Contents

Manufacturing Insight: Cnc Machining Services Adelaide

Precision CNC Machining Services in Adelaide

Honyo Prototype delivers advanced CNC machining solutions engineered for demanding industrial applications across Adelaide and Australia. Our facility specializes in high-accuracy CNC milling and turning operations, leveraging state-of-the-art multi-axis machinery to achieve tight tolerances down to ±0.005mm for complex metal and plastic components. With ISO 9001-certified processes and in-house engineering support, we consistently meet critical specifications for aerospace, medical, defense, and industrial sectors while maintaining rigorous material traceability and quality control protocols.

Eliminate procurement delays with our industry-leading Online Instant Quote system. Upload your STEP, IGES, or DWG files to receive a detailed technical assessment and competitive pricing within minutes—no manual submission or follow-up calls required. This seamless integration accelerates your prototyping and production timelines, ensuring rapid iteration and on-schedule project execution. Partner with Honyo for CNC machining services where technical precision, local Adelaide responsiveness, and digital efficiency converge to de-risk your manufacturing supply chain.

Technical Capabilities

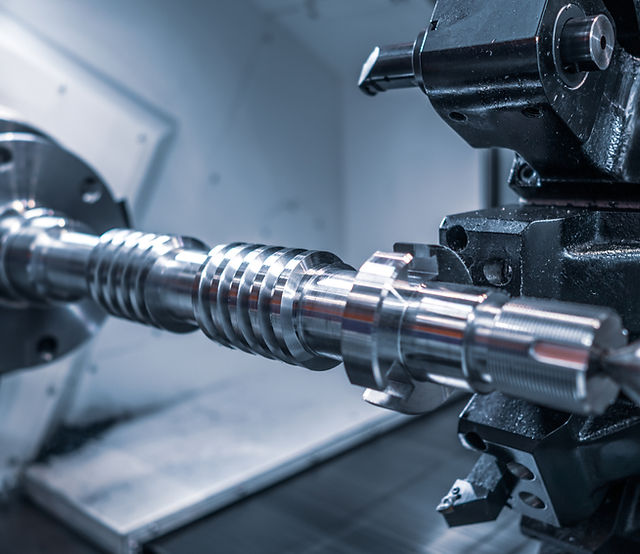

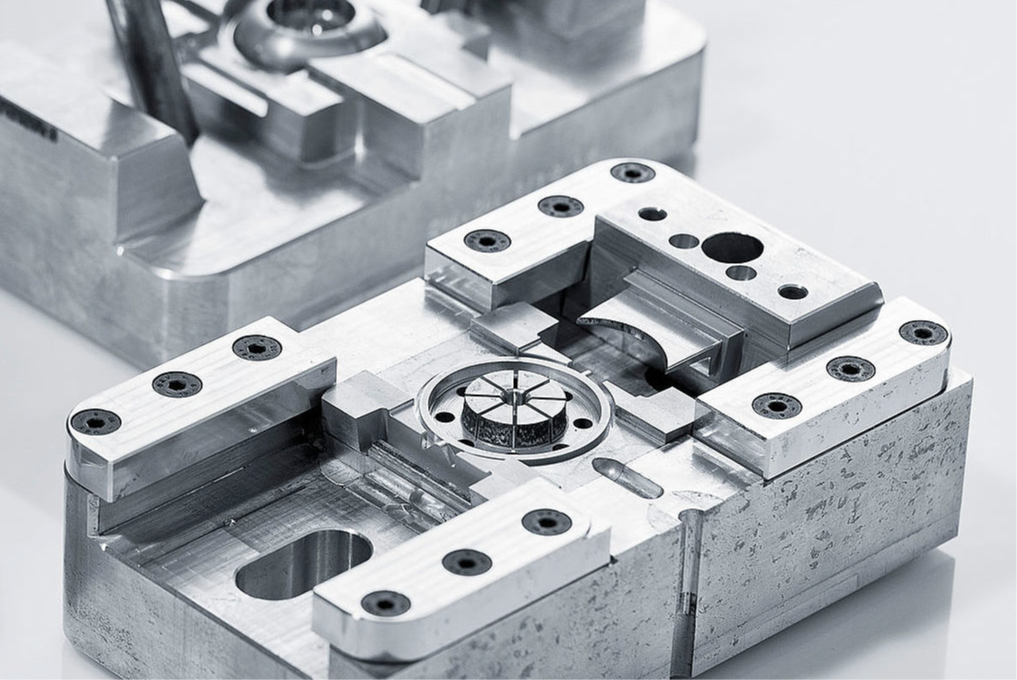

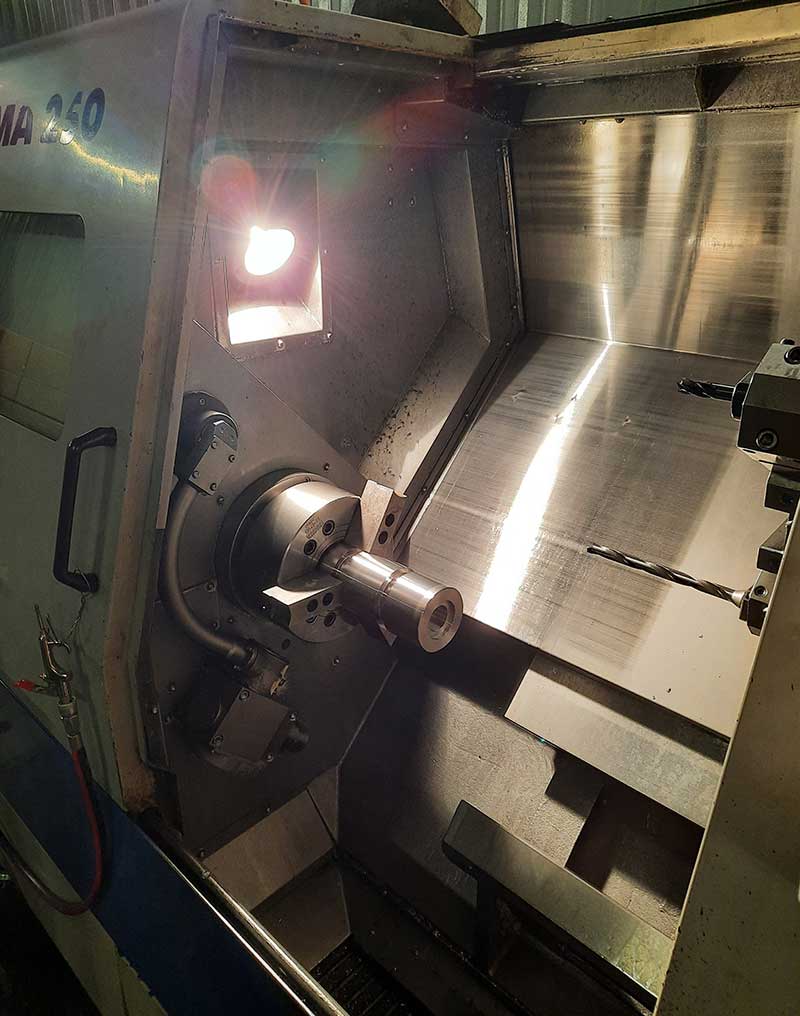

Honyo Prototype offers advanced CNC machining services in Adelaide, specializing in precision 3-axis, 4-axis, and 5-axis milling, as well as CNC turning for complex geometries and high repeatability. Our capabilities are engineered to support tight tolerance requirements, typically holding ±0.005 mm to ±0.025 mm depending on part geometry and material. We serve industries requiring high-accuracy prototypes and low-to-medium volume production runs, including aerospace, medical, defense, and industrial manufacturing.

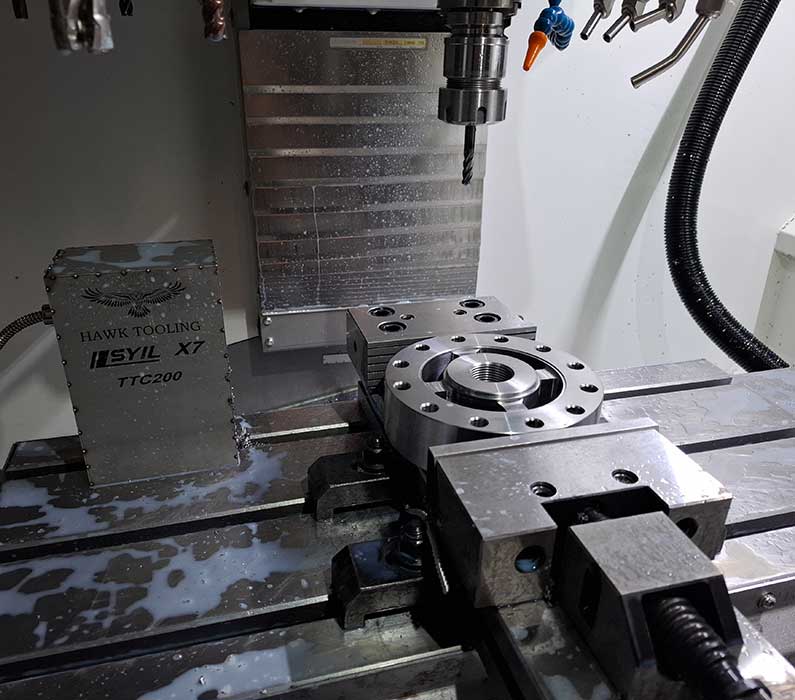

Our machining centers are equipped with state-of-the-art CNC controls, high-speed spindles, and automated tool changers to ensure consistent quality and reduced cycle times. In-process probing and post-process CMM inspection ensure dimensional accuracy and compliance with technical specifications.

