Contents

Manufacturing Insight: Cnc Mill Drill

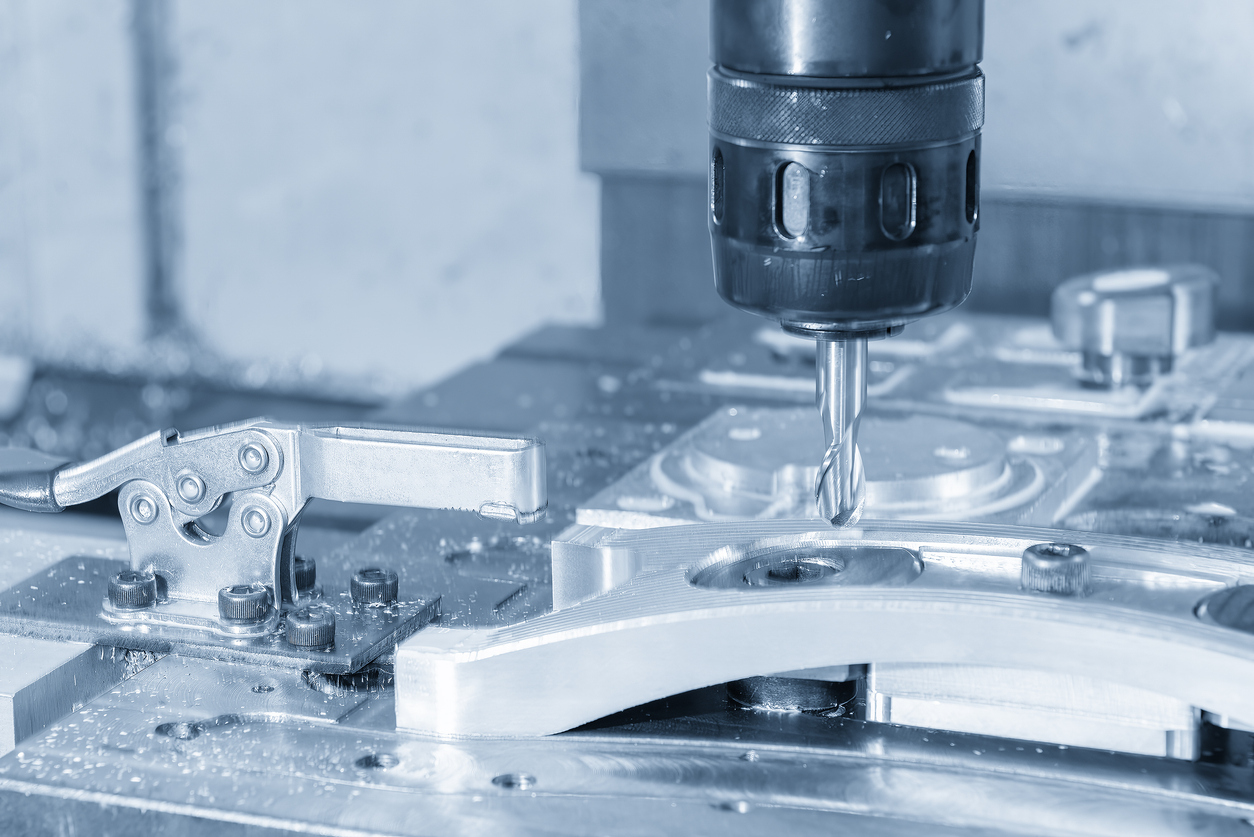

Precision CNC Mill-Drill Capabilities for Demanding Prototyping and Production

Honyo Prototype delivers advanced CNC machining services engineered to meet the exacting demands of complex mill-drill operations. Our integrated 3-, 4-, and 5-axis milling centers, combined with high-speed drilling capabilities, enable single-setup production of intricate geometries, tight-tolerance features, and multi-surface components. We consistently achieve ±0.005 mm tolerances across materials ranging from aerospace-grade aluminum and titanium to hardened steels and engineering plastics, ensuring dimensional accuracy and surface finishes that exceed industry standards. This precision reduces secondary operations and accelerates time-to-assembly for critical applications in aerospace, medical, and industrial automation.

Streamlined Quoting for Rapid Project Launch

Eliminate quoting delays that stall engineering timelines. Honyo’s Online Instant Quote system provides detailed, transparent pricing in seconds—not hours—for CNC mill-drill projects. Upload your STEP or IGES file, specify materials and quantities, and receive a validated cost breakdown with lead time estimates, all without sales intermediary. This engineer-centric platform leverages real-time machine availability and material cost data, empowering your team to iterate designs and initiate production faster.

