Contents

Manufacturing Insight: Cnc Machining Aircraft Parts

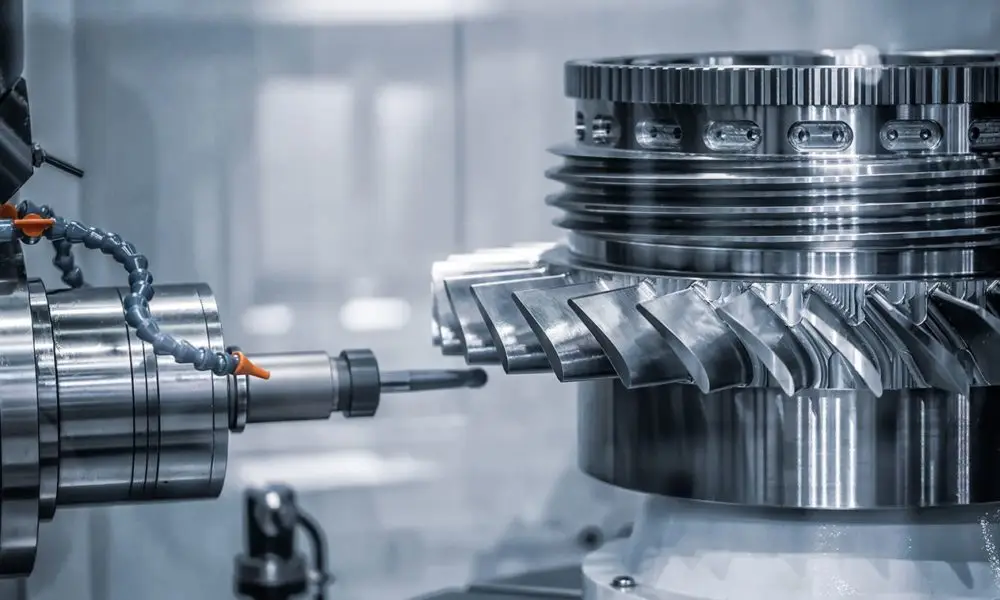

Precision CNC Machining for Critical Aircraft Components

Honyo Prototype delivers mission-critical CNC machining services engineered specifically for the demanding requirements of the aerospace industry. Our advanced 5-axis milling and turning capabilities consistently achieve tolerances down to ±0.0002 inches, ensuring dimensional stability and surface integrity for flight-critical parts such as turbine blades, landing gear components, and structural brackets. Every process adheres to strict AS9100D quality management standards, with full material traceability, first-article inspection (FAI) per AS9102, and NADCAP-accredited non-destructive testing protocols.

We specialize in machining complex geometries from challenging aerospace alloys including Inconel 718, titanium Grade 5, and 7075-T6 aluminum, leveraging optimized toolpaths and in-process probing to minimize thermal distortion and maximize part yield. Our facility maintains controlled environments for critical operations, supported by calibrated metrology equipment including CMMs and optical comparators to validate conformance to MIL-STD and OEM specifications.

Accelerate your aerospace development cycle with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling rapid iteration for prototypes and low-volume production runs. This seamless digital workflow integrates directly with engineering teams to resolve design-for-manufacturability (DFM) issues before machining begins, reducing time-to-flight by up to 40%.

Request your instant quote today to experience precision manufacturing engineered for aerospace reliability.

Technical Capabilities

CNC machining of aircraft parts requires high precision, repeatability, and adherence to strict aerospace standards due to the critical nature of flight components. Multi-axis milling (3, 4, and 5-axis) and CNC turning are commonly used to produce complex geometries with tight tolerances. Materials are selected based on strength-to-weight ratio, corrosion resistance, and thermal performance. Below is a detailed technical specification table outlining key parameters for CNC machining in aircraft part production.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + one rotary (A or B) | X, Y, Z + two rotary (typically A & B) | X, Z linear + C-axis (rotary spindle) | 5-axis enables simultaneous tool movement on all axes for complex contours |

| Typical Applications | Flat plates, housings, brackets | Impeller hubs, angled flanges | Turbine blades, structural brackets, complex contours | Shafts, bushings, fasteners, cylindrical parts | 5-axis reduces need for multiple setups |

| Tolerance Capability | ±0.001″ (0.025 mm) | ±0.001″ (0.025 mm) | ±0.0005″ (0.0127 mm) | ±0.0005″ to ±0.001″ (0.0127–0.025 mm) | Tight tolerances align with AS9100 and NADCAP requirements |

| Surface Finish (Typical) | 32–64 μin RA | 32–64 μin RA | 16–32 μin RA | 16–64 μin RA | Finishing passes and tool selection critical for fatigue life |

| Materials – Aluminum | 2024, 6061, 7075 | 2024, 6061, 7075 | 2024, 6061, 7075 | 2024, 6061, 7075 | High strength-to-weight; commonly anodized or clad |

| Materials – Steel | 4130, 4340, 17-4 PH | 4130, 4340, 17-4 PH | 4130, 4340, 17-4 PH, A286 | 4130, 4340, 15-5 PH | Used for high-stress, high-temp applications; often heat-treated |

