Introduction: Navigating the Global Market for cnc military

The global market for CNC military components presents a unique set of challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As these buyers seek reliable sources for precision-engineered parts, they often grapple with questions regarding quality, compliance, and cost-effectiveness. This guide addresses the critical aspects of sourcing CNC military products, providing a comprehensive overview of the various types of components available, their applications in defense and military operations, and essential supplier vetting processes.

Understanding the intricate landscape of CNC military manufacturing is vital for making informed purchasing decisions. Buyers will find insights into the latest technologies, including advanced CNC machining processes and materials, which can enhance the performance and reliability of military equipment. Furthermore, this guide delves into cost considerations, helping buyers navigate pricing models and negotiate effectively with suppliers.

By equipping B2B buyers with actionable insights and a strategic approach, this guide empowers them to confidently source CNC military components that meet stringent quality standards. Whether you are a defense contractor in Brazil or a procurement officer in Germany, this resource is designed to support your organization’s unique needs and ensure successful outcomes in the complex world of military supply chains.

Understanding cnc military Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machined Components | High precision, customizable materials, and complex geometries | Defense equipment, military vehicles, aerospace components | Pros: High quality, tailored solutions. Cons: Potentially higher costs. |

| CNC Prototyping | Rapid production of prototypes for testing and validation | Design validation, part testing, and iterative development | Pros: Quick turnaround, cost-effective. Cons: Limited in final product durability. |

| CNC Military Emblems | Ready-to-cut models for military insignia and unit crests | Customization for military units, ceremonial purposes | Pros: Fast production, variety of styles. Cons: May require additional editing for specific needs. |

| CNC Aerospace Components | Specialized for lightweight, high-strength applications | Aircraft manufacturing, missile systems, satellite components | Pros: Meets stringent aerospace standards. Cons: Complex supply chain management. |

| CNC Defense Systems | Integrated systems for military applications | Surveillance, communication, and weapon systems | Pros: Comprehensive solutions, enhanced performance. Cons: High initial investment. |

What Are the Characteristics of CNC Machined Components?

CNC machined components are known for their exceptional precision and ability to work with a variety of materials, including metals and plastics. They are highly customizable, allowing for complex geometries that meet the specific requirements of military applications. Buyers should consider the quality of the machining process and the supplier’s ability to meet stringent defense standards. While these components ensure reliability and performance, they may come at a higher price point, necessitating a careful evaluation of budget versus quality.

How Does CNC Prototyping Benefit Military Applications?

CNC prototyping allows for rapid production of parts, enabling organizations to test designs before full-scale manufacturing. This process is particularly beneficial in the military sector, where quick iterations can lead to better-performing equipment and systems. B2B buyers should focus on suppliers that offer advanced prototyping technologies, as these can significantly reduce development time and costs. However, it’s important to note that prototypes may not always possess the durability required for final products, so careful consideration of their intended use is crucial.

What Makes CNC Military Emblems Unique?

CNC military emblems provide ready-to-cut models for military insignia, making them ideal for customization and ceremonial purposes. These emblems come in various styles, allowing for personalization that reflects specific unit identities. B2B buyers should look for suppliers who can quickly produce these models and offer additional editing options. While they are efficient for production, potential buyers must be aware that some models may require further adjustments to meet specific design criteria.

What Are the Key Features of CNC Aerospace Components?

CNC aerospace components are designed with a focus on lightweight and high-strength characteristics, essential for applications in aviation and defense. They adhere to rigorous industry standards, ensuring safety and reliability in critical systems. Buyers in the defense sector should prioritize suppliers with experience in aerospace manufacturing and a proven track record of compliance with regulatory requirements. However, managing the supply chain can be complex, and buyers should be prepared for potential challenges in sourcing and logistics.

Why Are CNC Defense Systems Important for Military Operations?

CNC defense systems encompass integrated solutions tailored for military use, including communication, surveillance, and weaponry. These systems are crucial for enhancing operational efficiency and effectiveness in the field. B2B buyers should seek partnerships with manufacturers that offer comprehensive solutions and have a strong understanding of military specifications. While these systems provide significant advantages, the initial investment can be substantial, requiring careful financial planning and justification based on operational needs.

Key Industrial Applications of cnc military

| Industry/Sector | Specific Application of cnc military | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace and Defense | Precision Components for Aircraft and Drones | Enhanced performance, safety, and compliance with regulations | Certifications (ISO, ITAR), material specifications, lead times |

| Military Vehicle Manufacturing | Custom Parts for Armored Vehicles | Improved durability and operational efficiency | Quality control measures, testing protocols, rapid prototyping capabilities |

| Weapon Systems Development | Machined Parts for Firearms and Ammunition | High accuracy and reliability in critical applications | Compliance with military standards, traceability of materials |

| Communication Systems | Components for Secure Communication Equipment | Increased reliability and security in communications | Proven supplier history, technical support, and service capabilities |

| Naval Defense | Components for Submarines and Aircraft Carriers | Optimized performance and reduced maintenance costs | Specialized machining capabilities, material certifications, project timelines |

How is CNC Military Used in Aerospace and Defense?

In the aerospace and defense sector, CNC military applications focus on the production of precision components for aircraft and drones. These parts must meet strict safety and performance regulations, which necessitates high-quality machining. International buyers must prioritize suppliers with the right certifications, such as ISO and ITAR, to ensure compliance with global standards. Additionally, understanding material specifications and lead times is crucial for timely project execution.

