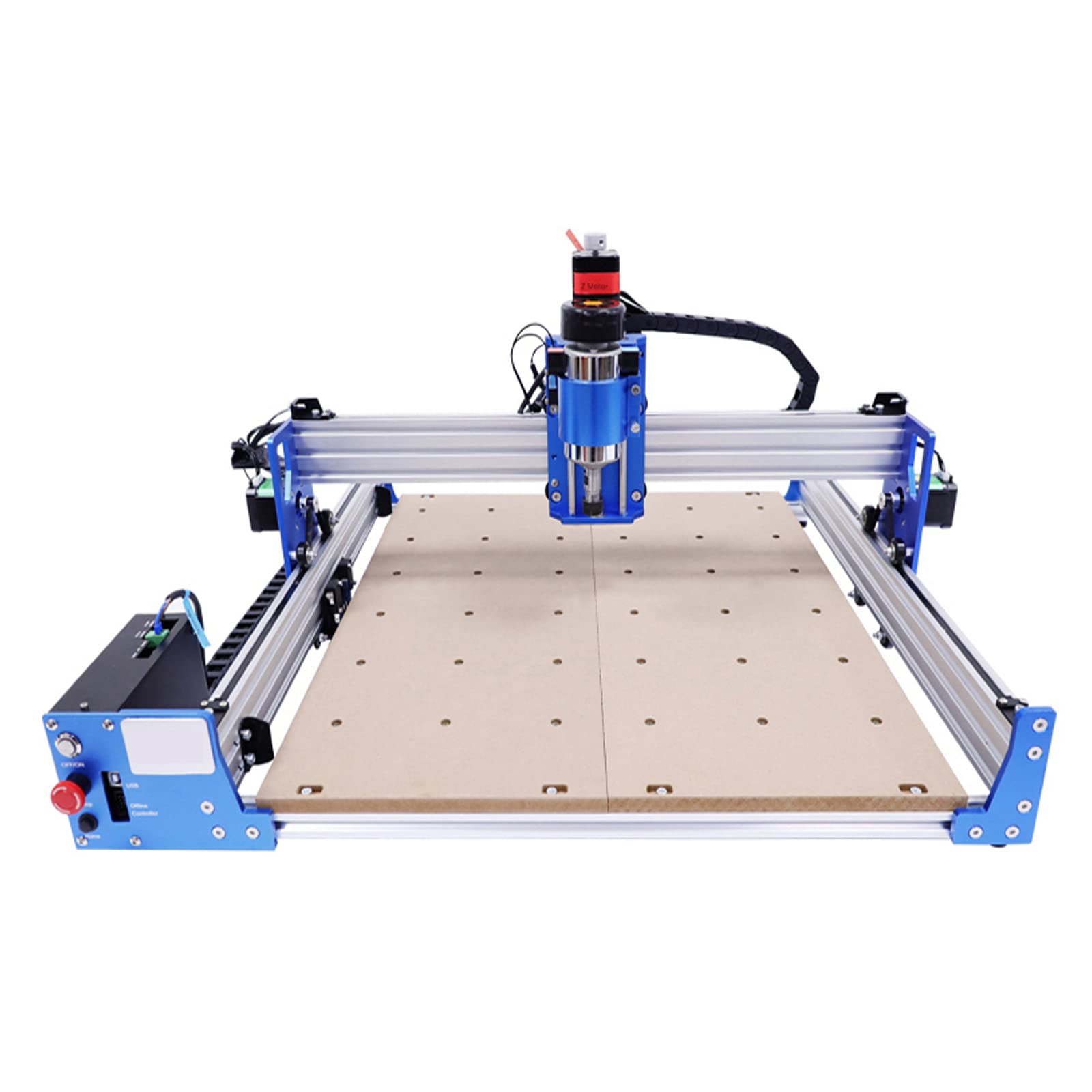

| Desktop CNC Milling Machines | Compact design, user-friendly software, lower RPM (up to 28,000 RPM) | Prototyping, small-scale production | Pros: Affordable, easy to operate. Cons: Limited to smaller parts. |

| Industrial CNC Machining Centers | Multi-axis capabilities, robust construction, high rigidity | Large-scale manufacturing, complex part production | Pros: High precision, versatile for various materials. Cons: Requires significant floor space and investment. |

| Mini CNC Milling Machines | Small footprint, suitable for limited space, lower power requirements | Educational institutions, small workshops | Pros: Cost-effective, ideal for beginners. Cons: Limited machining capabilities. |

