Contents

Manufacturing Insight: Cnc Military

Honyo Prototype: Precision CNC Machining for Military Applications

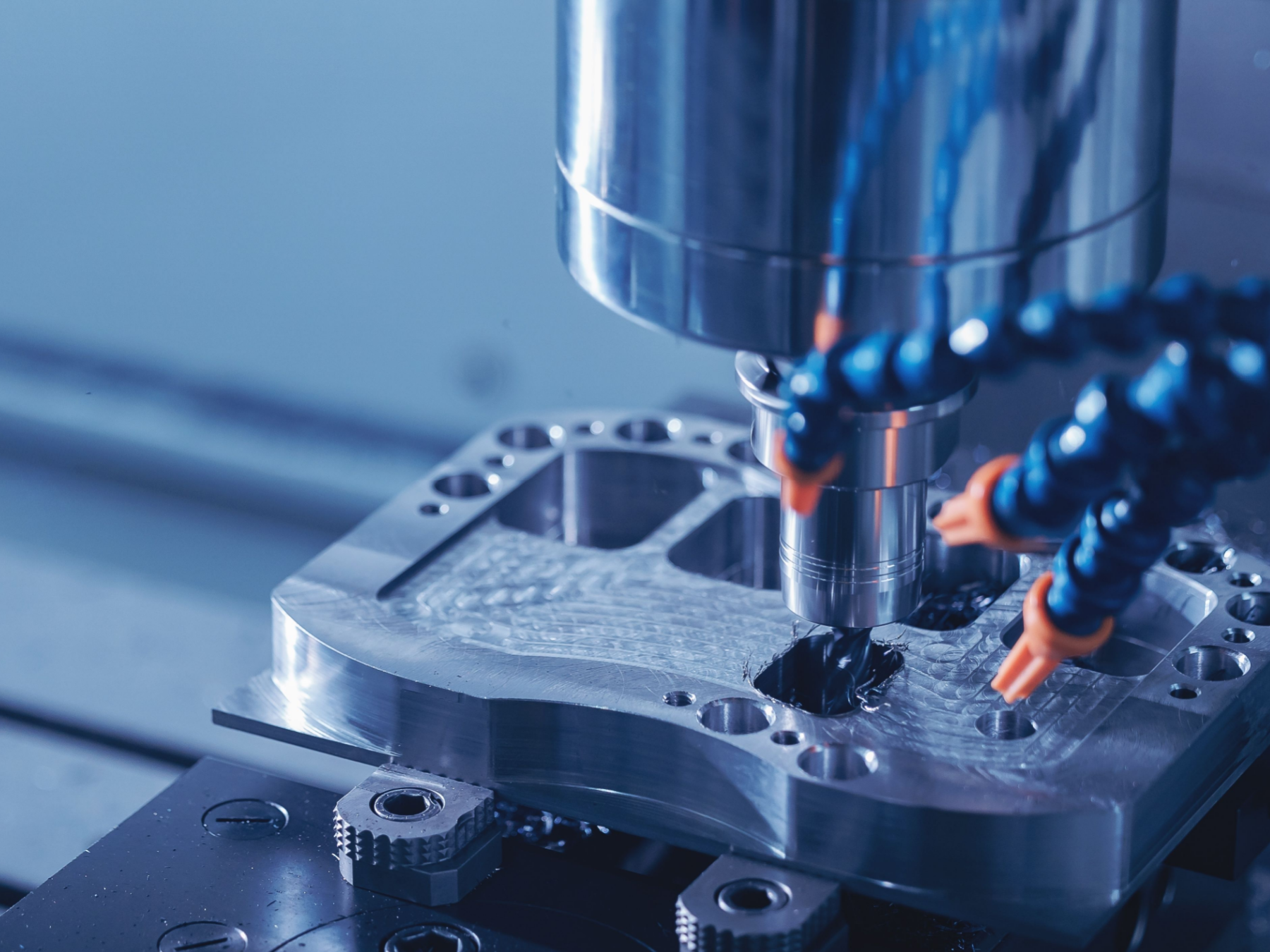

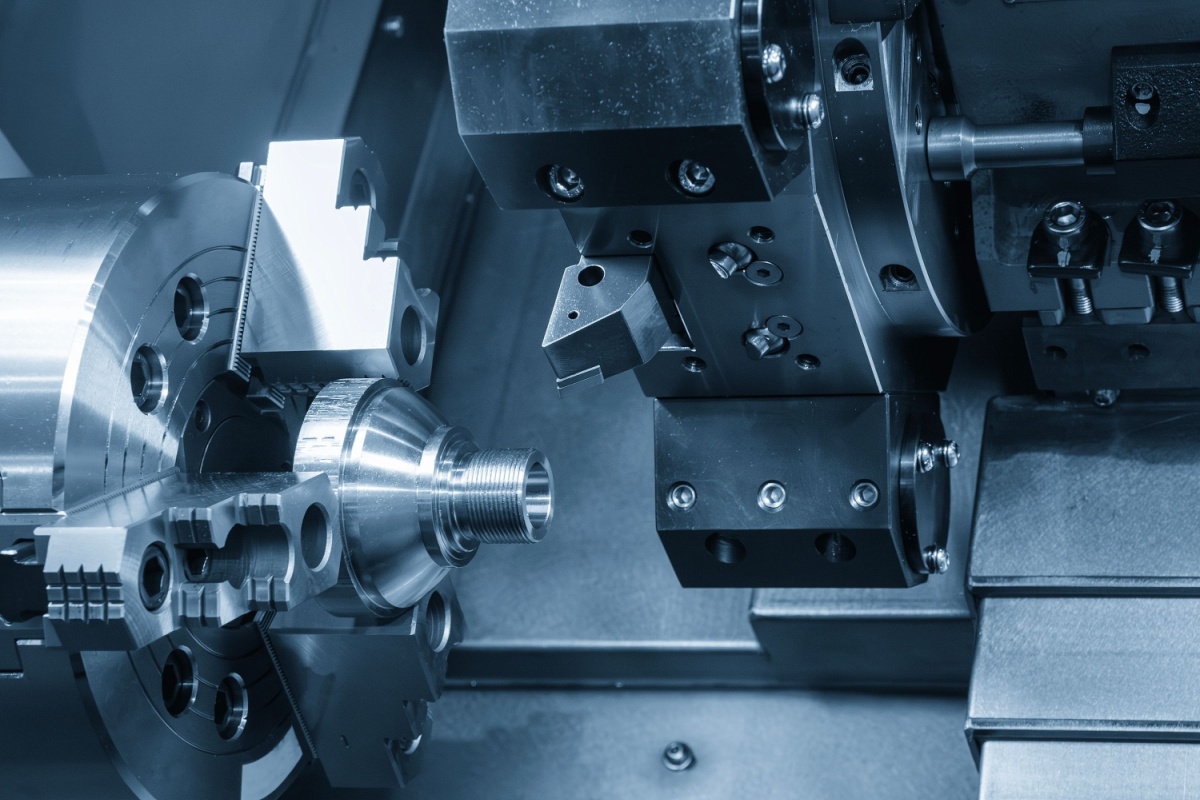

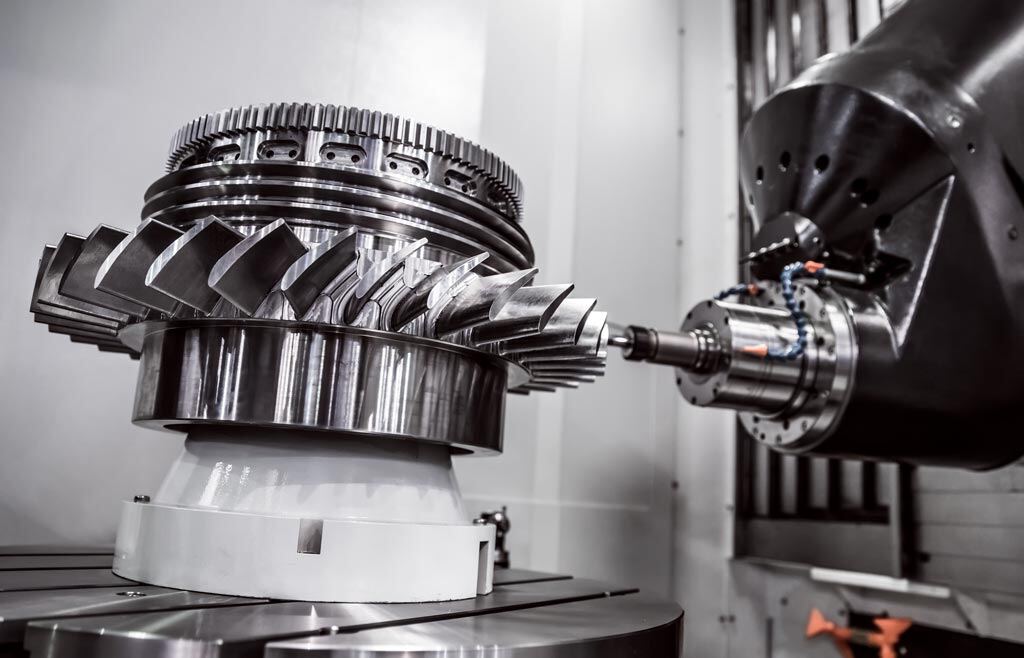

Honyo Prototype delivers mission-critical CNC machining services engineered specifically for the demanding requirements of the military and defense sector. Our advanced 3-, 4-, and 5-axis milling and turning centers, operated by veteran manufacturing engineers, consistently achieve tight tolerances down to ±0.0002″ on complex geometries in challenging materials including titanium, high-strength aluminum alloys, Inconel, and hardened steels. We maintain strict adherence to MIL-STD-883, AS9100, and ITAR compliance protocols, ensuring every component meets rigorous defense specifications for reliability, durability, and performance under extreme operational conditions. Our integrated quality management system features comprehensive in-process inspection, first-article reporting (FAI), and full material traceability to guarantee absolute conformance for critical subsystems, weapon platforms, and ruggedized electronics enclosures.

Accelerate your defense procurement timeline with Honyo’s Online Instant Quote platform. Upload your military-grade CAD files (STEP, IGES, XT, SolidWorks) directly to our secure portal and receive a detailed, no-obligation manufacturing assessment