What are the Custom Parts Needed for Military Vehicle Manufacturing?

Military vehicle manufacturing requires custom parts designed for armored vehicles to enhance durability and operational efficiency. CNC machining provides the capability to produce complex components that withstand extreme conditions. Buyers must consider quality control measures and testing protocols when sourcing these parts, as reliability is paramount in military applications. Rapid prototyping capabilities can also help in refining designs to meet specific operational needs.

How Are Machined Parts Essential in Weapon Systems Development?

In weapon systems development, CNC military applications are crucial for producing machined parts for firearms and ammunition. The precision of these components directly impacts their accuracy and reliability in critical scenarios. Buyers in this sector should ensure that their suppliers comply with military standards and maintain traceability of materials used in production. This guarantees that the parts meet the stringent quality requirements necessary for defense applications.

What Role Do CNC Machining Services Play in Communication Systems?

CNC military applications extend to communication systems, where components for secure communication equipment are manufactured. These parts must be reliable and secure, as they play a vital role in operational success. When sourcing for these applications, international buyers should look for suppliers with proven histories and robust technical support. Ensuring that the supplier understands the unique demands of military communication systems can significantly enhance project outcomes.

How Do CNC Machining Applications Benefit Naval Defense?

In naval defense, CNC military applications are employed to create components for submarines and aircraft carriers, optimizing performance while reducing maintenance costs. The complexity of these components requires specialized machining capabilities. Buyers must consider the supplier’s material certifications and their ability to meet project timelines. Collaborating with experienced partners can lead to innovations that enhance the operational readiness of naval fleets.

3 Common User Pain Points for ‘cnc military’ & Their Solutions

Scenario 1: Navigating Custom Specifications for Military Components

The Problem: B2B buyers in the military sector often face challenges in sourcing CNC machined components that meet stringent specifications and regulatory standards. The complexity of military contracts means that even minor deviations from technical drawings can lead to significant delays, increased costs, and potential compliance issues. Buyers may struggle to find suppliers who can provide parts that not only match their precise needs but also adhere to military specifications, which can vary greatly between contracts and projects.

The Solution: To effectively navigate these challenges, buyers should focus on establishing strong relationships with CNC suppliers who specialize in military applications. When sourcing, it’s crucial to conduct thorough due diligence on potential suppliers, including their certifications (e.g., ISO 9001, ITAR compliance) and previous work with military contracts. Buyers should provide detailed specifications, including tolerances, materials, and intended use cases, during initial discussions. Additionally, leveraging advanced technologies like CAD (Computer-Aided Design) to share 3D models can facilitate clearer communication and reduce the likelihood of misunderstandings. Implementing a collaborative approach, where feedback is encouraged throughout the design and production phases, can also lead to higher quality outcomes and greater satisfaction with the final products.

Scenario 2: Managing Production Timelines Amidst Supply Chain Disruptions

The Problem: Global supply chain disruptions have become increasingly common, impacting the availability of raw materials and components necessary for military CNC machining. B2B buyers often find themselves in a bind when suppliers experience delays or shortages, jeopardizing project deadlines and contract fulfillment. This can lead to costly penalties, strained relationships with government agencies, and a tarnished reputation in the industry.

The Solution: To mitigate these risks, buyers should adopt a proactive supply chain management strategy. This includes diversifying the supplier base to avoid over-reliance on a single source, which can lead to vulnerabilities. Establishing long-term partnerships with multiple CNC machining companies across different regions can help ensure a steady flow of materials and components. Additionally, buyers should consider implementing a just-in-time inventory system, which allows for more flexible production schedules and reduces the burden of holding excessive stock. Regular communication with suppliers about their inventory status and potential challenges can also foster transparency and enable quicker contingency planning when issues arise.

Scenario 3: Ensuring Quality Assurance in CNC Machining for Military Use

The Problem: Quality assurance is paramount in military applications, where the failure of a single component can have catastrophic consequences. B2B buyers often grapple with ensuring that CNC machined parts consistently meet the required quality standards. This challenge can be exacerbated by a lack of standardized processes across different suppliers, leading to variability in product quality and performance.

The Solution: To ensure consistent quality assurance, buyers should prioritize suppliers with robust quality management systems (QMS) in place. Before entering into contracts, it’s essential to assess the supplier’s QMS, looking for certifications such as ISO 9001 and adherence to military specifications. Buyers should also request detailed documentation of the supplier’s quality control processes, including inspection and testing protocols. Implementing a rigorous incoming inspection process for all received components can help catch potential quality issues before they escalate. Additionally, establishing key performance indicators (KPIs) related to quality metrics can enable buyers to monitor supplier performance over time, ensuring that they consistently meet the high standards required for military applications. Regular audits and feedback sessions can further strengthen the partnership and drive continuous improvement.

Strategic Material Selection Guide for cnc military

What Are the Key Materials for CNC Military Applications?

When selecting materials for CNC military applications, it is crucial to consider properties such as strength, weight, corrosion resistance, and manufacturability. Here, we analyze four common materials used in the military sector, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Aluminum Alloys: The Lightweight Champion

Aluminum alloys are widely used in military applications due to their excellent strength-to-weight ratio and corrosion resistance. Key properties include a temperature rating up to 150°C and good machinability.