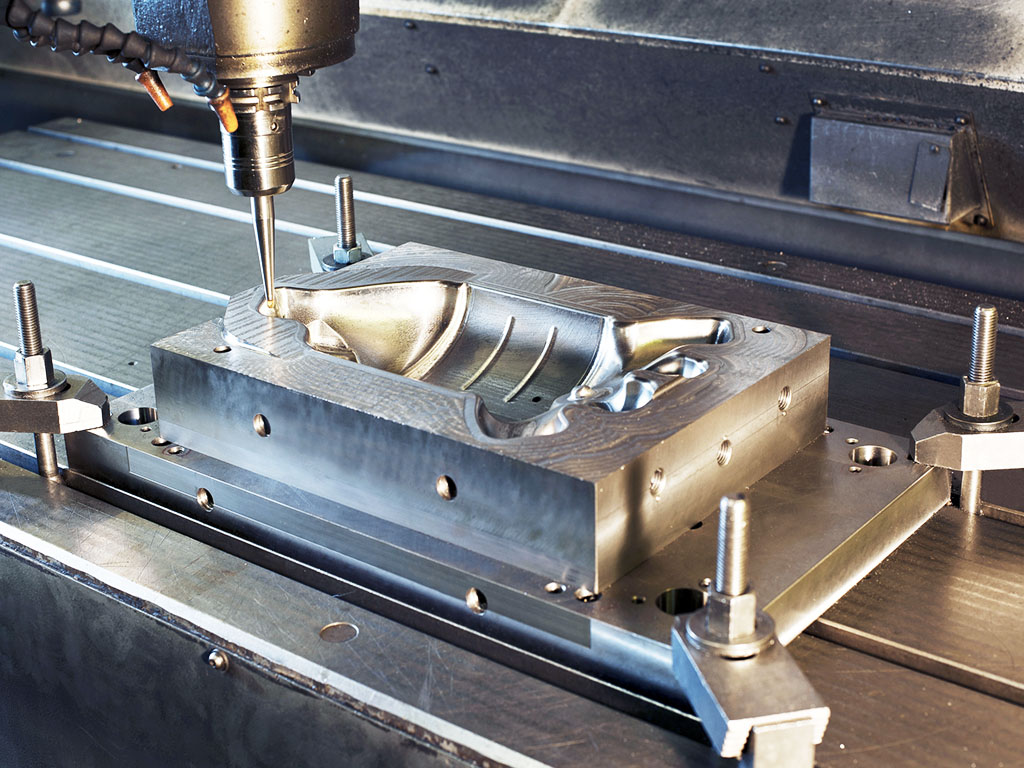

| 5-Axis CNC Milling Machines | Ability to machine complex geometries, simultaneous movement in multiple axes | Aerospace, custom tooling, intricate designs | Pros: Exceptional precision for complex parts. Cons: More complex operation and training required. |

What are High-Speed CNC Milling Machines and Their B2B Relevance?

High-speed CNC milling machines are characterized by their ability to achieve spindle speeds of up to 60,000 RPM. These machines are specifically engineered for efficient aluminum machining, allowing manufacturers to achieve faster cycle times and superior surface finishes. They are particularly suitable for industries such as aerospace and automotive, where precision and speed are paramount. B2B buyers should consider the initial investment and operational costs against the potential productivity gains.

How Do Desktop CNC Milling Machines Fit into B2B Applications?

Desktop CNC milling machines are compact and designed for ease of use, making them ideal for prototyping and small-scale production. With a spindle speed of up to 28,000 RPM, they can handle soft metals like aluminum effectively. This type of machine is particularly popular among startups and educational institutions due to its affordability and user-friendly software. Buyers should assess their production needs and consider the limited size and capabilities of these machines.

What Makes Industrial CNC Machining Centers Essential for Large-Scale Manufacturing?

Industrial CNC machining centers are robust machines designed for high-volume production and complex part manufacturing. They typically feature multi-axis capabilities, allowing for intricate designs and high precision. Suitable for large-scale operations, these machines can handle various materials beyond aluminum, making them a versatile investment. Buyers must evaluate their production requirements and floor space, as these machines often require significant investment and physical space.

Why Choose Mini CNC Milling Machines for Educational and Small Workshop Use?

Mini CNC milling machines are tailored for small workshops and educational settings, featuring a compact design and lower power requirements. They offer an affordable entry point into CNC machining, making them suitable for beginners. While these machines excel in basic machining tasks, they may not handle larger or more complex projects effectively. Buyers should weigh their educational or small-scale production goals against the machine’s limited capabilities.

How Do 5-Axis CNC Milling Machines Enhance Precision in Manufacturing?

5-axis CNC milling machines provide the capability to machine complex geometries through simultaneous movement across multiple axes. This feature makes them invaluable in industries like aerospace, where precision is crucial for custom tooling and intricate designs. Although they require more advanced operational skills and training, the exceptional precision they offer can justify the investment for companies focused on high-quality outputs. Buyers should consider the training and operational costs associated with these advanced machines.

Key Industrial Applications of cnc milling machine for aluminium

| Industry/Sector | Specific Application of CNC Milling Machine for Aluminium | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of aircraft components | High precision and lightweight parts reduce fuel consumption and enhance performance. | Certification standards (e.g., AS9100), material specifications, and lead times. |

| Automotive | Production of engine components and chassis parts | Improved durability and performance through precise machining of complex geometries. | Supplier reliability, technology compatibility, and after-sales support. |

| Electronics | Fabrication of housings and heat sinks | Enhanced thermal management and protection for electronic components. | Material sourcing (e.g., thermal conductivity), design flexibility, and prototyping capabilities. |

| Medical Devices | Creation of surgical instruments and implants | High precision and biocompatibility ensure safety and effectiveness in medical applications. | Compliance with medical regulations, material traceability, and customization options. |

| Renewable Energy | Manufacturing components for wind turbines and solar panels | Lightweight, strong parts improve energy efficiency and reduce overall costs. | Sustainability practices, material sourcing, and production scalability. |

How is CNC Milling Used in Aerospace Manufacturing?

In the aerospace industry, CNC milling machines for aluminum are pivotal in producing lightweight and high-precision components such as brackets, frames, and fuselage sections. These machines address the challenge of creating complex geometries while adhering to strict weight and safety regulations. International buyers, especially from regions like Africa and South America, must consider suppliers that meet rigorous certification standards, such as AS9100, to ensure compliance with industry requirements.

What Role Does CNC Milling Play in Automotive Production?

CNC milling is extensively utilized in automotive manufacturing for crafting engine components, chassis parts, and custom tooling. The precision offered by these machines enhances the durability and performance of vehicle parts, which is crucial in a competitive market. Buyers in Europe and the Middle East should prioritize suppliers with proven reliability and advanced technology compatibility, ensuring that they can meet evolving automotive standards and demands.

How is CNC Milling Beneficial for Electronics Fabrication?

In the electronics sector, CNC milling machines are employed to create housings and heat sinks from aluminum, which are essential for thermal management in electronic devices. This application allows for intricate designs that provide both protection and functionality. B2B buyers from regions like Vietnam and Brazil should focus on sourcing materials that offer optimal thermal conductivity, along with suppliers who provide design flexibility and rapid prototyping capabilities to keep pace with technological advancements.

