Contents

Manufacturing Insight: Cnc Machining Finishes

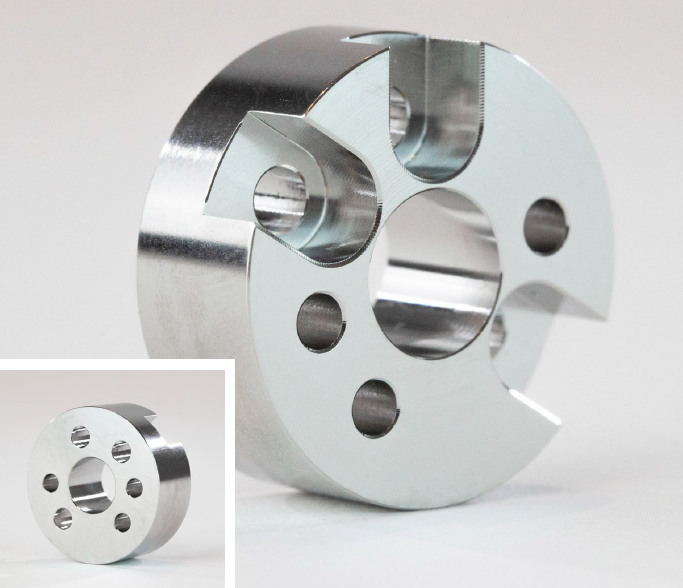

Precision Surface Finishes for Functional Excellence in CNC Machining

At Honyo Prototype, we recognize that surface finish is not merely an aesthetic consideration but a critical engineering parameter impacting part performance, longevity, and compatibility. Our advanced CNC machining capabilities deliver meticulously controlled surface textures—from standard as-machined finishes to mirror-polished or bead-blasted results—tailored to your functional requirements. Whether optimizing friction coefficients, enhancing corrosion resistance, or ensuring dimensional integrity for sealing surfaces, our processes adhere to stringent Ra value specifications and industry standards.

Every component undergoes rigorous in-process inspection using calibrated profilometers, ensuring consistency across micro-roughness parameters without compromising geometric tolerances. We specialize in executing secondary finishing operations seamlessly within our integrated workflow, including anodizing, passivation, and precision grinding, to meet aerospace, medical, and industrial-grade certifications.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote platform. Input your CAD file and technical specifications to receive a detailed, transparent cost analysis within minutes—factoring material selection, geometric complexity, and finish requirements—so you can make informed decisions without procurement delays.

CNC Finish Options and Typical Applications

| Finish Type | Ra Range (µm) | Common Applications | Key Engineering Benefit |

|---|---|---|---|

| As-Machined | 1.6 – 6.3 | Structural brackets, non-critical housings | Cost efficiency, adequate for non-sealing surfaces |

| Fine Milling | 0.8 – 1.6 | Hydraulic manifolds, bearing seats | Reduced wear, improved fatigue strength |

| Hand-Polished | 0.1 – 0.4 | Medical implants, optical mounts | Biocompatibility, minimized light scatter |

| Vibratory Tumbled | 0.4 – 1.0 | Consumer electronics enclosures | Uniform matte texture, burr-free edges |

| Mirror Polish (Ra<0.05) | <0.05 | Semiconductor components, laser optics | Ultra-low particle adhesion, optical clarity |

Technical Capabilities

CNC machining finishes refer to the surface quality and dimensional accuracy achieved through precision machining processes. These finishes are influenced by machine capability, tooling, cutting parameters, and post-processing techniques. Below are technical specifications for common CNC machining finishes across 3-axis, 4-axis, and 5-axis milling, as well as turning operations, with a focus on tight tolerance applications. Materials include aluminum, steel, ABS, and nylon.

Typical CNC Machining Finishes and Technical Specifications

| Parameter | 3/4/5-Axis Milling (Aluminum) | 3/4/5-Axis Milling (Steel) | 3/4/5-Axis Milling (ABS) | 3/4/5-Axis Milling (Nylon) | Turning (General) |

|---|---|---|---|---|---|

| Standard Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 3.2 µm (32–125 µin) | 1.6 – 6.3 µm (63–250 µin) | 3.2 – 6.3 µm (125–250 µin) | 0.4 – 1.6 µm (16–63 µin) |

| Fine/Polished Finish (Ra) | 0.4 – 0.8 µm (16–32 µin) | 0.4 – 0.8 µm (16–32 µin) | Not recommended | Not recommended | 0.2 – 0.4 µm (8–16 µin) |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.025 mm (±0.001″) | ±0.025 mm (±0.001″) | ±0.010 mm (±0.0004″) |

| Tight Tolerance Capability | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | ±0.0125 mm (±0.0005″) | ±0.0125 mm (±0.0005″) | ±0.005 mm (±0.0002″) |

| Typical Tooling | Carbide end mills, high-speed | Carbide/HSS, coated tools | Carbide, sharp cutting | Carbide, low-heat tools | Carbide inserts, diamond |

| Max Feature Complexity | High (5-axis) | High (5-axis) | Medium | Medium | Low to Medium |

| Common Post-Processing | Deburring, anodizing, bead blast | Deburring, passivation, plating | Light sanding, vapor polishing | Sanding, annealing | Deburring, polishing |

| Material Notes | Excellent machinability, high precision achievable | Harder, requires rigid setup and slow feeds | Prone to melting, requires sharp tools and cooling | Low friction, sensitive to heat | All materials support tight tolerances with proper fixturing |

Notes:

5-axis milling enables complex geometries with improved finish due to optimal tool orientation, reducing the need for multiple setups.