Pros: Aluminum is lightweight, making it ideal for applications where weight savings are critical, such as aircraft and vehicles. It also offers good corrosion resistance, which is essential for military equipment exposed to harsh environments.

Cons: While durable, aluminum alloys can be more expensive than other materials and may not perform well under extreme temperatures or high-stress conditions. Additionally, they can be less suitable for applications requiring high wear resistance.

Impact on Application: Aluminum is compatible with various media, including fuels and lubricants, but may not perform well in environments with high abrasion.

Considerations for International Buyers: Compliance with standards such as ASTM and European EN specifications is essential. Buyers from regions like Europe and the Middle East may prefer specific aluminum grades that meet local military specifications.

Steel: The Traditional Workhorse

Steel remains a staple in military manufacturing due to its high strength and durability. Key properties include a temperature rating up to 500°C and excellent wear resistance.

Pros: Steel is highly durable and can withstand significant stress, making it suitable for heavy-duty applications like armor plating and structural components. It is also relatively cost-effective compared to other high-performance materials.

Cons: Steel is heavier than aluminum, which can be a disadvantage in applications where weight is a concern. Additionally, it is prone to corrosion if not properly treated or coated.

Impact on Application: Steel components are often used in environments where high mechanical strength is required, such as in weapon systems and armored vehicles.

Considerations for International Buyers: Buyers should ensure compliance with military standards such as ASTM A36 or DIN 17100. The choice of steel grade may vary based on regional preferences and specific application requirements.

Titanium Alloys: The High-Performance Option

Titanium alloys are increasingly popular in military applications due to their exceptional strength, lightweight, and corrosion resistance. Key properties include a temperature rating of up to 600°C and excellent fatigue resistance.

Pros: Titanium offers a superior strength-to-weight ratio and is highly resistant to corrosion, making it suitable for demanding environments. It is also biocompatible, which is advantageous for medical applications in the military.

Cons: The primary drawback of titanium is its high cost and complex manufacturing processes, which can increase production timelines. Additionally, it is more challenging to machine than aluminum or steel.

Impact on Application: Titanium is ideal for high-performance applications such as aerospace components and advanced weapon systems, where weight and strength are critical.

Considerations for International Buyers: Buyers must consider compliance with stringent military specifications, such as AMS 4911. Regional preferences may dictate the choice of titanium grades based on specific operational requirements.

Composite Materials: The Future of Lightweight Solutions

Composite materials, particularly carbon fiber and fiberglass, are gaining traction in military applications due to their lightweight and high strength. Key properties include a temperature rating of up to 200°C and excellent fatigue resistance.

Pros: Composites are incredibly lightweight and can be engineered for specific applications, offering flexibility in design. They also exhibit excellent corrosion resistance and can be tailored for thermal and electrical insulation.

Cons: The primary disadvantage is the high cost of raw materials and the complexity of manufacturing processes, which can lead to longer lead times. Additionally, composites may not be suitable for all structural applications due to potential brittleness.

Impact on Application: Composites are increasingly used in aerospace and naval applications, where reducing weight is essential for performance.

Considerations for International Buyers: Compliance with international standards such as ASTM D3039 for tensile properties is crucial. Buyers should also consider the availability of composite materials in their region and any specific military requirements.

Summary of Material Selection for CNC Military Applications

| Material | Typical Use Case for cnc military | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aircraft components, vehicle parts | Lightweight and corrosion resistant | Expensive, limited high-stress performance | Medium |

| Steel | Armor plating, structural components | High strength and durability | Heavy, prone to corrosion | Low |

| Titanium Alloys | Aerospace parts, advanced weapon systems | Exceptional strength-to-weight ratio | High cost, complex machining | High |

| Composite Materials | Aerospace, naval applications | Lightweight and customizable | High cost, potential brittleness | High |

This strategic material selection guide provides essential insights for international B2B buyers in the military sector, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc military

What Are the Main Stages of CNC Manufacturing for Military Applications?

CNC (Computer Numerical Control) machining is a critical component in the manufacturing of military equipment, ensuring precision and reliability. The manufacturing process typically involves several key stages:

-

Material Preparation: This initial stage involves selecting the appropriate materials, which can range from high-strength alloys to composites, depending on the specific military application. Materials are often sourced from certified suppliers to ensure compliance with military standards. Once selected, materials undergo cutting or shaping to prepare them for the next stage.

-

Forming: During the forming phase, CNC machines utilize advanced techniques such as milling, turning, and drilling to shape the materials into the desired components. This stage is crucial for creating intricate designs and achieving the tight tolerances required in military applications. Technologies like 5-axis machining allow for more complex geometries, reducing the need for multiple setups and increasing overall efficiency.

-

Assembly: In this phase, individual components are assembled into larger systems or subassemblies. This step may involve welding, fastening, or other joining techniques, depending on the component’s design. The assembly must adhere to strict military specifications to ensure functionality and safety under operational conditions.

-

Finishing: The final stage involves surface treatments such as coating, plating, or anodizing to enhance durability and corrosion resistance. Finishing processes also include inspection and polishing to meet aesthetic and functional requirements. This stage is critical, as military components often face harsh environments.

What Key Techniques Are Used in CNC Military Manufacturing?

Several advanced techniques are employed in CNC manufacturing for military applications:

-

Precision Machining: High-precision CNC machines are essential for producing components that meet stringent military specifications. Techniques like CNC milling and turning ensure that parts are manufactured to exact dimensions and tolerances.