Why is CNC Milling Important for Medical Device Manufacturing?

CNC milling machines are crucial for producing surgical instruments and implants in the medical device industry. The high precision achieved through CNC machining ensures that components meet stringent safety and performance standards. Buyers in this field must ensure that their suppliers comply with medical regulations, maintain material traceability, and offer customization options to cater to specific medical applications.

How Does CNC Milling Contribute to Renewable Energy Solutions?

In the renewable energy sector, CNC milling is used to manufacture components for wind turbines and solar panels, benefiting from aluminum’s lightweight and durable characteristics. This application helps improve the energy efficiency of renewable systems while reducing costs. International buyers should consider suppliers that emphasize sustainability practices, have reliable material sourcing, and can scale production to meet growing energy demands.

3 Common User Pain Points for ‘cnc milling machine for aluminium’ & Their Solutions

Scenario 1: Difficulty Achieving Precision and Tolerances in Machining Aluminum Parts

The Problem: Many B2B buyers face challenges with precision when using CNC milling machines for aluminum. Aluminum is a versatile material, but achieving tight tolerances can be particularly challenging, especially when dealing with complex geometries. Factors such as improper tool selection, inadequate machine rigidity, and incorrect cutting parameters can lead to defects, increased scrap rates, and ultimately, higher production costs. For industries like aerospace or automotive, where precision is critical, this can significantly affect product quality and reliability.

The Solution: To overcome precision issues, buyers should prioritize sourcing CNC milling machines specifically designed for aluminum machining. Look for machines with high rigidity and stability, as these attributes minimize vibration and deformation during cutting. Additionally, utilizing specialized tooling designed for aluminum—such as micro end mills with optimized geometries—can greatly enhance machining accuracy. It’s essential to conduct thorough testing of cutting parameters (spindle speed, feed rate, and depth of cut) to establish the most effective settings for the specific aluminum alloy being used. Regular calibration and maintenance of the CNC machine will also ensure consistent performance, allowing for tighter tolerances and better overall quality.

Scenario 2: Inefficient Chip Removal Leading to Tool Wear

The Problem: A common pain point for B2B manufacturers is the inefficiency of chip removal during the CNC milling process. Aluminum produces chips that can quickly accumulate and obstruct the cutting area, leading to overheating, increased tool wear, and potential machine downtime. This issue is exacerbated when machining at high speeds or when using smaller tooling, which can further complicate effective chip evacuation.

The Solution: To mitigate chip removal challenges, buyers should invest in CNC milling machines equipped with advanced chip management systems. Machines that utilize a combination of pressurized air and coolant systems can effectively clear chips from the cutting area. Additionally, selecting the right cutting tools—those designed for optimal chip evacuation—can significantly enhance performance. Implementing a strategic approach to toolpath design can also facilitate better chip removal; for instance, using climb milling techniques can help in clearing chips more effectively than conventional milling. Regularly inspecting and maintaining the chip management system will ensure its efficiency and prolong the lifespan of cutting tools.

Scenario 3: High Operating Costs Due to Energy Inefficiency

The Problem: As energy costs continue to rise globally, B2B buyers are increasingly concerned about the operational expenses associated with running CNC milling machines for aluminum. Machines that consume excessive energy not only inflate operational costs but can also hinder competitiveness, especially in price-sensitive markets. Additionally, inefficient machines may require more maintenance, adding to the overall cost burden.

The Solution: To address energy inefficiency, buyers should look for CNC milling machines that incorporate energy-saving technologies. Machines equipped with variable frequency drives (VFDs) allow for optimized motor speed control based on the machining requirements, reducing energy consumption during less intensive tasks. Additionally, selecting machines with high-speed spindles can improve machining efficiency, resulting in shorter cycle times and lower energy usage per part produced. Implementing a preventive maintenance program will also enhance machine efficiency, ensuring that all components are functioning optimally and reducing unnecessary energy waste. Lastly, consider investing in training for operators to ensure they are using the machines efficiently, which can further reduce costs and improve productivity.

Strategic Material Selection Guide for cnc milling machine for aluminium

What are the Key Materials for CNC Milling Machines for Aluminum?

When selecting materials for CNC milling machines designed for aluminum, it’s crucial to consider their properties, advantages, disadvantages, and how they align with the specific needs of international B2B buyers. Below are analyses of four common materials used in CNC milling applications.

1. Aluminum Alloys (e.g., 6061, 7075)

Key Properties: Aluminum alloys, particularly 6061 and 7075, are known for their excellent strength-to-weight ratios, corrosion resistance, and good machinability. They exhibit temperature ratings up to 150°C and maintain structural integrity under varying loads.

Pros & Cons: The primary advantage of aluminum alloys is their lightweight nature, making them suitable for applications in aerospace and automotive industries. However, they can be more expensive than other materials and may require specialized tooling for effective machining, increasing manufacturing complexity.

Impact on Application: Aluminum alloys are compatible with various media, including air and water, making them suitable for diverse applications. Their corrosion resistance ensures longevity in outdoor and marine environments.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is vital for quality assurance. Buyers from regions like Africa and South America should also consider local availability and pricing fluctuations of these alloys, which can vary significantly.

2. Brass

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It can withstand temperatures up to 200°C and offers good electrical conductivity.

Pros & Cons: The primary advantage of brass is its ease of machining, allowing for intricate designs and high-speed operations. However, it is generally more expensive than aluminum and may not be suitable for high-stress applications.

Impact on Application: Brass is ideal for applications requiring high corrosion resistance, such as plumbing fittings and electrical connectors. Its compatibility with various media, including water and gases, makes it versatile.