within hours—not days—including DFM feedback, material cost breakdowns, and expedited lead time options. This transparent, real-time quoting system eliminates traditional procurement delays while providing the technical rigor expected by prime contractors and government agencies. Partner with Honyo Prototype for CNC machining where precision, security, and speed are non-negotiable assets in defense manufacturing.

Technical Capabilities

CNC Military-Grade Machining Specifications

Precision CNC machining for military applications demands high repeatability, tight tolerances, and compatibility with a range of high-performance materials. Below are the technical specifications focused on 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, tailored for defense and aerospace-grade components.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary) | X, Y, Z + A & B/C rotary | X, Z linear + C-axis (live tooling) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.003 mm (±0.0001″) | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) | ±0.002 mm (±0.0001″) | ±0.001 mm (±0.00004″) | ±0.002 mm (±0.0001″) |

| Typical Tolerance | ±0.0125 mm (±0.0005″) | ±0.0125 mm (±0.0005″) | ±0.005 mm (±0.0002″) | ±0.010 mm (±0.0004″) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 2.5 µm (32–100 µin) | 0.4 – 1.6 µm (16–63 µin) | 0.8 – 1.6 µm (32–63 µin) |

| Max Work Envelope (mm) | 760 x 460 x 350 | 610 x 510 x 510 | 500 x 400 x 400 | Ø380 x 650 length |