-

Additive Manufacturing: Increasingly, additive manufacturing (3D printing) is being integrated into military production processes. This technique allows for rapid prototyping and the creation of complex geometries that traditional machining methods may not achieve.

-

Automation: Automated solutions streamline the manufacturing process, enhancing efficiency and reducing lead times. This is particularly important for military contracts, which often have tight deadlines.

-

Robotics: Robotics play a significant role in assembly and material handling, improving consistency and reducing human error in the manufacturing process.

How Is Quality Assurance Implemented in CNC Military Manufacturing?

Quality assurance (QA) is a vital aspect of CNC military manufacturing, ensuring that all components meet the required standards for safety and performance. Key components of a robust QA system include:

-

International Standards Compliance: Adherence to international standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system (QMS) and helps organizations ensure consistent quality in their products and services.

-

Industry-Specific Certifications: In addition to ISO standards, military suppliers may need to comply with industry-specific certifications, such as CE marking for European markets or API specifications for certain defense-related components. These certifications ensure that products meet safety, health, and environmental protection standards.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specifications before they enter the production line.

- In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify any deviations from specifications, allowing for immediate corrective actions.

- Final Quality Control (FQC): Completed products undergo thorough inspections to verify that they meet all quality standards before shipment.

What Common Testing Methods Are Used in CNC Military Manufacturing?

Testing methods are critical in verifying the quality and safety of military components. Common methods include:

-

Dimensional Inspection: Utilizing tools such as calipers and coordinate measuring machines (CMM) to ensure that components meet specified dimensions and tolerances.

-

Functional Testing: Assessing components under simulated operational conditions to verify that they perform as intended.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, radiographic testing, and magnetic particle inspection are used to detect internal defects without damaging the components.

-

Environmental Testing: Components may be subjected to extreme temperatures, humidity, and other environmental factors to ensure reliability under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets, verifying supplier quality control is crucial. Here are some effective strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality control processes, compliance with standards, and overall manufacturing capabilities.

-

Quality Reports: Requesting detailed quality reports, including inspection results and certifications, can help buyers assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality assurance practices.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances, particularly when sourcing from diverse regions:

-

Regulatory Compliance: Different countries have varying regulations regarding military equipment and components. Buyers must ensure that suppliers comply with local and international laws.

-

Cultural Differences: Understanding cultural differences in business practices and communication can enhance collaboration and ensure smoother transactions.

-

Supply Chain Transparency: Establishing clear communication regarding supply chain practices can help mitigate risks associated with sourcing from international suppliers.

-

Building Relationships: Developing strong relationships with suppliers can lead to improved quality and reliability, as trust fosters better communication and responsiveness to quality issues.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting CNC military suppliers, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc military’

Introduction

This practical sourcing guide is designed for B2B buyers in the military and defense sectors who are looking to procure CNC (Computer Numerical Control) components and services. The guide provides a structured checklist to ensure that your sourcing process is efficient, compliant, and aligned with your project requirements.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the foundation of effective sourcing. Identify the exact components, materials, and tolerances required for your project. This step will help you communicate your needs to potential suppliers and ensure that they can meet your expectations.

- Considerations:

- Material types (e.g., aluminum, titanium, polymers)

- Dimensions and tolerances

- Functionality and application requirements

Step 2: Research Potential Suppliers

Begin by researching suppliers who specialize in CNC machining for military applications. Look for companies with a proven track record in the defense sector, as they will be familiar with compliance and regulatory standards.

- Where to look:

- Industry directories and trade shows

- Online reviews and testimonials

- Recommendations from industry peers

Step 3: Verify Supplier Certifications

Before engaging with suppliers, it’s vital to check their certifications. Look for ISO 9001 certification for quality management and ITAR (International Traffic in Arms Regulations) compliance if applicable. These certifications ensure that the supplier adheres to high standards of quality and security.

- Key Certifications:

- ISO 9001 for quality management

- ITAR for defense-related products

- AS9100 for aerospace quality management

Step 4: Request Detailed Proposals

Once you’ve narrowed down your list of suppliers, request detailed proposals that include pricing, lead times, and production capabilities. This will allow you to compare suppliers more effectively and make informed decisions.

- What to include in your request:

- Breakdown of costs (materials, labor, shipping)

- Production timelines and delivery schedules

- Any additional services offered (e.g., prototyping, assembly)

Step 5: Evaluate Supplier Capabilities

Assess the technological capabilities of each supplier. Look for advanced machinery, such as 5-axis CNC machines, which can produce complex components with high precision. This evaluation is crucial for ensuring that your supplier can meet the specific demands of your project.

- Questions to ask:

- What types of CNC machines do you operate?

- Can you provide examples of similar projects completed?

- What is your capacity for scaling production?

Step 6: Conduct Site Visits and Audits

If possible, conduct site visits to potential suppliers. This not only allows you to see their operations firsthand but also provides an opportunity to assess their quality control processes and overall work environment.

- What to observe:

- Cleanliness and organization of the facility

- Workflow and efficiency of production lines

- Employee expertise and engagement

Step 7: Establish Clear Communication Channels

Effective communication is essential for a successful partnership. Ensure that you have established clear lines of communication with your chosen supplier, including regular updates and feedback mechanisms.