Considerations for International Buyers: Buyers should be aware of the varying standards for brass alloys, such as JIS and ASTM. Additionally, understanding the local market for brass can help in negotiating better prices and ensuring timely delivery.

3. Stainless Steel

Key Properties: Stainless steel is known for its high tensile strength and excellent corrosion resistance. It can withstand high temperatures (up to 800°C) and is highly durable.

Pros & Cons: While stainless steel offers superior durability and resistance to wear, it is more challenging to machine than aluminum, requiring specialized tools and slower feed rates, which can increase production time and costs.

Impact on Application: Stainless steel is suitable for applications in harsh environments, such as chemical processing and marine applications, where corrosion resistance is critical.

Considerations for International Buyers: Compliance with international standards like ISO and ASTM is essential. Buyers should also consider the availability of stainless steel grades in their region to avoid supply chain disruptions.

4. Plastics (e.g., PEEK, Nylon)

Key Properties: Engineering plastics like PEEK and nylon are lightweight and offer good chemical resistance. They can withstand temperatures up to 260°C and have excellent wear resistance.

Pros & Cons: Plastics are generally less expensive and easier to machine than metals. However, they may not provide the same structural integrity as metals in high-load applications.

Impact on Application: Plastics are suitable for applications in electronics and automotive sectors where weight reduction is crucial. Their compatibility with various chemicals makes them ideal for specialized applications.

Considerations for International Buyers: Understanding the specific grades of plastics and their compliance with international standards is crucial. Buyers should also consider local sourcing options to minimize costs.

Summary Table of Material Selection for CNC Milling Machines

| Material | Typical Use Case for CNC Milling Machine for Aluminum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aerospace and automotive components | Lightweight with high strength | Higher cost and specialized tooling needed | High |

| Brass | Plumbing fittings and electrical connectors | Excellent machinability | More expensive and not for high-stress | High |

| Stainless Steel | Chemical processing equipment | Superior durability and corrosion resistance | Difficult to machine, higher production costs | High |

| Plastics | Electronics and automotive applications | Lightweight and cost-effective | Lower structural integrity than metals | Medium |

This strategic material selection guide provides actionable insights for B2B buyers looking to optimize their CNC milling processes for aluminum and related materials. Understanding the properties, advantages, and limitations of these materials can significantly impact production efficiency and product quality.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc milling machine for aluminium

What Are the Main Stages of Manufacturing CNC Milling Machines for Aluminum?

The manufacturing process of CNC milling machines specifically designed for aluminum involves several critical stages, each essential for ensuring precision and quality. Understanding these stages is crucial for B2B buyers looking to invest in reliable machinery.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The manufacturing journey begins with the selection of high-quality materials, primarily aluminum alloys known for their lightweight and strength, such as 6061 and 7075. These materials are sourced from reputable suppliers and undergo rigorous quality checks to ensure they meet the necessary specifications.

Once the materials are procured, they are cut into manageable sizes, typically in the form of sheets, plates, or extrusions. This initial processing is crucial as it sets the foundation for the machine’s structural integrity and performance. Advanced cutting techniques such as laser cutting or waterjet cutting are often employed to achieve precise dimensions and reduce waste.

2. Forming: How Are CNC Milling Machines Assembled?

Following material preparation, the forming stage involves the fabrication of machine components. This includes the production of the frame, spindle, and other essential parts. Manufacturers utilize CNC machining processes to create these components, ensuring that they achieve high accuracy and tight tolerances.

The assembly of these parts is a meticulous process where components are fitted together with precision. Key elements, such as the spindle, are aligned to minimize vibration and ensure stability during operation. This stage is vital, as even minor misalignments can affect the overall performance of the milling machine.

3. Finishing: What Techniques Are Used to Enhance Machine Quality?

Finishing processes are employed to enhance both the aesthetic and functional qualities of the CNC milling machines. Techniques such as anodizing or powder coating are commonly used to protect aluminum parts from corrosion and wear, thereby extending the machine’s lifespan.

Additionally, surface finishing techniques, like grinding and polishing, are applied to ensure that the contact surfaces are smooth, which is essential for minimizing friction during operation. This stage not only improves the machine’s performance but also contributes to its visual appeal, which can be a factor for B2B buyers concerned with branding and presentation.

What Quality Assurance Measures Are Essential for CNC Milling Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for CNC milling machines intended for aluminum. The following are essential QA measures that B2B buyers should be aware of when evaluating suppliers.

1. What International Standards Should Buyers Consider?

Manufacturers of CNC milling machines must adhere to various international standards, such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 ensures that the manufacturer maintains consistent quality in its processes, which is crucial for B2B buyers seeking reliability.

Additionally, certifications such as CE mark indicate compliance with European safety standards, while industry-specific certifications like API (American Petroleum Institute) are essential for machines intended for use in sectors like oil and gas. These certifications help buyers verify that the machines meet stringent performance and safety requirements.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to ensuring that each machine meets the required standards throughout the manufacturing process. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for defects and ensuring they meet specifications before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, random checks are conducted to monitor the quality of components as they are being produced. This helps identify any deviations early, allowing for corrective actions.

-

Final Quality Control (FQC): Once the machine is fully assembled, it undergoes comprehensive testing to ensure all components function correctly and meet performance specifications.

3. How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures employed by suppliers. This can be achieved through:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance systems in place. This firsthand evaluation provides insights into the supplier’s operational standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide transparency regarding their QA processes, including results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of the machine’s quality. This is especially important for international transactions where buyers may not have direct access to the manufacturing facilities.

What Are the Unique Quality Control Considerations for International B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, there are specific nuances in quality control to consider:

-

Cultural Differences in Quality Standards: Understand that quality expectations can vary significantly across regions. Buyers should establish clear communication regarding their quality requirements and ensure that suppliers are aligned with these expectations.

