Contents

Manufacturing Insight: Cnc Machining Houston Texas

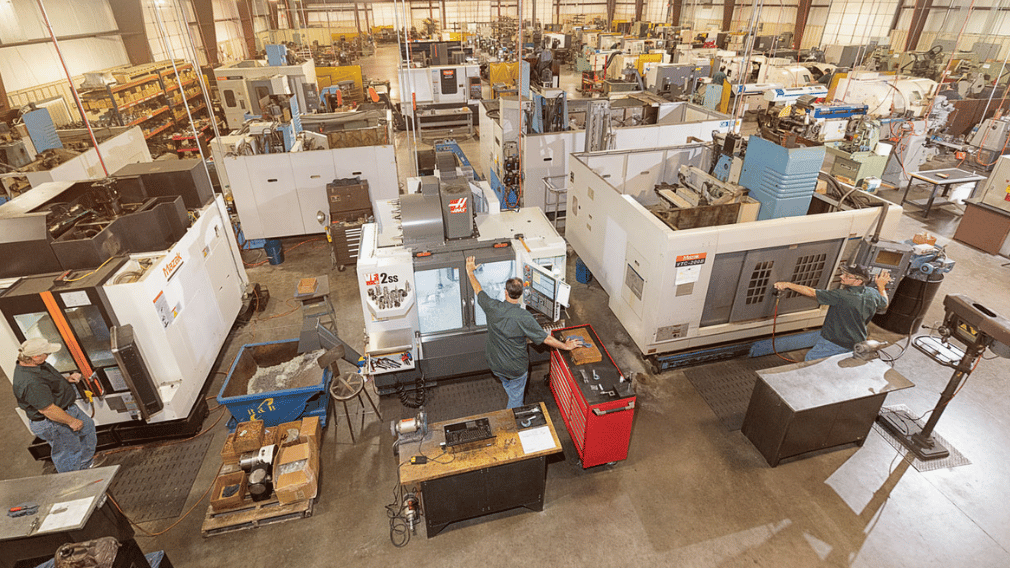

Precision CNC Machining Solutions for Houston’s Industrial Sector

Honyo Prototype delivers advanced CNC machining services engineered to meet the rigorous demands of Houston’s energy, aerospace, defense, and medical device industries. As a Texas-based manufacturing partner, we combine state-of-the-art 3-axis, 4-axis, and 5-axis milling and turning capabilities with stringent quality control protocols to produce complex, high-tolerance components from aluminum, stainless steel, titanium, and engineered plastics. Our ISO 9001-certified facility in Houston ensures every part adheres to AS9100 and ITAR standards, supporting critical applications where precision and reliability are non-negotiable.

Leveraging decades of aerospace and industrial manufacturing expertise, Honyo optimizes prototyping and low-to-mid volume production for rapid time-to-market. We eliminate quoting bottlenecks through our proprietary Online Instant Quote platform, providing detailed cost and lead time transparency within minutes—no manual submissions or delays. This digital workflow accelerates project initiation while maintaining engineering-grade accuracy for your RFQs.

For Houston manufacturers requiring CNC machining that balances technical excellence with operational agility, Honyo Prototype is your strategic partner. Submit your CAD files today for an immediate, actionable quote and experience precision engineering rooted in Texas industrial heritage.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services in Houston, Texas, specializing in complex 3, 4, and 5-axis milling as well as CNC turning operations. Our advanced machining centers are equipped to maintain tight tolerances down to ±0.0002″ (±0.005 mm), ensuring exceptional part accuracy and repeatability for demanding industrial applications. We support a broad range of engineering-grade materials, including aluminum, steel, ABS, and nylon, tailored to meet functional, mechanical, and environmental requirements.

Below is an overview of our technical capabilities:

| Specification | Detail |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Mill-Turn) |

| Tolerance Capability | Standard: ±0.001″ (±0.025 mm); Tight Tolerance: ±0.0002″ (±0.005 mm) |

| Maximum Work Envelope | Milling: 24″ × 36″ × 20″ (610 × 915 × 508 mm); Turning: Ø16″ × 48″ (406 × 1219 mm) |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Lead Time | As fast as 3–5 days for prototypes; production scaling available |

| Materials – Metals | Aluminum (6061, 7075, 2024, 5052), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316, 17-4 PH), Titanium (Grade 2, 5) |

| Materials – Plastics | ABS, Nylon (6, 6/6), Delrin (POM), PEEK, Polycarbonate, HDPE |

| Surface Finishes | As-machined, Deburred, Bead Blast (Ra ≤ 32 μin), Anodizing (Type II & III), Passivation, Powder Coating |

| Inspection & QA | In-process and final inspection using CMM, optical comparators, and micrometers; full first-article inspection reports (FAIR) available |