Below is a summary of our technical capabilities and supported materials:

| Capability | Specification |

|---|---|

| Milling Axes | 3-axis, 4-axis (indexing and continuous), 5-axis simultaneous |

| Turning | CNC turning with live tooling, bar feeding, and sub-spindle options |

| Tolerance | Standard: ±0.025 mm; Tight: ±0.005 mm (achievable on critical features) |

| Surface Finish | As-machined: Ra 3.2 μm; Optional polishing, anodizing, plating, and coating |

| Max Work Envelope (Milling) | 1000 x 600 x 500 mm (X, Y, Z) |

| Max Work Envelope (Turning) | Ø300 mm diameter x 500 mm length |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Supported Materials – Metals | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Mild Steel, Tool Steel, Titanium |

| Supported Materials – Plastics | ABS, Nylon (PA6, PA66), Delrin (POM), PEEK, PC, PVC |

| Quality Standards | ISO 9001:2015 compliant, First Article Inspection (FAI), PPAP documentation available |

| Additional Services | CAD/CAM programming, DFM analysis, in-house finishing, metrology and inspection reports |

Our facility in Adelaide supports rapid turnaround times with same-day quoting and expedited prototyping options. With a focus on precision and technical collaboration, Honyo Prototype ensures every machined component meets rigorous performance and quality standards.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC machining services in Adelaide through an optimized digital workflow designed for speed, accuracy, and engineering collaboration. Our process begins when clients upload native CAD files or industry-standard STEP/IGES formats via our secure online portal. This triggers an immediate automated analysis where our proprietary AI quotation engine evaluates geometric complexity, material requirements, tolerances, and feature density against live machine availability and material stock levels at our Adelaide facility. The AI generates a detailed technical quotation within 2 hours, including part-specific cost breakdowns, lead time estimates, and preliminary feasibility flags—eliminating traditional manual quote bottlenecks.

Following quotation acceptance, our engineering team initiates a rigorous Design for Manufacturability (DFM) review. This is not an automated step but a collaborative technical assessment where our Adelaide-based manufacturing engineers examine tool access, workholding strategies, tolerance stack-ups, and material utilization. We provide actionable DFM feedback within 24 hours, suggesting optimizations such as feature consolidation or tolerance relaxation that typically reduce costs by 15-25% without compromising functional requirements. Client approval of the DFM report is mandatory before proceeding, ensuring alignment on all technical parameters.

Production commences only after DFM sign-off, leveraging our Adelaide facility’s certified ISO 9001:2015 environment and advanced CNC equipment including 5-axis milling centers, precision lathes, and multi-spindle machines. Each job receives a dedicated production cell with real-time monitoring of spindle loads, tool wear, and dimensional verification via in-process CMM checks. Critical first-article inspections follow AS9102 standards for aerospace clients, with full FAI reports available upon request. Material traceability is maintained from stock receipt through final packaging, with common materials including 6061-T6, 7075-T6 aluminum, 303/316 stainless steel, and engineered plastics like PEEK.

Final quality validation occurs against the original CAD model using our Zeiss CONTURA CMM and optical comparators, generating comprehensive inspection reports with GD&T analysis. Parts are packaged using anti-corrosion VCI films and custom foam cradles for transit-sensitive components. Delivery utilizes tracked logistics partners with same-day dispatch options for Adelaide metro clients, typically achieving 3-5 business day turnaround from DFM approval for standard prototypes. All shipments include digital documentation packs accessible via client portal, containing as-built inspection data, material certifications, and process validation records. This integrated approach ensures Adelaide-based clients receive technically validated, production-ready components with full traceability and minimal time-to-part.

Start Your Project

Looking for precision CNC machining services in Adelaide? Partner with Honyo Prototype for high-quality, custom manufacturing solutions tailored to your specifications. With advanced CNC capabilities and a proven track record in rapid prototyping and low-volume production, we deliver accuracy, speed, and reliability.

Contact Susan Leo today at [email protected] to discuss your project requirements. While our state-of-the-art factory is based in Shenzhen, we provide seamless service and global shipping to clients in Adelaide and beyond. Trust Honyo Prototype for fast turnaround, competitive pricing, and engineering excellence.

| Service | Specification |

|---|---|

| Process | CNC Milling, CNC Turning |

| Materials | Aluminum, Steel, Stainless Steel, Brass, Plastics, and more |

| Tolerances | As tight as ±0.005 mm |

| Lead Time | As fast as 3–5 days for prototypes |

| Location | Factory in Shenzhen, China |

| Service Area | Adelaide, Australia and international clients |

Reach out now and get a free quote for your next precision machining project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.