-

Regulatory Compliance: Different countries may have varying regulations regarding machinery safety and performance. Buyers should ensure that suppliers are compliant with the regulations pertinent to their specific market.

-

Logistical Considerations: International shipping can impact the condition of machinery. Buyers should discuss packaging and handling procedures with suppliers to minimize the risk of damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance measures of CNC milling machines for aluminum is vital for B2B buyers. By focusing on material preparation, forming, and finishing processes, along with rigorous quality control measures, buyers can make informed decisions and ensure they select reliable suppliers capable of meeting their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc milling machine for aluminium’

When sourcing a CNC milling machine specifically designed for aluminum, it is essential to follow a structured approach to ensure you select the right equipment for your business needs. This guide provides a practical checklist to help international B2B buyers effectively navigate the procurement process.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical requirements for your CNC milling machine. Consider factors such as the types of aluminum alloys you’ll be machining, the complexity of the parts, and production volume. This will help you identify machines with the necessary capabilities, such as spindle speed, tool types, and build volume.

- Common specifications to define:

- Maximum material thickness and dimensions.

- Required precision and tolerance levels.

- Types of machining operations (milling, drilling, engraving).

Step 2: Research Different Machine Types

Familiarize yourself with the various types of CNC milling machines available on the market. Options may range from desktop models suitable for prototyping to industrial machines designed for high-volume production. Understanding these differences will aid in selecting a machine that aligns with your operational scale and budget.

- Key types to consider:

- Desktop CNC machines for small-scale or educational use.

- High-speed machines for industrial applications.

- Specialized machines with features for aluminum machining.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of suppliers to ensure they can meet your needs. Request detailed company profiles, product catalogs, and customer references. Look for suppliers who have experience in your industry and understand the specific challenges of machining aluminum.

- Questions to ask suppliers:

- What warranties and support services do you offer?

- Can you provide case studies or testimonials from similar businesses?

Step 4: Verify Certifications and Compliance

Ensure that the CNC milling machines comply with international quality and safety standards. This is particularly important if you are purchasing from overseas suppliers. Certifications such as ISO 9001 or CE marking can indicate a commitment to quality and safety.

- Check for:

- Relevant industry certifications.

- Compliance with local regulations in your region.

Step 5: Request Demonstrations or Samples

Before finalizing your purchase, request a demonstration of the machine or samples of machined parts. This will give you insight into the machine’s performance, ease of use, and the quality of the output. A hands-on evaluation can also help you determine if the machine meets your expectations.

- Considerations during evaluation:

- Observe the machine’s speed and precision.

- Evaluate the ease of programming and operation.

Step 6: Negotiate Terms and After-Sales Support

Once you have selected a machine, negotiate the terms of purchase, including pricing, delivery timelines, and payment options. Additionally, discuss after-sales support, including training, maintenance, and spare parts availability. A robust support system is crucial for minimizing downtime and ensuring smooth operations.

- Important aspects to cover:

- Warranty duration and coverage.

- Availability of training resources for your team.

Step 7: Finalize the Purchase Agreement

After negotiating terms, review and finalize the purchase agreement. Ensure all key details, including specifications, pricing, delivery schedules, and support services, are clearly documented. This protects both parties and ensures a smooth transaction.

By following this checklist, B2B buyers can make informed decisions when sourcing CNC milling machines for aluminum, ultimately leading to enhanced productivity and quality in their manufacturing processes.

Comprehensive Cost and Pricing Analysis for cnc milling machine for aluminium Sourcing

What Are the Key Cost Components in Sourcing CNC Milling Machines for Aluminum?

When evaluating the costs associated with sourcing CNC milling machines for aluminum, it is crucial to understand the various components that contribute to the overall price. These components typically include:

-

Materials: The primary materials involved in the manufacturing of CNC milling machines include high-grade steel, aluminum alloys, and electronic components. The cost of these materials can fluctuate based on global market conditions and availability.

-

Labor: Labor costs encompass the wages of skilled technicians and engineers involved in the design, assembly, and testing of the machines. Countries with higher labor costs may result in increased pricing for the final product.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these overhead costs.

-

Tooling: Specialized tooling, such as cutting tools and fixtures, is essential for effective machining of aluminum. The cost of tooling varies based on quality and durability, influencing the overall cost of the CNC machine.

-

Quality Control (QC): Rigorous QC processes are necessary to ensure that the machines meet industry standards. Investments in quality assurance can impact the final pricing but are crucial for reliability and performance.

-

Logistics: Shipping and handling costs, including customs duties and tariffs, can add significant expenses, particularly for international transactions. The choice of shipping method and distance can further influence logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary significantly based on competition, market demand, and supplier reputation.

How Do Price Influencers Affect CNC Milling Machine Costs?

Several factors influence the pricing structure for CNC milling machines, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing larger quantities can often lead to discounts due to economies of scale. Buyers should negotiate MOQs to optimize their purchasing costs.

-

Specifications and Customization: Customized machines designed to meet specific operational needs often come at a premium. Buyers should assess whether the custom features are essential or if standard models suffice.

-

Materials and Certifications: The choice of materials and the presence of industry certifications can affect pricing. Machines built with higher-quality materials or those that meet stringent certifications may command higher prices but offer better durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can greatly influence price. Established suppliers with proven track records may charge more but often provide better after-sales support and warranty options.

-

Incoterms: Understanding Incoterms is vital for international buyers as they define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Different terms can lead to significant variations in the total cost.

What Buyer Tips Can Help in Negotiating CNC Milling Machine Prices?

To navigate the complexities of pricing for CNC milling machines, international buyers can adopt several strategies:

-

Conduct Thorough Market Research: Understanding the pricing landscape and available options can empower buyers during negotiations. Gathering quotes from multiple suppliers can help identify competitive pricing.

