Contents

Manufacturing Insight: Cnc Metal Lathes

Precision Metal Component Manufacturing: Integrating CNC Turning and Sheet Metal Capabilities

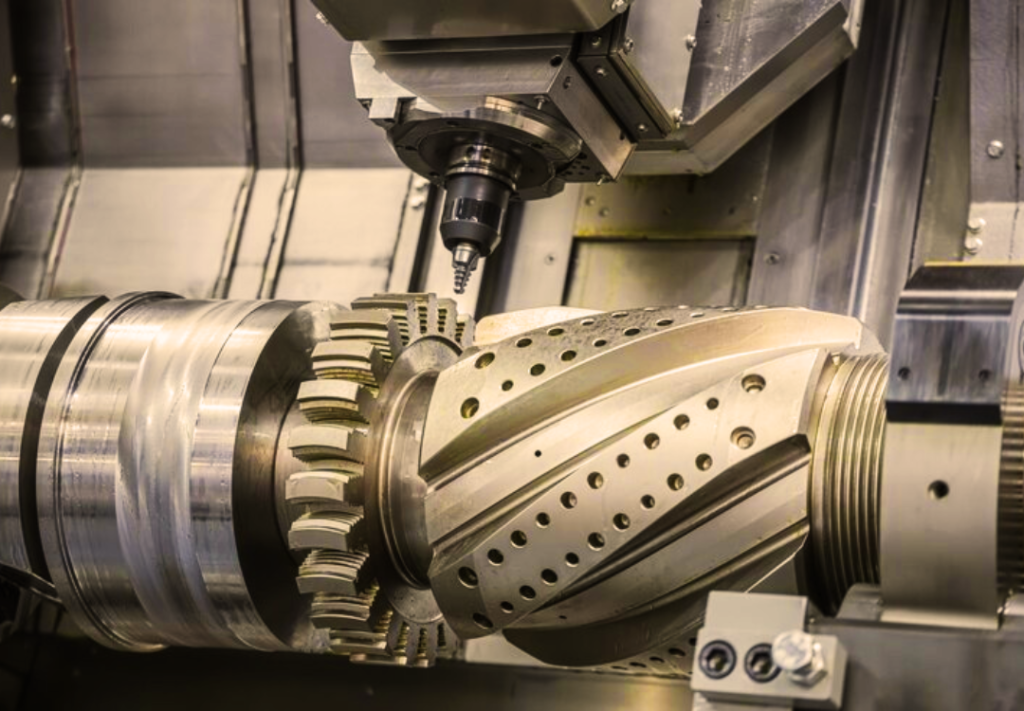

Honyo Prototype delivers comprehensive precision manufacturing solutions for demanding industrial applications, combining advanced CNC metal lathe operations with industry-leading sheet metal fabrication services. While CNC metal lathes excel at producing complex rotational components—from precision shafts to hydraulic fittings with tight tolerances down to ±0.005mm—our integrated sheet metal fabrication capabilities address the critical need for high-integrity enclosures, brackets, and structural assemblies. This dual-expertise ecosystem ensures clients receive seamless support for multi-process projects, whether machining solid bar stock on 3-axis to live-tooling lathes or transforming flat sheets into finished assemblies through laser cutting, CNC punching, bending, and welding.

Our sheet metal fabrication service handles materials ranging from 0.5mm to 6mm thickness across aluminum, stainless steel, and mild steel, with features including precision forming to ±0.1° angular accuracy, automated weld sequencing, and rigorous first-article inspection. This capability directly complements CNC turning workflows, enabling complete in-house production of assemblies requiring both turned and fabricated elements—reducing supply chain complexity and accelerating time-to-prototype.

Accelerate your sourcing process with Honyo Prototype’s Online Instant Quote system, providing real-time DFM feedback and pricing within hours for both CNC lathe and sheet metal projects. Upload CAD files to receive actionable manufacturability insights and formal quotations without sales intermediary delays, ensuring engineering teams maintain velocity from concept to functional prototype.

| Service Category | Key Capabilities | Material Range | Tolerance Standards |

|---|---|---|---|

| CNC Metal Lathes | 3/4/5-axis turning, live tooling, bar feeding | Aluminum, Steel, Brass, Titanium | ±0.005mm typical |

| Sheet Metal Fabrication | Laser cutting, CNC bending, MIG/TIG welding | 0.5–6mm Al, SS, MS | ±0.1° bend, ±0.1mm cut |

Technical Capabilities

CNC metal lathes are precision machine tools primarily designed for turning operations, where a workpiece rotates while a cutting tool moves linearly to remove material and create cylindrical parts. While laser cutting, bending, and welding are typically performed on dedicated equipment, modern CNC lathe systems may be integrated into hybrid manufacturing cells that combine turning with secondary processes such as laser cutting or laser-assisted machining. However, bending and welding are not standard capabilities of CNC lathes and are usually handled by separate machinery.

