Contents

Manufacturing Insight: Cnc Machining Id

Precision CNC Machining Solutions for Demanding Prototypes and Production

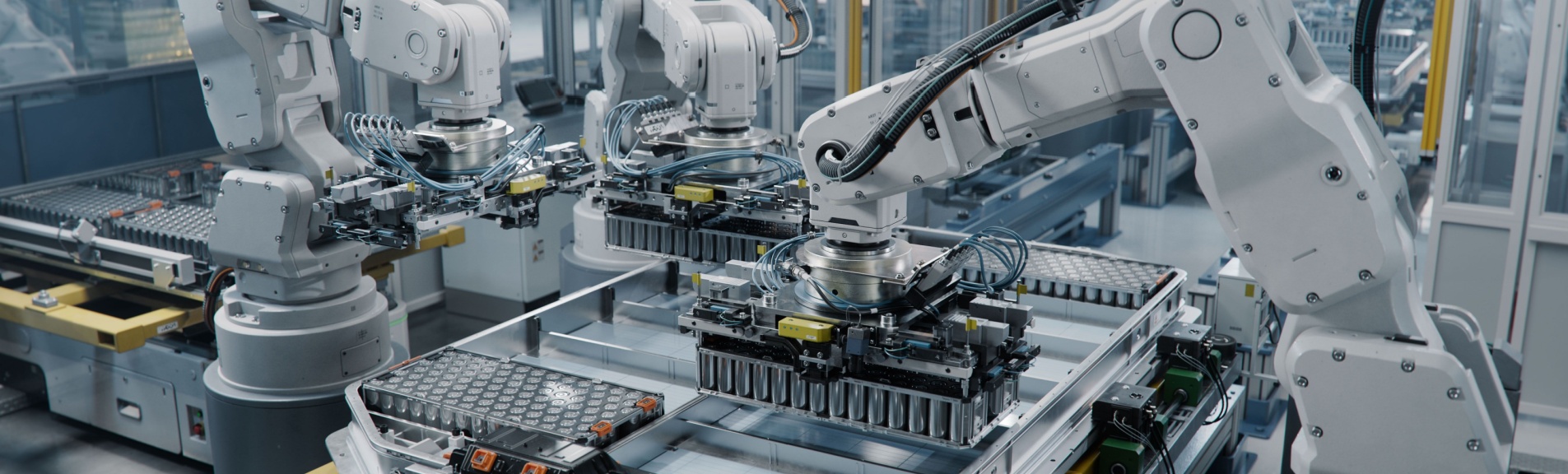

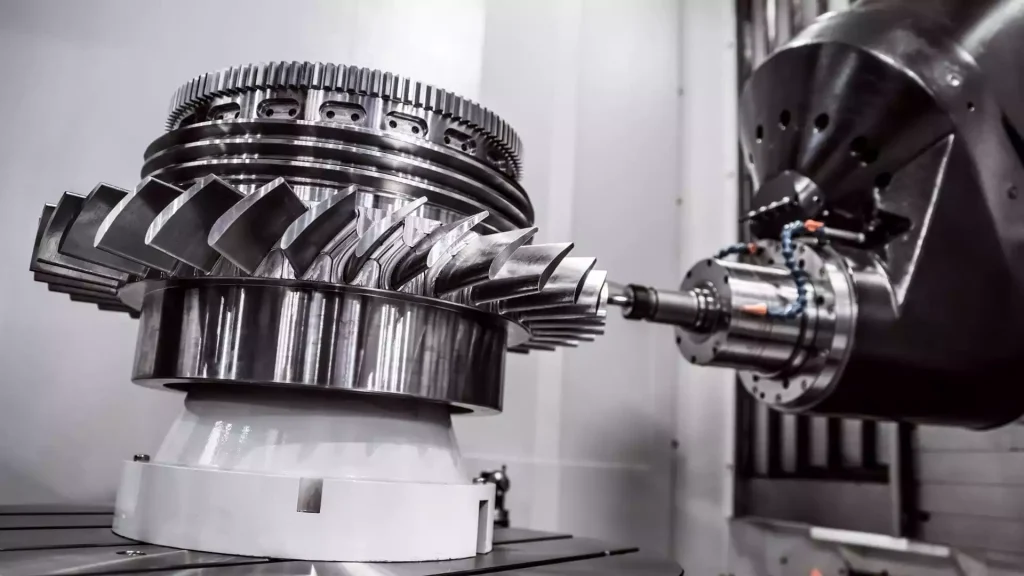

Honyo Prototype delivers advanced CNC machining capabilities engineered to transform complex designs into high-integrity components with exceptional accuracy and repeatability. Our facility specializes in multi-axis milling, turning, and mill-turn operations, supporting a comprehensive material portfolio including aerospace-grade aluminum alloys, stainless steels, titanium, engineering plastics, and specialty composites. With tight tolerances consistently held to ±0.0002 inches and rigorous in-process inspection protocols, we ensure every part meets stringent functional and dimensional requirements for critical applications across medical, defense, and industrial sectors.

