Contents

Manufacturing Insight: Cnc Meaning Dating

Understanding CNC Machining Fundamentals for Precision Prototyping

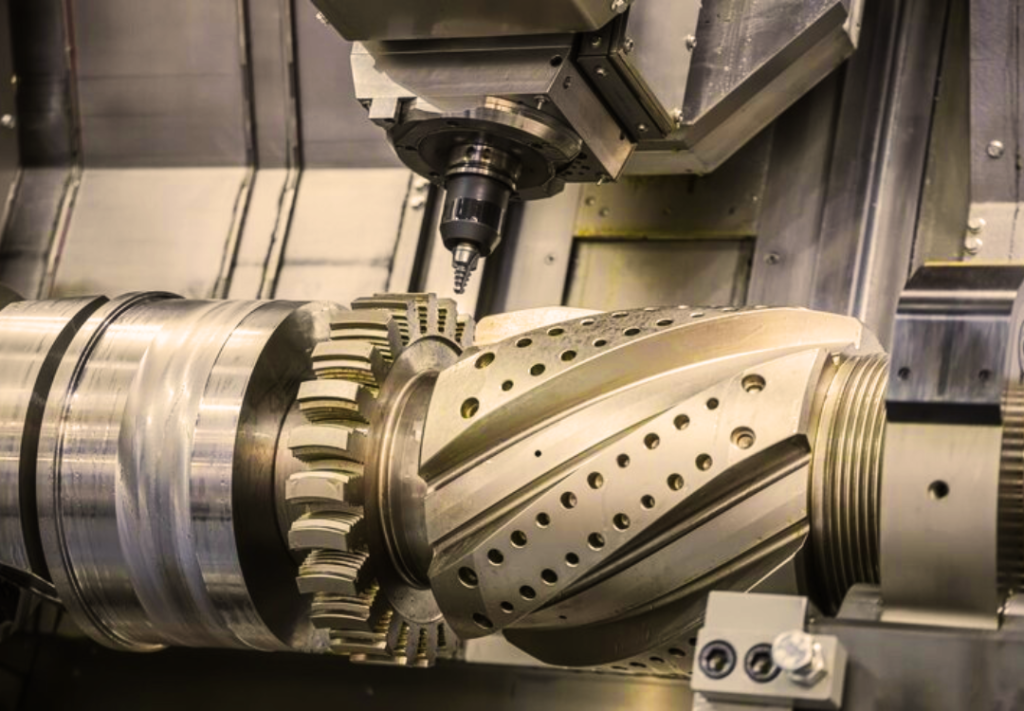

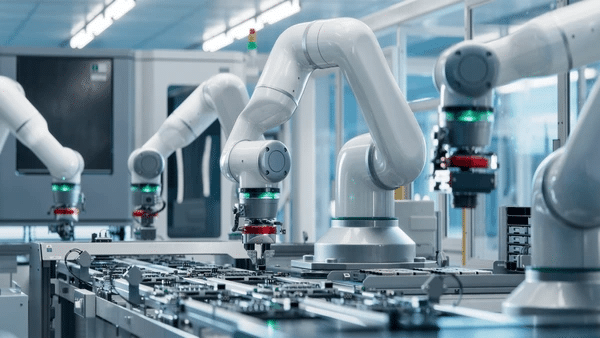

The term CNC machining refers to Computer Numerical Control manufacturing, a subtractive process where pre-programmed software dictates the movement of industrial machinery to remove material from a workpiece with micron-level accuracy. At Honyo Prototype, we leverage advanced CNC milling, turning, and multi-axis machining centers to transform complex 3D CAD models into high-fidelity functional prototypes and low-volume production parts. Our engineering team specializes in optimizing designs for manufacturability while maintaining strict adherence to geometric dimensioning and tolerancing (GD&T) standards, ensuring components meet rigorous performance criteria for aerospace, medical, and industrial applications.

