Contents

Manufacturing Insight: Cnc Machining Service Uk

Precision CNC Machining Services for UK Engineering Excellence

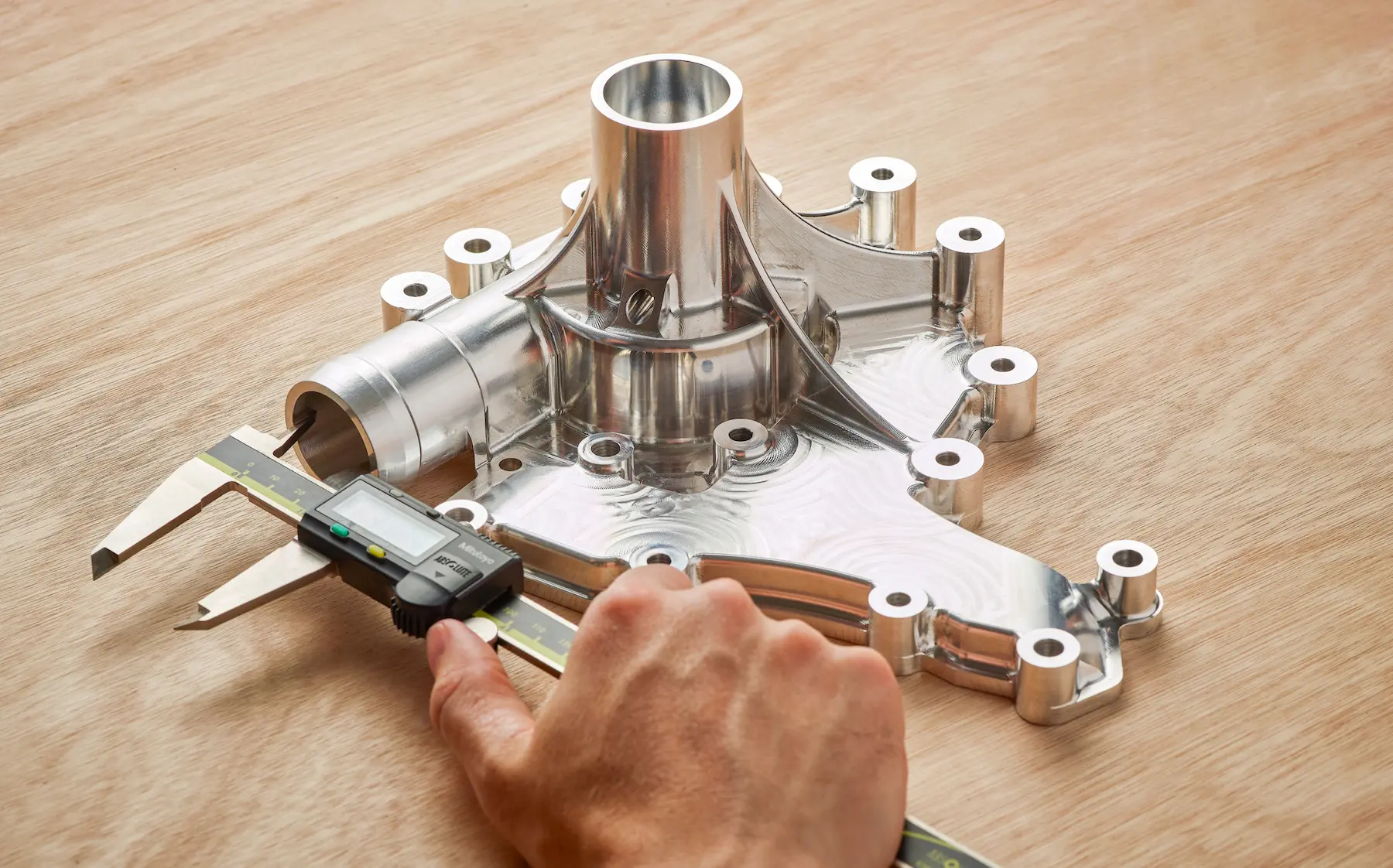

Honyo Prototype delivers advanced CNC machining solutions tailored to the demanding requirements of UK manufacturers, aerospace suppliers, automotive engineers, and medical device developers. Our UK-based facility utilises state-of-the-art 3-, 4-, and 5-axis machining centres to produce complex, high-integrity components from metals including aluminium, stainless steel, titanium, and engineering plastics, consistently achieving tight tolerances down to ±0.005mm. We support clients from prototype development through low-to-medium volume production, ensuring rigorous quality control via ISO 9001-certified processes and comprehensive in-house metrology.