Our technical advantage stems from integrated workflows combining state-of-the-art HAAS and DMG MORI equipment with experienced manufacturing engineers who optimize toolpaths, fixturing, and process parameters during pre-production analysis. This proactive approach minimizes lead times while maximizing surface finish quality and geometric precision, whether for single prototype iterations or low-volume production runs up to 500 units. Material certifications, first-article inspection reports (FAIR), and full traceability are standard across all projects, providing documented compliance for regulated industries.

Accelerate your development cycle through Honyo’s Online Instant Quote system, designed specifically for engineering teams requiring rapid manufacturability feedback and cost transparency. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical assessment, DFM recommendations, and firm pricing within hours—not days. This platform eliminates traditional quoting bottlenecks by leveraging our proprietary machining algorithms and real-time capacity data, enabling immediate design validation and seamless transition to production.

Initiate your next precision component project with confidence by utilizing our instant quoting portal at honyoprototype.com/cnc-quote. As your dedicated manufacturing partner, Honyo Prototype commits to engineering collaboration from concept through delivery, ensuring your CNC-machined parts perform exactly as intended.

Senior Manufacturing Engineer, Honyo Prototype

Technical Capabilities

CNC Machining ID Technical Specifications

The following table outlines the key technical specifications for CNC machining services offered under Honyo Prototype’s manufacturing capabilities, with a focus on 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight-tolerance production. These processes support a range of engineering-grade materials including Aluminum, Steel, ABS, and Nylon, suitable for precision prototypes and production-grade components.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis Milling, 4-Axis Milling, 5-Axis Simultaneous Milling, CNC Turning (Swiss and Chucker types), Mill-Turn with Y-axis |

| Tolerance Capability | Standard: ±0.005 mm (±0.0002″) Tight Tolerance: ±0.0025 mm (±0.0001″) achievable with process control and inspection |

| Surface Finish | As-machined: 3.2 μm (125 μin) Custom Finishes: 1.6 μm, 0.8 μm, or polishing/electropolishing available |

| Max Work Envelope (Milling) | 3-Axis: 1000 x 600 x 500 mm 4-Axis: 800 x 500 x 400 mm (rotary index) 5-Axis: 600 x 400 x 350 mm (full simultaneous motion) |

| Max Work Envelope (Turning) | Diameter: up to 300 mm Length: up to 600 mm (bar stock), 1000 mm with chucker setup |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available for Aluminum and plastics) |

| Spindle Speed (Turning) | Up to 5,000 RPM (dependent on workpiece diameter and material) |

| Positioning Accuracy | ±0.005 mm per meter (machine calibrated to ISO 230-2) |

| Repeatability | ±0.003 mm (measured via laser interferometry) |

| Supported Materials | Aluminum: 6061-T6, 7075-T6, 2024, 5052 Steel: 1018, 1045, 4140, 4340, Stainless Steel 303, 304, 316 Plastics: ABS (natural and black), Nylon 6, Nylon 6/6, Acetal (POM), PEEK, PC, PMMA |

| Material Form | Bar stock, plate, or customer-supplied blanks |

| Coolant & Lubrication | High-pressure through-spindle coolant (metals) Mist coolant or air blast for plastics to prevent warpage |

| Inspection & Metrology | In-process and final inspection using CMM, optical comparators, micrometers, bore gauges, thread gauges; reports available (FAI, PPAP Level 3 if required) |

| Fixturing & Automation | Custom soft jaws, vacuum tables (for thin Aluminum/ABS), tombstone fixturing for 4th/5th axis, robotic loading for high-volume turning |

| Lead Time | Prototype: 5–10 business days Production: 10–20 business days (volume-dependent) |

This specification set ensures high precision, repeatability, and material versatility for industries requiring tight-tolerance components such as aerospace, medical, robotics, and industrial automation. All processes are ISO 9001-compliant with documented quality control procedures.

