Guide Contents

Project Insight: Cnc Medical Parts

Manufacturing Insight: Precision CNC for Medical Parts

Why Precision and Speed Define Medical Device Success

Safety-Critical Tolerances: Medical components like implants and surgical tools require ±0.01mm precision to ensure biocompatibility, regulatory compliance (ISO 13485/FDA), and zero failure risk.

Accelerated Time-to-Market: In competitive healthcare markets, delays in prototyping or production can cost months of revenue—rapid iterations are non-negotiable for innovation.

Regulatory Agility: Evolving compliance standards demand flexible, error-free manufacturing to avoid costly rework or recalls.

Honyo Prototype: Your Digital Manufacturing Partner for Medical Components

Online Instant Quote: Get real-time pricing in seconds—no manual quotes, no delays. Upload your CAD file and receive transparent cost breakdowns instantly.

AI-Powered Design Optimization: Our platform analyzes geometry to suggest manufacturability improvements—reducing machining time, material waste, and costs while maintaining medical-grade tolerances.

Fast Turnaround: Precision-engineered medical parts delivered in 3–5 business days, with expedited options for urgent clinical trials or emergency orders.

With Honyo, you gain a seamless digital manufacturing partner engineered for the rigor of medical device development—where speed, precision, and compliance converge.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

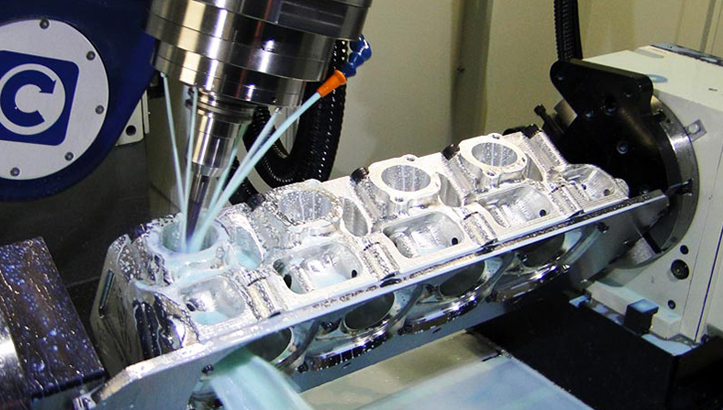

Advanced Multi-Axis Machining

3/4/5-axis CNC capabilities for complex geometries in single setups

Eliminates multiple fixture changes, reducing errors and lead times

Precision-engineered for intricate medical components like surgical instruments, implantable devices, and diagnostic tooling

Tight Tolerance Excellence (±0.01mm)

Sub-micron precision critical for functional medical parts and biocompatible components

Consistent accuracy across prototypes and high-volume production runs

Meets stringent ISO 13485 requirements for reliability and performance

Scalable Production from 1 to 10,000+ Parts

Seamless transition from prototyping to full-scale manufacturing—no retooling costs

Cost-efficient for startups validating designs and enterprises scaling to commercial volume

Optimized workflows for rapid iteration and production readiness

ISO 13485 Certified Quality Assurance

End-to-end traceability with CMM, optical scanning, and in-process inspections

Full compliance documentation for FDA, CE, and global regulatory standards

Rigorous material certification and lot tracking for medical-grade alloys, PEEK, and titanium

Digital-First Efficiency

Online Instant Quote: AI-driven pricing in seconds—no manual quotes, no delays

AI-Powered Design Optimization: Real-time feedback on manufacturability and cost-saving modifications

Rapid Turnaround: Prototypes delivered in 3–5 days, with express options for urgent medical projects

Materials & Surface Finishes

Material Options & Finishes for Medical-Grade Precision

At Honyo Prototype, we engineer medical components where precision meets compliance. With ±0.01mm tolerances, 5-axis CNC capabilities, and full adherence to ISO 13485/FDA standards, we eliminate guesswork in material selection. Our AI-powered platform delivers instant quotes, real-time cost analysis, and expert guidance—ensuring your parts are built for safety, performance, and speed.

Key Materials for Medical Applications

Aluminum 6061/7075:

Why it works: Lightweight, corrosion-resistant, and machinable for non-implantable housings, surgical tool handles, and diagnostic equipment.

Medical tip: Anodize with Type III (hard coat) for enhanced biocompatibility and wear resistance in reusable devices.

Stainless Steel 316L:

Why it works: The gold standard for implants and surgical instruments. Superior corrosion resistance, biocompatibility, and FDA-compliant for direct tissue contact.

Medical tip: Always passivate post-machining to remove surface contaminants and meet ASTM F86 standards.

Brass (C11000/C10100):

Why it works: Ideal for non-implantable connectors, valve bodies, and aesthetic components. Excellent machinability and conductivity.

