Contents

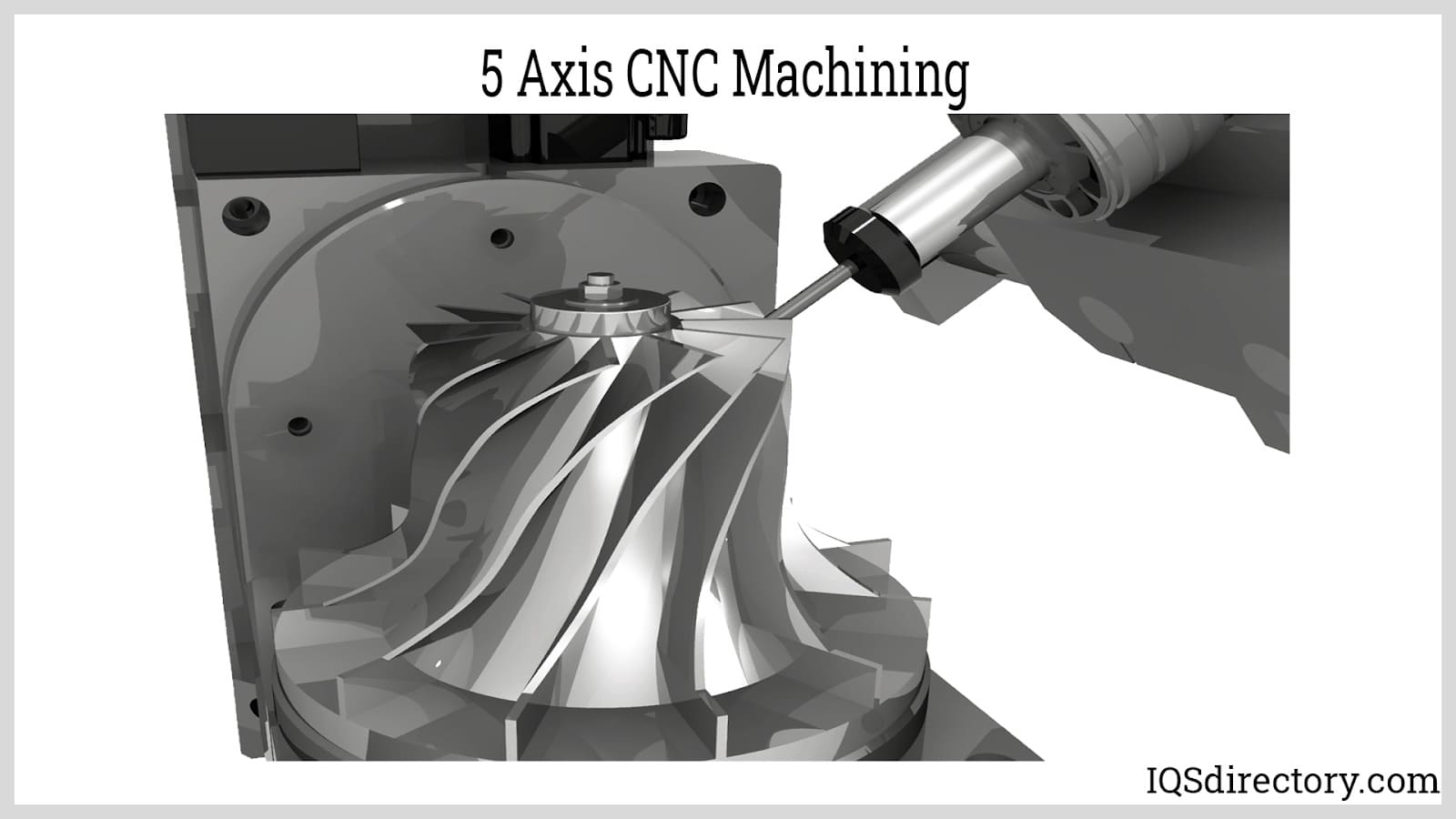

Manufacturing Insight: Cnc Machining 5 Axis

Precision Through Complexity: Honyo Prototype’s 5-Axis CNC Machining Solution

Achieving geometric complexity without compromising precision defines modern high-value manufacturing. Honyo Prototype delivers this critical capability through advanced 5-axis CNC machining, engineered to transform intricate designs into flawless physical components. Our synchronized multi-axis technology enables continuous cutting from five directions within a single setup, eliminating manual repositioning errors and significantly reducing lead times for parts with compound angles, deep cavities, or organic contours. This capability is essential for industries like aerospace, medical device manufacturing, and energy, where tolerances demand micron-level accuracy and surface integrity directly impacts performance.

