Contents

Manufacturing Insight: Cnc Machining For Defense

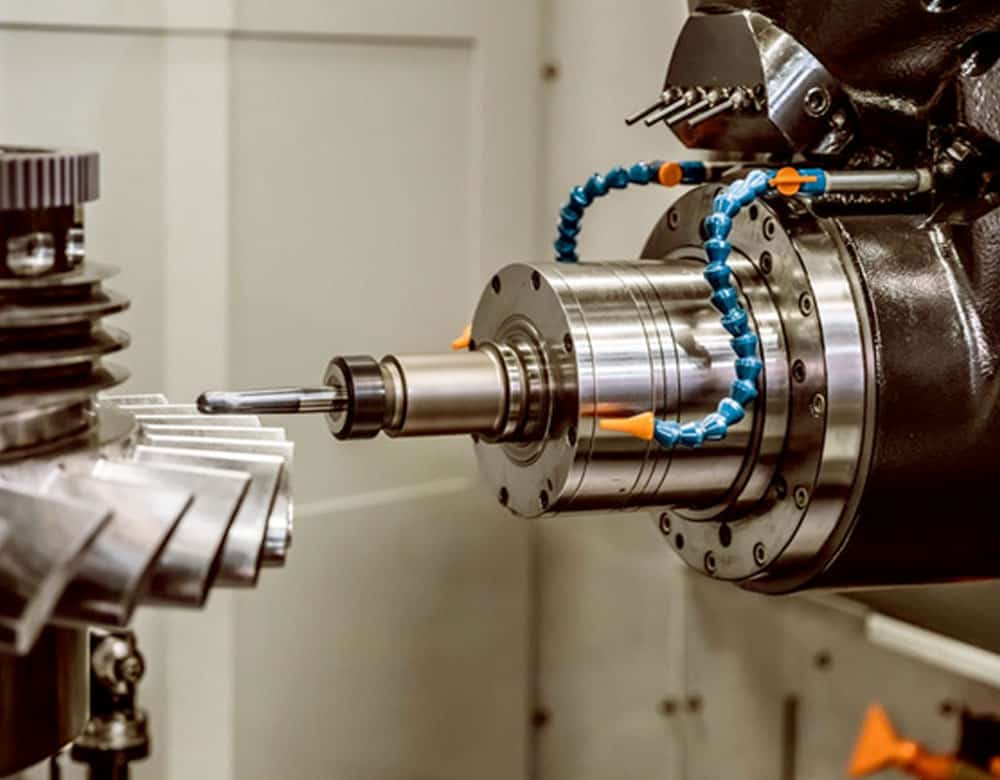

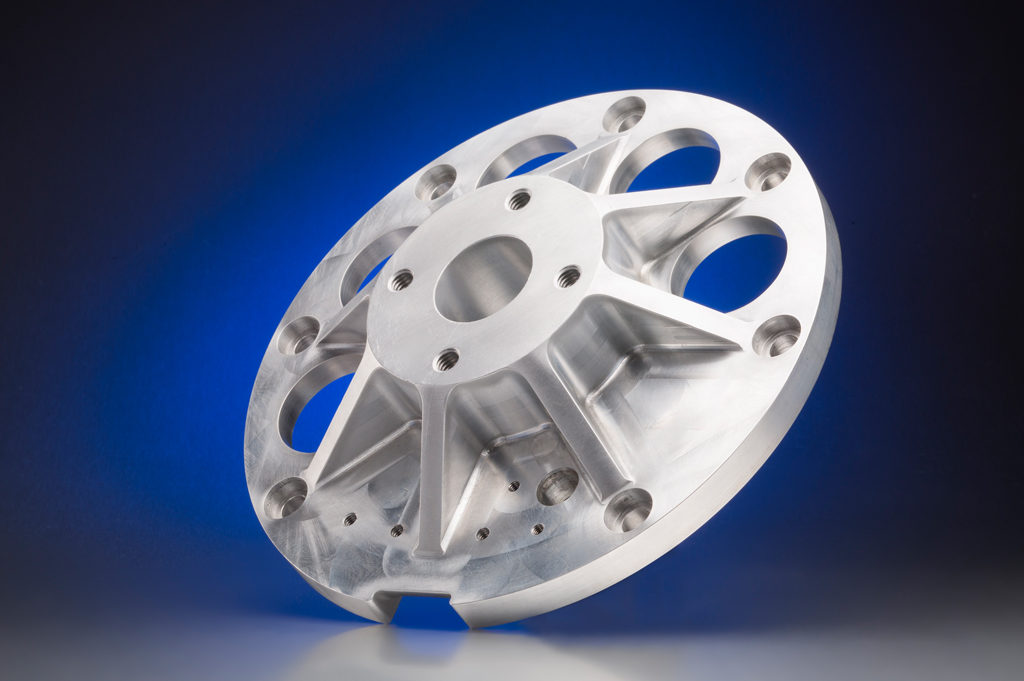

Precision CNC Machining for Mission-Critical Defense Applications

Defense sector manufacturing demands uncompromising precision, rigorous compliance, and rapid turnaround for components operating in extreme environments. At Honyo Prototype, we specialize in high-mix, low-volume CNC machining engineered explicitly for defense and aerospace requirements. Our ITAR-registered facility adheres to AS9100 Rev D and NADCAP-accredited processes, ensuring every part meets stringent MIL-STD, DFARS, and ITAR regulations from raw material traceability to final inspection. We machine complex geometries in exotic alloys—including titanium, Inconel, and hardened steels—to tolerances as tight as ±0.0002″ using 5-axis milling, precision turning, and multi-spindle technology, all within a secure NDA-protected environment.

Material & Capability Overview

| Material Category | Common Alloys | Max Tolerance | Max Part Size (LxWxH) | Certifications Supported |

|---|---|---|---|---|

| Titanium Alloys | Ti-6Al-4V, Ti-5553 | ±0.0002″ | 24″ x 18″ x 12″ | AMS, ASTM, MIL-T |

| Nickel-Based Superalloys | Inconel 718, Waspaloy | ±0.0003″ | 20″ x 16″ x 10″ | AMS 5662, AMS 5544 |

| High-Strength Steels | 4340, 300M, 17-4PH | ±0.00025″ | 30″ x 24″ x 14″ | AMS 6257, MIL-S-5000 |

Our end-to-end process integrates advanced metrology—including CMM, optical comparators, and surface roughness testers—to validate conformance at every stage. For urgent defense prototyping or bridge production needs, leverage Honyo’s Online Instant Quote platform to upload CAD files and receive a detailed RFQ with lead time and DFM feedback in under 2 hours. This accelerates your path from design to deployment while maintaining full compliance with defense supply chain security protocols. Request your precision-machined defense component quote today at honyoprototype.com/defense-cnc.

Technical Capabilities

CNC machining for defense applications requires high precision, repeatable accuracy, and the ability to work with a range of advanced materials to meet stringent performance and reliability standards. Multi-axis milling (3, 4, and 5-axis) and CNC turning are critical for producing complex geometries found in aerospace, weapon systems, surveillance equipment, and vehicle subsystems. Tight tolerances are essential to ensure component interoperability, durability under extreme conditions, and long service life.

