Contents

Manufacturing Insight: Cnc Machining Los Angeles

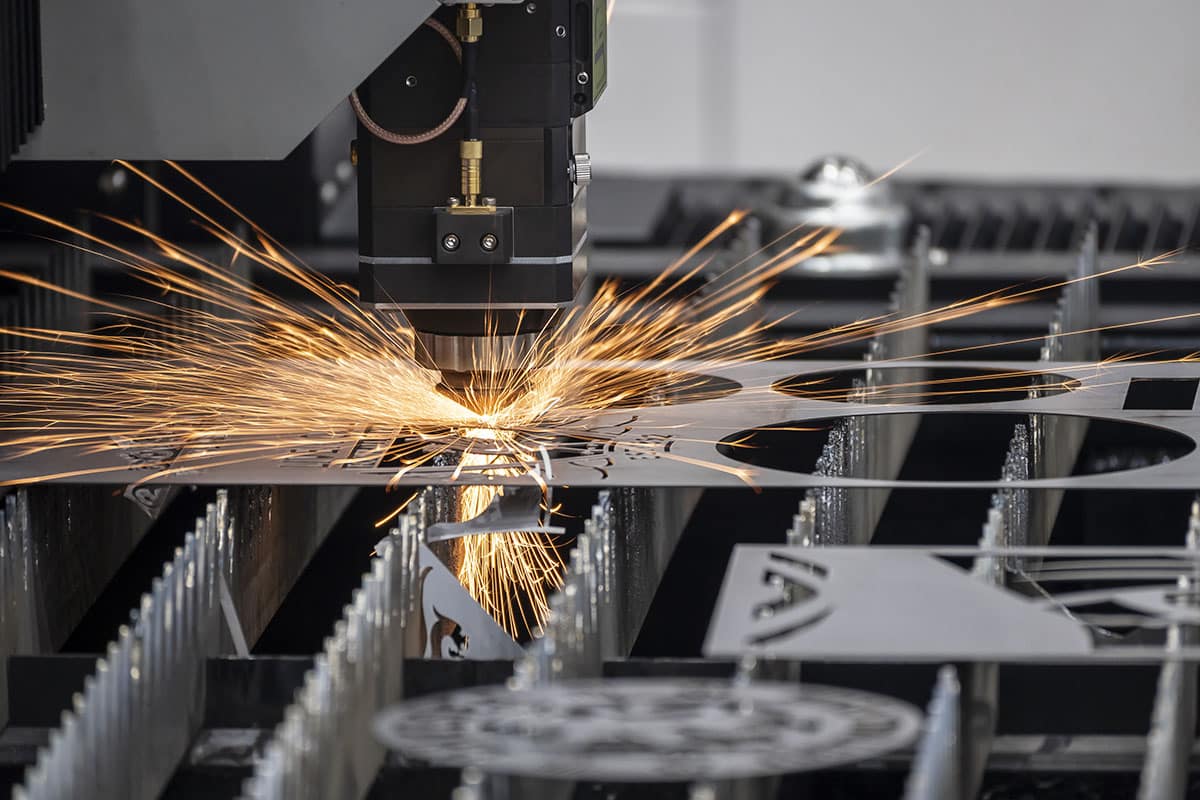

Precision CNC Machining Solutions for Los Angeles Industry Leaders

Honyo Prototype delivers advanced CNC machining services engineered to meet the demanding requirements of Los Angeles aerospace, medical, defense, and industrial technology sectors. Our Los Angeles facility combines state-of-the-art multi-axis milling and turning centers with rigorous AS9100-certified quality processes, ensuring components adhere to tolerances as tight as ±0.0002 inches across materials including titanium, Inconel, aluminum alloys, and engineering plastics. We specialize in rapid prototyping through low-volume production, providing end-to-end manufacturing from CAD model to validated part with certified material traceability and first-article inspection reports.

Accelerate Your Project Timeline with Digital Procurement

Eliminate traditional quoting delays with Honyo’s Online Instant Quote system. Upload your 3D model or technical drawing to receive a detailed, binding price and lead time estimate within minutes—no sales calls or manual review required. This digital workflow integrates seamlessly with your engineering team’s schedule, enabling faster iteration cycles and reducing time-to-prototype by up to 70% compared to conventional RFQ processes. For Los Angeles-based clients requiring urgent turnaround, our downtown LA facility supports same-day engineering review and 5-day rapid machining for qualified projects.

Partner with Honyo Prototype for CNC machining where precision engineering meets operational agility. Our commitment to technical excellence and digital-first customer experience ensures your complex components are manufactured right—on time and within specification. Access immediate pricing and capacity availability through our Online Instant Quote platform at honyoprototype.com.