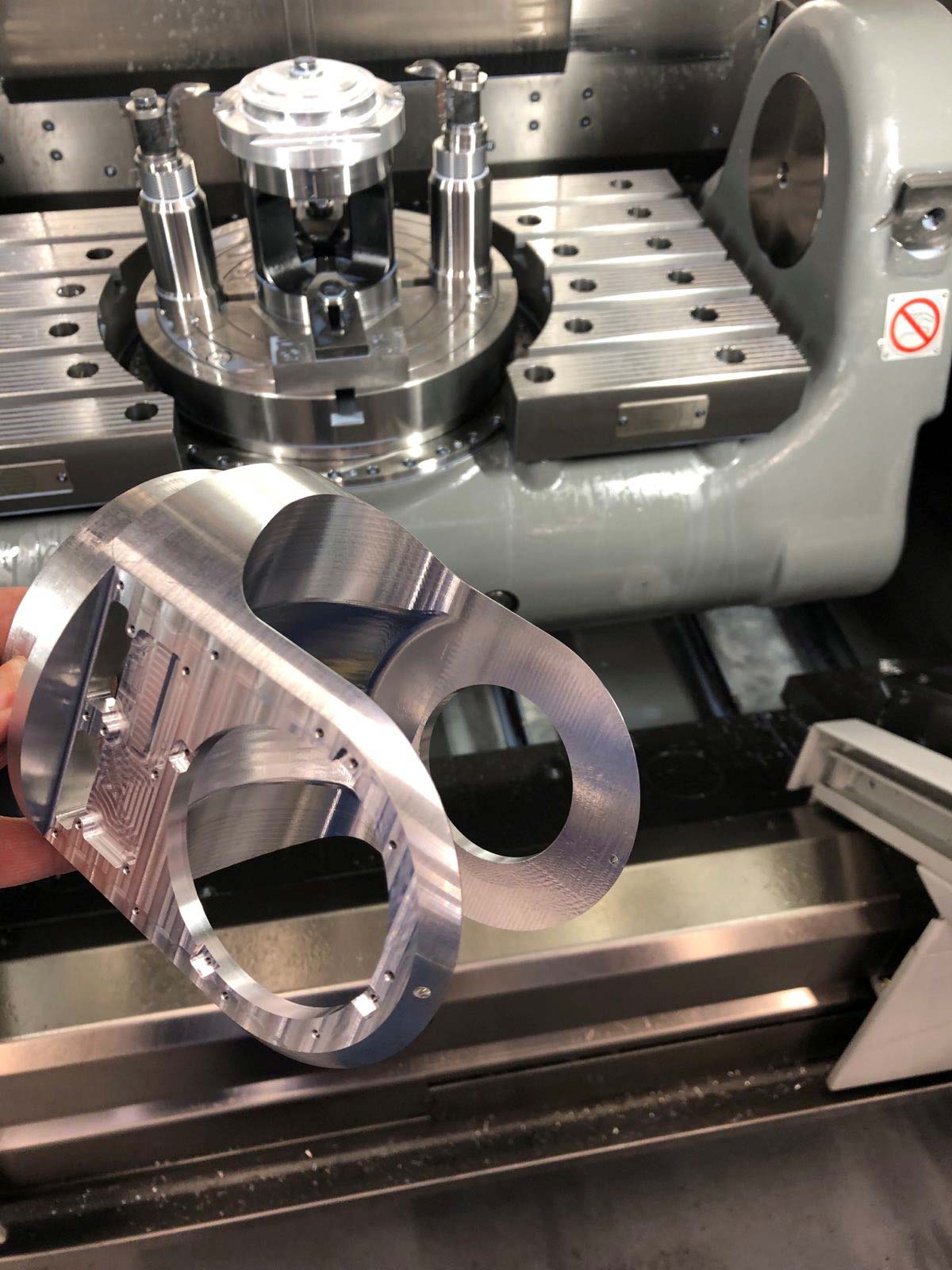

Honyo leverages state-of-the-art 5-axis machining centers paired with proprietary fixturing and adaptive toolpath strategies to handle challenging alloys, composites, and engineered plastics. We maintain rigorous process control across all operations, ensuring repeatability for both rapid prototypes and low-to-mid volume production runs. Our engineering team collaborates closely with clients during DFM analysis to optimize part geometry for manufacturability, minimizing waste and accelerating time-to-market.

Accelerate your project timeline immediately with Honyo’s Online Instant Quote system. Upload your 3D CAD file to receive a detailed, geometry-aware cost and lead time estimate within minutes—no manual submission delays. This seamless integration of technical expertise and digital efficiency ensures your complex 5-axis requirements transition smoothly from concept to certified, ready-to-assemble components. Partner with Honyo Prototype to convert design ambition into manufacturing reality.

Technical Capabilities

CNC machining with 3, 4, and 5-axis capabilities enables high-precision manufacturing of complex geometries across a range of engineering materials. At Honyo Prototype, we specialize in multi-axis milling and turning operations with tight tolerance control, ensuring repeatability and accuracy for prototyping and low-to-mid volume production.

Our 5-axis CNC machining centers allow simultaneous movement across X, Y, and Z linear axes, along with two rotational axes (typically A and B), enabling tool access from multiple angles without re-fixturing. This reduces setup time, improves accuracy, and supports intricate part features. 4-axis systems add one rotational axis (usually A-axis), ideal for cylindrical profiling with indexed complexity. 3-axis machining remains optimal for prismatic parts with straightforward geometries.