A critical differentiator for time-sensitive UK projects is our Online Instant Quote platform. Engineers and procurement teams can upload CAD files (STEP, IGES, DWG) and receive a detailed, transparent cost assessment within minutes—no manual back-and-forth or delays. This accelerates project initiation while providing immediate clarity on lead times, material options, and design feasibility feedback. For UK industries where speed-to-market and supply chain resilience are paramount, Honyo Prototype combines technical precision with operational agility to keep your projects on schedule.

Request a quote today to experience how our CNC machining services integrate seamlessly into your UK manufacturing workflow.

Technical Capabilities

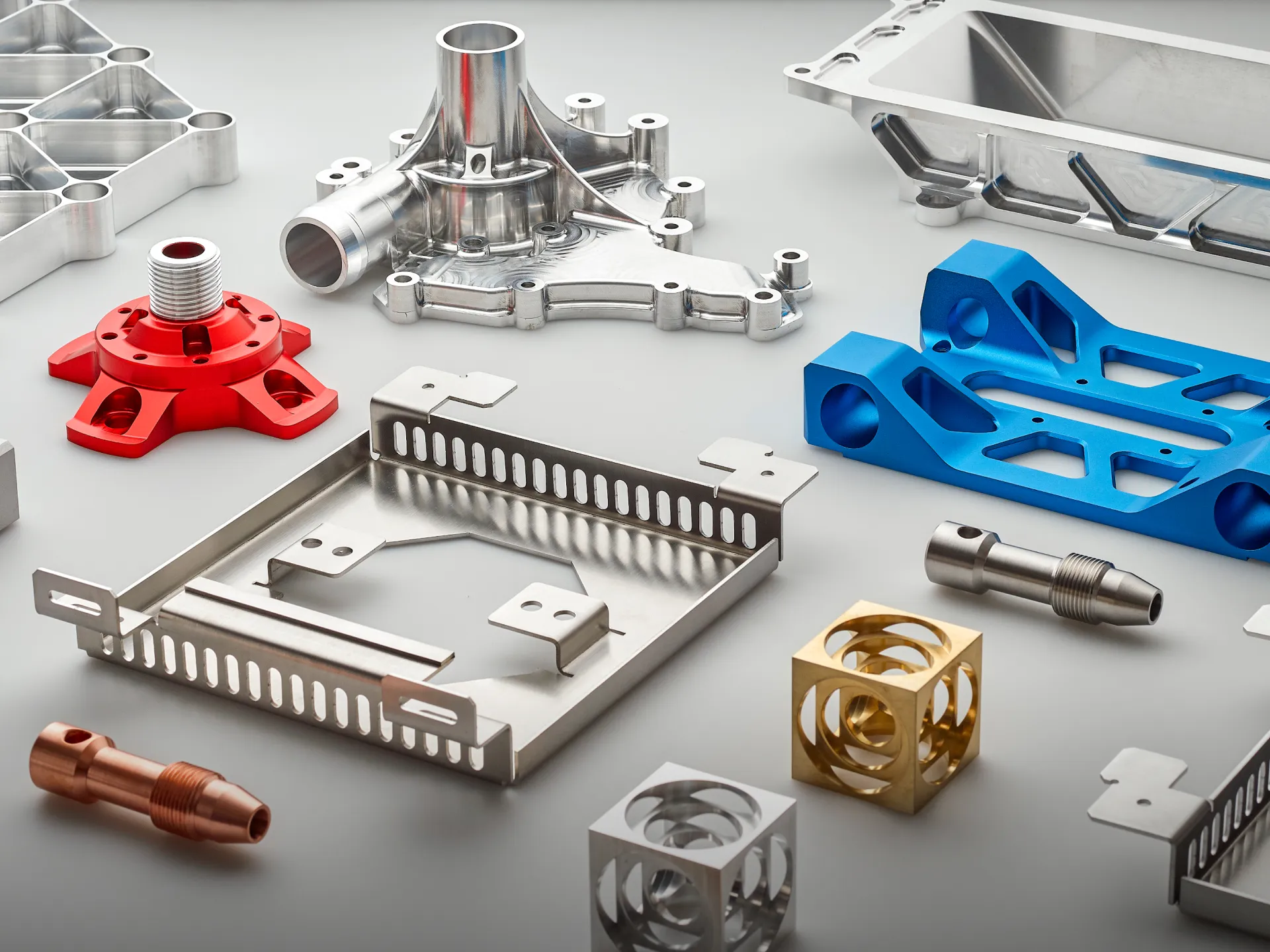

Honyo Prototype offers high-precision CNC machining services across the UK, specializing in multi-axis milling and turning operations for industries requiring tight tolerance components. Our capabilities span 3-axis, 4-axis, and 5-axis CNC milling, along with CNC turning for complex rotational geometries. We support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, ensuring optimal material properties for prototyping, low-volume production, and functional testing.

