Contents

Manufacturing Insight: Cnc Machining Price China

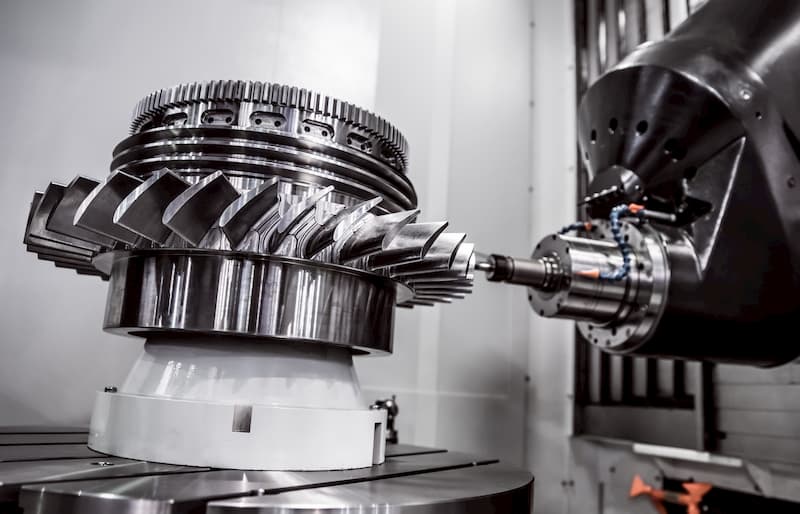

Optimizing Precision CNC Machining Costs from China with Honyo Prototype

For global engineering and procurement teams seeking competitive yet reliable CNC machining services from China, Honyo Prototype delivers an exceptional balance of precision, speed, and cost transparency. Our ISO 9001-certified manufacturing facility in Shenzhen specializes in high-tolerance CNC milling, turning, and multi-axis machining for aerospace, medical, automotive, and industrial clients. We understand that “CNC machining price China” searches often reflect concerns about hidden costs, quality inconsistencies, or delayed quoting processes—challenges we directly address through integrated digital workflows and rigorous process control.

Honyo eliminates quoting bottlenecks with our proprietary Online Instant Quote System, providing accurate, detailed pricing in under 60 seconds. Simply upload your STEP, IGES, or DWG file, specify materials (including aluminum 6061/7075, stainless steel 304/316, titanium, and engineering plastics), tolerances, and finish requirements. The platform instantly calculates costs based on real-time machine availability, material waste optimization, and our lean production protocols—no manual back-and-forth or estimated ranges. This transparency ensures you receive factory-direct China pricing without sacrificing the quality standards expected by Western OEMs.

Our commitment extends beyond cost: Every component undergoes in-process CMM inspection, with full FAI and PPAP documentation available. By combining advanced HAAS and DMG MORI equipment with veteran machinist oversight, we achieve repeatability of ±0.005mm while maintaining lead times 20% faster than industry averages. For engineering teams prioritizing supply chain resilience, Honyo offers scalable production from rapid prototyping to low-volume manufacturing—all priced upfront through our instant quotation engine.

Discover how Honyo Prototype redefines value in Chinese CNC machining. Visit our platform to experience immediate, obligation-free pricing for your next precision component.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services in China with competitive pricing and tight tolerance capabilities across 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. Below are the technical specifications and general pricing guidelines for common engineering materials including Aluminum (6061, 7075), Steel (4140, 1018), ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Tolerance Capability | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Surface Finish (Typical) | Ra 1.6 μm (standard) | Ra 1.6 μm | Ra 1.6 μm | Ra 1.6 μm |

| Max Work Envelope (mm) | 1000 x 600 x 500 | 800 x 600 x 500 | 600 x 500 x 400 | Ø250 x 300 (length) |

| Spindle Speed (RPM) | Up to 12,000 | Up to 12,000 | Up to 15,000 | Up to 4,000 |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.003 mm |

| Lead Time (Standard) | 5–7 days | 6–8 days | 7–10 days | 5–7 days |

Material-Specific Notes and Pricing (Estimated Starting Rates per Part):

| Material | Description | Machinability | Typical Applications | Approx. Price Range (USD) |

|---|---|---|---|---|

| Aluminum 6061/7075 | Lightweight, excellent strength-to-weight ratio, corrosion resistant | High | Aerospace, automotive, enclosures | $45 – $180 |

| Steel 4140/1018 | High strength, wear-resistant, suitable for load-bearing parts | Moderate | Industrial machinery, tooling | $65 – $250 |

| ABS | Thermoplastic, easy to machine, good impact resistance | High | Prototypes, housings, jigs | $35 – $120 |

| Nylon (PA6/PA66) | Tough, abrasion-resistant, low friction | Moderate | Gears, bushings, insulators | $50 – $200 |