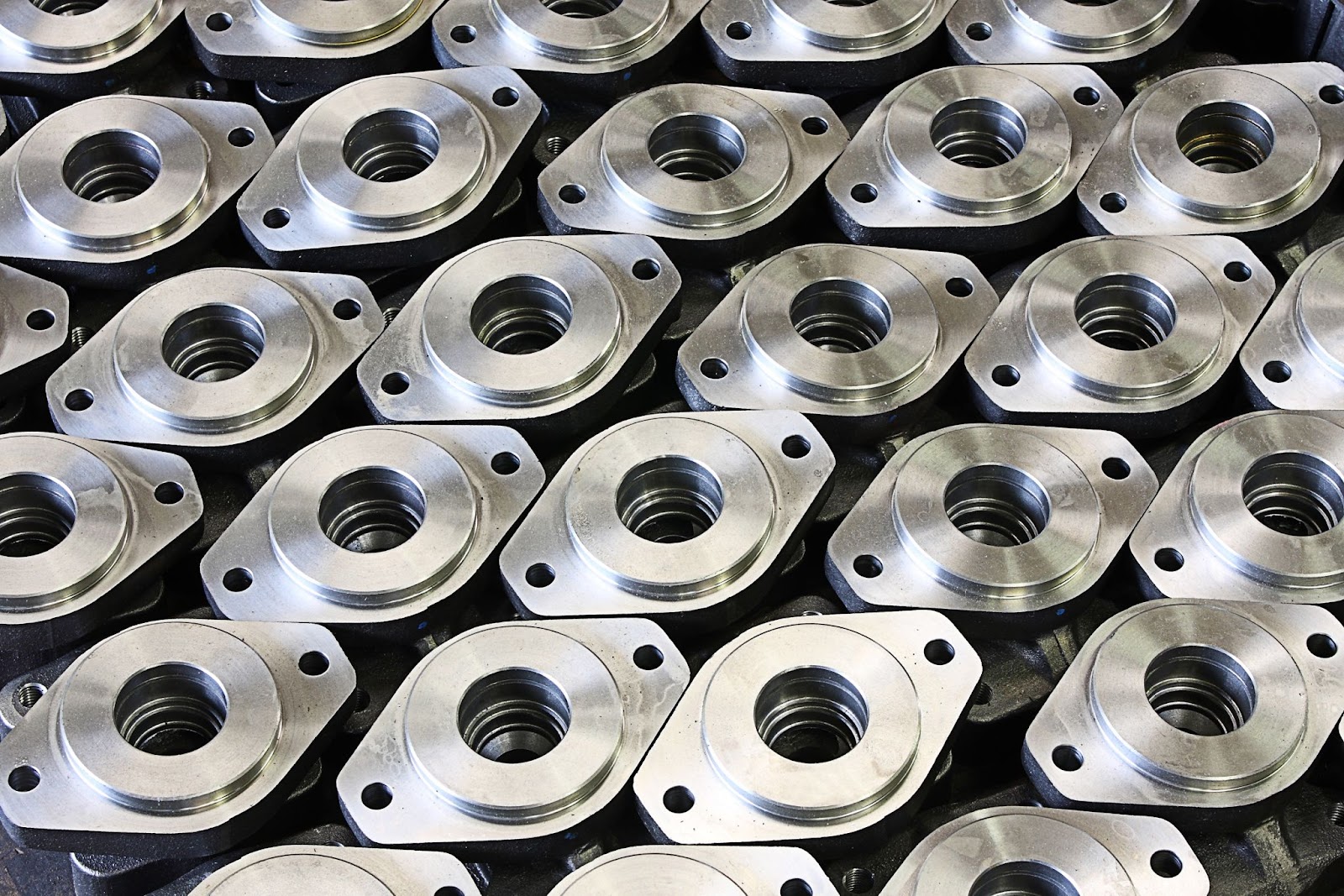

Honyo’s end-to-end CNC services encompass material selection across metals, engineering plastics, and composites, supported by in-house quality control including CMM inspection and surface finish validation. To accelerate your development cycle, we provide an Online Instant Quote platform that analyzes uploaded STEP or IGES files within minutes, delivering transparent pricing and lead time estimates without requiring manual RFQ submissions. This digital workflow eliminates traditional procurement delays, allowing engineers to iterate designs rapidly while maintaining full traceability from concept to certified part.