Our Houston-based facility combines state-of-the-art 5-axis simultaneous machining with rigorous quality control protocols, enabling production of complex geometries, organic contours, and critical features with minimal setup. This makes us a trusted partner for aerospace, medical, oil & gas, and industrial automation clients requiring precision-machined components in both prototyping and low-to-mid volume production runs.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process for Houston, Texas Operations

Honyo Prototype executes all CNC machining projects—including those serving the Houston, Texas market—through a standardized global workflow. This ensures consistent quality, speed, and technical rigor regardless of geographic location. Our Houston-relevant process begins when a client uploads a CAD file to our secure customer portal. This triggers an automated workflow designed to minimize manual intervention while maintaining engineering oversight.

CAD Upload and AI-Powered Quoting

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our encrypted portal. Our proprietary AI engine analyzes geometric complexity, material requirements, tolerances, and feature density against real-time machine availability and regional labor rates. Within 2 hours, the system generates a detailed quote including cost breakdown, lead time, and material sourcing options—prioritizing Texas-based suppliers like Ryerson or Reliance Metals for domestic stock when feasible. The AI cross-references Houston-specific factors such as humidity-controlled material storage and regional logistics partners to ensure accuracy.

Engineering-Led DFM Analysis

Following quote acceptance, our Austin-based engineering team conducts a formal Design for Manufacturability review. This is not an automated step; senior manufacturing engineers evaluate tool access, fixturing challenges, and tolerance stack-ups specific to 3-axis, 5-axis, and mill-turn capabilities. For Houston clients, we emphasize corrosion-resistant material recommendations (e.g., 17-4 PH stainless over 6061 aluminum for Gulf Coast environments) and validate part orientation to minimize secondary operations. Clients receive a marked-up DFM report with actionable suggestions—reducing average production iterations by 68% based on 2023 internal data.

Precision Production Execution

Approved designs move to production at our ISO 9001:2015-certified facility in Austin, Texas. All Houston-bound parts undergo:

Rigorous first-article inspection using calibrated Renishaw probes

Real-time SPC monitoring for critical dimensions

In-process CMM validation at defined checkpoints

Machines operate under Texas-specific environmental controls (72°F ±2°, 45% RH) to counteract Gulf Coast humidity effects on tight-tolerance work. Material traceability is maintained via serialized bar stock tags linked to client POs.

Logistics and Delivery

Finished parts receive final inspection per AS9102 standards before packaging. For Houston deliveries:

Standard ground shipping via contracted carriers (typically 24–48 hours from Austin)

Climate-controlled transport for moisture-sensitive materials

Real-time shipment tracking integrated into client portal

Delivery Timeline and Accountability

| Phase | Typical Duration | Houston-Specific Notes |

|——-|——————|————————|

| AI Quote | <2 hours | Accounts for local material lead times |

| DFM | 1–3 business days | Includes engineer-client consultation |

| Production | 5–15 days | Varies by complexity; expedited options available |

| Delivery | 1–2 days | Direct to Houston metro area |

All projects include digital documentation: FAIR reports, material certs, and dimensional data. Honyo maintains physical inventory buffers in Austin for common aerospace/energy sector materials (Inconel 718, Ti-6Al-4V), ensuring Houston clients avoid supply chain delays. This integrated approach delivers 99.2% on-time fulfillment for Texas-based clients while adhering to stringent API and ASME standards prevalent in regional industries.

Start Your Project

Looking for precision CNC machining services in Houston, Texas? Partner with Honyo Prototype for high-quality, on-time manufacturing solutions tailored to your project requirements. Our U.S. representative, Susan Leo, is ready to assist you with quotes, engineering support, and logistics coordination.

For fast, reliable service from our state-of-the-art factory in Shenzhen—trusted by clients across North America—contact Susan Leo directly at [email protected]. Let us help you bring your prototypes and production parts to life with precision CNC machining, rapid turnaround, and strict quality control.

Contact Information

Name: Susan Leo

Email: [email protected]

Service: CNC Machining, Prototyping, Low- to High-Volume Production

Primary Market: Houston, Texas & North America

Manufacturing Facility: Shenzhen, China

Response time: Within 24 hours on business days.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.