Technical Execution Backed by Manufacturing Expertise

Beyond speed, our process integrates DFM analysis at the quoting stage to identify potential manufacturability risks, minimizing costly revisions. Each mill-drill operation undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, with full traceability from raw material to finished part. Partner with Honyo to transform complex mill-drill requirements into certified, production-ready components—where precision engineering meets operational agility.

Technical Capabilities

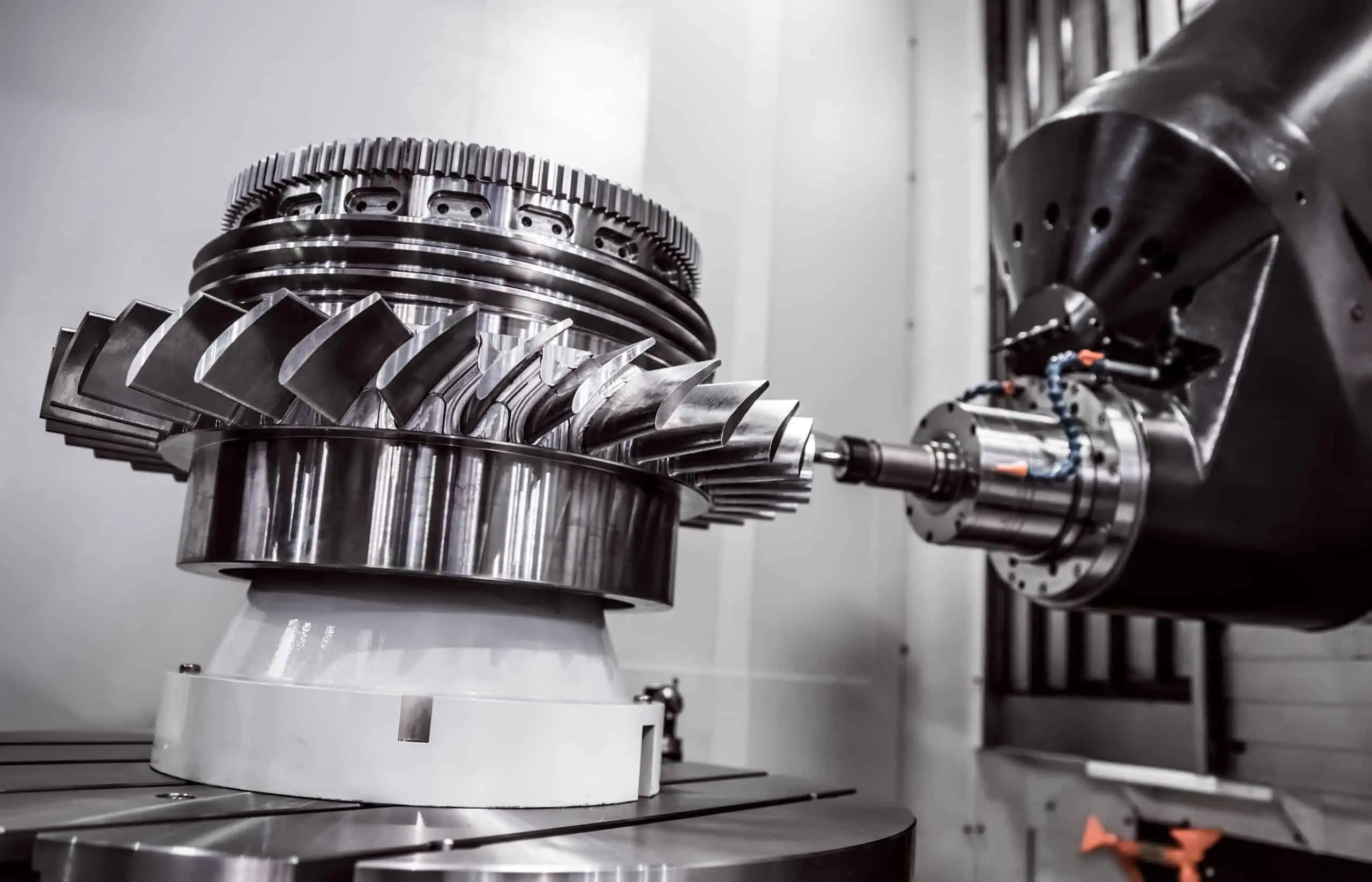

CNC mill drill machines are precision manufacturing systems designed for high-accuracy machining of complex geometries across a range of engineering materials. These machines integrate milling and drilling operations with advanced multi-axis control, enabling tight-tolerance production for prototyping and low-to-mid volume manufacturing. Below are the key technical specifications focused on 3/4/5-axis milling, turning capabilities, and performance with common materials such as aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Axes Configuration | 3-axis (X, Y, Z) standard; 4-axis adds rotary A or B axis; 5-axis supports simultaneous motion in X, Y, Z and two rotational axes (e.g., A and C), enabling complex contouring and single-setup machining |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed spindles available for aluminum and plastics); lower speeds (5,000–12,000 RPM) optimized for steel |