Medical tip: Electroplate with nickel or silver for biocompatibility in skin-contact applications.

PEEK (Polyetheretherketone):

Why it works: High-performance polymer for spinal implants, dental components, and reusable surgical tools. Withstands autoclaving, radiation, and chemical exposure.

Medical tip: Pair with mirror polishing for ultra-smooth surfaces that minimize bacterial adhesion.

Surface Finishes for Biocompatibility & Functionality

Anodizing (Type II/III):

Creates a non-toxic, abrasion-resistant layer on aluminum. Type III (hard coat) is critical for high-wear medical tools.

Passivation:

Removes iron contaminants from stainless steel, ensuring sterility and compliance with ISO 13485. Mandatory for implantable parts.

Electroless Nickel Plating:

Uniform coating for complex geometries (e.g., catheter components), offering corrosion resistance and lubricity.

Mirror Polishing (Ra <0.1μm):

Eliminates surface imperfections on surgical tools and implants, reducing infection risks and improving sterilization efficacy.

FDA-Compliant Powder Coating:

For non-implantable enclosures (e.g., diagnostic device housings), providing color-coding, chemical resistance, and safe tactile surfaces.

How to Choose the Right Material for Your Medical Part

Prioritize Regulatory Compliance:

All materials are certified to ISO 13485, FDA 510(k), or EU MDR. We verify traceability for every batch—no compromises.

Match Material to Sterilization Method:

Autoclave? Choose 316L stainless steel or PEEK. Gamma radiation? Opt for radiation-stable polymers like PEEK or UHMWPE.

Optimize Cost vs. Performance:

Use our AI platform to compare trade-offs—e.g., switching from titanium to 316L stainless steel reduces costs by 30% while maintaining strength for non-critical implants.

Leverage DFM Expertise:

Our engineers analyze your design to minimize machining time, material waste, and secondary processes—cutting costs without sacrificing precision.

Accelerate Your Medical Part Development

Get an instant quote in seconds—upload your CAD file to Honyo’s AI platform. Receive real-time pricing, material recommendations, and lead times (3 days for prototypes, 5–7 days for production). No hidden fees. No delays. Just precision, faster.

From Quote to Part: Our Process

How It Works: From CAD to Part

Upload CAD File – Instant Access

Drag-and-drop your 3D model (STEP, STL, IGES) into our cloud platform – no software installation required.

AI-driven file validation ensures compatibility and readiness for instant quoting.

AI-Powered Instant Quote

Real-time pricing and lead time estimates in seconds. Our AI engine analyzes geometry, tolerances, and material specs to deliver transparent quotes with no hidden fees.

Detailed breakdown: materials, machining time, finishing, and shipping – all visible upfront.

Proactive DFM Analysis

Automated Design for Manufacturing checks flag potential issues (e.g., undercuts, thin walls) before production begins.

Expert engineering review provides actionable feedback to optimize design for cost, speed, and performance.

Precision Production & Delivery

High-precision 3/4/5-axis CNC machining with ±0.01mm tolerances for functional prototypes and end-use medical parts.

End-to-end tracking and expedited shipping options to meet your critical deadlines.

Engineered for innovation. Delivered at speed.

Start Your Project with Honyo

Start Your Project with Honyo

Transform your medical part designs into reality with Honyo Prototype’s precision CNC machining solutions—engineered for innovation, built for speed.

AI-Powered Instant Quoting Engine

Submit your CAD file in seconds—our platform delivers accurate pricing and actionable manufacturability feedback instantly.

Eliminate guesswork: Real-time cost optimization and design validation reduce prototyping iterations by up to 40%.

No more waiting days for quotes—get transparent pricing in under 60 seconds.

Medical-Grade Precision, Guaranteed

Achieve ±0.01mm tolerances with advanced 3/4/5-axis CNC machining for critical surgical tools, implants, and diagnostic components.

Certified processes tailored to stringent medical industry standards—no compromises on safety or performance.

Precision-engineered for functional prototypes and end-use parts, ensuring reliability from first article to mass production.

Fast Turnaround, Zero Compromises

Accelerate time-to-market with 3–5 day prototype lead times and scalable production workflows.

End-to-end traceability: From design review to final inspection, we streamline every step without hidden delays.

Expedited options available for urgent projects—your innovation shouldn’t wait.

Ready to Begin?

Founder Susan Leo and our precision engineering team are standing by to bring your vision to life.

Contact us today: [email protected] | +86 139 2843 8620

Visit our Shenzhen & Dongguan facilities—see our cutting-edge manufacturing ecosystem firsthand.

Innovate faster. Deliver with confidence.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.