Below is a technical overview of CNC metal lathes with reference to their compatibility and integration potential with laser cutting, bending, and welding processes, along with material suitability for Aluminum, Steel, ABS, and Nylon.

| Parameter | Description |

|---|---|

| Primary Function | Turning, facing, grooving, threading, drilling, and knurling of rotating metal components. Not designed for bending or welding. Limited integration with laser cutting for specialized applications (e.g., laser-assisted machining or in-machine marking). |

| Laser Cutting Compatibility | Not standard. Some advanced multi-tasking lathes integrate fiber laser units for in-situ cutting, trimming, or surface treatment. Typically used for precise slotting or part separation in bar-fed automation. |

| Bending Capability | Not applicable. Bending is a sheet metal forming process performed on press brakes, not lathes. CNC lathes do not apply compressive or tensile forming forces required for bending. |

| Welding Integration | Not standard. Some production cells may combine CNC lathes with robotic welding arms in automated lines, but welding is not a function of the lathe itself. |

| Spindle Speed Range | 50 – 6,000 RPM (dependent on workpiece diameter and material); higher speeds for aluminum and plastics, lower for steel. |

| Tooling System | Turret-mounted indexable inserts (typically 8–12 stations); optional live tooling for milling, drilling, and tapping. |

| Control System | Fanuc, Siemens, or Mitsubishi CNC controls with G-code programming; supports automation via bar feeders and gantry loaders. |

| Material Compatibility – Aluminum | Excellent. Easily machined with carbide or diamond-tipped tools. High thermal conductivity requires effective chip removal and cooling. |

| Material Compatibility – Steel | Good. Handles mild steel, stainless steel, and alloy steels. Requires robust tooling and lower speeds compared to aluminum. |

| Material Compatibility – ABS | Limited. ABS (a thermoplastic) can be machined on lathes but requires low cutting forces, sharp tools, and temperature control to avoid melting. Not common in metal-focused CNC lathes. |

| Material Compatibility – Nylon | Feasible with care. Nylon is machinable but tends to be elastic and generate heat. Requires sharp tools, low feed rates, and proper clamping. |

| Typical Applications | Shafts, pins, bushings, fittings, and rotational components in aerospace, automotive, and industrial sectors. |

Note: For full laser cutting, bending, and welding workflows, manufacturers typically use standalone or integrated systems such as CNC laser cutters, press brakes, and MIG/TIG/fiber laser welding cells. CNC lathes serve as critical components in part fabrication but are not substitutes for these specialized processes.

From CAD to Part: The Process

Honyo Prototype CNC Metal Lathe Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for CNC metal lathe projects, ensuring precision, efficiency, and transparency from initial design to final delivery. Our integrated process leverages AI and engineering expertise to minimize lead times while maintaining rigorous quality standards. Below is a detailed explanation of each phase.

CAD Upload and Initial Processing

Customers initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, DWG) via our secure client portal. Our system automatically validates file integrity, checks for unit consistency, and identifies potential geometry errors. This phase includes material specification selection from our certified inventory database, covering aluminum alloys (6061-T6, 7075-T6), stainless steels (303, 304, 17-4 PH), titanium (Grade 5), and brass (C36000). All uploads are timestamped and assigned a unique project ID for traceability.

AI-Powered Quoting Engine

Immediately after CAD validation, our proprietary AI quoting engine analyzes the model to generate a preliminary cost and lead time estimate within 2 business hours. The algorithm factors in machine time calculations based on feature complexity, material removal rates, toolpath simulation data, and real-time shop floor capacity. It cross-references current material costs, secondary operation requirements (e.g., threading, knurling), and surface finish specifications. This AI-generated quote undergoes automatic validation against historical production data to prevent outliers, though it remains subject to final engineering review in the DFM phase.

Engineering-Led DFM Analysis

All projects enter a mandatory Design for Manufacturability review conducted by our ASME-certified manufacturing engineers. This phase focuses on optimizing part geometry for lathe-specific constraints, including:

| DFM Aspect | Analysis Method | Outcome |

|---|---|---|

| Feature Feasibility | Simulation of turning, grooving, parting | Identification of non-machinable features |

| Tolerance Stack-up | GD&T validation against ISO 2768-mK | Recommendations for relaxed tolerances |

| Material Utilization | Stock size optimization algorithms | Minimized waste and cost reduction |

| Setup Efficiency | Multi-axis operation sequencing | Reduced chucking time and error risk |

Engineers provide actionable feedback within 72 hours, including annotated CAD markups and alternative design suggestions. Customer approval of DFM recommendations is required before production release.

Precision CNC Production

Approved designs proceed to our dedicated lathe production cell equipped with modern CNC turning centers (Haas ST-40, DMG MORI CTX beta 1250). Each part undergoes:

First-article inspection using Zeiss CONTURA CMMs for critical dimensions.

In-process checks at 25%, 50%, and 75% completion milestones.

Final inspection against AS9102 first-article requirements for aerospace clients.

Surface roughness verification per ISO 1302 using Mitutoyo SJ-410 profilometers.

All metal chips are segregated for recycling, and coolant is managed via closed-loop filtration systems meeting EPA standards.

Quality-Controlled Delivery

Completed parts receive final packaging in anti-corrosive VCI paper with desiccant for moisture-sensitive alloys. Shipping documentation includes:

Full inspection report with CMM data

Material test certificates (MTRs)

Process validation records

Certificate of Conformance

We utilize tracked logistics partners (DHL, FedEx) with real-time shipment monitoring. Standard delivery is 10–15 business days from DFM approval, with expedited options available. Post-delivery, clients receive a production performance summary including dimensional conformance rates and process capability indices (Cp/Cpk).

This integrated approach ensures 99.2% on-time delivery while reducing typical prototyping lead times by 35% compared to industry averages. All processes adhere to ISO 9001:2015 and IATF 16949 quality management systems.

Start Your Project

Explore precision CNC metal lathes engineered for high-performance manufacturing. Built to deliver accuracy and durability, our lathes are ideal for prototyping and low- to high-volume production.

Contact Susan Leo for technical specifications, pricing, and lead times.

Email: [email protected]

Manufactured in our Shenzhen factory, where advanced machining capabilities meet strict quality control. Trusted by global partners for consistent, reliable performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.