- Communication tips:

- Set up regular check-ins during the project lifecycle

- Use project management tools for tracking progress

- Encourage open dialogue for addressing issues promptly

By following these steps, B2B buyers can streamline their sourcing process for CNC military components, ensuring that they select suppliers who can meet their specific needs while adhering to industry standards.

Comprehensive Cost and Pricing Analysis for cnc military Sourcing

What Are the Key Cost Components in CNC Military Sourcing?

When engaging in CNC military sourcing, understanding the cost structure is crucial for making informed decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials used in military applications include high-strength alloys and composites, which can be more expensive than standard materials due to their specialized properties and certifications.

-

Labor: Skilled labor is essential in CNC machining, particularly in military applications where precision and quality are paramount. Labor costs can vary based on geographic location, expertise required, and the complexity of the machining processes.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and facility operations. Given the stringent standards in military contracts, overhead can be higher due to the need for specialized equipment and compliance with regulations.

-

Tooling: Tooling costs vary based on the complexity of the parts being produced. Custom tooling may be required for specialized components, leading to higher upfront costs but potentially lower long-term costs through reduced cycle times and increased efficiency.

-

Quality Control (QC): Military applications demand strict adherence to quality standards. The costs associated with quality control processes, including testing and certification, are essential to ensure compliance with military specifications.

-

Logistics: Shipping and handling costs can add significant expenses, particularly for international transactions. Understanding Incoterms is vital for determining who bears these costs and responsibilities.

-

Margin: Suppliers typically include a margin in their pricing to cover their business risks and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect CNC Military Sourcing?

Several factors influence pricing in the CNC military sector:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Establishing a reliable demand can help negotiate better pricing.

-

Specifications and Customization: Highly specialized components require more intricate designs and processes, increasing costs. Standardized parts may be cheaper, so balancing customization with cost-effectiveness is crucial.

-

Material Selection: The choice of materials can drastically influence pricing. Specialty materials that meet military specifications often come with a premium.

-

Quality and Certifications: Suppliers with necessary certifications (e.g., ISO 9001, ITAR compliance) may charge more due to the assurance of quality and adherence to stringent military standards.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may command higher prices due to their experience and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery can affect overall costs. Options such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift financial responsibilities, influencing total cost calculations.

What Buyer Tips Can Enhance Cost-Efficiency in CNC Military Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Leverage volume orders and long-term contracts to negotiate better prices. Building a relationship with suppliers can also lead to favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs over the product’s lifecycle. This includes maintenance, operational costs, and potential downtime.

-

Understand Pricing Nuances: Be aware of regional pricing trends and fluctuations in material costs. Currency exchange rates can also impact pricing, especially for international transactions.

-

Evaluate Supplier Capabilities: Assess potential suppliers for their ability to meet military standards and their responsiveness to custom requests. A reliable partner can save costs in the long run by reducing errors and delays.

-

Seek Local Suppliers When Possible: Reducing shipping distances can lower logistics costs and lead times. Local suppliers may also have a better understanding of regional regulations and compliance requirements.

In summary, a comprehensive understanding of cost components, price influencers, and strategic buyer tips can significantly enhance the effectiveness of CNC military sourcing. While prices will vary, careful planning and negotiation can lead to more favorable outcomes.

Alternatives Analysis: Comparing cnc military With Other Solutions

Understanding Alternatives to CNC Military Solutions

In the landscape of military and defense manufacturing, CNC (Computer Numerical Control) technology has established itself as a leading method for producing precision components. However, B2B buyers must explore alternative solutions that can meet their specific needs, budget constraints, and operational requirements. This analysis compares CNC military solutions with other viable methods, allowing organizations to make informed decisions.

Comparison Table

| Comparison Aspect | Cnc Military | Alternative 1: Traditional Machining | Alternative 2: Additive Manufacturing |

|---|---|---|---|

| Performance | High precision and repeatability | Moderate precision, manual variability | High precision but material limits |

| Cost | Higher initial investment, but cost-effective at scale | Generally lower initial costs, higher labor costs | Variable costs, can be expensive for large parts |

| Ease of Implementation | Requires skilled operators and programming | Easier for operators familiar with manual tools | Steep learning curve for new technology |

| Maintenance | Regular maintenance needed for machines | Maintenance depends on equipment age | Minimal maintenance, but material supply can be an issue |

| Best Use Case | Large-scale production of complex parts | Low to medium volume production, prototyping | Rapid prototyping, custom parts in low volumes |

Detailed Breakdown of Alternatives

Traditional Machining

Traditional machining involves manual processes such as milling, turning, and drilling. This method can be effective for lower production volumes and simpler parts. While initial costs may be lower due to reduced machinery investment, labor costs can add up, particularly in regions where skilled labor is scarce. The variability in manual processes can lead to inconsistencies in quality, making this option less suitable for high-precision military applications. However, it may be advantageous for prototypes or projects with less stringent tolerances.