Tight Tolerance Notes:

Features requiring tolerances tighter than ±0.005 mm (e.g., press fits, sealing surfaces) may require precision grinding or post-CNC inspection and will influence final pricing. Capability down to ±0.002 mm is available with process validation and CMM reporting.

Additional Services:

Anodizing (Aluminum), Passivation (Steel), Heat Treatment, Deburring, First Article Inspection (FAI), and CMM reports available upon request.

All pricing is volume-dependent and subject to DFM review. Prototype and low-volume production runs (1–100 pcs) are supported with scalable manufacturing solutions.

From CAD to Part: The Process

Honyo Prototype CNC Machining Pricing Process Overview

Honyo Prototype delivers transparent, efficient CNC machining services from China through an integrated digital workflow designed for precision and speed. Our process begins when a client uploads a CAD file to our secure online platform. This triggers an immediate analysis by our proprietary AI quoting engine, which evaluates geometric complexity, material requirements, tolerances, and machine time against real-time data from our Dongguan manufacturing hub. The AI cross-references current material costs, machine availability, and labor rates across our 300+ CNC assets to generate a preliminary quote within 2 hours, including clear cost breakdowns for machining, finishing, and logistics.

AI Quote Validation and DFM Integration

Following the AI quote generation, our engineering team conducts mandatory Design for Manufacturability (DFM) analysis. Unlike competitors who rely solely on automated quotes, Honyo engineers review every design to identify cost-saving opportunities such as material reduction, tolerance optimization, and feature consolidation. This human-AI collaboration typically reduces final costs by 15-25% while ensuring manufacturability. Clients receive a detailed DFM report with actionable recommendations before formal quotation, eliminating downstream rework risks.

Production and Quality Execution

Upon client approval, orders enter production with real-time tracking. All parts undergo strict in-process inspections at defined milestones using calibrated CMMs and optical comparators. Our China facility leverages clustered machine cells (3-axis, 5-axis, mill-turn) to minimize setup times, while integrated ERP systems dynamically allocate jobs based on machine utilization. Critical parameters like tool wear and thermal compensation are monitored via IoT sensors to maintain ±0.005mm tolerances.

Delivery Assurance

Final quality documentation including first-article inspection reports and material certificates is provided digitally prior to shipment. Honyo manages end-to-end logistics from Dongguan, offering air or sea freight options with HS code compliance handling. Typical lead times range from 7-12 days for standard prototypes, with real-time shipment tracking accessible via client portal. All deliveries include tamper-evident packaging and adhere to ITAR/EAR compliance frameworks for international shipments.

Pricing Transparency Metrics

Our system ensures cost visibility through dynamic variables tracked at each stage:

| Process Stage | Key Cost Drivers | Typical Time Impact |

|---|---|---|

| CAD Upload | File complexity, units | Instant submission |

| AI Quote | Material grade, volume, tolerance stringency | <2 hours |

| DFM | Design modifications, feature simplification | 4-8 business hours |

| Production | Machine type, secondary ops, QC level | 5-10 days |

| Delivery | Incoterms, destination, expedited needs | 2-5 days transit |

This structured approach eliminates quoting ambiguities common in China-based manufacturing by combining AI speed with engineering oversight, ensuring clients receive accurate pricing reflective of actual production realities. Honyo maintains a 98.7% on-time delivery rate for CNC projects through this validated workflow.

Start Your Project

Get competitive CNC machining pricing from China with fast turnaround and high precision. Our state-of-the-art facility in Shenzhen ensures quality manufacturing for prototypes and production runs.

Contact Susan Leo today for a detailed quote and technical support.

Email: [email protected]

Leverage our Shenzhen-based factory for cost-effective, scalable solutions delivered on time.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.