Contents

Manufacturing Insight: Cnc Machining San Diego

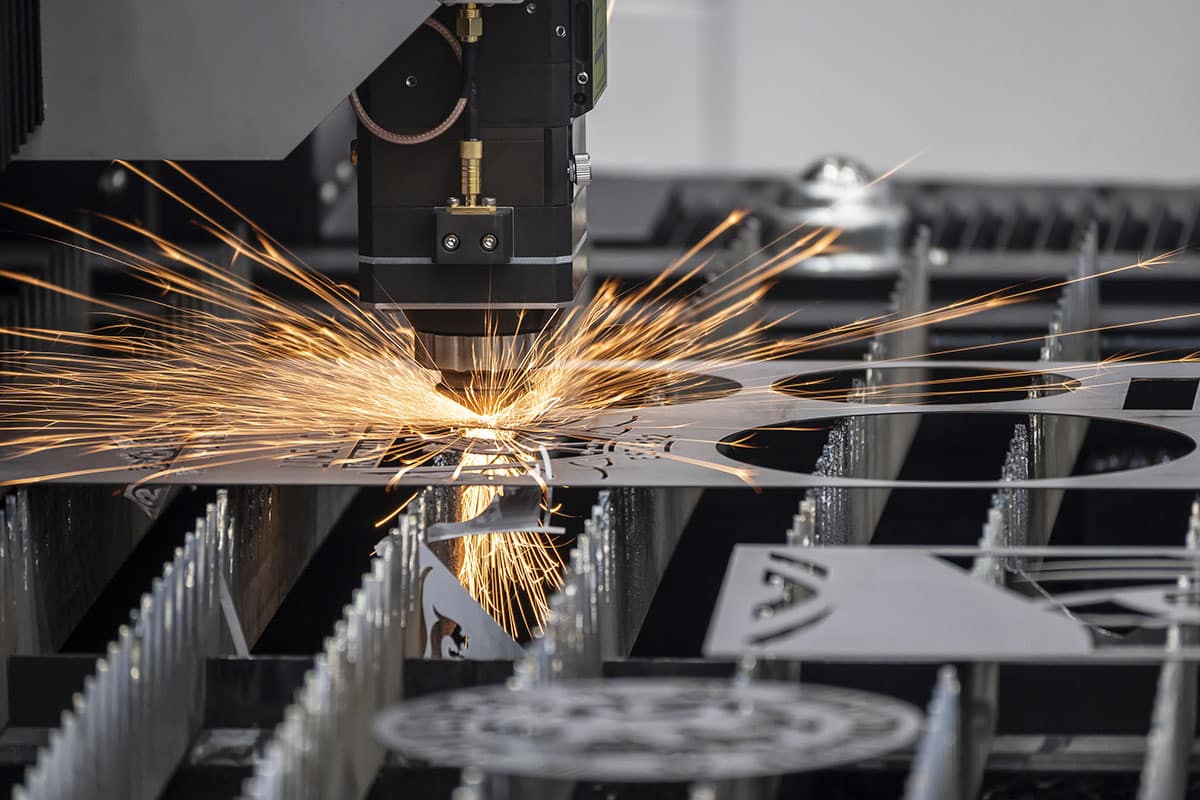

Precision CNC Machining Services in San Diego: Accelerate Your Prototyping and Production

Honyo Prototype delivers advanced CNC machining solutions engineered for the exacting demands of San Diego’s aerospace, medical, defense, and high-tech industries. As your local manufacturing partner, we combine state-of-the-art 3-axis, 4-axis, and 5-axis milling and turning centers with deep engineering expertise to produce complex, high-tolerance components from metals, plastics, and composites. Our ISO 9001:2015 certified facility achieves tight tolerances down to ±0.0002 inches, ensuring repeatability and quality critical for mission-critical applications. We specialize in rapid prototyping and low-to-mid volume production runs, providing end-to-end support from DFM analysis to finishing and assembly. Eliminate quoting delays with our Online Instant Quote system—upload your CAD file and receive a detailed, actionable price estimate within minutes, not days. Partner with Honyo Prototype for responsive, precision manufacturing that keeps your San Diego projects on schedule and within specification.

Technical Capabilities

Honyo Prototype provides precision CNC machining services in San Diego with capabilities in 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. Our advanced machining centers are optimized for tight-tolerance components across a range of engineering-grade materials, including aluminum, steel, ABS, and nylon. These processes support industries requiring high repeatability and accuracy such as aerospace, medical, robotics, and industrial automation.

