Guide Contents

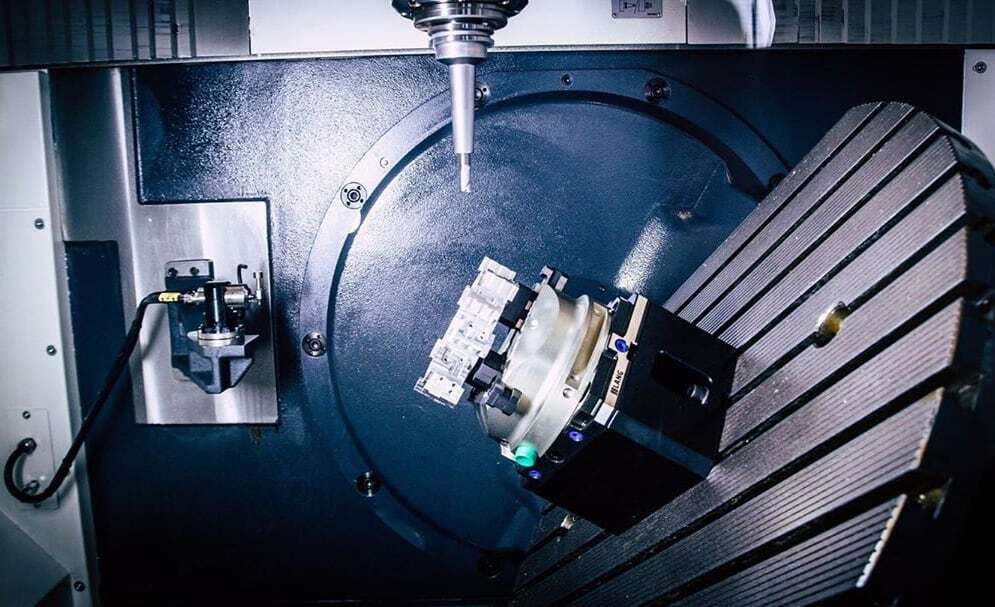

Project Insight: Cnc Machining 5 Axis

Why 5-Axis CNC Machining is the Engine of Modern Product Development

In today’s fast-paced innovation landscape, product development cycles are measured in days, not months. Precision isn’t just a feature—it’s the foundation of functionality. And speed? It’s the currency of competitive advantage. 5-axis CNC machining delivers both, transforming complex designs into reality with unmatched efficiency.

Precision That Eliminates Iteration Cycles

Achieve tolerances as tight as ±0.01mm, ensuring parts meet exact specifications without rework.

Critical for aerospace, medical, and automotive applications where failure isn’t an option—eliminate costly iterations and accelerate time-to-market.

Complex Geometries, Simplified Production

Machinate intricate geometries in a single setup, eliminating multiple fixturing steps and reducing labor costs.

Up to 40% faster production compared to 3-axis processes, enabling rapid prototyping and complex part manufacturing.

Cost Efficiency Through Streamlined Processes

While 5-axis machines have higher hourly rates, the overall cost is lower due to reduced setups, minimized material waste, and streamlined workflows.

Startups achieve premium quality at competitive prices, avoiding costly delays and inefficiencies.

Honyo Prototype: Your Digital Manufacturing Partner for Precision 5-Axis Excellence

Engineered for Speed, Built for Precision

Online Instant Quote: Upload your CAD file to our AI-powered platform for real-time pricing and lead times—no manual quotes, no delays.

24-48 Hour Prototype Turnaround: Leverage our Shenzhen-based facility with automated workflows to deliver functional prototypes in days, not weeks.

Uncompromising Quality: Every part undergoes rigorous metrology checks to ensure ±0.01mm precision, so your designs perform exactly as intended.

