Contents

Manufacturing Insight: Cnc Machining Vs Injection Molding

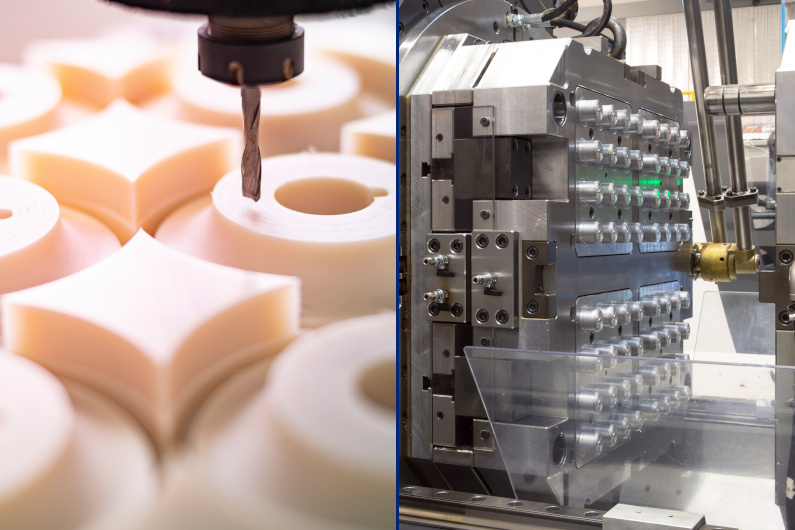

Choosing between CNC machining and injection molding represents a critical strategic decision in product development, directly impacting prototyping speed, cost efficiency, and scalability for production. While CNC machining excels for low-volume, high-precision metal or plastic parts and functional prototypes directly from solid stock, injection molding becomes economically superior for medium-to-high volume production runs of plastic components, demanding significant upfront tooling investment. The challenge often lies in bridging the gap between initial prototypes and full-scale manufacturing, where traditional hard tooling lead times and costs can stall validation and market entry.

Honyo Prototype addresses this exact challenge through our integrated Rapid Tooling & Injection Molding services. We specialize in producing high-quality, production-intent prototypes and low-to-mid volume runs using rapid steel or aluminum tooling, significantly reducing the time and cost barrier typically associated with injection molding. This capability allows engineering teams to validate part design, material selection, and manufacturability under near-production conditions long before committing to expensive production molds. Our process ensures seamless transition from prototype to volume production, mitigating risk and accelerating time-to-market.

Leverage Honyo’s expertise to determine the optimal path for your specific part requirements and production volume. Explore our capabilities and obtain immediate cost visibility using our Online Instant Quote system, designed to accelerate your path to production.

Technical Capabilities

Technical Comparison: CNC Machining vs Injection Molding for Steel/Aluminum Molds with T1 Sample in 7 Days

When developing molds for injection molding using CNC machining, the process combines precision manufacturing with material-specific performance characteristics. Below is a detailed technical comparison focused on Aluminum and Steel molds, ability to achieve T1 samples within 7 days, and compatibility with common thermoplastics such as ABS and Nylon.

| Parameter | CNC Machined Aluminum Mold | CNC Machined Steel Mold |

|---|---|---|

| Base Mold Material | 7075-T6, 6061-T6 Aluminum Alloys | P20, H13, 420 Stainless, or S136 Tool Steel |

| Hardness (Typical) | 95–110 HB | 28–54 HRC (depending on grade and treatment) |

| Machinability | High – faster cutting speeds, lower tool wear | Moderate to low – slower speeds, higher tool wear |

| Lead Time for T1 Sample | Achievable in 5–7 days with streamlined design | 7–14 days; 7-day T1 possible with high-speed CNC and parallel workflows |

| Surface Finish (As-Machined) | 0.8–3.2 µm Ra (polishable to <0.4 µm Ra) | 0.8–1.6 µm Ra (readily polishable to mirror finishes) |

| Thermal Conductivity | High (~130–180 W/m·K) – faster cooling | Lower (~25–40 W/m·K) – slower cycle times |

| Mold Lifespan | 1,000–10,000 cycles (prototype/low volume) | 100,000+ cycles (high-volume production) |

| Common Use Case | Rapid prototyping, bridge tooling, T1 validation | High-volume production, engineering-grade parts |

| Compatible Resins | ABS, Nylon (PA6, PA66), PP, PMMA | ABS, Nylon (glass-filled or unfilled), PC, PPS |

| Moisture Sensitivity (Mold) | Slight risk of corrosion if not coated | Resistant when using stainless or treated steel |

| Post-Processing Requirements | Minimal; optional hard coat or plating | May require heat treatment, nitriding, or PVD coating |

| Dimensional Accuracy | ±0.025 mm | ±0.0125 mm |

Notes on T1 Sample in 7 Days

Achieving a T1 sample within 7 days is highly dependent on part complexity, mold configuration (e.g., 2-plate vs. 3-plate), and resin selection. CNC-machined aluminum molds are the preferred route for rapid T1 delivery due to faster machining times and superior thermal conductivity, which reduces trial cycle duration. With optimized CAD/CAM programming, high-speed CNC machining, and in-house injection molding capabilities, T1 parts in aluminum molds using ABS or Nylon can consistently be delivered within one week.

Steel molds can meet the 7-day T1 target only under aggressive scheduling, utilizing pre-hardened steels like P20 and integrating parallel operations (e.g., machining and mold base prep in tandem). However, this often requires premium costing and is less common for complex geometries.

Material Compatibility Summary

ABS: Flows well, low to medium viscosity. Suitable for both aluminum and steel molds. Requires adequate venting and polish.