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional methods. This approach is especially beneficial for rapid prototyping and producing custom parts in low volumes. While it offers high precision, the materials used can be limited compared to those available for CNC machining. Additionally, the initial setup costs can be variable and sometimes high, depending on the complexity of the parts being produced. As this technology continues to evolve, it presents exciting opportunities for military applications, particularly in creating lightweight structures or components.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate manufacturing method for military applications hinges on several factors, including production volume, budget, and the specific requirements of the components being produced. CNC military solutions excel in high-precision, large-scale production but require a significant investment in both equipment and skilled labor. Traditional machining may serve well for simpler, lower-volume projects, while additive manufacturing offers unique advantages for custom parts and rapid prototyping. B2B buyers should carefully assess their operational goals, available resources, and the specific demands of their projects to determine the most suitable solution. By aligning manufacturing capabilities with strategic objectives, organizations can enhance efficiency and maintain competitive advantages in the military and defense sectors.

Essential Technical Properties and Trade Terminology for cnc military

What Are the Key Technical Properties in CNC Military Manufacturing?

When engaging in CNC military manufacturing, understanding specific technical properties is essential for ensuring quality and performance. Here are several critical specifications that B2B buyers should be aware of:

1. Material Grade

Material grade refers to the classification of materials used in CNC machining, such as aluminum alloys, stainless steel, or titanium. Each material has unique properties, including strength, weight, and corrosion resistance, making it suitable for different military applications. Selecting the appropriate material grade is crucial for meeting durability and operational requirements, especially in high-stress environments.

2. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension. In military applications, tolerances are often stringent, requiring precision machining to ensure that parts fit and function correctly. A tight tolerance can enhance the performance and reliability of components, which is vital for mission-critical applications. Understanding tolerance levels can help buyers ensure they are sourcing components that meet their specific operational needs.

3. Surface Finish

Surface finish describes the texture of a manufactured surface and is critical in military applications for reducing friction, improving wear resistance, and enhancing aesthetic appeal. Various surface finishes, such as anodizing or powder coating, can also protect parts from environmental factors. Buyers should specify the required surface finish to ensure compatibility with operational conditions.

4. Hardness

Hardness measures a material’s resistance to deformation and wear. Military components often require materials with high hardness to withstand harsh conditions and mechanical stress. Hardness specifications can influence the longevity and reliability of components, making it essential for buyers to consider this property when selecting materials for their applications.

5. Weight

Weight is an important specification in military applications, particularly for equipment and vehicles where reducing weight can enhance performance and fuel efficiency. Lightweight materials, such as composites or advanced alloys, are often preferred. Understanding weight specifications helps buyers optimize their products for mobility and operational effectiveness.

What Are Common Trade Terms Used in CNC Military Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in the CNC military sector. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the military sector, working with OEMs ensures that components meet the specific standards required for military applications, facilitating compliance with regulations and ensuring quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to determine their purchasing strategy and budget. It can also impact inventory management and cash flow, especially for smaller projects.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other information for specific products or services. It is a key step in the procurement process, allowing buyers to compare options and make informed decisions based on cost, quality, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers navigate shipping logistics, risk management, and cost responsibilities in cross-border procurement.

5. ITAR (International Traffic in Arms Regulations)

ITAR refers to U.S. regulations that control the export and import of defense-related articles and services. For international buyers, compliance with ITAR is critical when sourcing military components from U.S. manufacturers, as it ensures adherence to national security protocols.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions and effectively navigate the complexities of CNC military procurement.

Navigating Market Dynamics and Sourcing Trends in the cnc military Sector

What Are the Key Trends Shaping the CNC Military Market?

The CNC military sector is undergoing significant transformation driven by advancements in technology and the evolving geopolitical landscape. One of the primary global drivers is the increasing demand for precision and efficiency in military manufacturing, spurred by the need for rapid deployment and adaptability in modern warfare. This has led to an uptick in the adoption of automated CNC solutions, enhancing production speed and accuracy while reducing human error.

Emerging technologies, such as AI-driven manufacturing and IoT integration, are changing how military components are designed and produced. International B2B buyers are increasingly seeking suppliers who can provide advanced CNC machining services that leverage these technologies. For instance, the ability to simulate machining processes and predict potential failures through digital twins is becoming a standard requirement.

Additionally, the market dynamics are influenced by global supply chain challenges, particularly in regions like Africa and South America, where logistics and infrastructure can pose significant hurdles. Buyers in these regions must prioritize suppliers that demonstrate resilience and flexibility in their sourcing strategies. Furthermore, collaboration between military contractors and technology providers is fostering innovation, allowing for the development of specialized materials and components tailored to specific defense applications.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the CNC Military Sector?

Sustainability is becoming a critical consideration for B2B buyers in the CNC military sector. The environmental impact of manufacturing processes has come under scrutiny, leading to a push for greener practices. Companies are increasingly required to adopt sustainable sourcing methods, which include utilizing eco-friendly materials and reducing waste throughout the manufacturing cycle.

Ethical sourcing is equally important, as buyers are keen to ensure that their suppliers adhere to responsible labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential benchmarks for suppliers in the military sector. Buyers must evaluate their supply chains for compliance with these standards, as non-compliance can lead to significant reputational risks and operational disruptions.

Moreover, there is a growing trend toward utilizing sustainable materials, such as recycled metals and biodegradable composites, in CNC manufacturing. This shift not only helps mitigate environmental impact but also aligns with the increasing demands from governments and consumers for accountability in sourcing practices. B2B buyers must stay informed about the latest certifications and material innovations to ensure that their procurement processes align with these sustainability goals.

What Is the Historical Context of CNC Machining in the Military Sector?