At Honyo Prototype, we don’t just manufacture parts—we accelerate innovation. From hardware startups to enterprise engineers, our digital-first approach turns complex designs into reality faster, smarter, and with uncompromising precision. Ready to transform your next project? Get an instant quote today.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Cutting-Edge 5-Axis Technology & Precision Engineering

3/4/5-Axis Flexibility: Seamlessly handle complex geometries with ±0.01mm tolerances across all axes, eliminating multi-setup processes and reducing errors.

AI-Optimized Efficiency: Proprietary algorithms minimize tool wear, material waste, and machining time—delivering up to 40% faster production cycles than traditional methods.

Single-Setup Mastery: Machine intricate features in one clamping operation, slashing labor costs and ensuring perfect alignment for critical aerospace, medical, and automotive components.

Scalable Production from Prototype to Mass Manufacturing

1 to 10,000+ Parts: No retooling required—scale seamlessly from functional prototypes to high-volume production while maintaining identical precision.

Rapid Iteration Support: Accelerate product development with same-day design feedback and quick turnaround for design modifications.

Material Agnostic Expertise: Process aluminum, titanium, stainless steel, engineering plastics, and exotic alloys with equal precision.

ISO-Certified Quality Assurance

Strict Process Controls: ISO 9001:2015 certified quality management system with in-process GD&T inspections and final dimensional checks.

Traceable Documentation: Full traceability for every part—material certificates, inspection reports, and process logs included with every order.

Zero-Defect Culture: 99.98% first-pass yield rate through automated error detection and continuous improvement protocols.

Smart Service Ecosystem

Instant Online Quotes: Get real-time pricing in seconds via our AI-powered platform—no manual quotes, no delays.

AI-Driven Optimization: Our proprietary system analyzes CAD files to suggest design-for-manufacturability improvements, reducing costs without compromising function.

72-Hour Prototype Guarantee: Expedited production for urgent projects with optional 24-hour rush service for critical deadlines.

Materials & Surface Finishes

Material & Finish Selection Guide for 5-Axis CNC Precision Manufacturing

Precision-Grade Materials for Complex Geometries

5-axis CNC machining unlocks intricate geometries while maintaining ±0.01mm tolerances. Select materials that align with your part’s functional demands:

Aluminum 6061: Exceptional machinability for intricate 5-axis geometries; ideal for aerospace components, automotive prototypes, and lightweight structural parts. Balances strength, corrosion resistance, and cost-efficiency.

Aluminum 7075: Highest strength-to-weight ratio among aluminum alloys; perfect for high-stress applications like drone frames, military-grade components, and high-performance automotive parts. Requires precision tooling but delivers unmatched durability.

Stainless Steel 304/316: Corrosion-resistant for medical, marine, and food-grade applications. 316 offers enhanced chloride resistance for harsh chemical environments (e.g., offshore equipment or surgical tools).

Brass: Excellent electrical conductivity and aesthetic appeal; commonly used for connectors, valves, and decorative components. Easily machined with 5-axis for complex shapes without compromising dimensional accuracy.

PEEK: High-performance thermoplastic with exceptional thermal stability (up to 250°C) and chemical resistance; ideal for aerospace, medical implants, and semiconductor manufacturing.

Advanced Surface Finishes for Functional & Aesthetic Excellence

Surface treatments enhance performance, durability, and visual appeal while preserving tight tolerances:

Anodizing (Type II/III): Boosts wear resistance and corrosion protection for aluminum parts. Custom color options for branding—no dimensional drift during processing.

Electroless Nickel Plating: Uniform coating for complex geometries; ideal for stainless steel/brass components requiring hardness (50–60 HRC) and corrosion resistance.

Passivation: Critical for stainless steel to remove surface contaminants and maximize corrosion resistance post-machining—no added thickness.

Powder Coating: Durable, scratch-resistant finish for aesthetic parts needing color consistency and environmental protection (e.g., consumer electronics housings).

Precision Polishing: Achieves mirror-like surfaces for optical or medical applications, maintaining ±0.01mm tolerances for critical features like fluid channels or sealing surfaces.