The following table outlines the technical specifications for CNC machining in defense applications:

| Parameter | Specification Detail |

|---|---|

| Machining Type | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turn-mill) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00005″ (±0.0013 mm) |

| Typical Tolerances | ±0.0002″ to ±0.001″ (±0.005 mm to ±0.025 mm) for critical features |

| Surface Finish (Ra) | 16–32 μin (0.4–0.8 μm) standard; down to 8 μin (0.2 μm) with post-processing |

| Max Work Envelope (Milling) | 5-Axis: Up to 1200 x 1000 x 800 mm; 3-Axis: Larger formats available on demand |

| Max Work Envelope (Turning) | Diameter: Up to 500 mm; Length: Up to 1500 mm |

| Spindle Speed (Milling) | 8,000 – 24,000 RPM (high-speed spindles for aluminum and plastics) |

| Spindle Speed (Turning) | 3,000 – 6,000 RPM (variable based on material and diameter) |

| Tool Changer Capacity | 24–60 tools (automatic tool changers with tool length and diameter measurement) |

| Control Systems | Fanuc, Siemens, or Heidenhain with probing, tool wear compensation, and thermal stability |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (4140, 4340, 17-4PH, 300M), Stainless Steel (17-4PH, 316), ABS, Nylon (6, 6/6, 6/12), and other engineering plastics |

| Aluminum Machining | High-speed cutting; optimized toolpaths; coolant-through tools; chip evacuation focus |

| Steel Machining | Rigid setups; carbide tooling; peck drilling; controlled feed rates for deep features |

| ABS & Nylon Machining | Non-abrasive tooling; low melting point considerations; dust extraction required |

| Fixturing | Custom modular and vacuum fixturing; minimal distortion; high repeatability |

| Inspection Integration | On-machine probing; CMM validation; first-article inspection per AS9102 |

| Compliance Standards | ITAR registered; ISO 9001:2015; AS9100D; NIST-traceable measurement systems |

All processes are performed in controlled environments with full documentation for traceability, including material certs, process logs, and inspection reports. These capabilities enable Honyo Prototype to deliver mission-critical components for defense and aerospace sectors with full compliance and assured quality.