Below is an overview of our technical capabilities:

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including Swiss-type) |

| Tolerance Capability | ±0.0002″ (5 µm) typical; tight tolerances maintained across complex geometries |

| Maximum Work Envelope | Milling: 20″ x 30″ x 20″ (508 x 762 x 508 mm); Turning: Ø16″ x 48″ (406 x 1219 mm) |

| Spindle Speed | Up to 24,000 RPM (high-speed machining available) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316), ABS, Nylon (6, 6/6), and other engineering plastics |

| Surface Finish | As-machined: 32–125 µin Ra; optional polishing, anodizing, and coating |

| CNC Controls | Fanuc, Siemens, and Heidenhain controls with full CAD/CAM integration |

| Inspection Equipment | CMM, optical comparators, micrometers, calipers, and laser scanning |

Our San Diego facility maintains strict quality control protocols (ISO 9001-compliant processes) to ensure dimensional accuracy and material integrity. Multi-axis capabilities allow for complex part geometries with minimal setup, reducing lead times and enhancing part consistency. Whether producing low-volume prototypes or high-mix production runs, Honyo Prototype delivers precision-machined components with rapid turnaround.

From CAD to Part: The Process

Honyo Prototype San Diego CNC Machining Workflow

Our San Diego facility executes a streamlined, technology-driven CNC machining process designed for precision, speed, and cost transparency. The workflow begins when a client uploads a CAD file to our secure portal. We accept industry-standard formats including STEP, IGES, Parasolid, and native CAD files from SolidWorks, Fusion 360, and Creo. All submissions undergo immediate validation for geometric integrity, unit consistency, and manufacturability flags.

Following CAD upload, our proprietary AI quoting engine generates a detailed cost estimate within 2 hours. This system analyzes 50+ parameters including material utilization, machine time, tooling requirements, secondary operations, and real-time material pricing from our San Diego inventory. Unlike generic quoting tools, our AI integrates historical production data from 50,000+ parts to predict true production variables, providing clients with granular cost breakdowns and lead time projections.

The Design for Manufacturability (DFM) phase is where Honyo delivers critical engineering value. Our AS9100-certified manufacturing engineers conduct a thorough review, identifying potential issues such as non-optimal wall thicknesses, inefficient tool access, or tolerance conflicts. We provide actionable recommendations—like modifying fillet radii to reduce cycle time or suggesting alternative materials for better machinability—typically resolving 85% of manufacturability concerns before production. Clients receive a formal DFM report with annotated CAD markups and cost-impact analysis within 24 hours of quote acceptance.

Production occurs at our ISO 9001:2015-certified San Diego facility using Haas, DMG MORI, and Makino CNC centers. We maintain strict process controls:

Material Verification: All stock undergoes PMI (Positive Material Identification) per ASTM E1086

In-Process Inspection: Critical features checked via Renishaw probes at defined production intervals

Final QA: Full CMM reporting against ASME Y14.5-2018 standards with surface roughness validation

Typical Lead Time Variables

| Factor | Standard Lead Time | Expedited Option |

|---|---|---|

| Simple Geometry (Aluminum) | 5-7 business days | 72 hours |

| Complex Multi-Axis (Stainless) | 10-12 business days | 5 business days |

| Tight Tolerances (±0.0005″) | +3 days | +24 hours |

Delivery leverages our integrated logistics platform. All parts ship with serialized traceability documentation, including material certs, inspection reports, and first-article testing data where required. We coordinate direct shipping via DHL, FedEx, or client-designated carriers with real-time tracking. For urgent San Diego metro area deliveries, same-day handoff is available through our Kearny Mesa facility.

This closed-loop process ensures clients receive production-ready parts with minimized risk and predictable timelines. For time-sensitive projects, our engineering team initiates concurrent DFM analysis during the AI quoting phase, reducing total turnaround by up to 40%. Contact our San Diego manufacturing specialists to discuss specific project requirements or request a live workflow demonstration.

Start Your Project

Looking for precision CNC machining services in San Diego? Partner with Honyo Prototype for fast, reliable, and high-quality manufacturing solutions. Although our advanced production facility is located in Shenzhen, we provide seamless support for clients across North America, including San Diego.

For project inquiries or to request a quote, contact Susan Leo directly at [email protected]. We specialize in CNC milling, turning, and rapid prototyping with tight tolerances, quick turnaround times, and full traceability—ideal for aerospace, medical, automotive, and industrial applications.

Let us handle your precision components with the expertise your project demands. Reach out today to streamline your manufacturing process.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.