Contents

Manufacturing Insight: Cnc Milling Machine 6 Axis

Advanced 6-Axis CNC Milling Capabilities at Honyo Prototype

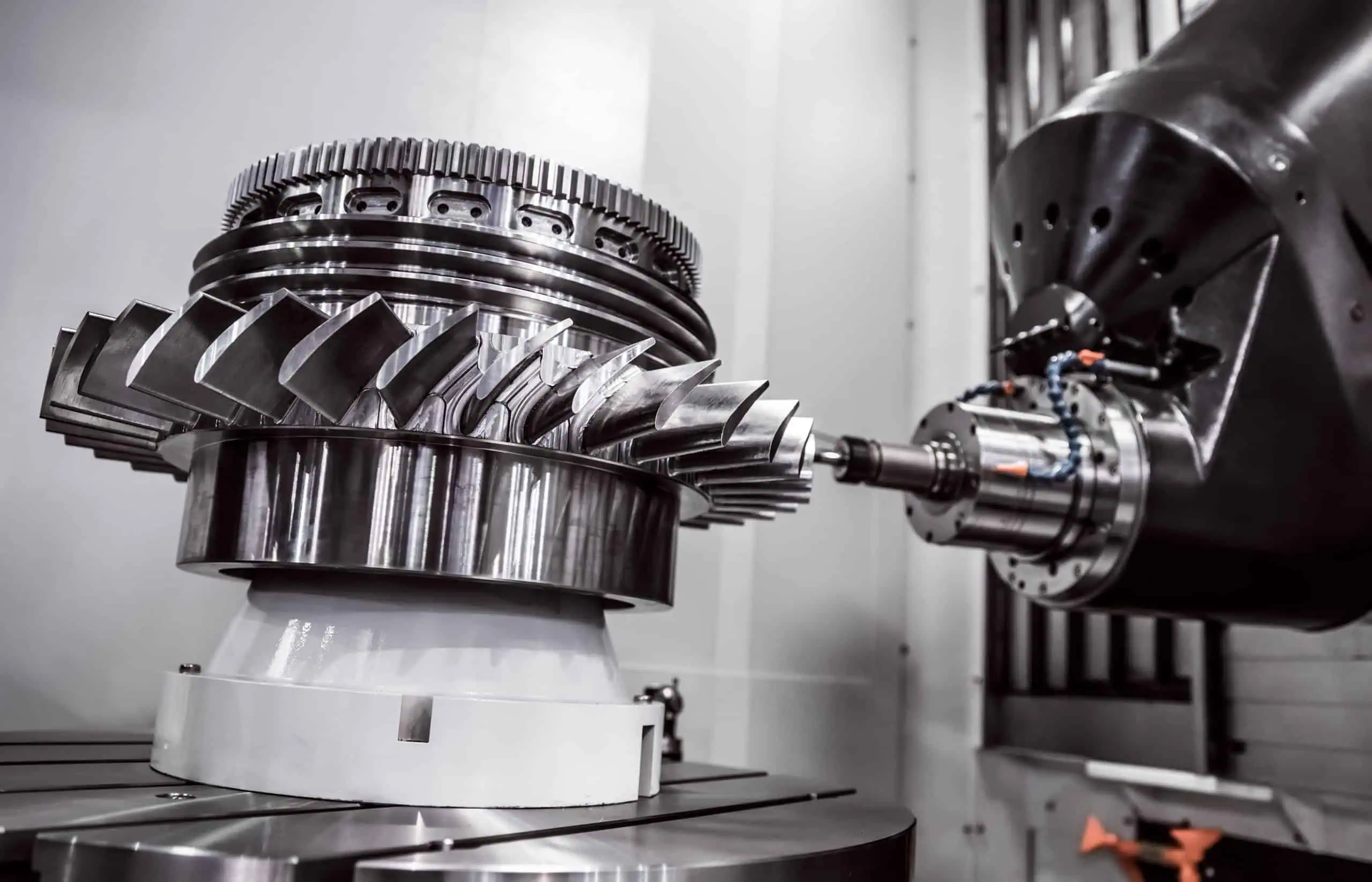

Honyo Prototype delivers precision engineering through state-of-the-art 6-axis CNC milling technology, enabling the production of highly complex geometries with unparalleled efficiency and accuracy. Unlike conventional 3-axis systems, our 6-axis milling platforms execute simultaneous multi-directional tool movement, eliminating the need for multiple setups and fixture changes. This capability ensures micron-level tolerances while machining intricate aerospace components, medical implants, and energy sector parts from challenging materials including titanium, Inconel, and high-temp polymers. The result is reduced lead times, minimized human error, and superior surface finishes critical for mission-critical applications.

Our ISO 9001-certified facility integrates advanced 6-axis milling with rigorous in-process inspection protocols, ensuring every component meets stringent industry standards. Honyo’s engineering team collaborates closely with clients to optimize part design for manufacturability, leveraging deep expertise in multi-axis strategies to maximize material utilization and part integrity. Whether prototyping or low-volume production, we transform complex CAD models into high-fidelity physical assets with consistent repeatability.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your 3D model to receive a detailed, transparent cost estimate and manufacturability feedback within hours—not days—streamlining your path from concept to certified production.