-

Focus on Total Cost of Ownership (TCO): Instead of just considering the initial purchase price, buyers should evaluate the TCO, which includes operational costs, maintenance, and potential downtime. This perspective can lead to more informed purchasing decisions.

-

Negotiate Terms and Pricing: Don’t hesitate to negotiate on price, payment terms, and delivery schedules. Suppliers may offer flexibility, especially for larger orders or long-term partnerships.

-

Consider Long-term Relationships: Establishing a reliable relationship with suppliers can lead to better pricing and support over time. Consider exploring supplier partnerships that can provide ongoing benefits.

-

Be Aware of Pricing Nuances: International buyers must understand local market conditions, currency fluctuations, and regional factors that may affect pricing. Staying informed can help in making strategic purchasing decisions.

Disclaimer on Indicative Prices

Prices for CNC milling machines can vary widely based on the aforementioned factors. It is advisable to obtain tailored quotes directly from suppliers to receive the most accurate and relevant pricing information for your specific needs.

Alternatives Analysis: Comparing cnc milling machine for aluminium With Other Solutions

Introduction: Exploring Alternatives to CNC Milling Machines for Aluminum

When evaluating manufacturing processes for aluminum components, it’s essential to consider various technologies that can achieve similar objectives. While CNC milling machines are a popular choice for their precision and versatility, alternative solutions may offer specific advantages depending on the application, budget, and operational needs. This analysis compares CNC milling machines with two viable alternatives: laser cutting and water jet cutting.

Comparison Table

| Comparison Aspect | CNC Milling Machine for Aluminum | Laser Cutting | Water Jet Cutting |

|---|---|---|---|

| Performance | High precision, complex geometries | Excellent for flat cuts, limited thickness | Good precision, can cut thick materials |

| Cost | Higher initial investment, but lower operational costs | Moderate initial costs, variable operational costs | High initial costs, high operational costs |

| Ease of Implementation | Requires skilled operators and setup | User-friendly, less training required | Requires specialized training and setup |

| Maintenance | Regular maintenance needed for moving parts | Minimal maintenance; optics need cleaning | High maintenance due to wear on components |

| Best Use Case | High-tolerance parts, 3D machining | Thin sheets, intricate designs | Thick materials, non-metal cutting |

Detailed Breakdown of Alternatives

Laser Cutting: Pros and Cons

Laser cutting is a widely used technology for cutting metals and other materials. It excels in precision and speed, making it ideal for producing intricate designs in aluminum sheets. The primary advantages of laser cutting include lower operational costs due to minimal material waste and the ability to cut complex shapes quickly. However, it is less effective for thicker materials and can produce heat-affected zones that may compromise material integrity. For businesses focused on flat, detailed cuts, laser cutting presents a compelling alternative.

Water Jet Cutting: Pros and Cons

Water jet cutting employs high-pressure water mixed with abrasives to cut materials, making it suitable for a diverse range of materials, including aluminum. One of the standout benefits of water jet cutting is its ability to cut through thick materials without introducing heat, which prevents warping and maintains the structural integrity of the aluminum. However, the initial investment and operational costs can be significantly higher compared to CNC milling machines. Additionally, the process may require specialized training for operators and frequent maintenance due to wear on the cutting components.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate manufacturing solution for aluminum components involves understanding the specific requirements of your projects, including material thickness, complexity, and precision needs. CNC milling machines are ideal for high-tolerance applications and complex geometries, while laser cutting is excellent for intricate designs in thinner materials. Water jet cutting offers versatility for thicker materials without the risk of heat distortion. By carefully evaluating the performance, cost, and implementation aspects of each technology, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for cnc milling machine for aluminium

What Are the Key Technical Properties of CNC Milling Machines for Aluminum?

When selecting a CNC milling machine for aluminum, understanding the technical specifications is crucial for ensuring optimal performance and meeting production requirements. Here are some essential properties to consider:

-

Spindle Speed (RPM)

Spindle speed refers to how fast the machine’s spindle rotates, measured in revolutions per minute (RPM). For aluminum machining, high spindle speeds (typically between 10,000 to 60,000 RPM) are advantageous as they allow for faster cutting rates and finer finishes. Higher speeds reduce cutting forces and heat generation, which is critical for maintaining the integrity of aluminum. -

Material Compatibility

The CNC milling machine must be compatible with various aluminum alloys, such as 6061 and 7075, each with different mechanical properties. Understanding the machine’s ability to handle specific grades of aluminum is essential for B2B buyers focused on industries like aerospace or automotive, where material specifications are stringent. -

Tolerance Levels

Tolerance indicates the permissible limit of variation in a physical dimension of the machined part. CNC machines capable of achieving tight tolerances (e.g., ±0.001 inch or ±0.025 mm) are critical for applications requiring high precision, such as intricate aerospace components. Buyers should assess their project needs against the machine’s tolerance capabilities to ensure quality production. -

Build Volume

The build volume describes the maximum size of the workpiece that can be accommodated by the CNC milling machine. For businesses needing to mill larger aluminum parts, selecting a machine with an appropriate build volume (e.g., 7” x 9” x 3.3” or larger) is vital for efficiency and cost-effectiveness. -

Feed Rate

The feed rate indicates how quickly the cutting tool moves through the material, usually measured in inches per minute (IPM). A higher feed rate can improve productivity but must be balanced with the spindle speed and cutting tool capabilities to avoid compromising the quality of the finished product. -

Cooling System

Effective cooling systems are essential in aluminum machining to manage heat generated during the milling process. Options like evaporative cooling or minimal quantity lubrication help maintain optimal temperatures, reduce tool wear, and enhance surface finishes. Understanding the cooling options available can be a decisive factor for B2B buyers.

What Are Common Trade Terms Related to CNC Milling Machines?