| Spindle Speed (RPM) | Up to 20,000 | Up to 15,000 | Up to 18,000 | Up to 6,000 (main spindle) |

| Tool Changer Capacity | 24–30 tools | 30 tools | 30–40 tools | 12–20 live tools |

| Common Materials | Aluminum 6061-T6, 7075-T6, Steel 4140, 17-4 PH, ABS, Nylon 6/66, PEEK | Same as 3-axis, with added capability for complex geometries | High-strength alloys, hardened steels, composites, thermoplastics | Aluminum, Steel (including stainless), ABS, Nylon (for prototyping) |

| Coolant System | High-pressure through-spindle | High-pressure through-spindle | High-pressure through-spindle with mist control | Through-tool coolant, flood options |

| Applications | Flat components, housings, brackets | Indexing features, angled holes | Complex contours, aerodynamic surfaces, impellers | Shafts, bushings, connectors, fasteners |

Material-Specific Notes

Aluminum alloys are widely used for lightweight structural components and housings due to favorable strength-to-weight ratios and excellent machinability. High-strength steels such as 4140, 4340, and 17-4 PH stainless are employed in load-bearing and high-wear applications. ABS and Nylon are utilized in non-structural military enclosures, jigs, and prototypes where chemical resistance and electrical insulation are required. These polymers are machined with sharp tooling and optimized feeds to prevent melting or burring.

