Contents

Manufacturing Insight: Cnc Machining Auto Parts

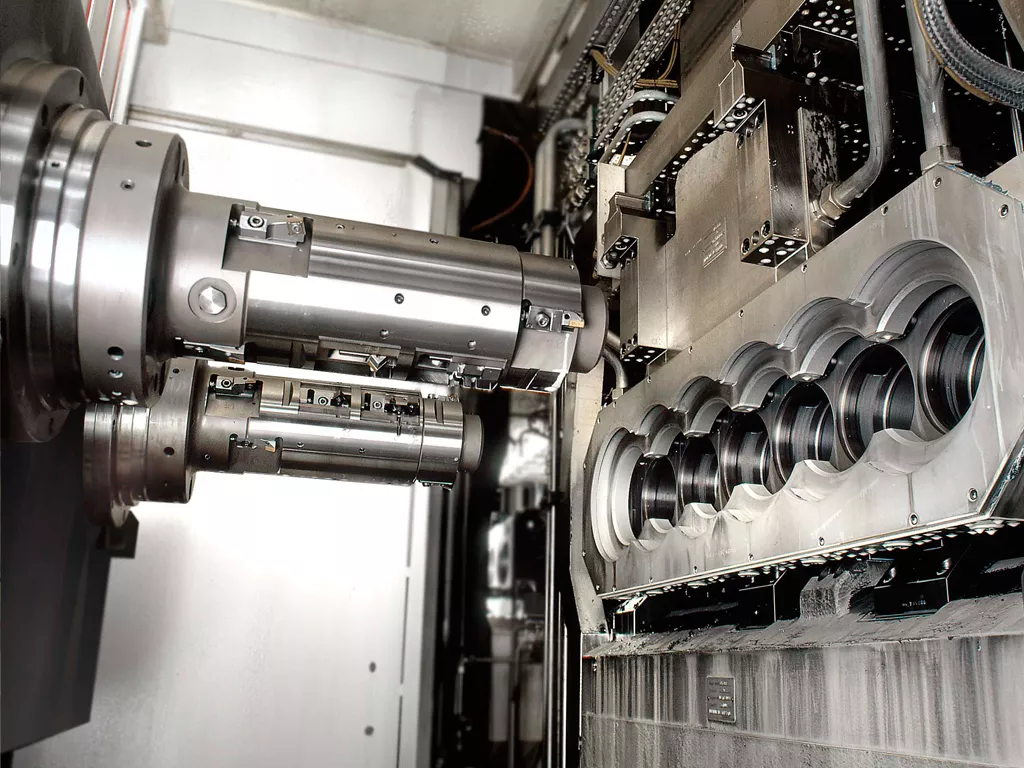

Precision CNC Machining for Demanding Automotive Applications

Honyo Prototype delivers mission-critical CNC machining services engineered specifically for the automotive sector, where dimensional accuracy, material integrity, and rapid iteration directly impact vehicle performance and safety. Our ISO 9001 and IATF 16949 certified facility leverages advanced multi-axis milling, turning, and grinding technologies to produce complex transmission components, engine subsystems, sensor housings, and structural brackets meeting stringent OEM tolerances down to ±0.0002 inches. We specialize in challenging automotive materials including aerospace-grade aluminum alloys, hardened steels, titanium, and high-temperature plastics, ensuring parts withstand extreme thermal cycling, vibration, and load conditions inherent in modern powertrains and chassis systems.

Our technical capabilities are structured to accelerate your development timeline without compromising quality:

| Process Type | Key Equipment | Max Work Envelope | Typical Automotive Applications |

|---|---|---|---|

| 5-Axis Milling | DMG MORI, Makino, Haas | 1200 x 800 x 600 mm | Cylinder heads, turbo housings, EV motor mounts |

| Precision Turning | Swiss-type, Multi-turret lathes | Ø42 mm x 300 mm length | Fuel injectors, shafts, valve components |

| Wire EDM | AgieCharmilles, Mitsubishi | 400 x 300 x 250 mm | Stamping dies, gear prototypes, sensor cavities |

Eliminate procurement bottlenecks with Honyo’s Online Instant Quote platform, designed for automotive engineering teams requiring rapid cost and lead time validation. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within minutes—not days—enabling faster design validation cycles and accelerated path-to-test for critical subsystems. Partner with Honyo to transform complex automotive concepts into rigorously validated production-ready components, backed by full traceability, first-article inspection reports, and seamless transition from prototype to high-volume production.