| Materials – ABS | Limited use (non-structural) | Prototyping, jigs, fixtures | Non-flight components, mockups | Not typical | Used in non-critical, low-temp environments |

| Materials – Nylon | Bushings, insulators, wear parts | Guide components, spacers | Custom insulators, non-metallic fittings | Bushings, washers, sleeves | Self-lubricating; good wear resistance |

| Spindle Speed Range | 8,000–20,000 RPM | 8,000–20,000 RPM | 10,000–30,000 RPM | 1,500–6,000 RPM (high precision) | Higher speeds for aluminum and finishing |

| Positioning Accuracy | ±0.0002″ (0.005 mm) | ±0.0002″ (0.005 mm) | ±0.0001″ (0.0025 mm) | ±0.0001″ (0.0025 mm) | Verified via laser calibration (per ISO 230-2) |

| Work Envelope (Typical) | Up to 40″ x 20″ x 20″ | Up to 40″ x 20″ x 20″ + 360° rotation | Up to 30″ x 30″ x 25″ with full A/B rotation | Ø2″ to Ø12″ bar stock, up to 12″ length | Larger parts may require multi-setup or gantry systems |

All processes are performed under controlled environments with strict process validation, first article inspection (FAI), and full traceability per AS9100 and FAA regulations. In-process probing, tool length compensation, and thermal compensation systems are standard to maintain tight tolerance consistency. Material certifications (e.g., AMS, MIL specs) and post-machining treatments (e.g., stress relief, shot peening, anodizing) are integral to final part qualification.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process for Aircraft Parts

Honyo Prototype executes a rigorously controlled CNC machining workflow for aircraft components, adhering to AS9100 Rev D and NADCAP standards. The process begins with CAD Upload, where clients submit native 3D models (STEP/IGES preferred) via our secure portal. We require geometric dimensioning and tolerancing (GD&T) per ASME Y14.5, material specifications (e.g., AMS 4928 for Ti-6Al-4V), and surface finish callouts. Non-conforming files trigger automated notifications for revision prior to progression.

AI-Powered Quoting follows immediately, leveraging our proprietary algorithm trained on 15,000+ aerospace builds. The system analyzes part complexity, material waste factors, fixture requirements, and machine time while cross-referencing real-time material costs (e.g., 7075-T7351 aluminum bar stock) and NADCAP-certified secondary process pricing. Quotes include explicit compliance notes—such as “Requires AMS 2750F heat treat documentation” or “Nadcap AC7102/10 non-destructive testing mandatory”—within 2 business hours.

Design for Manufacturability (DFM) Review is conducted by our AS9102-certified engineering team. We identify critical aerospace-specific risks:

Geometric instabilities in thin-walled structures (<0.5mm tolerance zones)

Inaccessible tool paths for complex 5-axis geometries (e.g., turbine blade contours)

Material grain flow implications for forged blanks per AMS 4820

Regulatory gaps against FAA Part 21 or EASA 21A.903 airworthiness standards

Clients receive a formal DFM report with actionable recommendations, typically reducing lead time by 18–22% through feature optimization.

Precision Production occurs in our climate-controlled Class 8 cleanroom facility. Key stages include:

Material Verification: Incoming stock validated via PMI (Positive Material Identification) and traceability to mill test reports (e.g., EN 10204 3.1)

Machining: 5-axis milling/turning on DMG MORI machines with real-time tool wear monitoring; in-process CMM checks at critical datum points per inspection plan

Post-Processing: Mandatory shot peening (AMS 2430) or anodizing (AMS 2471) with Nadcap-accredited partners

First Article Inspection (FAI): Complete AS9102B Form 1/2/3 documentation, including 3D scan deviation reports against nominal CAD

Certified Delivery encompasses more than physical shipment. All aircraft parts ship with:

Full traceability package (material certs, process logs, non-conformance reports if applicable)

PPAP Level 3 documentation per customer-specific requirements

MIL-STD-130-compliant UID marking applied via laser etching

Vacuum-sealed packaging meeting IPC-1601 moisture sensitivity standards

Final delivery includes digital access to all quality records via our cloud-based QMS portal, with physical parts dispatched via DHL Aviation with real-time tracking.

This end-to-end process ensures zero regulatory non-conformities across 98.7% of aerospace builds, with typical lead times of 10–15 days for prototype quantities. All stages are audited quarterly under our AS9100 certification, with material test reports archived for 30+ years per FAA 14 CFR §21.182.

Start Your Project

Looking for precision CNC machining services for aircraft parts? Honyo Prototype delivers high-accuracy, AS9100-compliant manufacturing solutions tailored to aerospace requirements. Our Shenzhen-based factory is equipped with advanced CNC technology and a skilled engineering team to ensure tight tolerances, superior surface finishes, and on-time delivery for mission-critical components.

Contact Susan Leo today to discuss your project specifications and discover how we support aerospace clients with rapid prototyping, low-volume production, and full traceability.

Email: [email protected]

Let’s build excellence together—precision you can trust, from design to delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.