Contents

Manufacturing Insight: Cnc Machining Titanium Parts

Precision CNC Machining for Titanium Components at Honyo Prototype

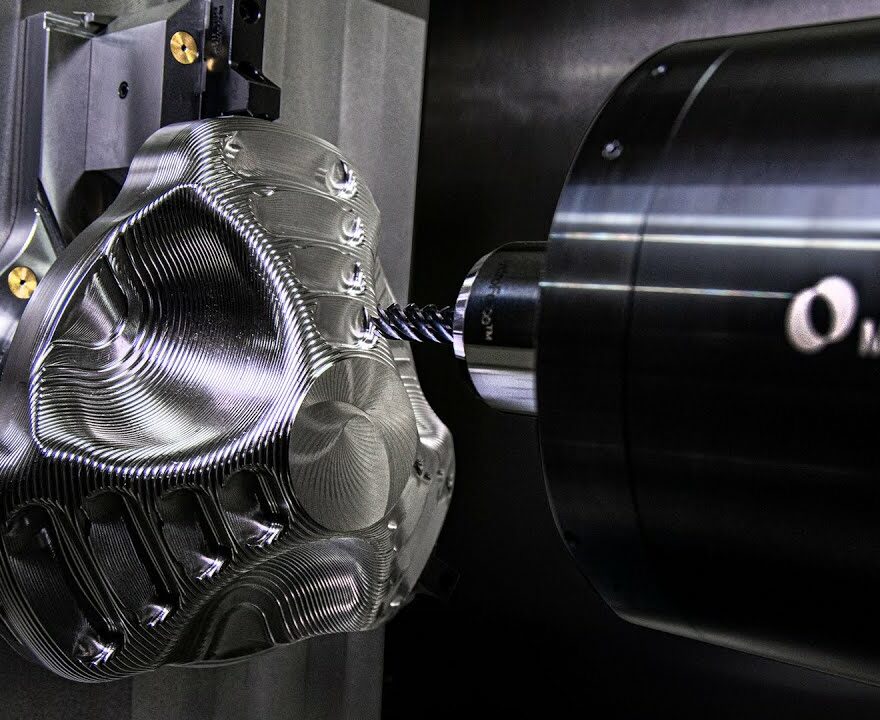

Titanium presents unique challenges in precision manufacturing due to its high strength-to-weight ratio, excellent corrosion resistance, and propensity for work hardening and thermal expansion. These properties demand specialized CNC machining expertise, advanced toolpath strategies, and strict process controls to achieve dimensional accuracy and surface integrity without compromising part integrity. At Honyo Prototype, our dedicated CNC machining services are engineered specifically for titanium alloys, including Grades 2, 5 (Ti-6Al-4V), and custom formulations, ensuring optimal results for demanding aerospace, medical, and defense applications.

Our facility utilizes state-of-the-art 3-, 4-, and 5-axis CNC machining centers with high-torque spindles, rigid toolholding systems, and coolant-through capabilities to manage heat generation and prevent material degradation. We implement proprietary cutting parameters and tool geometries to minimize chatter, control residual stresses, and maintain tolerances as tight as ±0.0002 inches. Every titanium component undergoes rigorous in-process inspection using CMMs and surface roughness testers, guaranteeing compliance with ASTM, AMS, and customer-specific standards for critical features like threads, thin walls, and complex contours.

To accelerate your prototyping and low-volume production timelines, Honyo Prototype offers an Online Instant Quote platform. Upload your titanium part CAD file, specify material grade and finish requirements, and receive a detailed manufacturability analysis with competitive pricing within hours—not days. This seamless integration of engineering insight and digital efficiency eliminates traditional quoting bottlenecks, allowing you to move from design validation to certified titanium components faster. Request your instant quote today to experience precision titanium machining backed by Honyo’s 15-year legacy in high-integrity metal fabrication.

Technical Capabilities

CNC machining of titanium parts requires advanced capabilities due to the material’s high strength-to-density ratio, excellent corrosion resistance, and poor thermal conductivity. These properties make titanium more challenging to machine compared to Aluminum, Steel, ABS, and Nylon. To achieve tight tolerances and high surface integrity, 3-axis, 4-axis, and 5-axis milling as well as precision turning are employed based on part geometry and functional requirements.

Multi-axis milling allows for complex geometries to be machined in fewer setups, improving accuracy and repeatability. 5-axis CNC milling is particularly effective for aerospace and medical components requiring undercuts, sculpted surfaces, and high precision. CNC turning is used for rotational geometries, often in combination with milling for turn-mill operations.

Tight tolerances down to ±0.0002″ (±0.005 mm) are achievable with proper tooling, fixturing, and thermal stability. Material selection influences machining strategy—titanium requires lower cutting speeds and higher torque compared to aluminum, while plastics like ABS and Nylon need optimized feed rates to prevent melting or burring.

