Contents

Manufacturing Insight: Cnc Mill Turn Machine

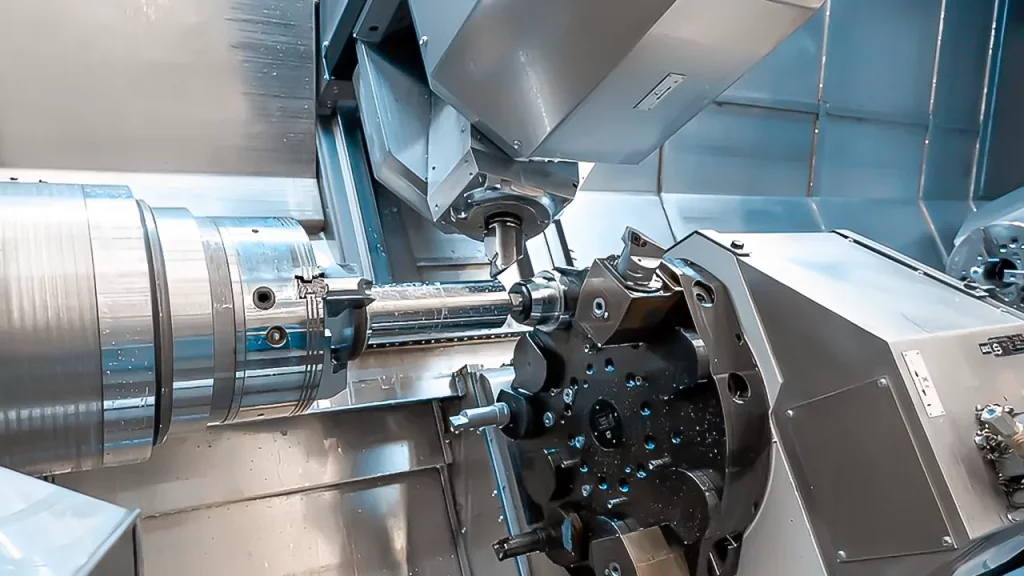

Precision Integrated Manufacturing Through Advanced CNC Mill-Turn Technology

Honyo Prototype delivers exceptional component manufacturing by leveraging state-of-the-art CNC mill-turn machines, merging the highest levels of milling and turning capability into a single, seamless process. Our HAAS and DMG MORI mill-turn centers execute complex geometries—such as precision shafts with cross-drilled holes, hydraulic manifolds with integrated sealing surfaces, or aerospace bracket assemblies requiring concentricity within ±0.005mm—in one fixture setup. This eliminates cumulative tolerances from multiple operations, reduces lead times by up to 60%, and ensures superior part integrity critical for demanding industries like medical device development and industrial automation.

Unlike conventional sequential machining approaches, Honyo’s mill-turn solutions integrate live tooling, Y-axis milling, and sub-spindle technology to machine intricate features on turned components without manual repositioning. The result is consistent micron-level accuracy across multi-faceted parts that would otherwise require costly secondary operations or assembly.

Technical Comparison: Mill-Turn vs. Traditional Methods

| Capability | Traditional Process Chain | Honyo Mill-Turn Solution |

|---|---|---|

| Setup Changes | 3-5+ setups per complex part | Single setup |

| Typical Tolerance Stack | ±0.025mm to ±0.050mm | ±0.005mm to ±0.010mm |

| Lead Time for 50 Complex Parts | 10-14 business days | 4-6 business days |

Accelerate your prototyping and low-volume production cycles with Honyo’s Online Instant Quote system. Upload your STEP or Parasolid file to receive a detailed manufacturability analysis and competitive pricing within 2 hours—no sales calls or email delays. Our platform automatically identifies optimal mill-turn strategies for your design, highlighting opportunities to reduce costs through integrated machining. For engineers requiring rapid validation of complex components, this direct digital workflow eliminates procurement bottlenecks while maintaining full technical transparency. Partner with Honyo Prototype to transform intricate designs into precision-engineered realities with unmatched speed and repeatability.