All processes adhere to MIL-STD-883, AS9100, and ISO 2768 for geometric tolerancing and quality assurance. First article inspection (FAI) and full CMM reporting are standard for lot traceability and compliance.

From CAD to Part: The Process

Honyo Prototype Military CNC Manufacturing Process

Honyo Prototype executes a rigorously controlled CNC machining workflow for military-grade components, designed to meet stringent defense sector requirements including ITAR, DFARS, MIL-STD-810, and NADCAP standards. The process begins with secure CAD file submission via our encrypted portal, which validates file integrity and automatically applies ITAR/EAR classification protocols. All data resides in FISMA-compliant servers with audit trails meeting DFARS 252.204-7012 cybersecurity mandates.

AI-Powered Quoting System

Our proprietary AI engine analyzes uploaded CAD geometry against military material databases (e.g., AMS 4928 titanium, MIL-A-8625 aluminum anodizing) to generate instant quotes with DFARS-compliant cost breakdowns. The system flags potential non-conformities to MIL-STD-348 dimensional tolerancing or AMS 2750 pyrometry requirements during quoting, reducing revision cycles by 65% compared to manual methods. Quotes include explicit compliance attestations for ITAR-controlled technical data.

Military-Grade DFM Analysis

Design for Manufacturability (DFM) undergoes dual-phase validation: First, automated checks against MIL-HDBK-516 structural integrity criteria and MIL-STD-130 marking specifications. Second, human review by AS9100-certified engineers specializing in defense applications, focusing on failure mode mitigation for extreme environments (e.g., -54°C to 125°C per MIL-STD-810H). Critical features receive tolerance stack-up analysis per ASME Y14.5-2018 GD&T standards, with all recommendations documented in ITAR-restricted reports.

Production Execution

Machining occurs in segregated cleanrooms (ISO Class 7) using Haas VF-4SSY and DMG MORI CTX beta 1250 machines with real-time SPC monitoring. Key protocols include:

Material traceability via blockchain-linked heat numbers meeting MIL-STD-130N

In-process inspections using Zeiss CONTURA CMMs with NIST-traceable calibration

First-article testing per AS9102B with full FAIR documentation

Cyber-physical security: All CNC programs undergo cryptographic signing to prevent unauthorized modifications

Delivery Assurance

Final delivery includes MIL-PRF-39003-compliant packaging with environmental monitoring logs. Each shipment contains:

DFARS 252.204-7012 cybersecurity compliance certificates

Complete material test reports (MTRs) with AMS/ASTM certifications

3D inspection datasets in QIF format per ISO 10303-238

ITAR-controlled shipping documentation via certified couriers

Process Performance Metrics

| Stage | Avg. Duration | Military-Specific Compliance Focus |

|——-|—————|———————————–|

| CAD Upload to Quote | <2 hours | ITAR classification, DFARS data sovereignty |

| DFM Validation | 24-48 hours | MIL-STD-810 environmental resilience |

| Production | 5-10 days | AS9100 Rev D process control |

| Delivery | 24-72 hours | ITAR/EAR shipping documentation |

*Varies by part complexity; includes mandatory CMM rechecks after stress relief per AMS 2750*

This end-to-end process ensures zero-defect delivery for mission-critical components while maintaining full auditability for DOD supply chain requirements. All personnel undergo annual ITAR/EAR refresher training with security clearances as mandated by contract specifications.

Start Your Project

For precision CNC machining solutions tailored to military specifications, contact Susan Leo at [email protected]. Our ISO-certified manufacturing facility in Shenzhen delivers high-reliability components with strict adherence to defense industry standards. With advanced CNC capabilities and a focus on quality, Honyo Prototype ensures on-time production of mission-critical parts. Reach out today to discuss your technical requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.