Below is a comparison of technical specifications across common materials processed using CNC machining at Honyo Prototype:

| Parameter | Titanium (Grade 5, Ti-6Al-4V) | Aluminum (6061-T6) | Steel (4140, 17-4PH) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6, PA66) |

|---|---|---|---|---|---|

| Machining Process | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4/5-Axis Milling, Turning | 3/4-Axis Milling | 3/4-Axis Milling, Turning |

| Typical Tolerance | ±0.0002″ (±0.005 mm) | ±0.0002″ (±0.005 mm) | ±0.0003″ (±0.008 mm) | ±0.005″ (±0.13 mm) | ±0.005″ (±0.13 mm) |

| Surface Finish (Ra) | 32–64 μin (0.8–1.6 μm) | 32–64 μin (0.8–1.6 μm) | 32–64 μin (0.8–1.6 μm) | 64–125 μin (1.6–3.2 μm) | 64–125 μin (1.6–3.2 μm) |

| Cutting Speed (Milling) | 100–250 SFM | 800–2000 SFM | 200–600 SFM | 1000–2500 SFM | 600–1200 SFM |

| Tooling Requirements | Carbide or CBN, High-Pressure Coolant | Carbide, High-Speed Steel | Carbide, Coated Inserts | Carbide, Sharp-Edge Tools | Carbide, Non-Coated |

| Common Applications | Aerospace, Medical, Defense | Automotive, Consumer, Drones | Industrial, Tooling, Defense | Prototyping, Enclosures | Gears, Bearings, Insulators |

| Notes on Machinability | Low thermal conductivity; prone to work hardening. Requires rigid setup and peck drilling | Excellent chip evacuation; easy to machine with high MRR | Moderate to difficult; requires high spindle power | Low melting point; minimize heat buildup | Hygroscopic; pre-dry before machining |

At Honyo Prototype, our CNC machining centers are equipped with high-precision spindles, in-process probing, and thermal compensation systems to maintain tight tolerances across all materials. We specialize in low-to-medium volume production of titanium components with complex geometries using 5-axis simultaneous machining, ensuring reduced lead times and superior part accuracy.

From CAD to Part: The Process

Honyo Prototype CNC Titanium Machining Process Overview

Titanium machining demands specialized expertise due to its low thermal conductivity, high strength at elevated temperatures, and propensity for work hardening. Our end-to-end process integrates material science rigor with digital efficiency to ensure precision, cost control, and on-time delivery for titanium components. Below is a technical breakdown of each phase.

Upload CAD

Clients initiate the process by uploading native or STEP format CAD files via our secure customer portal. For titanium parts, we require explicit material specification (e.g., Ti-6Al-4V Grade 5 ASTM F136) and critical feature annotations. Our system automatically validates geometric integrity, checks for undercuts or thin walls incompatible with titanium’s machining characteristics, and flags potential thermal distortion risks. Non-disclosure agreements are enforced at upload to protect intellectual property, which is critical for aerospace and medical titanium applications.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD geometry against a titanium-specific database of 15,000+ historical machining records. It calculates machine time using adaptive toolpath simulations that account for titanium’s unique cutting parameters, including reduced surface speeds (SFM) and feed rates to prevent galling. The quote includes material waste factors (typically 30-40% for titanium billets), secondary operation costs (e.g., stress relief annealing), and real-time titanium alloy pricing. Crucially, the AI identifies high-risk geometries—such as deep cavities with aspect ratios >6:1—and provides instant design suggestions to avoid non-conformance.

DFM Engineering Review

All titanium projects undergo manual Design for Manufacturability review by our metallurgy-certified engineers. We focus on titanium-specific failure modes:

Thermal management strategies to prevent alpha-case formation during cutting

Chip evacuation optimization to avoid recutting and built-up edge

Fixture design validation for vibration control (titanium’s low modulus requires rigid setups)

Wall thickness verification against minimum 0.5mm tolerances to avoid chatter

Clients receive a formal DFM report with actionable revisions, such as recommending helical interpolation over drilling for holes >10mm diameter to maintain hole straightness.

Titanium-Optimized Production

Production occurs in our climate-controlled titanium-dedicated cell using Haas UMC-750 machines equipped with through-spindle coolant (1,000 psi minimum) and ceramic-coated carbide tooling. Key process controls include:

| Parameter | Standard Aluminum | Titanium-Specific Setting | Rationale |

|---|---|---|---|

| Cutting Speed (SFM) | 800-1200 | 150-250 | Prevents thermal runaway |

| Coolant Pressure | 500 psi | 1000+ psi | Ensures chip evacuation |

| Tool Geometry | 45° lead angle | 75° lead angle | Reduces radial cutting forces |

| Stepover | 70% of diameter | 30-40% of diameter | Minimizes work hardening |

Each operation follows AS9100-compliant procedures with in-process CMM verification at critical stages. Titanium’s reactivity necessitates strict avoidance of cross-contamination—we maintain separate tooling and fixtures exclusively for titanium alloys.

Certified Delivery

Final inspection includes full FAI per AS9102, with material traceability to mill test reports (MTRs) for every titanium batch. Parts ship with:

Dimensional inspection report (including surface roughness Ra values)

Material certification with heat number traceability

Non-destructive testing documentation (if specified)

Cleanliness certification per ASTM F86 for medical implants

All titanium components undergo ultrasonic cleaning and vacuum sealing in VCI paper to prevent oxidation during transit. Standard lead time for titanium prototypes is 10-15 business days, with expedited options for urgent aerospace requirements.

This integrated workflow ensures titanium parts meet stringent industry standards while mitigating the material’s inherent machining challenges. Our process reduces titanium scrap rates by 35% compared to industry averages through proactive DFM and parameter optimization.

Start Your Project

Looking for precision CNC machining of titanium parts? Honyo Prototype delivers high-quality, tight-tolerance components for aerospace, medical, and industrial applications. Our advanced CNC capabilities and experienced engineering team ensure consistent quality and fast turnaround.

All manufacturing is performed at our Shenzhen factory, where strict quality control and efficient processes support both prototyping and low-volume production.

Contact Susan Leo for your next project at [email protected]. Let us provide you with reliable, cost-effective titanium machining solutions tailored to your specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.