All parts are machined to strict quality standards with typical tolerances held to ±0.005 mm (±0.0002″) depending on geometry and feature size. Critical dimensions can be controlled to ±0.002 mm upon request with appropriate inspection documentation (e.g., CMM reports).

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling) |

| Tolerance (Standard) | ±0.005 mm (±0.0002″) |

| Tight Tolerance Option | Down to ±0.002 mm with process validation and inspection reports |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin); fine finishes available upon request |

| Max Work Envelope (Milling) | 1000 mm × 600 mm × 500 mm (X×Y×Z) – varies by machine |

| Max Turning Diameter | Up to Ø300 mm; bar feed support up to Ø50 mm |

| Materials – Metals | Aluminum (6082, 7075, 2024), Steel (080M40, EN24, EN16B), Stainless Steel (303, 304, 316) |

| Materials – Plastics | ABS, Nylon (PA6, PA66), POM (Delrin), PEEK, PMMA, PC |

| Tooling & Fixturing | High-precision carbide tooling; custom fixtures for batch repeatability |

| Inspection | In-process checks; final inspection with CMM, micrometers, and optical comparators |

| Lead Time (Typical) | 5–10 business days depending on complexity and volume |

| Certifications | ISO 9001:2015 compliant processes; full traceability and documentation |

We support DFM feedback prior to machining and offer post-processing options including anodizing, passivation, bead blasting, and precision deburring. Our UK-based facility ensures fast turnaround and direct engineering support for mission-critical components in aerospace, medical, automotive, and industrial sectors.

From CAD to Part: The Process

Honyo Prototype UK CNC Machining Service Workflow

Honyo Prototype delivers precision CNC machining services across the UK through a streamlined, technology-driven process designed for speed, accuracy, and manufacturability. Our end-to-end workflow begins with CAD submission and concludes with certified delivery, integrating AI efficiency with engineering expertise at critical stages.

Upload CAD

Clients initiate the process by uploading 3D CAD files (STEP, IGES, or native formats) via our secure online portal. The system automatically validates file integrity, checks for unit consistency (millimeters/inches), and confirms geometric completeness. Unsupported formats or incomplete models trigger immediate feedback, ensuring only production-ready data progresses. This stage establishes the technical foundation for quoting and manufacturing.

AI-Powered Quoting

Uploaded CAD data feeds into our proprietary AI quoting engine, which analyzes part geometry, material requirements, tolerances, and surface finishes against real-time production parameters. The AI cross-references live machine availability, material stock levels at our UK facilities, and historical process data to generate an accurate cost and lead time estimate within 2 hours. Crucially, this is not an automated black box; all AI outputs undergo validation by a UK-based manufacturing engineer to adjust for complex features, secondary operations, or non-standard requirements before the quote is finalized.

Engineering-Led DFM Analysis

Every project enters a mandatory Design for Manufacturability (DFM) review conducted by our UK engineering team. This phase identifies potential production risks such as excessive tool changes, thin wall instabilities, or tolerance stack-up issues. We provide actionable feedback through an interactive report highlighting:

| DFM Focus Area | Common Issue | Honyo Resolution |

|---|---|---|

| Geometry | Non-machinable undercuts | Suggests alternative tool paths or design modifications |

| Tolerances | Over-specified ±0.005mm on non-critical features | Recommends standard ±0.025mm to reduce cost/time |

| Material | Inappropriate grade for application | Proposes UK-sourced alternatives (e.g., 6082-T6 vs. 7075) |

Clients receive detailed recommendations via secure portal with annotated visuals. Approval requires explicit sign-off, ensuring alignment before metal cutting begins.

