Contents

Manufacturing Insight: Cnc Mill Tool Holders

Precision Tool Holding: The Foundation of Reliable CNC Milling Operations

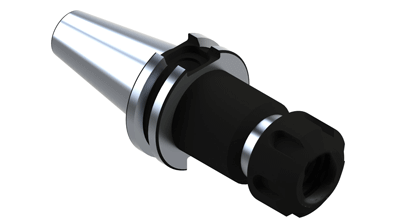

At Honyo Prototype, we recognize that CNC mill tool holders are far more than simple adapters—they are critical interfaces dictating machining accuracy, tool life, and process stability. Suboptimal tool holding introduces runout, vibration, and premature tool wear, directly impacting part quality and production economics. Our engineering team designs and manufactures high-performance tool holders—包括 CAT, BT, HSK, and ER collet systems—to stringent ISO standards, ensuring micron-level concentricity, balanced rigidity, and thermal stability for demanding applications.

Leveraging decades of precision machining expertise, Honyo integrates advanced materials like pre-stressed alloy steels and proprietary heat treatments to deliver tool holders that minimize deflection under heavy cuts while maintaining repeatability across thousands of cycles. Every component undergoes rigorous metrology validation, including runout testing at operational RPMs, to guarantee it meets the exacting tolerances required in aerospace, medical, and automotive prototyping. This commitment to engineering integrity ensures your CNC milling process achieves optimal metal removal rates without compromising surface finish or dimensional accuracy.

Streamline your path from design to production with Honyo’s Online Instant Quote platform. Upload your CAD files for tool holders or complex machined assemblies, and receive a detailed manufacturability analysis with competitive pricing in under 60 seconds. Our system dynamically evaluates geometry, material selection, and tolerance requirements to provide transparent, no-obligation quotes—accelerating procurement while eliminating estimation delays. Partner with Honyo Prototype for tool holding solutions engineered to maximize your spindle uptime and part consistency.

Technical Capabilities

CNC mill tool holders are critical components in precision machining systems, especially in 3-, 4-, and 5-axis milling and turning operations where tight tolerances, rigidity, and repeatability are essential. These holders secure cutting tools in the spindle and must maintain high concentricity, minimal runout, and excellent damping characteristics. While the tool holders themselves are typically made from high-strength steel or alloy steel for durability and thermal stability, the materials referenced—aluminum, steel, ABS, and nylon—are often relevant in related tooling components, fixtures, or prototypes rather than the holders themselves.

Below is a technical specification table detailing key attributes of CNC mill tool holders used in high-precision applications:

| Feature | Specification |

|---|---|

| Holder Type | Common types include CAT (BT), HSK, ER collet, hydraulic, shrink fit, and milling chucks. HSK is preferred for 4- and 5-axis due to high rigidity and accuracy. |

| Taper Accuracy | Precision ground to ≤ 0.0002″ (5 µm) total indicator reading (TIR) to ensure secure spindle engagement and minimize runout. |

| Runout | ≤ 0.0001″ (2.5 µm) at 3× diameter (3×D) for tight-tolerance work; shrink fit and hydraulic holders achieve the lowest values. |

| Balancing | Balanced to G2.5 at 25,000 RPM for high-speed 5-axis applications to prevent vibration and tool wear. |

| Pull Stud Force | Designed to withstand high clamping forces (e.g., 8,000–12,000 lbs for CAT40) for secure retention during aggressive milling. |

| Material (Holder) | Alloy steel (e.g., 4140, 8620) or high-strength tool steel, heat-treated to 58–62 HRC for wear resistance and longevity. |

| Surface Finish | Precision-ground and often coated (e.g., black oxide, TiN) to reduce friction and corrosion. |

| Compatibility | Supports tool shanks including straight, Weldon, and metric; ER collets accommodate a range of diameters (1–13 mm typical). |

| Thermal Stability | Designed to maintain concentricity under thermal expansion; shrink fit holders use thermal expansion for micron-level gripping. |

| Rigidity | High torsional and lateral stiffness to prevent deflection during deep cuts and high feed rates in steel and titanium. |

| Applications | 3-axis: general milling; 4-axis: indexed and rotary work; 5-axis: continuous contouring with complex tool paths; all suitable for tight-tolerance (< ±0.0005″) work. |

| Material Notes (Aluminum, Steel, ABS, Nylon) | Aluminum and steel are common workpiece materials requiring rigid holders; ABS and nylon are non-metallic materials used in prototyping—these require sharp tools and stable holders to maintain dimensional accuracy due to low melting points and deflection tendencies. |

