Contents

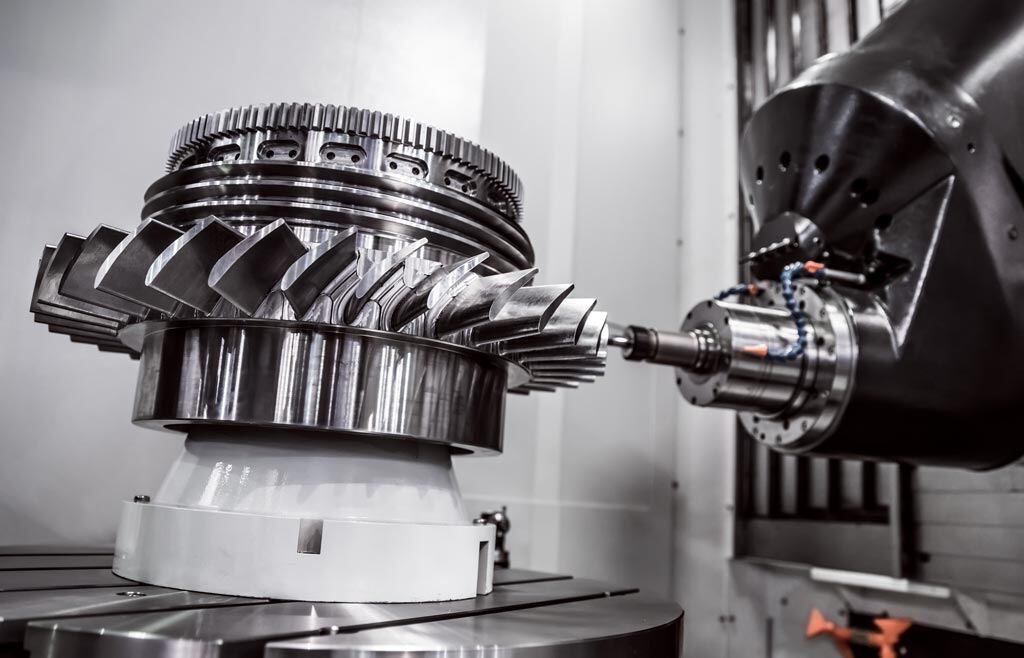

Manufacturing Insight: Cnc Machines Working

Precision CNC Machining Capabilities at Honyo Prototype

At Honyo Prototype, our advanced CNC machining services deliver exceptional precision and repeatability for complex metal and plastic components. We leverage state-of-the-art 3-axis, 4-axis, and 5-axis milling centers alongside high-speed turning centers to transform engineering designs into functional prototypes and low-to-mid-volume production parts. Our facility maintains tight tolerances down to ±0.005mm, ensuring dimensional accuracy critical for aerospace, medical, and industrial applications.

Material Expertise and Process Rigor

Our machining workflow supports a comprehensive range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steels (303, 316), titanium, brass, and engineering plastics like PEEK and Delrin. Each operation undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, adhering to ISO 9001 quality management standards. We optimize toolpaths for minimal cycle times without compromising surface finish or structural integrity, directly addressing your timeline and performance requirements.

Accelerate Your Project Timeline

Understanding the urgency of engineering development cycles, Honyo Prototype offers an Online Instant Quote system that provides transparent, detailed pricing in seconds. Upload your STEP or IGES file, specify material and quantity, and receive a manufacturability assessment alongside a formal quotation—eliminating days of procurement delays. This seamless integration of technical capability and digital efficiency ensures your project moves from design validation to physical part with unmatched speed.

Operational Transparency Through Technology

| Feature | Benefit to Client |

|---|---|

| Real-time Machining | Live progress tracking via secure client portal |

| Material Certification | Full traceability with mill test reports included |

| First Article Inspection | Comprehensive report with all critical dimensions |

We engineer solutions where precision meets agility, ensuring your CNC-machined components meet exact specifications while accelerating time-to-market. Initiate your next project with confidence through our integrated digital workflow.

Technical Capabilities

CNC Machine Technical Specifications for 3/4/5-Axis Milling and Turning – Focus on Tight Tolerance Applications

The following table outlines key technical specifications for CNC machining processes commonly used at Honyo Prototype for high-precision parts in aluminum, steel, ABS, and nylon. These capabilities support tight tolerance requirements typical in aerospace, medical, and industrial automation sectors.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A-axis (rotary around X) | X, Y, Z + A and B/C axes (dual rotary) | Primary Z and X axes, with optional C-axis for milling |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Typical Tolerance Range | ±0.010 mm (standard), down to ±0.005 mm (tight) | ±0.010 mm, down to ±0.005 mm | ±0.008 mm, down to ±0.003 mm | ±0.005 mm (diameter), ±0.010 mm (length) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (machined), down to 0.4 µm with polishing | 0.8 – 3.2 µm | 0.8 – 1.6 µm (complex contours) | 0.4 – 1.6 µm (turning), 0.8 – 3.2 µm (grooving/parting) |

| Spindle Speed (max) | 12,000 RPM (standard), up to 24,000 RPM (high-speed) | 12,000 RPM | 12,000 – 20,000 RPM | 4,000 – 6,000 RPM (chuck), up to 12,000 RPM (collet) |

| Spindle Power | 15 – 22 kW | 15 – 22 kW | 18 – 30 kW | 7 – 15 kW |

| Tool Capacity (ATC) | 20 – 30 tools | 24 – 30 tools | 30 – 60 tools | 8 – 12 tools (live tooling optional) |