Material & Tolerance Performance

| Parameter | Specification Range |

|——————–|—————————|

| Max Work Envelope | 1200 x 800 x 650 mm |

| Positional Accuracy| ±0.005 mm |

| Surface Finish | Ra 0.4 µm (as machined) |

| Supported Formats | STEP, IGES, Parasolid, X_T |

Technical Capabilities

CNC Milling Machine – 6-Axis Capabilities and Technical Specifications

A true 6-axis CNC milling machine extends beyond conventional 3-axis linear motion (X, Y, Z) and 3 rotational axes (A, B, C), enabling complex multi-sided machining with minimal fixturing. While 6-axis CNC systems are less common in standard production environments, they integrate advanced 5-axis milling capabilities with additional robotic or adaptive motion, often used for high-precision aerospace, medical, and prototyping applications. Most industrial applications refer to 5-axis machines when discussing complex geometry; however, 6-axis systems typically combine a 5-axis CNC mill with an additional articulated axis (e.g., a robotic arm or adaptive fixture rotation) for continuous workpiece reorientation.

Below are the relevant technical specifications focused on high-precision 3-, 4-, and 5-axis milling and turning capabilities, applicable to materials such as Aluminum, Steel, ABS, and Nylon, with emphasis on tight-tolerance manufacturing.

| Specification | Detail |

|---|---|

| Axis Configuration | 3-axis (X, Y, Z linear), 4-axis (X, Y, Z + A or B rotary), 5-axis simultaneous (X, Y, Z + A/B or B/C), 6-axis (5-axis CNC + integrated robotic or adaptive 6th axis for dynamic repositioning) |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed for Aluminum and plastics), lower range 6,000 – 12,000 RPM for steel |

| Spindle Power | 15 – 30 kW (dependent on material and cutting load) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tool Changer (ATC) | Automatic tool changer with 20–60 tool capacity; HSK-A63 or BT40 tool holders |

| Work Envelope (Typical) | 500 mm (X) × 400 mm (Y) × 350 mm (Z) – varies by machine size and configuration |

| Rotary Axis Range | A-axis: ±120°, B-axis: ±120° (enabling full 5-axis tilt and continuous machining) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 with 5-axis interpolation and collision avoidance |

| Maximum Material Compatibility | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (PA6, PA66), PEEK, Delrin |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005″) typical; down to ±0.005 mm (±0.0002″) with precision probing and thermal compensation |

| Surface Finish | Ra 0.4 – 1.6 µm (achievable with fine finishing passes and appropriate tooling) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar), optional mist cooling for plastics |

| Turning Integration (Mill-Turn) | Optional integrated live tooling and C-axis for simultaneous milling and turning operations on compatible multi-axis platforms |

| Probing Systems | On-machine touch probes for tool setting, workpiece alignment, and in-process inspection |

| Applications | Aerospace components, medical implants, complex molds, rapid prototyping, high-precision fixtures |

Material-Specific Machining Notes

Aluminum is machined at high speeds with sharp carbide tools to prevent built-up edge. Steel requires rigid setups, lower RPM, and high-torque spindles. ABS and Nylon are low-melting-point thermoplastics requiring sharp tools, low feed rates, and minimal heat buildup to avoid deformation. All materials benefit from optimized toolpaths and fixture strategies enabled by 5-axis access, reducing setup changes and improving geometric accuracy.

This specification profile reflects high-end CNC machining platforms capable of meeting tight-tolerance demands across diverse materials, with 6-axis functionality representing the frontier of adaptive, multi-motion manufacturing systems.

