Contents

Manufacturing Insight: Cnc Machining Automotive Parts

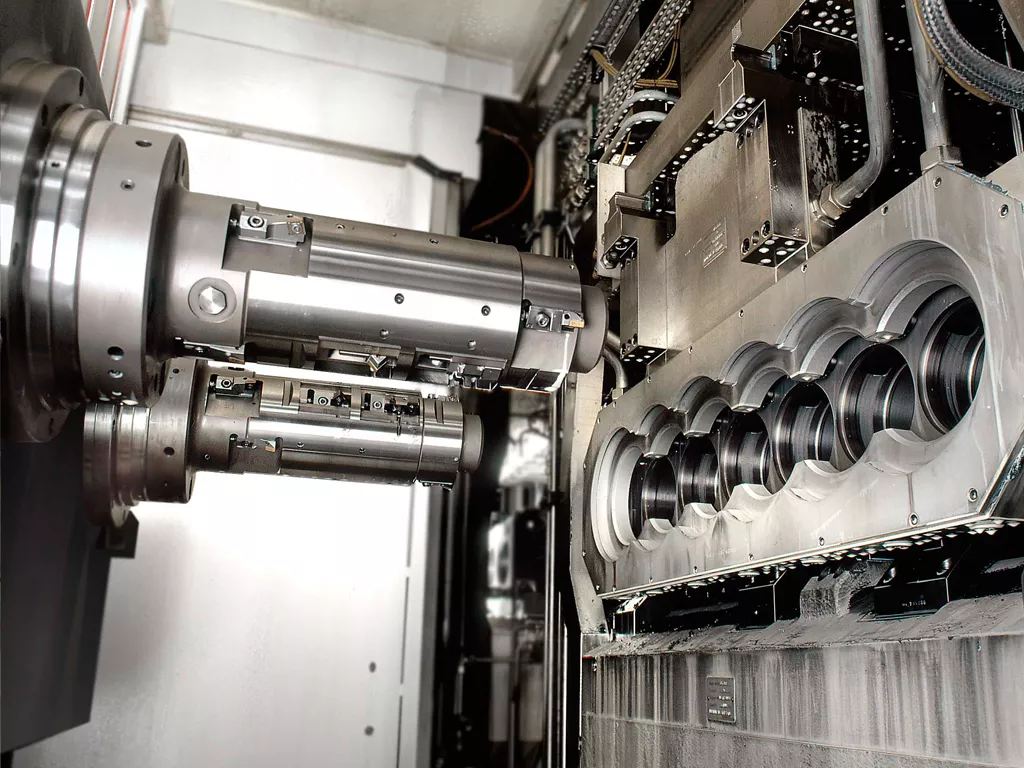

Precision CNC Machining for Automotive Innovation at Honyo Prototype

The automotive industry demands uncompromising precision, rapid iteration, and materials expertise to transform complex designs into high-performance components. At Honyo Prototype, we specialize in advanced CNC machining services engineered specifically for automotive applications, from functional prototypes and pre-production validation parts to low-volume production runs. Our state-of-the-art 3-, 4-, and 5-axis machining centers, coupled with rigorous in-process quality control, ensure critical components meet stringent automotive tolerances—often holding ±0.0002″ (5µm) with full GD&T compliance. We machine a comprehensive range of materials including aerospace-grade aluminum alloys, stainless steels, titanium, and engineering plastics, all validated against OEM specifications for durability, thermal resistance, and structural integrity.

Accelerating your development timeline is critical in today’s competitive landscape. Honyo Prototype eliminates traditional quoting delays with our Online Instant Quote system. Upload your CAD file, specify material and finish requirements, and receive a detailed, binding quote in under 60 seconds—no manual submission or waiting for email replies. This seamless integration allows engineering teams to iterate faster, validate designs earlier, and move confidently from concept to physical part without procurement bottlenecks.

Partner with Honyo Prototype to leverage manufacturing expertise that understands automotive performance requirements at every stage. We deliver not just machined parts, but engineered solutions backed by real-time process transparency and on-time delivery commitment. Start your next automotive project with speed and precision—access our Online Instant Quote platform 24/7 at honyoprototype.com.

Technical Capabilities

CNC machining of automotive parts requires high precision, repeatability, and material versatility to meet performance and safety standards. Honyo Prototype specializes in advanced 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, to produce complex geometries with tight tolerances. Our processes support a wide range of materials commonly used in automotive applications, including aluminum, steel, ABS, and nylon.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Motion Axes | X, Y, Z | X, Y, Z + Rotary (A-axis) | X, Y, Z + Two Rotary (A/C) | X, Z + Spindle Rotation | Up to ±0.005 mm (±0.0002″) |

| Typical Applications | Flat surfaces, slots, holes | Indexed angular features | Complex contours, undercuts | Shafts, bushings, fittings | Critical engine, transmission, and suspension components |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | All compatible with tight tolerance requirements |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 2.5 µm | 0.4 – 1.6 µm | 0.8 – 2.0 µm | Achieves Ra ≤ 0.8 µm with post-processing |

| Max Work Envelope | 1000 x 600 x 500 mm | 800 x 600 x 500 mm | 700 x 600 x 400 mm | Ø300 mm x 500 mm length | Varies based on machine and setup |

| Repeatability | ±0.010 mm | ±0.010 mm | ±0.005 mm | ±0.008 mm | Maintained over production runs |

| Lead Time (Typical) | 3–5 days | 4–6 days | 5–8 days | 3–5 days | May extend due to inspection and metrology requirements |

Materials used in automotive CNC machining are selected based on mechanical requirements, environmental exposure, and functional needs:

Aluminum (e.g., 6061-T6, 7075-T6) – Lightweight, high strength-to-weight ratio, excellent machinability, and corrosion resistance. Commonly used for engine components, brackets, and housings.