Technical Capabilities

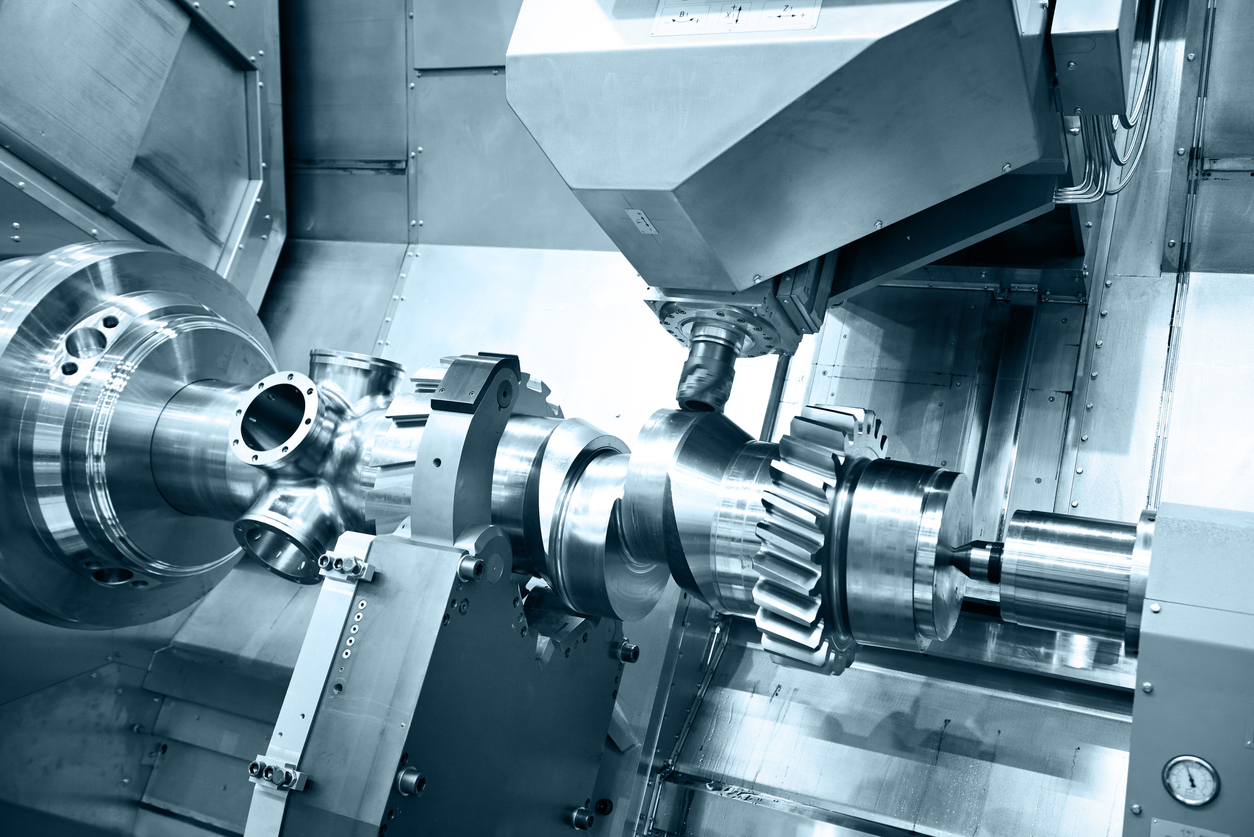

CNC Mill Turn Machines combine precision milling and turning operations in a single setup, enabling complex geometries with high accuracy. These machines are ideal for multi-axis machining, particularly in 3, 4, and 5-axis configurations, allowing simultaneous movement across multiple planes. They are widely used for components requiring tight tolerances, such as aerospace, medical, and automotive parts. The integration of milling and turning reduces cycle time and improves part concentricity.

The following table outlines key technical specifications relevant to 3/4/5-axis CNC mill turn machines, focusing on capabilities related to milling, turning, tight tolerances, and material compatibility.

| Specification | Detail |

|---|---|

| Machine Type | Multi-Tasking CNC Mill Turn Center (Live Tooling Capable) |

| Axis Configuration | 3-Axis (X, Y, Z), 4-Axis (X, Y, Z, B or C), 5-Axis Simultaneous (X, Y, Z, A/B or B/C) |

| Spindle Speed (Milling) | Up to 12,000 RPM (high-speed options up to 24,000 RPM available) |

| Spindle Speed (Turning) | Up to 4,500 RPM (depends on chuck size and workpiece mass) |

| Tool Magazine Capacity | 12–60 tools (depending on model and automation integration) |

| Positioning Accuracy | ±0.005 mm (0.0002 in) |

| Repeatability | ±0.002 mm (0.0001 in) |

| Typical Tolerance Range | ±0.01 mm to ±0.005 mm (tight tolerance applications down to ±0.002 mm with thermal compensation and in-process metrology) |

| Surface Finish (Ra) | 0.8–3.2 µm (achievable; polishable to <0.4 µm) |

| Work Envelope (Max Turning Diameter) | Up to Ø400 mm (15.7 in), depending on machine size |