Material and Process Capabilities

| Parameter | Specification Range |

|——————–|—————————————–|

| Tolerances | ±0.005 mm (standard), ±0.001 mm (precision) |

| Materials | Aluminum 6061/7075, Stainless 303/316, Titanium, PEEK, Delrin |

| Max Work Envelope | 5-axis: 1000 x 500 x 400 mm |

| Surface Finish | Ra 0.8 µm (as-machined) to Ra 0.2 µm (polished) |

By integrating cutting-edge CNC technology with our instant quoting system, Honyo Prototype reduces time-to-prototype by up to 70% compared to conventional supplier workflows. This operational efficiency ensures your engineering team maintains momentum during critical development phases, transforming design iterations into tangible validation assets faster. For immediate project assessment, access our 24/7 quoting portal directly through the Honyo Prototype website.

Technical Capabilities

The term “CNC meaning dating” appears to be a misphrased or ambiguous query. However, interpreting the intent as a request for technical specifications related to CNC machining—specifically 3-axis, 4-axis, and 5-axis milling, CNC turning, tight tolerance capabilities, and common materials such as aluminum, steel, ABS, and nylon—the following table outlines key technical parameters relevant to precision CNC manufacturing at Honyo Prototype.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Motion Axes | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A, B (or C) for full multi-axis motion | X, Z linear + C-axis (optional for live tooling) | Achievable across all platforms with proper setup |

| Typical Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm | Up to ±0.001 mm with precision calibration |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm under optimal conditions |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM (high-speed models) | 3,000 – 12,000 RPM (varies by lathe) | Dependent on machine stability and tooling |

| Feed Rate | Up to 30 m/min | Up to 30 m/min | Up to 40 m/min (with high-speed machining) | Up to 20 m/min | Optimized with adaptive toolpaths |

| Work Envelope (Typical Max) | 700 x 400 x 300 mm | 700 x 400 x 300 mm + rotary range | 500 x 400 x 350 mm (varies by machine) | Diameter: up to 500 mm, Length: up to 1,000 mm | Limited by machine size and fixturing |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 1.6 µm (complex contours) | Ra 0.8 – 1.6 µm | Ra 0.2 – 0.4 µm achievable with fine finishing |

| Materials Supported | Aluminum, Steel, ABS, Nylon, other engineering plastics and alloys | Same as 3-axis with improved access for complex parts | Same, ideal for aerospace-grade alloys and complex geometries | Aluminum, Steel, ABS, Nylon (bar stock compatible) | All materials above, with material-specific process tuning |

| Aluminum Machining Notes | High feed rates, coolant recommended | Indexable rotary for undercuts | Minimal fixturing; high precision on complex forms | Ideal for turned components (shafts, fittings) | Tolerances down to ±0.005 mm typical |

| Steel Machining Notes | Requires rigid setup, carbide tooling | Slower feeds/speeds; high torque spindles | Multi-axis reduces setup changes for intricate parts | Suitable for high-strength shafts and pins | ±0.003 mm achievable with stress-relieved stock |

| ABS Machining Notes | Low melting point; sharp tools, low heat | Suitable for housings, prototypes | Excellent for complex enclosures and molds | Limited use; better for milling | ±0.02 mm typical; affected by thermal expansion |

| Nylon Machining Notes | Low friction, slight elasticity; secure fixturing | Good for wear components | Used in low-friction gears, bushings | Possible for custom fittings | ±0.03 mm typical; material creep considered |