| Positioning Accuracy | ±0.005 mm (±0.0002″) typical; high-precision models achieve ±0.002 mm (±0.00008″) |

| Repeatability | ±0.003 mm (±0.0001″) across all axes |

| Tool Changer | Automatic Tool Changer (ATC) with 12–30 tool capacity; optional side or carousel mount |

| Control System | Fanuc, Siemens, or Heidenhain CNC controls with 5-axis simultaneous interpolation and tool path optimization |

| Tolerance Capability | ±0.01 mm (±0.0004″) standard; down to ±0.005 mm (±0.0002″) with process optimization and environmental control |

| Work Envelope (Typical) | 500 x 400 x 300 mm (X, Y, Z); larger models available up to 1000 x 600 x 500 mm |

| Turning Capability | Integrated turning function available on mill-turn centers; live tooling enables milling while part is rotating; C-axis contouring for precise angular positioning |

| Materials Compatibility | |

| Aluminum (e.g., 6061, 7075) | High-speed machining with sharp carbide tools; coolant-through tooling recommended; excellent surface finish and chip evacuation |

| Steel (e.g., 4140, 1018, Stainless 304/316) | Lower spindle speeds, rigid tooling, and high-torque spindles required; use of coolant and peck drilling for deep holes |

| ABS | Low cutting forces; optimized with high RPM, sharp tools, and light passes to prevent melting; minimal clamping force needed |

| Nylon (e.g., PA6, PA66) | Requires sharp tools and controlled feed rates to avoid deformation; use of air blasting for chip removal due to material stickiness |

| Coolant System | Flood coolant standard; optional through-spindle coolant and mist cooling for plastics and precision steel work |

| Fixture Compatibility | Compatible with modular fixturing, vacuum tables (for plastics), and rotary tables for 4th/5th axis operations |

| Surface Finish | Achieves Ra 0.8–1.6 µm (32–63 µin) typical; down to Ra 0.4 µm (16 µin) with finishing passes and proper tool selection |

These specifications reflect industrial-grade CNC mill drill systems suitable for high-precision applications in aerospace, medical, and automotive sectors. Multi-axis configurations significantly reduce setup time and improve geometric accuracy, especially for complex parts requiring tight tolerances across multiple features. Material-specific toolpaths and cutting parameters are essential to maintain dimensional stability and surface quality.

From CAD to Part: The Process

Honyo Prototype CNC Milling and Drilling Process Overview

Honyo Prototype executes CNC milling and drilling operations through a streamlined, technology-driven workflow designed for precision, speed, and manufacturability. The process begins when a client uploads their CAD model to our secure online portal. We accept industry-standard formats including STEP, IGES, Parasolid, and native files from SolidWorks, Fusion 360, and Creo. All data is protected under ISO 27001-certified cybersecurity protocols to ensure intellectual property confidentiality.

AI-Powered Quoting System

Immediately after CAD upload, our proprietary AI engine analyzes the geometry, material specifications, tolerances, and feature complexity. This system cross-references real-time machine availability, tooling requirements, and material costs to generate an accurate quote within 2 hours. Unlike basic quoting tools, our AI flags potential manufacturability concerns such as thin walls, deep cavities, or non-standard hole depths, providing actionable feedback before formal order placement. Clients receive a detailed cost breakdown with visual annotations highlighting areas for optimization.

Engineering-Led DFM Analysis

Upon quote acceptance, the design enters our mandatory Design for Manufacturability (DFM) phase. Dual-certified manufacturing engineers (ASME Y14.5 GD&T specialists) conduct a rigorous review focusing on CNC-specific constraints. Key evaluations include tool access for drilling operations, optimal hole depth-to-diameter ratios, avoidance of internal radii smaller than standard end mill sizes, and strategic feature grouping to minimize setups. We provide a formal DFM report with revision suggestions—typically resolving 85% of issues before cutting metal. This phase targets completion within 24 hours for standard parts.