Note: While aluminum, ABS, and nylon are not used in the construction of CNC tool holders due to insufficient strength and thermal resistance, they are frequently machined using these holders. Proper holder selection ensures minimal vibration and precise tool control, which is critical when achieving tight tolerances in both metallic and non-metallic workpieces.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven workflow for CNC mill tool holder production, ensuring precision, efficiency, and traceability from initial design to final delivery. Our process is engineered specifically for high-tolerance components like CAT, BT, HSK, and ISO taper tool holders, where geometric accuracy and material integrity are non-negotiable.

CAD Upload

Clients submit 3D CAD models in native or STEP/IGES formats via our secure client portal. For tool holders, we require complete geometric definitions including taper angles (e.g., 7:24 for CAT/BT), flange dimensions, drawbar notch specifications, and coolant through-hole geometry. All submissions undergo automated validation for file integrity and unit consistency before entering the quotation pipeline.

AI-Powered Quotation

Our proprietary AI engine analyzes the CAD geometry against live shop floor data, including machine availability (5-axis vertical mills, precision grinders), material stock (typically pre-hardened tool steel like 4140 or HPM-50), and real-time labor rates. The system identifies critical features requiring tight tolerances (e.g., ±0.0002″ on taper diameters) and generates a detailed quote within 2 hours. This includes breakdowns for precision grinding cycles, runout testing protocols, and optional balancing certification (G2.5 at 25,000 RPM).

DFM Analysis

Engineers conduct a rigorous Design for Manufacturing review focused on tool holder-specific challenges. Key checks include verifying minimum wall thickness around coolant passages to prevent distortion during heat treatment, assessing grindability of internal taper features, and confirming drawbar notch geometry compatibility with common retention knobs. We flag risks such as inadequate relief for collet retention grooves or non-optimal stress concentrations at flange transitions. Clients receive a formal DFM report with actionable recommendations, typically within 24 business hours.

Production Execution

Approved designs move to production with strict adherence to tiered quality gates. Material certs (e.g., SAE 4140 with ≤0.035% lead for grindability) are verified upon receipt. Machining sequences prioritize thermal stability: rough milling precedes heat treatment (to 48-52 HRC), followed by precision grinding of tapers and faces on Studer S41 machines. Every holder undergoes mandatory post-grind inspection on a Zeiss CONTURA CMM for taper profile accuracy (±0.0001″), face runout (<0.0002″), and concentricity. Balancing is performed per ISO 1940-1 standards when specified.

Delivery and Traceability

Completed tool holders are packaged in anti-corrosion VCI bags with serialized traceability tags linking to full production records. Delivery includes a comprehensive quality dossier containing CMM inspection reports, material certs, and hardness test results. Standard lead time is 10-15 business days from DFM approval, with expedited 7-day options available. All shipments include real-time logistics tracking via our client portal, with final delivery confirmation triggering automatic archival of the project in our AS9100-compliant quality management system.

This integrated process ensures every tool holder meets the rigidity, balance, and repeatability demands of high-speed machining environments while minimizing client risk through embedded quality validation at each phase.

Start Your Project

Looking for high-precision CNC mill tool holders for your manufacturing operations? Honyo Prototype offers durable, industry-grade tool holders engineered for optimal performance and repeatability.

Our factory in Shenzhen ensures strict quality control and fast production turnaround, meeting the demands of modern CNC machining environments.

For product inquiries or custom solutions, contact Susan Leo at [email protected]. Let’s discuss how we can support your tooling requirements with reliable, high-performance components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.