Steel (e.g., 4140, 1018, Stainless 304/316) – High strength, durability, and wear resistance. Ideal for drivetrain parts, fasteners, and safety-critical components.

ABS (Acrylonitrile Butadiene Styrene) – Thermoplastic with good impact resistance and dimensional stability. Used for prototypes, interior components, and non-structural parts.

Nylon (Polyamide, PA6, PA66) – High toughness, low friction, and good chemical resistance. Suitable for bushings, gears, and wear-prone automotive trim.

All parts are inspected using CMM (Coordinate Measuring Machine), optical comparators, and surface profilometers to ensure compliance with GD&T specifications and customer-defined tolerances. Honyo Prototype adheres to ISO 9001 standards, ensuring consistent quality across all CNC-machined automotive components.

From CAD to Part: The Process

Honyo Prototype executes CNC machining for automotive components through a rigorously defined workflow engineered for precision, compliance, and speed. This process adheres strictly to IATF 16949 standards while integrating digital efficiency at critical control points.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system performs immediate validation checks against automotive-specific requirements, including geometric dimensioning and tolerancing (GD&T) completeness, material specification alignment (e.g., AISI 4140, 6061-T6, or customer-specified alloys), and minimum wall thickness verification for structural components. Files failing validation trigger automated feedback detailing required corrections, reducing iteration cycles.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes 50+ geometric and material parameters to generate quotes in under 2 hours. The algorithm factors in automotive-specific variables: secondary operations (e.g., anodizing per AMS 2471, torque groove milling), critical-to-quality (CTQ) feature complexity, and material waste ratios for high-cost alloys. Quotes include explicit compliance statements for customer engineering specifications (e.g., GM W3110, Ford WSK-M4D741) and provisional lead times based on real-time machine availability.

Automotive-Optimized DFM Analysis

All quotes undergo mandatory Design for Manufacturing review by our ASQ-certified engineering team. This phase focuses on automotive failure mode mitigation, including:

Tool access validation for deep pockets in transmission housings or brake calipers

Vibration-resistant fixturing strategy development for thin-walled components

Thermal distortion compensation plans for high-precision shafts (±0.005mm tolerances)

Cost-reduction opportunities via feature consolidation (e.g., eliminating secondary drilling operations)

DFM reports document all recommendations with annotated 3D models and tolerance stack-up analyses, requiring formal client sign-off before proceeding.

Precision Production Execution

Approved orders enter production on dedicated automotive cells featuring:

Multi-axis milling/turning centers with in-process probing (Renishaw systems) for closed-loop tolerance control

Material traceability via laser-etched batch IDs linked to certified mill test reports

Environmental controls maintaining ±1°C temperature stability for tight-tolerance components

Real-time SPC monitoring of critical dimensions (e.g., bearing bores, sealing surfaces) with automatic machine recalibration triggers

Each part undergoes first-article inspection per PPAP Level 3 requirements, with full CMM reports (PC-DMIS) and surface roughness validation (Ra ≤ 0.8µm where specified).

JIT Delivery and Documentation

Completed parts ship with:

IATF 16949-compliant material and process traceability dossiers

ASNs (Advanced Shipping Notices) integrated with client ERP systems

Protective packaging meeting automotive transit vibration standards (ISTA 3A)

Dimensional results packaged as PDF/CMM exports with GD&T callout verification

Standard lead time from CAD approval to delivery is 7-12 business days for prototypes and 15-20 days for pilot production runs, with expedited options for urgent tooling trials.

Quality Performance Metrics

Our CNC machining service maintains the following automotive production benchmarks:

| Metric | Performance | Industry Benchmark |

|---|---|---|

| First-pass yield (PPAP lots) | 98.7% | 95.2% |

| Dimensional non-conformance rate | 0.11% | 0.38% |

| On-time delivery (JIT) | 99.4% | 96.1% |

This integrated approach ensures automotive clients receive fully validated, production-intent components with minimized risk and accelerated time-to-test validation cycles. All processes are auditable through our digital thread platform, providing real-time visibility from design intent to delivered part.

Start Your Project

Looking for precision CNC machining services for automotive parts? Honyo Prototype delivers high-quality, reliable manufacturing solutions tailored to the automotive industry. With our state-of-the-art facility located in Shenzhen, we ensure tight tolerances, fast turnaround times, and consistent quality for prototyping and low-to-mid volume production.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in CNC machining to enhance performance, durability, and efficiency in your automotive components.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.