| Bar Capacity (if applicable) | Ø20–65 mm (0.8–2.6 in) for bar-fed models |

| Control System | Fanuc, Siemens, or Heidenhain with 5-axis interpolation and tool path optimization |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) for deep drilling and chip evacuation |

| Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66), and other engineering plastics |

| Machining of Plastics | Requires optimized feeds/speeds, sharp tooling, and chip management; Nylon and ABS typically machined with carbide tools at moderate speeds |

| Thermal Compensation | Standard on high-precision models to maintain dimensional stability during long runs |

| In-Process Probing | Optional touch probe for auto-part zero, tool measurement, and closed-loop tolerance control |

| Automation Ready | Compatible with gantry loaders, robotic arms, and pallet systems for lights-out manufacturing |

These machines deliver high repeatability and accuracy across diverse materials. Aluminum and steel parts benefit from high metal removal rates and fine surface finishes, while ABS and nylon require controlled parameters to prevent melting or deformation. The ability to perform milling and turning in one setup ensures tighter concentricity and reduced fixturing errors, making CNC mill turn centers essential for high-precision, complex components.

From CAD to Part: The Process

Honyo Prototype CNC Mill-Turn Process Overview

Honyo Prototype employs a rigorously defined workflow for CNC mill-turn projects, engineered to maximize precision, reduce lead times, and mitigate production risks. This integrated process spans from initial design submission through final delivery, leveraging automation and expert engineering oversight at critical junctures.

Upload CAD

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system automatically validates file integrity, confirms geometric completeness, and checks for unit consistency (e.g., mm vs. inches). Incomplete geometries or non-manufacturable features trigger immediate client alerts, preventing downstream delays. All data is encrypted and staged in our production management system for auditability.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into our proprietary AI quoting module. This system analyzes part geometry, material requirements, tolerances, and surface finishes to generate a preliminary cost and lead time estimate within 15 minutes. The AI cross-references historical machine utilization data, material scrap rates, and real-time shop floor capacity. Crucially, it flags potential high-risk features (e.g., deep cavities, thin walls <0.5mm) requiring engineering review, ensuring quotes reflect achievable manufacturability—not optimistic assumptions.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our AS9100-certified manufacturing engineers. This phase is not automated; it combines AI-generated insights with human expertise to:

Identify unnecessary tight tolerances increasing cost

Propose optimal workholding strategies for mill-turn efficiency

Suggest geometry modifications to avoid secondary operations

Validate toolpath feasibility for live-tooling and Y-axis milling

Confirm material suitability for multi-axis machining stresses

Clients receive a formal DFM report with actionable recommendations, often reducing production costs by 18–32% through collaborative design refinement.

Precision Mill-Turn Production

Approved designs enter production on our HAAS DT-15Y or DMG MORI CTX beta 1250 mill-turn centers. Key capabilities include:

| Parameter | Specification | Application Impact |

|---|---|---|

| Max Turning Ø | 200 mm | Complex housings, shafts |

| Live Tooling | 12-station turret, C/Y/B axes | Milling, drilling, tapping in one setup |

| Spindle Speed | 10,000 RPM | High-precision finishing |

| Sub-Spindle | Integrated pick-off capability | Eliminates secondary operations |

| Tolerance Control | ±0.005 mm | Aerospace/medical compliance |

Each part undergoes in-process CMM verification at critical stages. Our MES tracks tool wear compensation in real-time, and first-article inspection reports (FAIR) are generated per AS9102 standards before full batch release.

Certified Delivery & Traceability

Completed parts undergo final dimensional validation against client-specified GD&T. All deliverables include:

Material certification (e.g., EN 10204 3.1)

Full FAIR with CMM data plots

Process nonconformance report (if applicable)

Serialized traceability logs from raw material to shipment

Parts ship in anti-corrosion packaging with real-time logistics tracking. Our 99.2% on-time delivery rate is underpinned by buffer capacity allocation during the AI quoting phase, ensuring committed deadlines are met even during peak demand cycles.

This closed-loop process transforms digital designs into certified, production-ready components while minimizing client engineering burden—proven through 1,200+ successful mill-turn projects annually across aerospace, medical, and robotics sectors.

Start Your Project

Looking for precision CNC mill turn machining services? Contact Susan Leo at [email protected] to discuss your project requirements.

Our state-of-the-art manufacturing facility is located in Shenzhen, China, enabling fast turnaround and high-quality production for prototypes and low-volume runs.

We specialize in multi-axis CNC milling and turning, delivering tight-tolerance components with superior surface finish and consistency.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.