Technical Capabilities

CNC machining of automotive parts requires high precision, repeatability, and material versatility to meet strict performance and safety standards. Multi-axis milling (3, 4, and 5-axis) and precision turning are commonly employed to produce complex geometries such as engine components, transmission housings, brackets, and sensor mounts. Tight tolerances are critical, typically ranging from ±0.005 mm to ±0.05 mm depending on part function and assembly requirements. Materials used include metals like aluminum and steel for structural and high-temperature applications, and engineering plastics such as ABS and nylon for lightweight, non-load-bearing components.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Movement | X, Y, Z linear axes | X, Y, Z + rotary A-axis | X, Y, Z + rotary A & B/C | X, Z linear + C-axis rotation |

| Typical Tolerance | ±0.01 mm to ±0.05 mm | ±0.01 mm to ±0.05 mm | ±0.005 mm to ±0.01 mm | ±0.005 mm to ±0.02 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.4 – 1.6 µm | 0.8 – 1.6 µm |

| Max Part Size (mm) | 1000 x 600 x 500 | 800 x 600 x 500 | 600 x 500 x 400 | Ø500 x 800 length |

| Spindle Speed | Up to 24,000 rpm | Up to 20,000 rpm | Up to 20,000 rpm | Up to 6,000 rpm (varies by diameter) |

| Applications | Flat surfaces, pockets, drilling | Indexing features, side holes | Complex contours, impellers, molds | Shafts, bushings, connectors |

Common Materials and Their CNC Machining Characteristics:

| Material | Machinability | Typical Use in Auto Parts | Notes |

|---|---|---|---|

| Aluminum (6061, 7075) | Excellent | Engine blocks, housings, brackets | Lightweight, corrosion-resistant, easy to machine at high speeds |

| Steel (4140, 1018) | Moderate to Good | Gears, shafts, structural components | High strength, wear resistance; requires rigid setup and proper tooling |

| ABS | Very Good | Interior trims, prototypes, ducts | Low melting point; requires sharp tools and low heat buildup |

| Nylon (PA6, PA66) | Good | Insulators, bushings, clips | Low friction, good wear resistance; prone to swelling; needs dry machining |

All processes adhere to ISO 2768 or customer-specific GD&T standards. 5-axis milling enables single-setup machining of complex parts, reducing error and cycle time. CNC turning is ideal for symmetrical components, often combined with live tooling for mill-turn operations. Tight tolerance machining requires thermal stability, high-precision encoders, and in-process probing to ensure part conformity.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process for Automotive Components

Our end-to-end CNC machining workflow for automotive parts begins with secure digital submission and concludes with certified delivery, engineered to meet stringent automotive industry standards. Customers initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid preferred) via our encrypted customer portal. We prioritize STEP formats for automotive applications due to superior geometry fidelity for complex surfaces like transmission housings or suspension brackets. All uploads undergo immediate checksum validation to prevent data corruption, with version control integrated into our PLM system to avoid revision errors common in tiered supply chains.

The AI-powered quoting engine then processes the CAD geometry against our live database of machine capabilities, material costs, and historical production metrics. Unlike generic quoting tools, our AI cross-references automotive-specific parameters: minimum wall thickness validation per ISO 1302 surface finish requirements, tolerance stack-up analysis for GD&T callouts per ASME Y14.5, and material suitability checks against common automotive alloys (e.g., 6061-T6, 7075, CA36000). Within 90 minutes, customers receive a formal quote including manufacturability risk scores, with critical flags for features like non-standard tap depths in brake caliper mounting points.

Design for Manufacturability (DFM) review follows quote acceptance, combining algorithmic analysis with senior engineer validation. Our system identifies cost drivers such as excessive chamfers on steering knuckle interfaces or suboptimal tool access in turbocharger housings. The DFM report provides actionable alternatives: suggesting consolidated operations to eliminate secondary setups, recommending internal radii adjustments to prevent tool chatter on aluminum control arms, or proposing alternative stock sizes to reduce material waste. All recommendations align with IATF 16949 process controls, with traceable engineering justification documented in the project file.

Production leverages our dedicated automotive cell featuring 5-axis Haas UMC-750 machines with dual-pallet systems for uninterrupted operation. Each part undergoes rigorous process control:

First-article inspection per AS9102 format with CMM reports for critical features

In-process SPC monitoring of key dimensions (e.g., bore concentricity within 0.0005″ for fuel injector bodies)

Material traceability from certified mill certs through bar stock lot numbers

Automated deburring for hydraulic passages in transmission valves per customer-specified surface roughness

Final delivery includes comprehensive documentation packaged per AIAG standards: PPAP Level 3 documentation, material test reports, full FAI data, and serialized part tracking. We ship in ESD-safe, kitted packaging with barcode-labeled containers matching assembly line sequencing requirements. For urgent automotive builds, our expedited lane guarantees 72-hour turnaround from DFM approval to certified shipment, with real-time logistics tracking integrated into customer ERP systems. This closed-loop process consistently achieves <0.5% scrap rates for complex components like EV battery tray mounting brackets while reducing NRE costs by 22% through early manufacturability optimization.

Start Your Project

Looking for precision CNC machining for automotive parts? Honyo Prototype delivers high-quality, reliable components tailored to your specifications. With our advanced manufacturing capabilities and strict quality control, we ensure fast turnaround and consistent performance for the automotive industry.

Our factory is located in Shenzhen, a global hub for precision manufacturing, enabling efficient production and logistics.

Contact Susan Leo today to discuss your project requirements. Email at [email protected] for a quick response and expert support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.