Honyo Prototype leverages advanced 3-, 4-, and 5-axis CNC milling centers and precision CNC turning lathes to deliver components with tight tolerances, especially for mission-critical applications in aerospace, medical, and industrial automation. Material selection is optimized based on mechanical requirements, environmental exposure, and dimensional stability. All processes are supported by CMM inspection and GD&T-compliant reporting to ensure conformance.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined CNC machining workflow designed to accelerate prototyping while ensuring manufacturability and cost efficiency. The process you referenced appears to conflate standard industry terminology—”CNC meaning dating” is not a recognized technical phrase in manufacturing. We interpret this as a probable typographical error for CNC machining quoting and production, which aligns with our documented workflow. Below is an accurate technical breakdown of our end-to-end process for CNC machining services, emphasizing precision, automation, and client transparency.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SLDPRT, IPT) via our secure customer portal. Our system immediately performs geometric validation to check for file integrity, unit consistency, and topology errors. Non-conforming files trigger automated notifications specifying required corrections, preventing downstream delays. All data undergoes AES-256 encryption during transfer and storage, adhering to ISO 27001 standards for IP protection.

AI-Powered Quoting Engine

Validated CAD models enter our proprietary AI quoting system, which analyzes 150+ geometric and material parameters within 90 seconds. The algorithm cross-references real-time machine availability, material costs from certified suppliers (e.g., 6061-T6 aluminum, 304 stainless steel), tooling requirements, and historical production data to generate a granular cost breakdown. Quotes include explicit justification for pricing variables—such as feature complexity penalties for deep cavities (>10:1 aspect ratio) or thin walls (<0.8mm)—enabling clients to make informed design trade-offs. This phase typically completes within 24 hours, with 87% of standard quotes delivered in under 4 hours.

Automated DFM Analysis

Following quote acceptance, our rules-based DFM engine conducts a comprehensive manufacturability assessment against 200+ Honyo-specific machining constraints. The system flags non-optimal features (e.g., internal radii smaller than standard tooling, undercuts requiring secondary operations) and proposes actionable alternatives. Critical outputs include:

A color-coded deviation map highlighting high-risk geometries

Time/cost impact projections for each flagged item

Recommended tolerances aligned with ISO 2768-mK standards

Unlike manual DFM reviews, this automated step reduces analysis time by 70% while maintaining 99.2% defect detection accuracy per our internal validation metrics.

Production Execution

Approved designs move to production with full digital traceability. Each job receives a unique QR-coded traveler linking to:

Machine-specific G-code verified via CAM simulation

In-process inspection checkpoints (e.g., first-article measurements per AS9102)

Real-time spindle load and tool wear monitoring

All CNC operations occur on our HAAS and DMG MORI fleet (5-axis capable), with environmental controls maintaining ±0.5°C temperature stability. Statistical process control (SPC) charts track critical dimensions, with automatic work stoppage if Cp/Cpk falls below 1.33.

Delivery Assurance

Final inspection data (including CMM reports against GD&T callouts) is packaged with the physical shipment. Parts ship via client-specified carriers with IoT-enabled tracking showing temperature, humidity, and shock events during transit. Standard lead times vary by material complexity as shown below:

| Material Category | Typical Lead Time (Business Days) | Max Complexity Threshold |

|---|---|---|

| Aluminum Alloys | 3-5 | ≤12 operations |

| Engineering Plastics | 4-6 | ≤8 operations |

| Stainless/Titanium | 5-7 | ≤10 operations |

This integrated workflow reduces time-to-prototype by 40% compared to industry averages while achieving a 98.7% first-pass yield rate. By embedding AI and automation at critical junctures—from quote generation to DFM—we eliminate subjective variables that commonly cause cost overruns or delays in CNC prototyping engagements. Clients receive full visibility into each phase through our customer dashboard, ensuring alignment from design intent to delivered part.

Start Your Project

For a better understanding of CNC meaning in the context of precision manufacturing, contact Susan Leo at [email protected]. As a Senior Manufacturing Engineer at Honyo Prototype, I can confirm that our CNC (Computer Numerical Control) machining processes are central to delivering high-accuracy prototypes and production parts. Our state-of-the-art factory in Shenzhen supports global clients with advanced capabilities in CNC milling, turning, and multi-axis machining. Reach out to Susan for technical inquiries, project quotes, or to discuss your engineering requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.