The CNC machining industry has a rich history within the military sector, dating back to the mid-20th century when precision manufacturing became paramount for defense applications. Initially, traditional machining methods were prevalent, but the introduction of CNC technology revolutionized the way military components were produced.

By automating the machining process, CNC technology significantly improved the accuracy and repeatability of manufacturing, which was critical for developing sophisticated military equipment. Over the decades, CNC machining has evolved, incorporating advanced materials and techniques that have enhanced the capabilities of military applications. Today, CNC machining is integral to producing a wide range of military components, from intricate weapon systems to essential vehicle parts, reflecting the ongoing commitment to innovation and excellence in the defense industry.

In summary, understanding the current market dynamics, prioritizing sustainability, and appreciating the historical context of CNC machining can equip international B2B buyers with the insights needed to navigate the complexities of sourcing in the military sector effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc military

-

How do I solve quality assurance issues when sourcing CNC military components?

Ensuring quality assurance in CNC military components starts with thorough supplier vetting. Look for manufacturers with ISO 9001 certification, which indicates a commitment to quality management. Request samples and conduct factory audits to evaluate their processes. Additionally, establish clear quality standards and metrics upfront, and consider implementing regular inspections during production. Collaborate closely with your supplier to address any potential quality issues early in the process, fostering a transparent relationship that prioritizes quality. -

What is the best way to customize CNC military components for specific applications?

The best approach to customization involves clear communication of your requirements to the supplier. Provide detailed specifications regarding dimensions, materials, and tolerances. It’s beneficial to work with manufacturers experienced in military applications, as they understand the regulatory and performance standards involved. Utilize prototyping services to test designs before full production, allowing for adjustments based on performance evaluations. Engaging in iterative feedback during the design phase can lead to optimal customized solutions that meet your specific application needs. -

What are the typical minimum order quantities (MOQs) for CNC military components?

Minimum order quantities for CNC military components can vary significantly based on the supplier and the complexity of the parts. Many manufacturers set MOQs to ensure cost-effectiveness and efficiency in production. It is common to see MOQs ranging from 50 to 500 units, but some suppliers may accommodate lower quantities for prototyping or initial orders. Always discuss your specific needs with the supplier, as they may be willing to negotiate MOQs depending on your long-term partnership potential. -

How can I assess the reliability of a CNC military supplier?

To assess supplier reliability, start by researching their reputation in the industry. Look for customer testimonials and case studies that showcase their experience with military contracts. Additionally, verify their certifications, such as ISO and ITAR, which indicate compliance with international standards. Engaging in direct communication with the supplier regarding their production capabilities, lead times, and past performance can provide further insights. Establishing a trial order can also help evaluate their reliability before committing to larger orders. -

What payment terms should I expect when sourcing CNC military components?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (typically 30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer payment in full before production, especially for new customers. It’s essential to discuss payment terms early in negotiations and consider options like letter of credit for larger orders to mitigate financial risk. Understanding the supplier’s financial practices can also help establish a trustworthy relationship. -

What logistics considerations should I keep in mind when importing CNC military components?

When importing CNC military components, consider the shipping methods, customs regulations, and potential tariffs that may apply. Work with suppliers who have experience in international shipping to navigate these complexities. Ensure that all documentation is complete and compliant with both your country’s and the supplier’s regulations. Additionally, factor in lead times for shipping and customs clearance, as delays can impact project timelines. Developing a logistics plan that includes contingencies for unexpected delays is advisable. -

How do I ensure compliance with international trade regulations for CNC military components?

Ensuring compliance with international trade regulations requires a thorough understanding of both your country’s and the supplier’s regulations regarding military components. Familiarize yourself with export control laws, such as ITAR in the U.S., and ensure that your supplier is compliant. It is prudent to request documentation verifying their compliance status. Consulting with a legal expert in international trade can also help you navigate these regulations, ensuring that your transactions are lawful and minimizing the risk of penalties. -

What are the best practices for maintaining a long-term partnership with a CNC military supplier?

To maintain a successful long-term partnership, prioritize open communication and transparency with your supplier. Regularly share feedback on their products and services, and be proactive in discussing any challenges that arise. Establishing a collaborative approach to problem-solving can strengthen your relationship. Additionally, consider working together on innovations or process improvements that benefit both parties. Building trust through reliability and mutual respect will foster a productive partnership that can adapt to changing needs over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Military Manufacturers & Suppliers List