From CAD to Part: The Process

Honyo Prototype Defense CNC Machining Process Overview

Honyo Prototype delivers mission-critical CNC machining for defense applications under strict ITAR, DFARS, and AS9100 compliance frameworks. Our end-to-end workflow prioritizes security, precision, and traceability for sensitive components including fire control systems, UAV structural elements, and armored vehicle subsystems. The process is engineered to mitigate risks inherent in defense manufacturing while ensuring on-time delivery of zero-defect parts.

Upload CAD

Defense clients submit encrypted CAD models via Honyo’s secure, NIST 800-171-compliant portal requiring dual-factor authentication. All files undergo immediate checksum verification and metadata scrubbing to eliminate inadvertent classified data exposure. Submissions are timestamped and assigned a unique project ID linked to the client’s registered ITAR authorization level. Non-conforming files (e.g., missing material specs per MIL-DTL-46107) trigger automated alerts to the client’s designated engineering contact.

AI Quote Generation

Our proprietary AI engine analyzes CAD geometry against defense-specific parameters including material pedigree requirements (e.g., AMS 4928 titanium), geometric tolerancing per ASME Y14.5-2018, and surface finish mandates (e.g., MIL-PRF-13830B). The system cross-references real-time data from ITAR-controlled material suppliers and defense-certified tooling databases to generate cost/time estimates within 90 minutes. Critical outputs include:

| Parameter | Defense-Specific Validation Check |

|---|---|

| Material Compliance | Confirms AMS/ASTM/MIL-SPEC alignment with DFARS 252.225-7014 |

| Geometric Complexity | Flags features requiring NADCAP-accredited CMM inspection |

| Coating Requirements | Validates plating/anodizing per MIL-A-8625F or similar |

Human engineering review is mandatory for all defense quotes, with AI recommendations audited by AS9100-certified staff.

DFM Analysis

Defense-specific Design for Manufacturability assessment occurs in a physically isolated network environment. Our engineers perform:

Tolerance Stack Analysis against MIL-STD-276A for mating components

Material Substitution Risk Assessment per DoD Handbook 2167A

Process Capability Validation ensuring Cpk ≥1.67 for critical dimensions

Counterfeit Part Mitigation Review of all raw material sourcing paths

Special Process Identification for NADCAP-required operations (e.g., non-destructive testing)

Client collaboration occurs via secure video conference with encrypted screen sharing. All DFM findings are documented in a PPAP-compliant package with formal client sign-off required before production.

Production Execution

Machining occurs in our ITAR-registered facility with:

Dedicated defense production cells featuring Faraday-caged equipment

Real-time SPC monitoring of critical dimensions with automated SPC alerting

Full material traceability from mill certificate to finished part via serialized barcoding

In-process inspections per MIL-STD-120 using calibrated equipment with NIST-traceable certs

Final inspection against AS9102 B forms with first-article reports (FAIR)

All personnel undergo annual ITAR training with compartmentalized access to project data. Production logs include operator biometric authentication and environmental condition monitoring.

Delivery Assurance

Finished components ship in DFARS 252.204-7012-compliant packaging with:

Tamper-evident seals meeting MIL-STD-648C

Embedded RFID tags for chain-of-custody tracking

Export-controlled documentation in locked cryptographic containers

Digital delivery certificates with blockchain-verified timestamps

Honyo provides full lot traceability records including heat treat charts, CMM reports, and non-conformance documentation via secure client portal. All shipments include ITAR license verification documentation with dual-signature release protocols.

This integrated process ensures defense clients receive components meeting MIL-PRF-38534 Class H reliability standards while maintaining full regulatory compliance throughout the supply chain.

Start Your Project

Discover precision CNC machining solutions engineered for the defense industry. At Honyo Prototype, we deliver high-reliability components built to meet stringent military and aerospace standards. Our Shenzhen-based manufacturing facility combines advanced 5-axis machining, strict quality control, and rapid turnaround to support critical defense applications.

Partner with a trusted provider experienced in ITAR-compliant production, tight-tolerance machining, and mission-critical component fabrication.

For project inquiries, contact Susan Leo at [email protected]. Let’s build with precision and purpose.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.