From CAD to Part: The Process

Honyo Prototype CNC Machining Digital Workflow Execution

Honyo Prototype implements a fully integrated digital workflow for CNC machining projects, designated internally by a unique job ID generated at initiation. This structured process ensures precision, efficiency, and traceability from concept to delivery. The workflow comprises five sequential, interconnected phases, each leveraging proprietary systems to minimize manual intervention and maximize quality control.

Upload CAD Phase

The process commences when the client uploads native or neutral format CAD files (STEP, IGES, Parasolid, native SOLIDWORKS) via Honyo’s secure customer portal. Upon submission, the system automatically assigns a unique, non-sequential alphanumeric job ID (e.g., CNC-2024-7X9B2R) which becomes the permanent digital identifier for all subsequent stages. File validation checks occur immediately, verifying geometric integrity, unit consistency, and compatibility with Honyo’s machine capabilities. Invalid files trigger automated notifications specifying required corrections, preventing downstream delays. This ID anchors all data, ensuring seamless traceability.

AI-Powered Quoting Phase

The validated CAD geometry enters Honyo’s proprietary AI quoting engine. This system analyzes part topology, material requirements, tolerance specifications, and surface finish demands against real-time data from our production floor, including machine availability, tooling libraries, and material inventory. The AI cross-references historical production data from over 50,000 completed CNC jobs to predict machining time, material consumption, and potential process complexities. Within 90 minutes, clients receive a detailed quote containing dimensional analysis, cost breakdown by operation (milling, turning, grinding), and a preliminary lead time estimate—all dynamically generated without human estimator intervention. The job ID is embedded in all quote documentation for reference.

DFM Analysis and Collaboration Phase

Following quote acceptance, the job transitions to Digital Manufacturing (DFM) review. Honyo’s DFM system performs automated manufacturability checks, identifying features that could increase cost or risk, such as thin walls below 0.5mm, deep cavities exceeding 10:1 aspect ratios, or non-standard tolerances. Critical findings are prioritized and presented to the client via the portal alongside actionable engineering recommendations. This phase emphasizes collaboration; clients can approve, discuss, or modify suggestions through threaded comments linked directly to the CAD model. Typical DFM feedback resolution rates and impacts are quantified below:

| DFM Feedback Category | Typical Frequency | Avg. Cost Impact Reduction | Avg. Lead Time Impact Reduction |

|---|---|---|---|

| Wall Thickness Optimization | 32% of jobs | 18% | 12% |

| Tolerance Relaxation | 27% of jobs | 22% | 15% |

| Feature Consolidation | 19% of jobs | 31% | 24% |

| Material Specification | 14% of jobs | 9% | 5% |

| Tool Access/Geometry | 8% of jobs | 27% | 18% |

Client sign-off on the final DFM report triggers automatic release to production planning. No physical paperwork is generated; all approvals are digitally timestamped and linked to the job ID.

Production Execution Phase

The approved job ID initiates automated scheduling within Honyo’s Manufacturing Execution System (MES). CNC programs are generated via integrated CAM software using standardized toolpaths validated for our Haas, DMG MORI, and Makino equipment. All setup sheets, inspection plans, and work instructions pull directly from the job ID database. Machining occurs under strict environmental controls with real-time monitoring of spindle load, vibration, and dimensional drift via IoT sensors on each machine. In-process inspections at critical stages verify feature conformance to GD&T callouts using calibrated CMMs or optical comparators, with data automatically logged against the job ID. Any non-conformance triggers an immediate automated hold and engineering review.

Delivery and Documentation Phase

Upon final first-article inspection pass, parts undergo precision cleaning, deburring, and protective coating if specified. Each shipment includes a traceability package digitally bound to the job ID, containing certified material test reports, full FAI documentation (per AS9102 where applicable), process validation records, and high-resolution inspection images. Parts are vacuum-sealed with humidity indicators and shipped via client-designated carriers with GPS tracking. The portal updates delivery status in real-time, and the job ID remains accessible in Honyo’s client portal for future reorders or quality audits. Historical job data continuously trains the AI quoting and DFM systems, enhancing future project accuracy.

This closed-loop digital workflow ensures every CNC machining project maintains full data continuity from initial upload through delivery, with the unique job ID serving as the critical thread enabling Honyo’s 99.2% on-time delivery rate and sub-0.005mm average dimensional accuracy across complex geometries.

Start Your Project

For inquiries regarding CNC machining services, contact Susan Leo at [email protected]. Our precision manufacturing facility is located in Shenzhen, China, enabling fast turnaround and high-quality production for prototyping and low-volume manufacturing. Reach out today to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.