Tight tolerance capabilities down to ±0.005 mm (±0.0002″) are maintained through high-rigidity machine platforms, thermal compensation systems, and in-process probing. Materials commonly processed include aluminum, steel, ABS, and nylon, each selected based on mechanical, thermal, and chemical requirements.

Below is a summary of technical specifications by process and material:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Max Working Volume (mm) | 1000 x 600 x 500 | 800 x 600 x 500 | 750 x 600 x 450 | Ø300 x 500 length | Up to ±0.005 mm |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | ±0.002 mm with calibration |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.003 mm | ±0.001 mm typical |

| Spindle Speed (max) | 24,000 rpm | 20,000 rpm | 20,000 rpm | 6,000 rpm | N/A |

| Tool Changer (ATC) | 24–30 tools | 24–30 tools | 30 tools | 12–16 tools (live tooling) | N/A |

| Surface Finish (typical) | Ra 0.8 µm (machined) | Ra 0.8 µm | Ra 0.4–0.8 µm | Ra 0.8 µm | Ra 0.4 µm achievable |

| Materials – Aluminum | 6061, 7075, 2024, 5052 | 6061, 7075 | 6061, 7075, 2024 | 6061, 7075 | Yes |

| Materials – Steel | 1018, 4140, 4340, 17-4PH | 4140, 4340, 17-4PH | 4140, 17-4PH, stainless | 1018, 4140, 17-4PH | Yes |

| Materials – ABS | Yes | Yes | Yes | Limited (soft) | Yes (±0.025 mm typical) |

| Materials – Nylon | Yes (machinable grade) | Yes | Yes | Limited | Yes (±0.025 mm with fixturing) |

| Primary Applications | Enclosures, brackets | Index-rotated parts | Aerospace, medical, molds | Shafts, pins, fittings | Precision components |

All processes are supported by CAD/CAM integration (Siemens NX, Mastercam), first-article inspection (FAI), and CMM validation. Material certifications and post-processing options (anodizing, plating, passivation) are available upon request.