Familiarity with industry jargon is essential for effective communication and negotiation in the CNC machining market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC machines, buyers should consider OEMs for quality assurance and compatibility with specific applications. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers, as it affects inventory management and production planning. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is essential for comparing costs and services among different CNC milling machine manufacturers, helping buyers make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international transactions to clarify the responsibilities of buyers and sellers. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery obligations, ensuring smoother transactions. -

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools through computer programming. This technology enables precise and repeatable machining processes, making it a cornerstone of modern manufacturing. -

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

CAD/CAM software integrates design and manufacturing processes, allowing for the seamless transition from design to machining. Utilizing CAD/CAM systems can enhance efficiency and accuracy in CNC milling operations, making them essential for B2B buyers in design-heavy industries.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing CNC milling machines for aluminum, ensuring they select the right equipment for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the cnc milling machine for aluminium Sector

What Are the Key Market Trends Impacting the CNC Milling Machine for Aluminium Sector?

The global market for CNC milling machines tailored for aluminum is experiencing significant growth, driven by the increasing demand for lightweight materials in industries such as aerospace, automotive, and electronics. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, several key trends are emerging.

Firstly, technological advancements are reshaping the landscape. The integration of Industry 4.0 concepts—such as automation, IoT connectivity, and advanced analytics—enables manufacturers to optimize production processes and reduce downtime. This shift is particularly relevant for buyers looking to increase efficiency and precision in their machining operations.

Another trend is the rising preference for high-speed CNC machines, which can achieve faster cycle times and superior surface finishes. Machines with spindle speeds exceeding 60,000 RPM are becoming more common, allowing for intricate designs and reduced burr formation. Such capabilities are crucial for sectors demanding high precision, like medical device manufacturing.

Additionally, there is a growing emphasis on versatility in machine design. Buyers are increasingly interested in CNC machines that can handle various materials beyond aluminum, such as brass and plastics, making them more cost-effective and adaptable to changing project requirements. This trend is especially relevant for emerging markets, where companies are looking to maximize their investments in technology.

How Are Sustainability and Ethical Sourcing Influencing B2B Procurement in the CNC Milling Machine Sector?

Sustainability is becoming a critical consideration in the procurement of CNC milling machines for aluminum. The environmental impact of manufacturing processes and the materials used is under scrutiny, prompting B2B buyers to prioritize machines that minimize waste and energy consumption.

One significant aspect is the adoption of machines that utilize evaporative cooling systems, which reduce the need for traditional coolant disposal and lower operational costs. Additionally, manufacturers that emphasize the use of recyclable materials in their machines are gaining traction among environmentally conscious buyers.

Ethical sourcing practices are also gaining importance. Companies are increasingly looking for suppliers who adhere to fair labor practices and transparent supply chains. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming crucial indicators of a supplier’s commitment to sustainability.

By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their brand reputation but also align with global initiatives aimed at reducing carbon footprints and promoting responsible manufacturing practices.

What Is the Historical Context of CNC Milling Machines for Aluminium?

The evolution of CNC milling machines for aluminum dates back to the mid-20th century, when the advent of computer numerical control revolutionized machining processes. Initially, these machines were limited in capability, primarily focused on simple tasks. However, technological advancements over the decades have led to significant improvements in precision, speed, and automation.

In the 1980s and 1990s, the introduction of high-speed machining and the use of advanced materials in machine construction marked a turning point. These innovations allowed for the efficient machining of aluminum and other non-ferrous metals, making CNC milling machines indispensable in industries requiring high precision and complex geometries.

Today, as manufacturers face increasing competition and demand for customized solutions, CNC milling machines have become more sophisticated. The integration of smart technologies and automation is now standard, allowing for greater flexibility and efficiency in production processes. This historical context underscores the importance of investing in advanced CNC technologies to meet the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc milling machine for aluminium

-

How do I choose the right CNC milling machine for aluminum?

Selecting the appropriate CNC milling machine for aluminum depends on various factors, including your production volume, the complexity of parts, and the specific aluminum alloys you’ll be working with. Look for machines with high spindle speeds (ideally above 20,000 RPM) for efficient cutting and a robust construction to handle the rigidity of aluminum. Additionally, consider the machine’s precision capabilities, tool compatibility, and software support. Engaging with suppliers for demonstrations can also help ensure the machine meets your operational needs. -

What are the key features to consider in a CNC milling machine for aluminum?

Key features to evaluate include spindle speed, feed rate, and the machine’s rigidity. A high-speed spindle (above 20,000 RPM) allows for faster machining and improved surface finishes. Rigid construction minimizes vibrations, which is crucial for maintaining precision during machining. Additionally, ensure the machine supports various tooling options, has effective chip removal systems, and includes advanced control software for programming and monitoring operations efficiently. -

What is the typical lead time for ordering a CNC milling machine for aluminum?

Lead times for CNC milling machines can vary based on the manufacturer, machine specifications, and customization requirements. Generally, standard models may take 4-12 weeks for delivery, while custom-built machines can extend lead times to 12-20 weeks. It’s advisable to communicate directly with suppliers about your timeline and any urgent requirements, as they can provide insights into production schedules and shipping logistics. -

How can I verify the credibility of a CNC milling machine supplier?

To vet a CNC milling machine supplier, start by checking their industry reputation through customer testimonials and case studies. Look for certifications, such as ISO 9001, which indicate adherence to quality standards. Additionally, request references from existing clients and inquire about their experiences. Engaging in direct conversations with the supplier about their manufacturing processes and support services can also provide valuable insights into their reliability. -

What are the minimum order quantities (MOQs) for CNC milling machines?

MOQs for CNC milling machines can vary significantly depending on the supplier and the type of machine. Some manufacturers may have a MOQ of one machine, especially for standard models, while others may require larger orders for custom machines. It’s essential to discuss your needs with potential suppliers to understand their policies and negotiate terms that align with your business requirements. -

What payment terms are typically offered for international orders of CNC milling machines?