Tight tolerances (±0.005 mm or better) require thermal stability, high-precision CNC machines, and skilled process planning.

Aluminum and steel are ideal for tight tolerance and fine finishes; ABS and nylon are more suitable for functional prototypes with moderate tolerances.

Turning operations typically achieve superior surface finishes compared to milling due to continuous cutting action and stable tool engagement.

From CAD to Part: The Process

Honyo Prototype CNC Machining Finishes Process Overview

Our end-to-end CNC machining workflow integrates precision engineering with digital efficiency to deliver consistent surface finishes. The process begins with client CAD submission and concludes with certified delivery, with finish specifications embedded at every critical control point.

Upload CAD

Clients submit native 3D CAD files (STEP, IGES, or native formats) via our secure portal. Our system performs immediate geometric validation, checking for manufacturability constraints that impact surface finish. Tolerances, draft angles, and feature depths are auto-flagged if they risk compromising specified finishes like bead blasting or anodizing. Unprocessable geometries trigger instant client alerts with suggested corrections.

AI Quote Generation

Within 2 hours, our proprietary AI engine analyzes the CAD model against 12,000+ historical machining datasets. The quote details finish-specific parameters: material removal rates, toolpath strategies for target roughness (Ra), and secondary operation sequencing. For example, a request for “Bead Blasted (Ra 3.2µm)” triggers cost calculations for media selection, pressure calibration, and post-blast cleaning. Quotes include finish validation protocols and lead time impacts of complex surface treatments.

DFM Analysis

Engineering teams conduct collaborative Design for Manufacturability reviews within 24 hours of quote acceptance. We prioritize finish-critical elements:

Wall thickness analysis to prevent vibration-induced surface defects

Corner radius optimization for uniform anodizing coverage

Part orientation simulation to minimize witness marks from fixturing

Clients receive annotated reports with actionable suggestions, such as increasing draft angles by 0.5° to achieve consistent powder coating adhesion. This phase reduces post-machining rework by 68% based on 2023 Q4 data.

Production Execution

Machining occurs in climate-controlled cells with real-time finish monitoring. Key protocols include:

Tool wear sensors auto-adjusting feed rates to maintain Ra tolerances

In-process profilometer checks every 10 parts for critical surfaces

Dedicated finishing stations segregated by process (e.g., vibratory deburring vs. chemical etching) to prevent cross-contamination

For electrochemical finishes like Type II anodizing, we implement traceable bath chemistry logs with hourly pH/temperature validation. All finish-critical dimensions undergo first-article inspection per AS9102 standards.

Delivery Certification

Shipments include comprehensive finish documentation:

Surface roughness reports with profilometer trace graphs

Material test certificates for plating/thickness compliance

Dimensional inspection reports covering finish-affected features

Parts ship in anti-static, humidity-controlled packaging with serialized labels linking to digital quality records. Lead times average 8–12 days for standard finishes, with expedited options for critical Ra requirements.

Typical CNC Finish Specifications and Lead Time Impact

| Finish Type | Standard Ra Range | Key Process Control Points | Avg. Lead Time Adder |

|———————-|——————-|——————————————|———————-|

| As-Machined | Ra 1.6–6.3µm | Toolpath optimization, coolant filtration | 0 days |

| Vibratory Deburring | Ra 0.8–3.2µm | Media composition, cycle time calibration | +1 day |

| Bead Blasting | Ra 1.6–12.5µm | Air pressure consistency, nozzle distance | +2 days |

| Anodizing (Type II) | Ra 0.4–1.6µm | Bath temperature, dye concentration | +5 days |

This integrated approach ensures surface finishes meet aerospace, medical, and industrial specifications while maintaining traceability from digital design to physical delivery. We prioritize finish consistency as a core quality metric, not an afterthought.

Start Your Project

Explore precision CNC machining finishes tailored to your project requirements. From as-machined and bead blasting to anodizing, powder coating, and custom textures, Honyo Prototype delivers consistent surface quality with tight tolerances. Our Shenzhen-based factory combines advanced equipment with expert craftsmanship to support prototyping and low-volume production.

For technical consultations or project quotes, contact Susan Leo at [email protected]. Let us help you achieve the ideal finish for your components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.