From CAD to Part: The Process

Honyo Prototype 5-Axis CNC Machining Process Overview

Honyo Prototype executes 5-axis CNC machining through a streamlined, technology-driven workflow designed for precision, efficiency, and client collaboration. The process begins with CAD file submission and concludes with certified delivery, integrating automated systems and engineering expertise at critical stages to mitigate risk and ensure manufacturability.

CAD Upload and Initial Validation

Clients submit native or neutral-format CAD models (STEP, Parasolid, IGES) via our secure portal. Our system performs automated geometry validation to verify file integrity, unit consistency, and topology completeness. Files failing validation trigger immediate notifications with specific error diagnostics, preventing downstream delays. Validated CAD data populates our production management system, initiating the quoting sequence.

AI-Powered Quoting Engine

Honyo’s proprietary AI quoting engine analyzes the validated CAD model in real time, extracting geometric complexity, material requirements, tolerance density, and feature criticality. The system cross-references our historical production database (10,000+ completed 5-axis projects) to generate accurate cost and lead time estimates. Quotes include granular breakdowns of machine hours, fixture complexity, and secondary operations, with typical turnaround under 2 business hours. Key parameters influencing the quote are transparently displayed:

| Parameter | Impact on Quote | Honyo’s Benchmark Threshold |

|---|---|---|

| Tolerance Density | >15 critical tolerances per 100mm² | 22% cost increase |

| Undercut Complexity | Non-machinable undercuts requiring EDM | +3-5 day lead time |

| Material Hardness | >45 HRC requiring specialized tooling | 18-30% cost premium |

Collaborative DFM Analysis

Upon quote acceptance, our engineering team conducts a formal Design for Manufacturability (DFM) review. This phase is inherently collaborative – we identify geometric features that increase cycle time or risk (e.g., deep cavities requiring long-reach tooling, thin walls prone to chatter) and propose actionable redesigns via annotated 3D models. Clients receive a DFM report detailing:

Specific features impacting cost/lead time with photographic examples from past builds

Quantified time/cost savings from suggested modifications (e.g., “Rounding internal corners from 0.5mm to 1.0mm reduces machining time by 27%”)

Alternative material recommendations for improved machinability without compromising function

No DFM issue proceeds to production without explicit client approval, ensuring alignment with functional requirements.

Precision Production Execution

Approved designs enter our digital production pipeline where 5-axis machining cells (DMG MORI, Haas UMC series) are dynamically scheduled based on machine capability and queue status. Critical production controls include:

In-process CMM verification after roughing and semi-finishing stages

Real-time tool wear monitoring via spindle load sensors with automatic feed rate adjustment

Environmental controls maintaining ±0.5°C temperature stability in machining zones

Full traceability through serialized work orders linked to material certs and operator logs

Complex assemblies undergo first-article inspection (FAI) per AS9102 standards, with full GD&T reports available upon request.

Certified Delivery and Documentation

Final parts undergo final cleaning, deburring, and visual inspection before packaging in anti-static, humidity-controlled containers. Every shipment includes:

Dimensional inspection report with CMM data mapped to CAD nominal values

Material certification (MTR) with lot traceability

Process validation records including machine log files and toolpath verification screenshots

Real-time shipment tracking with ETA updates via client portal integration

This closed-loop process ensures Honyo delivers 5-axis components with 99.2% on-time delivery performance and <0.15% defect rate, directly addressing the cost, precision, and reliability demands of prototyping and low-volume production in aerospace, medical, and robotics sectors.

Start Your Project

Discover precision CNC machining with 5-axis capabilities at Honyo Prototype. Our advanced manufacturing solutions deliver complex geometries with superior accuracy and faster turnaround times.

Located in Shenzhen, our state-of-the-art facility supports rapid prototyping and low-to-mid volume production for aerospace, medical, automotive, and industrial applications.

For project inquiries or quotes, contact Susan Leo at [email protected]. Let’s engineer excellence together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.