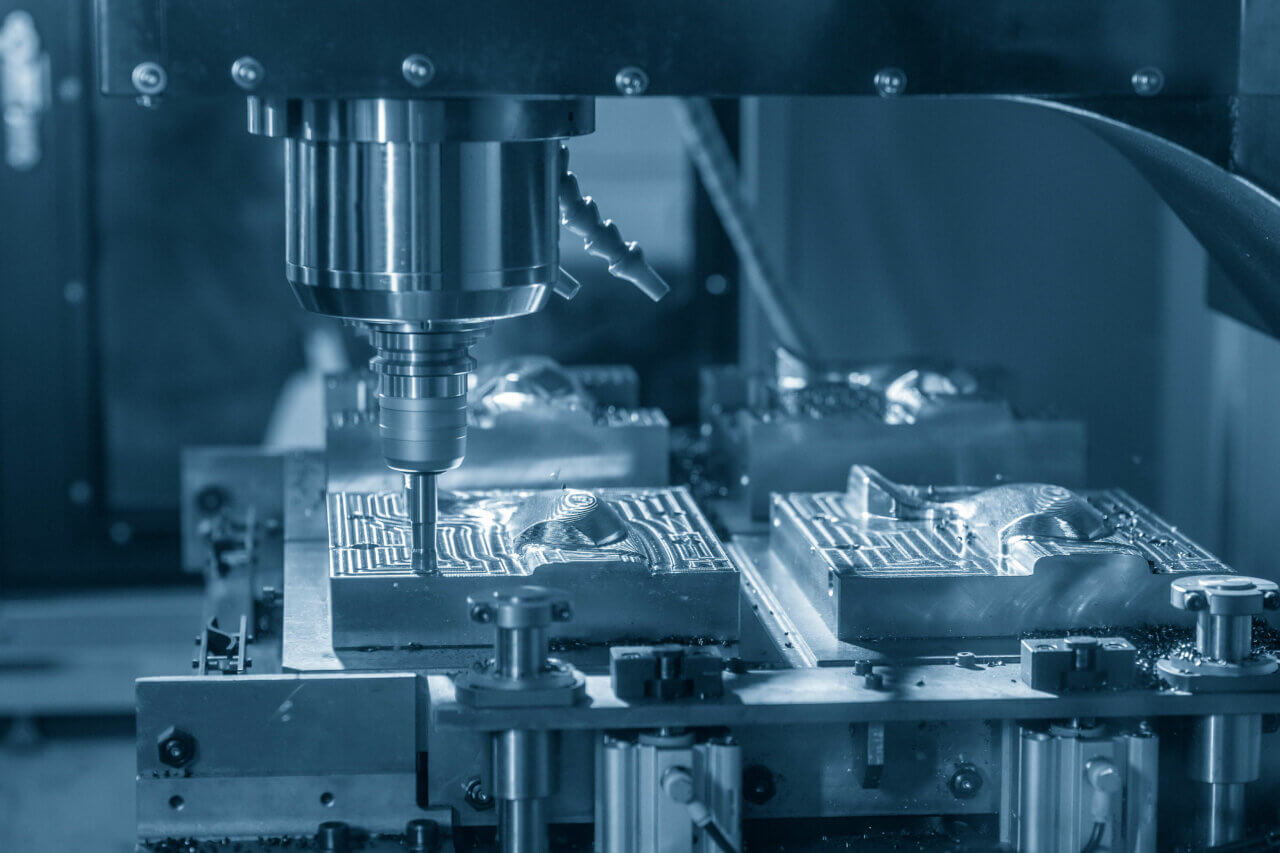

Precision Production Execution

Approved designs move to production on our network of Haas, DMG MORI, and Makino 3- to 5-axis machining centers with 0.0002″ (5µm) positional accuracy. For milling and drilling sequences, we implement:

Automated tool path validation via Mastercam Sim 7X to eliminate collisions

In-process probing for critical hole location verification (e.g., ±0.001″ positional tolerance)

Coolant-through tooling for deep hole drilling to prevent chip packing

Real-time SPC monitoring of surface finishes and dimensional drift

All operations adhere to ISO 9001:2015 and IATF 16949 protocols, with first-article inspection reports available upon request.

Tracked Delivery and Traceability

Finished parts undergo final CMM validation against the original CAD model before packaging. Every shipment includes a digital traceability package containing:

Material certification (e.g., 6061-T6 aluminum mill test reports)

Process-specific documentation (drill cycle parameters, tool IDs used)

Dimensional inspection data for critical features

Parts ship via DHL or FedEx with real-time GPS tracking, typically within 5–10 business days for standard orders. Rush services (72-hour turnaround) are available for qualified projects with pre-approved DFM.

This integrated workflow reduces time-to-part by 30% compared to industry averages while maintaining >99.5% first-pass yield rates for complex milled/drilled components. Clients retain full visibility through our customer portal, which provides live updates from CAD upload through delivery confirmation.

Start Your Project

Looking for precision CNC mill drill services? Honyo Prototype delivers high-accuracy machining with fast turnaround times. Our state-of-the-art facility in Shenzhen ensures cost-effective, scalable production for prototypes and low-volume runs.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory located in Shenzhen, China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.