Guide Contents

Project Insight: Cnc Machining Companies In China

The Critical Role of Speed and Precision in Modern Product Development

Why Speed Matters for Hardware Innovation

Accelerate time-to-market with rapid iteration cycles—reduce development cycles by up to 50% compared to traditional workflows

Validate designs faster to mitigate risks before mass production, avoiding costly late-stage revisions

Stay ahead of competitors through agile prototyping that keeps pace with evolving market demands

Precision as the Foundation of Functional Prototypes

Achieve ±0.01mm tolerances for critical functional components—ensuring parts perform as intended in real-world conditions

Eliminate costly rework with consistent, repeatable quality across 3/4/5-axis machining processes

Deliver end-use parts that meet aerospace, medical, and automotive-grade engineering standards—no compromises

How Honyo Prototype Redefines CNC Machining in China

Online Instant Quote: Get real-time pricing and lead times within seconds via our AI-driven platform—no back-and-forth emails

AI-Powered Design Optimization: Automated DFM (Design for Manufacturability) analysis to refine geometries, reduce costs, and accelerate production

3-5 Day Prototype Delivery: Industry-leading turnaround with seamless digital workflow from upload to doorstep

Partner with Honyo Prototype to transform your vision into reality—where precision meets speed, and innovation is delivered in days, not weeks.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

At Honyo Prototype, we engineer precision components that accelerate innovation. Our Shenzhen-based facility combines cutting-edge technology with agile manufacturing processes to deliver functional prototypes and end-use parts with exceptional accuracy, reliability, and speed—empowering hardware startups and engineers to bring ideas to market faster.

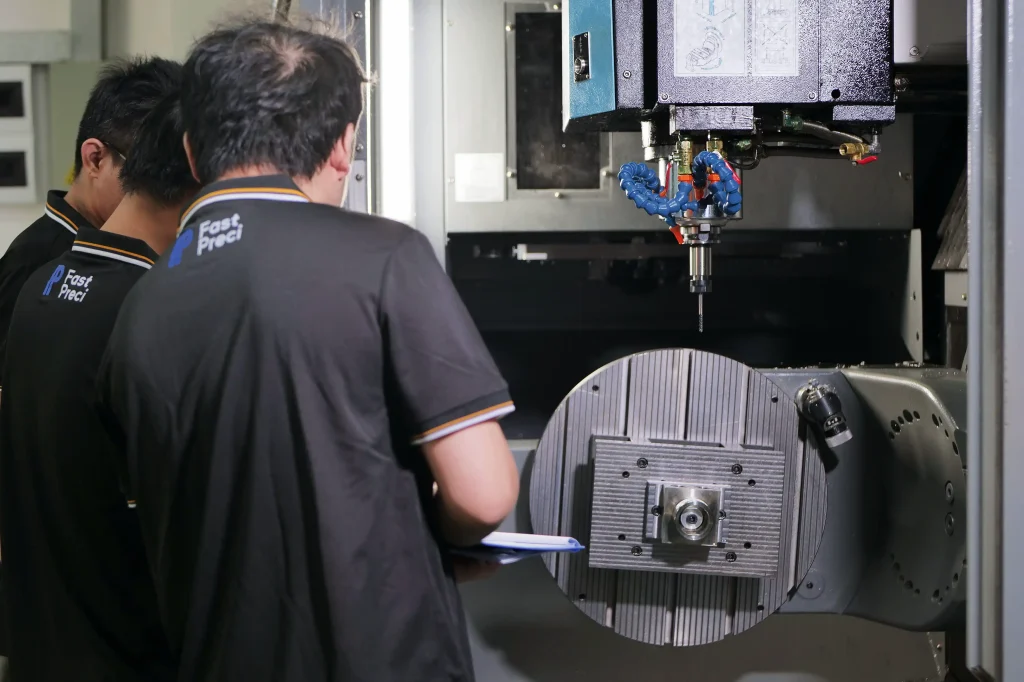

Advanced Multi-Axis Machining Technology

3/4/5-axis CNC machining for complex geometries, intricate details, and multi-faceted designs in a single setup

Tight tolerances of ±0.01mm to meet aerospace, medical, and automotive-grade specifications

Support for diverse materials including aerospace-grade aluminum alloys, stainless steel, titanium, engineering plastics (ABS, POM, PTFE), and composites

Scalable Production Capacity

Seamless transition from 1 prototype to 10,000+ units with zero minimum order quantities (MOQs)

Flexible batch processing designed for evolving project needs—from initial validation to mass production

Dedicated production lines optimized for both low-volume prototyping and high-volume runs without compromising quality

ISO-Certified Quality Assurance

Rigorous in-process inspections and final QA checks against GD&T standards for dimensional accuracy

Full traceability with detailed quality documentation for regulatory compliance (ISO 9001 certified)

Continuous process improvement via AI-driven analytics to eliminate defects before they occur

Smart Manufacturing Ecosystem

Online Instant Quote: AI-powered pricing analysis delivered in seconds with transparent cost breakdowns (materials, labor, machining, finishing)

AI-Powered DFM Optimization: Real-time design feedback to eliminate manufacturability issues and reduce costs before production begins

Rapid Turnaround: Prototypes delivered in 3–5 days; expedited 24–48 hour options available for critical projects—50% faster than Western suppliers on average

Materials & Surface Finishes

Material Options & Finishes for Precision Manufacturing

At Honyo Prototype, we combine global material expertise with China’s manufacturing efficiency to deliver precision-engineered parts that meet your exact specifications. Our AI-powered platform ensures optimal material selection, cost efficiency, and rapid delivery—so you can focus on innovation, not logistics.