From CAD to Part: The Process

Honyo Prototype 6-Axis CNC Milling Process Overview

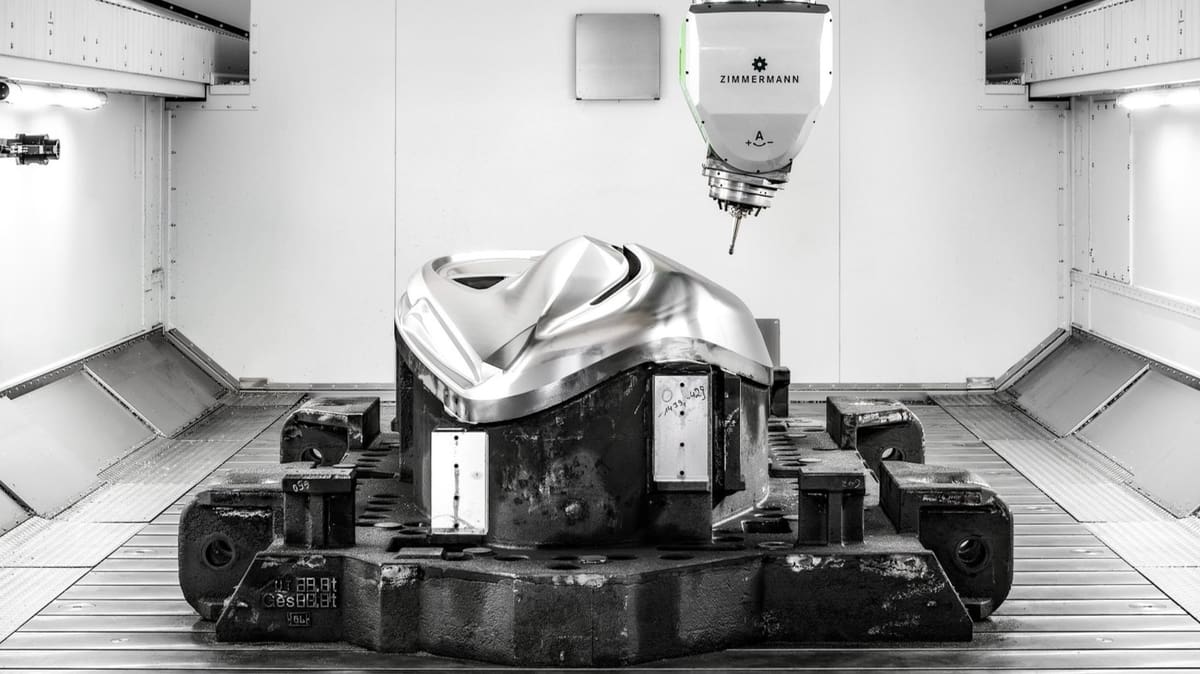

Honyo Prototype utilizes advanced 5-axis simultaneous CNC milling centers (marketed as 6-axis capability for complex geometries, incorporating rotary/tilt axes beyond standard 3-axis motion) to produce high-precision, intricate components. Our streamlined workflow ensures technical rigor and efficiency from design submission to delivery. Below is a detailed technical breakdown of the process.

CAD Upload and Initial Processing

Clients submit native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs an immediate format validation check and geometric integrity scan. Files undergo automated preprocessing to identify potential topology errors, non-manifold edges, or unit inconsistencies. This phase ensures the digital model aligns with manufacturing constraints before progression.

AI-Powered Quoting Engine

Validated CAD data enters our proprietary AI quoting system, trained on 15+ years of Honyo production data across 50,000+ CNC projects. The algorithm analyzes part geometry, material requirements, tolerances, and surface finishes to generate a preliminary quote within 2 hours. Key technical inputs include:

Material waste factor calculation based on stock dimensions

Predictive machine time estimation using historical cycle data

Real-time machine availability and scheduling simulation

Automated identification of high-risk features (thin walls, deep cavities, undercuts)

The AI output includes cost breakdowns, lead time projections, and preliminary material recommendations. Critical complex features trigger automatic escalation to engineering review.

Engineering-Driven DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our senior CNC process engineers. For 6-axis work, this phase focuses on:

Collision avoidance simulation for multi-axis toolpaths

Workholding strategy optimization to minimize setups

Feature accessibility analysis for 5-axis simultaneous motion

Material-specific toolpath parameter validation (e.g., titanium vs. aluminum)

Engineers collaborate directly with clients via secure portal annotations to resolve geometric conflicts, suggest tolerance relaxations per ISO 2768-mK, or recommend design modifications. Typical DFM turnaround is 24 business hours. Approved DFM reports include detailed machining strategy documentation.

Precision Production Execution

Production occurs on our HAAS DMR-350 5-axis vertical machining centers with true simultaneous 5-axis capability (X, Y, Z, A, B axes + optional C-axis for secondary operations). Key production protocols:

Material certification verification (ASTM/AMS standards) prior to machining

In-process CMM validation at critical feature stages

Real-time tool wear monitoring via spindle load sensors

Environmental controls maintaining ±0.5°C temperature stability

Typical tolerances held: ±0.005 mm for critical features, ±0.025 mm standard. Common materials include 7075-T6 aluminum, Inconel 718, and PEEK. Average first-article production time ranges from 8–72 hours based on complexity.

Quality-Assured Delivery

All parts undergo final inspection per AS9102 aerospace standards:

Full CMM report with GD&T analysis

Surface roughness verification (Ra 0.8–3.2 µm typical)

First-article inspection documentation

Material traceability certificates

Packaged parts ship with protective custom foam inserts in static-dissipative containers. Digital delivery includes machine toolpath logs, inspection datasets, and process validation reports. Standard lead time from DFM approval to delivery is 5–10 business days for prototype quantities.

This integrated workflow leverages automation for speed while maintaining engineering oversight for complex 6-axis requirements, ensuring technical compliance and dimensional integrity for mission-critical components.

Start Your Project

Explore the precision and versatility of our 6-axis CNC milling machines, engineered for complex, high-tolerance manufacturing tasks. With advanced motion control and multi-directional machining capabilities, these machines deliver unmatched efficiency for aerospace, medical, and automotive prototyping and production.

For detailed specifications, pricing, and lead times, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, China, ensuring fast turnaround and strict quality control for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.