| Work Envelope (Max Travel) | 760 x 460 x 510 mm | 760 x 460 x 510 mm + 360° A-axis | Varies by machine; typically 600 x 600 x 500 mm | Max swing: 300 mm, Max length: 500 mm |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6/66) | Same as 3-axis | Same as 3-axis, with enhanced capability for complex steel and nylon geometries | Aluminum, Steel, ABS (limited), Nylon (bar stock only) |

| Coolant System | Flood coolant standard, optional mist or through-spindle | Flood or high-pressure coolant | High-pressure or minimum quantity lubrication (MQL) | Flood coolant with chip conveyor |

| Control System | Fanuc, Siemens, or Heidenhain | Same as 3-axis | Siemens 840D, Fanuc 31i, or Heidenhain TNC7 | Fanuc or Siemens |

| Applications | Flat geometries, prismatic parts | Indexing features, undercuts | Complex contours, organic shapes, aerospace components | Cylindrical parts, shafts, bushings, fittings |

Notes on Material Machinability and Tight Tolerances:

Aluminum (6061, 7075): High machinability, excellent for high-speed 3–5-axis milling. Achieves tight tolerances with minimal thermal distortion. Commonly used in prototypes and lightweight structural components.

Steel (4140, 303/316 Stainless): Requires higher cutting forces and rigid setups. 5-axis milling enables complex features with tolerances down to ±0.005 mm. Turning provides excellent dimensional control for shafts and fittings.

ABS: Low melting point; requires sharp tools and moderate speeds. Best suited for 3-axis milling and simple turning. Tolerances typically held to ±0.025 mm due to thermal expansion.

Nylon (6, 66): Exhibits creep and moisture absorption. Machined dry or with air blast. Tight tolerances (±0.010 mm) achievable with stable fixturing and post-machining stabilization.

These specifications reflect Honyo Prototype’s capability to deliver precision-machined components across diverse materials and geometries, with documented process controls to ensure repeatability and conformance to tight tolerance requirements.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined CNC machining workflow designed to maximize efficiency, quality, and client transparency from initial design submission through to final shipment. This integrated process ensures manufacturability is prioritized while minimizing lead times and non-conformances.

The process initiates when a client uploads their native or neutral format CAD file (STEP, IGES, Parasolid, or native SOLIDWORKS/Inventor) to our secure customer portal. This triggers immediate ingestion into our proprietary AI-powered quoting engine. Unlike basic cost calculators, this system performs multi-dimensional analysis: it assesses geometric complexity, material utilization, required tooling, machine time estimation based on feature recognition, and preliminary tolerance feasibility against ISO 2768 standards. The output is a detailed technical quote within 2-4 business hours, including part-specific manufacturability flags and alternative material suggestions where applicable.

Upon quote acceptance and purchase order placement, the file enters our formal Design for Manufacturability (DFM) review stage. A dedicated manufacturing engineer conducts a hands-on analysis using Mastercam and CAMWorks software, scrutinizing wall thicknesses, hole depths, undercuts, surface finish requirements, and datum structure. Critical to this phase is the collaborative dialogue; engineers proactively contact clients to resolve borderline geometries, suggest cost-saving modifications like chamfer substitutions for sharp corners, or recommend post-processing optimizations. All DFM findings and client-approved changes are documented in a secure revision-controlled folder accessible to the client.

Approved designs transition directly to production planning. Our scheduling system assigns jobs to optimal CNC resources within our facility—prioritizing 3-axis, 4-axis, or 5-axis HURCO, HAAS, or DMG MORI machines based on part complexity and material (aluminum 6061-T6, stainless 304/316, titanium, engineering plastics). Each job receives a unique work order triggering automated material kitting from our climate-controlled stock. Machining occurs under strict ISO 9001:2015 protocols with real-time in-process inspections using Faro Arms and Mitutoyo CMMs at predefined checkpoints. Secondary operations like tapping, deburring, or heat treatment are sequenced within the same workflow without external handoffs.

Final quality validation occurs against the original CAD model via full-spectrum CMM reports and first-article inspection (FAI) documentation per AS9102 where required. Parts undergo ultrasonic cleaning and passivation (for stainless) before vacuum-sealed ESD-safe packaging with desiccant. Our logistics team coordinates global shipments via DHL, FedEx, or client-specified carriers, providing real-time tracking and customs documentation. Every shipment includes certified material test reports (MTRs), dimensional reports, and a traceable production certificate linking the physical part to its digital manufacturing record.

The following table summarizes key phase durations for standard CNC projects:

| Process Phase | Typical Duration | Key Outputs |

|---|---|---|

| CAD Upload to AI Quote | 2-4 business hours | Technical quote, DFM preliminary flags |

| DFM Review & Approval | 1-3 business days | Approved drawing, modification log |

| Production | 3-10 business days | In-process inspection records, MTRs |

| Quality & Delivery | 1-2 business days | Final inspection report, shipment docs |

This closed-loop methodology ensures that Honyo Prototype delivers precision CNC machined components with demonstrable process control, reducing time-to-market while maintaining rigorous quality standards expected in aerospace, medical, and industrial sectors. Client access to real-time production dashboards provides full visibility without disrupting manufacturing flow.

Start Your Project

See our CNC machines in action at our Shenzhen factory and discover how Honyo Prototype delivers precision manufacturing for your prototyping and production needs.

Contact Susan Leo to request a live factory tour or receive sample work documentation.

Email: [email protected]

Let’s discuss your next project with real-time support from our engineering team.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.