Precision-Grade Material Selection Guide

Aluminum 6061: Ideal for structural components requiring a balance of strength, weight, and corrosion resistance. Widely used in aerospace, automotive, and consumer electronics with excellent machinability and cost efficiency in China’s supply chain.

Aluminum 7075: High-strength alloy for demanding applications like military, racing, and robotics. Delivers exceptional performance in high-stress environments while maintaining tight tolerances (+/- 0.01mm).

Stainless Steel 304: Versatile, non-magnetic, and corrosion-resistant. Perfect for medical devices, food processing equipment, and marine hardware where hygiene and durability are critical.

Stainless Steel 316: Enhanced corrosion resistance with molybdenum content. Ideal for chemical processing, offshore equipment, and surgical instruments in harsh environments.

Brass: Excellent electrical conductivity and machinability. Commonly used for electrical connectors, valves, and decorative elements with minimal tool wear and fast production cycles.

PEEK: High-performance thermoplastic for extreme conditions. Resists chemicals, high temperatures (>250°C), and wear—ideal for aerospace, medical implants, and semiconductor manufacturing.

Surface Finish Options to Enhance Performance

Anodizing (Aluminum-specific): Creates a durable, corrosion-resistant oxide layer with optional coloration for functional and aesthetic needs. Ideal for outdoor or high-wear applications.

Powder Coating: Electrostatically applied polymer coating for enhanced durability, color options, and environmental protection on metal parts.

Polishing: Achieves a mirror-like surface finish for optical components or high-end aesthetics, improving wear resistance and visual appeal.

Electroplating: Deposits thin metal layers (e.g., nickel, chrome) for conductivity, corrosion protection, or decorative finishes on compatible materials.

Passivation (Stainless Steel): Chemical treatment to remove contaminants and enhance corrosion resistance for medical and food-grade applications.

Smart Material Selection with AI-Powered Platform

Instant Online Quoting: Upload your CAD file for real-time pricing, lead times, and material recommendations—no manual quotes required.

AI-Powered Optimization: Our platform analyzes your design requirements to suggest the most cost-effective and high-performance material/finish combination, considering factors like mechanical properties, environmental exposure, and manufacturability.

Fast Turnaround Guarantee: Leverage Shenzhen’s strategic manufacturing ecosystem for 3–5 day prototype delivery and 1–2 week production cycles—accelerating your time-to-market.

Cost Efficiency: Achieve 30–50% savings vs. Western suppliers while maintaining ISO-certified precision, thanks to optimized material sourcing and streamlined processes.

💡 Pro Tip: Choosing the right material early reduces prototyping iterations by up to 40%—saving time, costs, and ensuring your design meets functional requirements from day one. Start with Honyo’s AI-driven platform to optimize your project in minutes, not weeks.

From Quote to Part: Our Process

Streamlined Workflow: From CAD to Part in Record Time

At Honyo Prototype, our AI-driven platform transforms your CAD files into precision-engineered parts with industry-leading speed and transparency. Here’s how it works:

1. Upload Your CAD File

Drag-and-drop support for STEP, IGES, STL, DWG, and other industry-standard formats

Instant file validation—our system checks compatibility and integrity in seconds

No technical expertise required: upload, analyze, and proceed seamlessly

2. Instant AI-Powered Quote

Real-time pricing within 60 seconds—no waiting for manual quotes

Transparent breakdown: materials, machining time, labor, and overhead costs

AI identifies cost-saving opportunities and design optimizations before production starts

Leverages China’s optimized manufacturing ecosystem for 30–50% lower costs vs. Western suppliers

3. Expert DFM Analysis

AI-assisted manufacturability review + human-engineer validation for critical tolerances

Receive actionable feedback to refine geometry, material choices, and tolerances

Eliminate rework risks and accelerate time-to-market with precision-first design adjustments

4. Precision Production & Delivery

3/4/5-axis CNC machining with ±0.01mm tolerances for functional prototypes and end-use parts

Multi-stage quality control: in-process inspections, final metrology, and ISO-certified checks

Global delivery in 3–5 days for prototypes with real-time shipment tracking and proactive updates

Why Honyo?

We combine Shenzhen’s advanced manufacturing infrastructure with AI-driven efficiency to deliver perfect parts, faster. No hidden fees. No delays. Just precision you can trust.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision Engineering for Critical Applications

±0.01mm tolerances across 3/4/5-axis CNC machining for functional prototypes and end-use parts

Aerospace-grade quality control systems with ISO 9001-certified processes

Designed for high-stress applications—medical devices, robotics, and aerospace components

Smart Cost Efficiency Without Compromise

30–50% lower costs than Western suppliers through optimized operations and local material sourcing

Transparent pricing with no hidden fees—see exact costs instantly via our AI platform

Reduced waste via lean manufacturing: 25% lower material usage vs. industry averages

AI-Powered Instant Quoting & DFM Optimization

Upload CAD files in seconds for real-time quotes and automated manufacturability feedback

AI-driven design analysis identifies cost-saving opportunities and material optimizations

No more back-and-forth—get actionable insights to refine your design before production

Unmatched Speed from Prototype to Production

Prototypes delivered in 3–5 days, production batches in 7–10 days

Dedicated rapid-response team for urgent projects (24/7 engineering support)

Global logistics coordination with real-time tracking and customs clearance expertise

Your Trusted Partner in Shenzhen

Founder Susan Leo and our precision engineering team personally oversee every project

Visit our Shenzhen/Dongguan facilities for collaborative design sessions and quality inspections

Contact us today:

✉️ [email protected] | 📞 +86 139 2843 8620

Let’s build what’s next—faster, smarter, and with uncompromising precision.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.