Payment terms for international orders of CNC milling machines can differ by supplier, but common arrangements include a deposit (20-50%) upfront with the balance due upon shipping or delivery. Some suppliers may offer financing options or payment through letters of credit, which can enhance security in international transactions. Always review the payment terms carefully and ensure they are documented in the contract to avoid misunderstandings. -

How do I ensure quality assurance (QA) for CNC milling machines?

To ensure quality assurance when purchasing a CNC milling machine, request detailed specifications and certifications from the supplier. Many reputable manufacturers conduct rigorous testing on their machines before shipping. You can also inquire about warranty terms and post-purchase support, including training and maintenance services. If possible, visit the supplier’s facility to observe their production processes and quality control measures firsthand. -

What logistics considerations should I keep in mind when importing a CNC milling machine?

When importing a CNC milling machine, consider shipping methods, customs duties, and local regulations. Choose between air freight for faster delivery or sea freight for cost-effectiveness, keeping in mind that larger machines may require special handling. Understand your country’s import regulations and ensure you have the necessary documentation ready for customs clearance. Collaborating with a logistics partner experienced in heavy machinery can streamline the process and mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Milling Machine For Aluminium Manufacturers & Suppliers List

1. Bantam Tools – Desktop CNC Milling Machine

Domain: bantamtools.com

Registered: 2013 (12 years)

Introduction: This company, Bantam Tools – Desktop CNC Milling Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. DATRON – High-Speed CNC Machines

Domain: datron.com

Registered: 1995 (30 years)

Introduction: DATRON CNC machines are designed for high-speed machining of non-ferrous metals, particularly aluminum. Key features include:

– High-speed spindles reaching up to 60,000 RPM.

– Optimized carbide CNC tool designs for efficient chip evacuation and superior surface finishes.

– Evaporative minimum-quantity cooling system that eliminates the need for secondary cleanup and coolant disposal.

– Large work…

3. ShopSabre – CNC Routers

Domain: shopsabre.com

Registered: 2002 (23 years)

Introduction: Aluminum & Brass Machining products include: IS-A Series CNC Router – Industrial and Commercial Use, Auto Unload, starting at $99,995; IS-M Series CNC Router – Fastest and Most Accurate, Industrial and Commercial Use, starting at $57,995; Industrial Series CNC Router – Machine Tool Grade, starting at $40,350; IS EVA Series CNC Router – Marine/EVA Foam Applications, starting at $53,095; Pro Series …

4. Laguna – CNC Router for Aluminium

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: CNC router for aluminium, 2×3 size, suitable for prototype work, compatible with 220V power supply, designed for cutting aluminium 6061 plates ranging from 3/8 to 5/8 inches thick. Suggested brands include Laguna (Chinese made), Cammaster (US made), Shopsabre (US made), and Iridium (Canadian). Recommended spindle specifications: 2-3 hp, 18000 rpm, with HSD being a preferred Italian brand. Addition…

5. STYLECNC – Best CNC Routers for Aluminum

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: 2025 Best CNC Routers for Aluminum, Brand: STYLECNC, Table Sizes: 2′ x 3′, 4′ x 4′, 4′ x 8′, 5′ x 10′, Functions: Cutting, Carving, Engraving, Milling, Turning, Drilling, Axis: 3 Axis, 4th Axis, 4 Axis, 5 Axis, Capability: 2D Machining, 2.5D Machining, 3D Machining, Price Range: $2,580.00 – $150,000.00, Suitable for: Simple aluminum fabrication (small desktop CNC router), 3D milling works (4th axi…

6. CNC Master – High-Speed Aluminium Milling

Domain: en.industryarena.com

Registered: 2013 (12 years)

Introduction: 1. **Machine Type**: CNC Milling Machine for Aluminium

2. **Component Size**: Less than 2″ square

3. **Spindle Speed Requirements**: High spindle speed, recommended around 24000 RPM, with options up to 30000 RPM or higher.

4. **Tool Size**: 1/8″ tools, requiring high surface speed (235 m/min at 24000 RPM).

5. **Spindle Power**: Options discussed include 3.5kW to 18kW spindles.

6. **Spindle Torque*…

7. Avid CNC – BenchtopPro 2424

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: CNC machines considered for aluminum machining: Avid CNC BenchtopPro 2424, Phantom CNC (4′ x 4′), Langmuir MR1. Desired working area: 2′ x 2′, possibly larger. Drilling performance inquiry for holes in the range of 0.040″ to 0.250″. Preference for high spindle RPMs (10,000 – 24,000 RPM) for drilling, with a note on using end mills for larger holes. Mention of a PrintNC router built for $1800 CDN, …

Strategic Sourcing Conclusion and Outlook for cnc milling machine for aluminium

In conclusion, the strategic sourcing of CNC milling machines for aluminum is essential for businesses aiming to enhance operational efficiency and product quality. By leveraging advanced technologies, such as high-speed spindles and optimized tooling, manufacturers can significantly reduce cycle times while achieving superior finishes. It is crucial for international buyers, especially those in Africa, South America, the Middle East, and Europe, to consider factors such as machine capabilities, support services, and supplier reliability when making purchasing decisions.

Investing in the right CNC milling machine not only fosters innovation but also positions companies to respond effectively to market demands and competitive pressures. As the industry evolves, staying ahead of technological advancements will be key to maintaining a competitive edge.

We encourage B2B buyers to engage with reputable suppliers to explore tailored solutions that meet their specific machining needs. By prioritizing strategic sourcing, businesses can unlock new levels of productivity and precision in their aluminum machining processes. Embrace the future of manufacturing by investing in CNC technology that drives growth and sustainability.