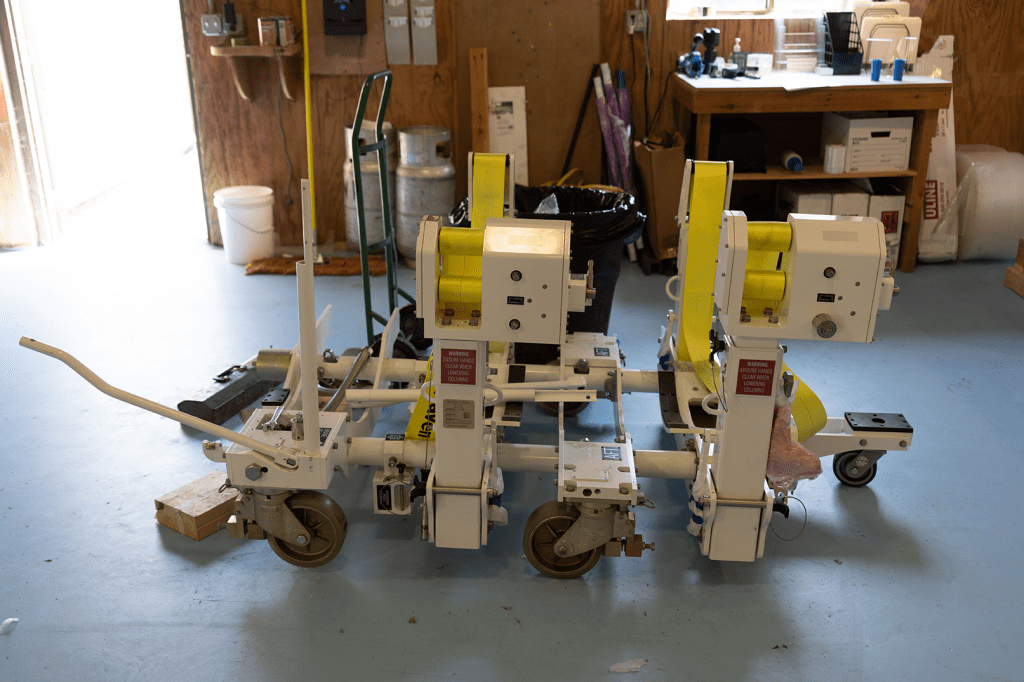

1. CNC Military Emblems – 3D Military Unit Crests

Domain: cncmilitaryemblems.com

Registered: 2012 (13 years)

Introduction: CNC Military Emblems provides ready to cut 3D models of military unit crests. Models are frequently added, and custom requests can be made for specific unit crests. All models are created using Aspire by Vectric and are available in .3dclip, .stl, and grayscale height map formats. Each crest is offered in three styles: plain 3D model, dish model, and sculpted dish model. Crests with mottos can be …

2. Coleys – Precision Components

Domain: coleys.com

Registered: 1997 (28 years)

Introduction: Coleys provides high-quality precision components for the military and defense industry, including specialized CNC manufacturing services for leading prime contractors, defense organizations, and government contract agencies. Key products include:

– Gear Boxes

– Military vehicles and transfer case housings

– Drain Machines

– Firearm parts (takedown pins, safety selectors)

– Axle and suspension com…

3. Owens Industries – Precision CNC Machining Services

Domain: owensind.com

Registered: 1996 (29 years)

Introduction: Owens Industries specializes in manufacturing ultra-precise components for the military and defense industry using advanced CNC machining techniques. Key offerings include:

1. **CNC Machining Services**:

– CNC Lathes/Turning

– 5 Axis Machining

– EDM Machining

– Micromachining

– Mill Turn Machining

– Deburring

2. **Precision Military Components**:

– Manufactured with tight …

4. CNCWMT – Precision Defense Components

Domain: cncwmt.com

Registered: 2018 (7 years)

Introduction: CNC machining is widely used in the defense industry for producing high-precision components for aerospace systems, weapon systems, armor, vehicle components, and communication and electronics equipment. It is critical for ensuring the reliability and performance of these systems.

5. Miller CNC – Military & Defense CNC Machining Services

Domain: millercnc.com

Registered: 2009 (16 years)

Introduction: Miller CNC specializes in military and defense CNC machining services, including 3-axis and 5-axis milling, and CNC turning. They manufacture complex components for ground defense vehicles, aircraft, spacecraft, and electronics. Key materials worked with include hard-to-machine exotic alloys such as Titanium, Inconel 625 and 718, Monel, Invar, Kovar, Haynes Custom 455, and various stainless steels…

6. CNC Jobs – Military Personnel Opportunities

Domain: cnc.jobs

Introduction: CNC Jobs for Military Personnel: Opportunities for serving or retired Armed Forces members to join as warranted police officers or in police staff support roles. Roles include Authorised Firearms Officer (AFO) and Police Staff Firearms Instructor. Benefits include a desirable four on/four off 12-hour shift pattern for work/life balance, overtime availability, and the chance to work in scenic locat…

7. Ram Tool Inc – Precision CNC Machining for Military & Defense

Domain: ramtoolinc.com

Registered: 1999 (26 years)

Introduction: CNC machining services for military and defense industries, including precision CNC machined parts and components such as military vehicle parts, weapons and weapon systems components, communication and navigation equipment, protective and tactical gear, military medical equipment, military tents and shelters, and military training and simulation equipment. Services offered include custom machinin…

Strategic Sourcing Conclusion and Outlook for cnc military

In today’s rapidly evolving defense landscape, strategic sourcing for CNC military applications is not just advantageous; it is essential. By leveraging advanced CNC machining technologies, businesses can ensure the production of high-quality, precision components that meet stringent military standards. This not only enhances operational efficiency but also fosters innovation in product development.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must prioritize partnerships with suppliers who demonstrate a commitment to quality assurance, compliance with industry regulations, and the capability to scale production efficiently. The emphasis on timely delivery and the integration of automation in manufacturing processes will significantly impact your ability to meet project deadlines and budgetary constraints.

Looking ahead, the CNC military sector presents vast opportunities for growth and collaboration. Buyers should actively seek out suppliers who can offer tailored solutions and are willing to invest in the latest technologies. By doing so, you position your organization to not only fulfill current military needs but also to adapt to future demands in an increasingly competitive global market. Engage with your suppliers today to explore how strategic sourcing can elevate your operational capabilities.