Technical Capabilities

Honyo Prototype offers precision CNC machining services in Los Angeles with advanced capabilities in 3, 4, and 5-axis milling, CNC turning, and tight-tolerance manufacturing. Our facility supports a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, ensuring high repeatability, accuracy, and surface finish for prototyping and low-to-mid volume production.

| Feature | Specification Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis) |

| Positioning Accuracy | ±0.0002″ (5 µm) on critical dimensions |

| Repeatability | ±0.0001″ (2.5 µm) across production runs |

| Typical Tolerance Range | ±0.001″ (25 µm); tight tolerances down to ±0.0002″ (5 µm) achievable with inspection |

| Max Work Envelope (Milling) | 30″ x 20″ x 20″ (762 x 508 x 508 mm) – 5-axis; larger with indexing |

| Max Turning Diameter | 16″ (406 mm) with bar feed capability up to 2.5″ (63.5 mm) |

| Spindle Speed (Milling) | Up to 24,000 RPM, high-speed machining for improved surface finish |

| Surface Finish (Typical) | 32–64 µin Ra; post-process options for <16 µin Ra |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6/66) |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, custom packaging |

| Quality Control | CMM, optical comparators, micrometers, calipers; full FAI and PPAP reporting available |

| Lead Times | As fast as 3–5 days for machined prototypes; production runs scalable based on volume |

Our Los Angeles CNC machining center is equipped with Haas, DMG MORI, and Makino platforms, enabling complex geometries and high-precision components for aerospace, medical, robotics, and industrial applications. All tight-tolerance parts are inspected in-house to ensure compliance with ISO 2768 and customer-specific GD&T requirements.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process: Los Angeles Facility Execution

Honyo Prototype executes CNC machining projects from Los Angeles through a rigorously defined technical workflow designed for precision, speed, and manufacturability validation. All processes leverage our Southern California-based infrastructure, ensuring regional logistics advantages and direct oversight.

CAD File Upload and Initial Validation

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs automated geometry validation, checking for unit consistency, surface integrity, and file corruption. Los Angeles-specific routing ensures files are prioritized to our Torrance-based engineering team, minimizing latency. Non-conforming files trigger immediate client notification with specific error diagnostics.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes geometric complexity, feature density, and tolerance stacks against real-time machine availability at our LA facility. The algorithm cross-references material costs from local Southern California suppliers, machine hour rates for HAAS and DMG MORI equipment, and labor benchmarks. Clients receive a granular quote within 2 hours, itemizing: base machining time, secondary operation costs (deburring, anodizing), and material surcharges. The system flags ambiguous GD&T callouts or non-standard materials for manual review.

Engineering-Led DFM Analysis

Quotes trigger formal engagement with our Los Angeles-based manufacturing engineering team. Every design undergoes manual DFM scrutiny focusing on:

Tool accessibility for 3+2 axis milling within HAAS VF-2SS and DMU 50 constraints

Wall thickness validation against material-specific deflection limits (e.g., aluminum 6061-T6 minimum 0.030″)

Tolerance stack-up analysis for critical interfaces using Monte Carlo simulation

Material waste reduction via nested stock optimization

Engineers collaborate directly with client design teams via secure video conference to resolve conflicts, proposing alternatives such as chamfer substitutions for sharp internal radii or strategic feature relocation. Revised CAD models are re-validated before approval.

Precision Production Execution

Approved designs move to our Torrance production floor. Key protocols include:

Material certification: All stock (e.g., 7075-T651, 303 stainless) is sourced from ISO 9001-certified Southern California vendors with full mill test reports

First-article inspection: CMM validation of critical features against CAD nominal values using Zeiss CONTURA systems

In-process gauging: Statistical process control (SPC) with real-time tool wear compensation on all CNC cells

Environmental controls: Temperature-stabilized machining cells (±1°F) for micron-level accuracy on tight-tolerance components

Batch runs implement poka-yoke fixtures and automated tool presetters to maintain repeatability. All operations comply with AS9100 aerospace standards where applicable.

Regional Logistics and Delivery

Finished components undergo final QA per client-specified inspection criteria (CMM reports, visual standards). Los Angeles projects benefit from:

Dedicated regional shipping via bonded carriers (FedEx Priority, UPS Next Day Air)

Consolidated freight options for multi-part assemblies

Direct handoff to LA-area clients within 24 hours of completion

Customs documentation support for cross-border shipments to Tijuana maquiladoras

Standard lead times reflect LA-specific efficiencies:

| Complexity Tier | Typical Lead Time (Business Days) | Includes |

|---|---|---|

| Prototype (1-5 parts) | 3-5 | First-article inspection, basic packaging |

| Bridge Production (6-50 parts) | 7-10 | Full SPC documentation, kitted assembly |

| Production Run (51+ parts) | 12-15 | PPAP Level 3, serialized traceability |

All deliveries include digital dossiers containing inspection reports, material certs, and process validation data. Honyo’s Los Angeles facility maintains 98.7% on-time delivery performance for CNC machining projects within Southern California.

Start Your Project

Looking for precision CNC machining services in Los Angeles? Partner with Honyo Prototype for fast, reliable, and high-quality manufacturing solutions tailored to your prototyping and production needs.

Although our advanced manufacturing facility is based in Shenzhen, we provide seamless service to clients in Los Angeles and across the U.S. With strict quality control, cutting-edge CNC technology, and efficient logistics, we ensure on-time delivery without compromising precision.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.