Nylon (PA6/PA66): Hygroscopic; requires pre-drying. Higher processing temperatures (260–290°C). Steel molds preferred for glass-filled grades due to abrasion resistance, but aluminum works for unfilled nylon in short runs.

For rapid validation and low-volume output, CNC-machined aluminum molds offer the best balance of speed, cost, and performance. For extended life and high-volume repeatability, steel molds produced via CNC remain the industry standard.

From CAD to Part: The Process

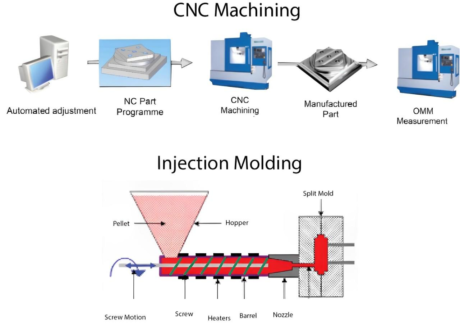

Honyo Prototype CNC Machining vs. Injection Molding Process Overview

At Honyo Prototype, we deploy a streamlined, technology-driven workflow to determine the optimal manufacturing process—CNC machining or injection molding—based on your part requirements. This ensures cost efficiency, quality, and speed without compromising engineering integrity. Below is our standardized process, highlighting critical decision points between the two methodologies.

Upload CAD

Customers initiate the process by uploading a 3D CAD model (STEP, IGES, or native formats) to our secure portal. Our system immediately performs a preliminary geometry analysis. For CNC machining, we assess feature complexity, material block utilization, and tolerance feasibility. For injection molding, we evaluate draft angles, wall thickness uniformity, and undercuts. This initial scan determines which process path the quote engine prioritizes, though both options remain available for comparison.

AI-Powered Quoting

Our proprietary AI engine generates instant preliminary quotes by cross-referencing the CAD geometry against live material pricing, machine availability, and historical production data. For CNC machining, pricing is driven by machine hours, toolpath complexity, and material waste. For injection molding, the quote includes mold tooling costs (typically $1,500–$15,000+), cycle time, and per-part pricing. The AI flags volume thresholds where injection molding becomes cost-effective (usually >500 parts), while CNC remains optimal for low-volume or high-mix production. Customers receive transparent cost breakdowns for both processes within 2 business hours.

Engineering-Driven DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. For CNC machining, we verify tool access, minimize setup changes, and recommend material-specific tolerances (±0.005″ typical). For injection molding, we rigorously evaluate gate locations, ejection feasibility, and mold steel requirements. Critical issues—such as insufficient draft angles for molding or thin walls prone to chatter in CNC—are documented with annotated 3D models. We provide actionable redesign suggestions to reduce costs or improve yield, ensuring manufacturability before production begins. This phase typically takes 1–3 business days and is included at no cost.

Production Execution

Upon DFM approval and order confirmation, production commences under strict process controls. CNC machining leverages our 5-axis mills and lathes with real-time in-process inspection, achieving tight tolerances in metals, plastics, and composites. Lead times average 3–10 days. Injection molding requires mold fabrication (7–21 days), followed by molding trials with first-article inspection. We use industrial-grade hydraulics or electric presses with cavity pressure monitoring, targeting 99.5%+ process capability (CpK). All parts undergo dimensional validation per AS9102 or customer-specific standards.

Quality-Controlled Delivery

Final parts ship with comprehensive documentation: First Article Inspection (FAI) reports for both processes, material certifications, and surface finish verification. CNC parts include CMM reports for critical features; injection-molded parts include mold flow analysis summaries. We consolidate shipments via tracked logistics with a standard 2-day transit window. For injection molding, we retain mold tools for future orders at no storage fee, enabling rapid reorders.

Process Selection Guidance

The following table summarizes key differentiators to inform your process decision:

| Parameter | CNC Machining | Injection Molding |

|---|---|---|

| Ideal Volume | 1–500 parts | 500+ parts |

| Lead Time (Production) | 3–10 days | 10–28 days (includes mold fabrication) |

| Cost Drivers | Machine hours, material waste | Mold tooling, cycle time, material |

| Material Flexibility | Metals, plastics, composites (stock) | Thermoplastics only (pellet form) |

| Part Complexity | Complex geometries, tight tolerances | High repeatability, thin walls |

| Secondary Operations | Often required (e.g., tapping, finishing) | Minimal (e.g., gate removal) |

Honyo’s integrated workflow eliminates guesswork by combining AI efficiency with deep manufacturing expertise. We proactively guide customers toward the most economical, technically sound solution—whether CNC machining for rapid prototyping or injection molding for scalable production. Contact our engineering team for a part-specific process recommendation and DFM consultation.

Start Your Project

When comparing CNC machining versus injection molding for your next prototyping or production project, understanding the differences in cost, lead time, material options, and part complexity is critical to making the right manufacturing decision. At Honyo Prototype, we specialize in both high-precision CNC machining and scalable injection molding services, delivering rapid turnaround and consistent quality from our ISO-certified factory in Shenzhen, China.

For low-volume prototypes or complex geometries requiring tight tolerances, CNC machining offers unmatched flexibility. For high-volume production runs of identical parts, injection molding provides superior cost efficiency and repeatability. Our engineering team can help you evaluate which process best suits your design, timeline, and budget.

Contact Susan Leo at [email protected] to discuss your project requirements and receive a tailored manufacturing recommendation. With in-house tooling, advanced 5-axis CNC capabilities, and full-service molding, Honyo Prototype is your trusted partner for rapid manufacturing in Shenzhen.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.