Precision Production

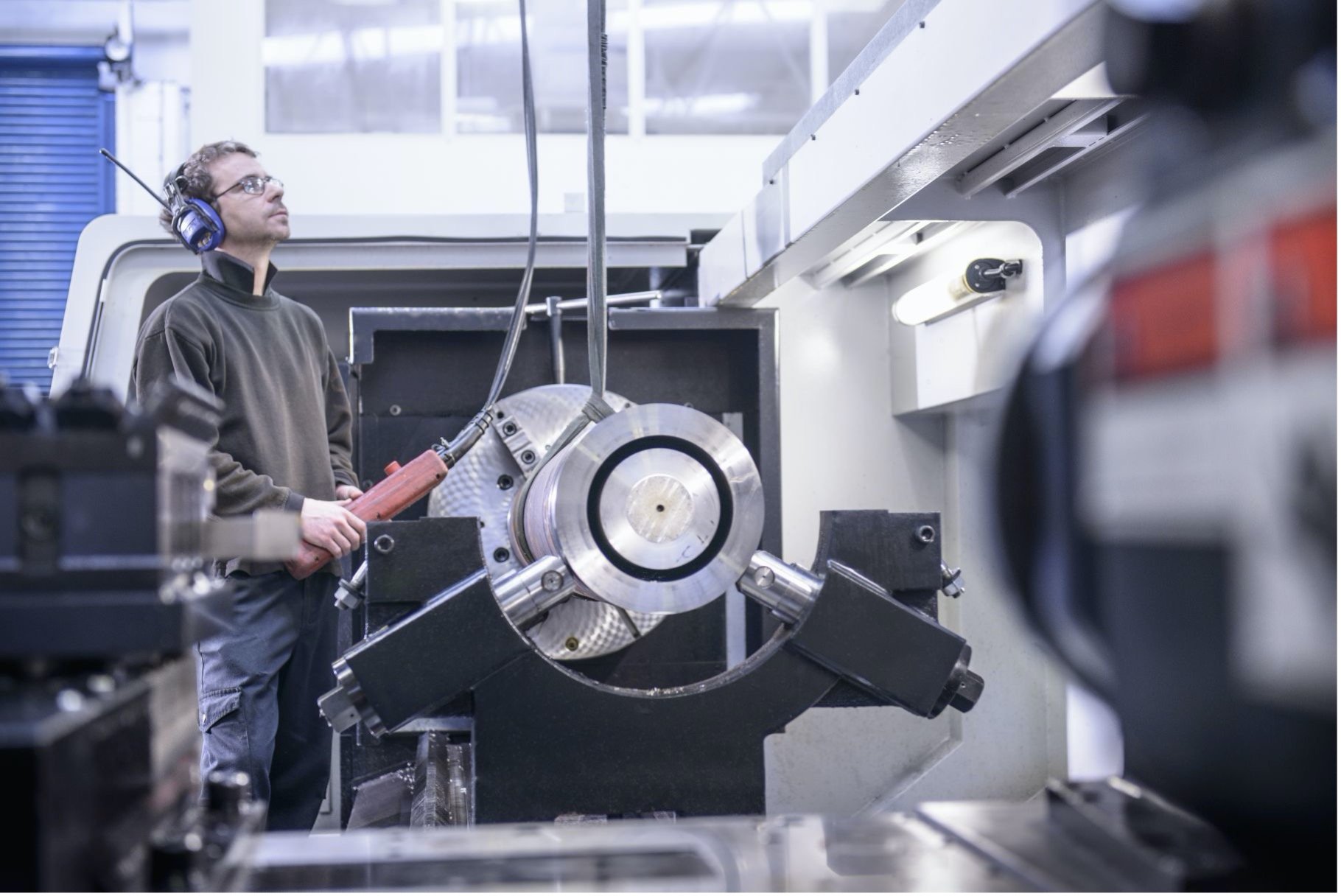

Approved orders move to our UK-based machining cells equipped with Haas, DMG MORI, and Makino CNC systems. Production follows strict protocols:

Material certification (Mill Test Reports provided) and first-article inspection occur before full batch runs. In-process checks using Faro arms or CMMs verify critical dimensions at defined intervals. Complex assemblies undergo sub-assembly validation. All processes comply with ISO 9001:2015 standards, with full traceability from raw material to finished part.

Certified Delivery

Final parts undergo dimensional validation against the original CAD model, with a full inspection report (including GD&T verification) issued. UK deliveries utilize tracked couriers with 24–48 hour coverage; time-critical shipments receive dedicated logistics coordination. Every consignment includes:

Signed certificate of conformance

Material test documentation

As-machined dimensional report

Packaging certified for transit security

Real-time shipment tracking is accessible via client portal, with delivery confirmation triggering project closure and feedback solicitation.

This integrated approach minimizes iterations, reduces time-to-part by up to 40% versus traditional methods, and ensures every UK client receives aerospace-grade quality with responsive local support.

Start Your Project

For precision CNC machining services in the UK, trusted by engineering and product development teams, contact Susan Leo at [email protected]. Honyo Prototype delivers high-accuracy, low-volume CNC machined parts with fast turnaround, ideal for prototypes and bridge production. Though our advanced manufacturing facility is based in Shenzhen, we support UK clients with seamless communication, strict quality control, and international shipping. Partner with us for reliable, cost-effective machining solutions engineered to meet exact specifications.

Contact:

Susan Leo

Email: [email protected]

Manufacturing Base:

Shenzhen, China

| Service Feature | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling, CNC turning |

| Materials | Aluminum, steel, stainless steel, brass, plastics, and more |

| Tolerances | As tight as ±0.005 mm |

| Lead Time | As fast as 5–7 days for prototypes |

| Finishes | As-machined, anodizing, powder coating, plating, bead blasting |

| Quality Standards | ISO 9001-compliant processes |

| Supported Industries | Automotive, medical, robotics, aerospace, consumer electronics |

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.