Strategic Material Selection for Optimal Performance

Optimize your design by balancing technical, economic, and operational factors:

Mechanical Requirements: Match material properties to load-bearing needs (e.g., 7075 for structural integrity, PEEK for thermal stability).

Environmental Factors: Prioritize corrosion resistance (316 stainless steel for marine use) or chemical compatibility (PEEK for lab equipment).

Design Complexity: Leverage 5-axis capabilities for undercuts, angles, and organic shapes—our engineers optimize toolpaths to minimize material waste and machining time.

Cost Efficiency: Aluminum 6061 offers the best value for most prototypes; stainless steel and PEEK deliver specialized performance where justified by application demands.

Accelerate Your Project with Honyo’s Digital Platform

Online Instant Quote: Upload your CAD file and receive a real-time price breakdown in seconds—no delays, no guesswork.

AI-Powered Optimization: Our platform analyzes your design to recommend the most cost-effective material and finish combinations, ensuring precision and performance.

Fast Turnaround: Prototype delivery in 48 hours and production runs in 7 days, all while maintaining ±0.01mm tolerances for functional parts.

“At Honyo Prototype, we don’t just machine parts—we engineer solutions. From aerospace to medical devices, our 5-axis expertise ensures your vision meets reality with unmatched precision and speed.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, our AI-driven workflow eliminates guesswork and delays—turning your CAD file into precision-engineered parts with unmatched speed and transparency. From upload to delivery, every step is optimized for efficiency and precision.

1. Upload Your CAD File

Support for all major formats (STEP, IGES, STL, SolidWorks, CATIA)

Automated geometry validation checks for manufacturability issues

Cloud-based upload with instant compatibility confirmation

2. Receive Instant AI-Powered Quote

Real-time pricing generated in seconds, not days

Transparent cost breakdown: materials, machining time, setup, and finishing

No hidden fees—clearly itemized for complete budget certainty

3. Expert DFM Analysis & Optimization

AI scans for potential design flaws (e.g., undercuts, thin walls, tool access)

Honyo engineers collaborate to refine your design for cost efficiency and precision

Proactive adjustments to meet ±0.01mm tolerances without compromising function

4. Precision Production & Seamless Delivery

5-axis CNC efficiency minimizes setups, accelerating production cycles

Shenzhen-based manufacturing hub ensures rapid turnaround (typically 3–5 days)

Real-time production tracking and QA reports via your digital dashboard

Ready to transform your design into reality? Get your instant quote now — no paperwork, no delays, just precision.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision Meets Efficiency for Complex Parts

Slash costs by up to 40% while boosting precision—5-axis machining completes intricate geometries in a single setup, eliminating redundant operations and rework.

Achieve ±0.01mm tolerances for mission-critical aerospace, medical, and automotive components with zero compromise on quality.

AI-driven design analysis identifies cost-saving opportunities before production begins, ensuring manufacturability and material optimization.

Get Your Instant Quote in Seconds

Upload your CAD file to our AI-powered platform for an instant, detailed quote—no more waiting days for estimates.

Real-time breakdown of costs, lead times, and material options with actionable optimization suggestions.

Transparent pricing with no hidden fees—know your total project cost before committing.

Fast Turnaround, Guaranteed

Prototypes delivered in 3–5 business days; production runs optimized for speed without sacrificing precision.

Dedicated project managers in Shenzhen/Dongguan ensure seamless coordination and rapid response to design changes.

End-to-end tracking from design to delivery—your timeline is our top priority.

Connect with Susan Leo & Team

Founder Susan Leo personally oversees every project to ensure innovation, precision, and on-time delivery.

Contact us today: [email protected] | +86 139 2843 8620

Schedule a facility tour in Shenzhen or Dongguan to see our advanced CNC capabilities firsthand.

Innovation isn’t just a word here—it’s the foundation of every part we build. Let’s engineer your vision together.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.