Contents

Manufacturing Insight: Cnc Machines Tools

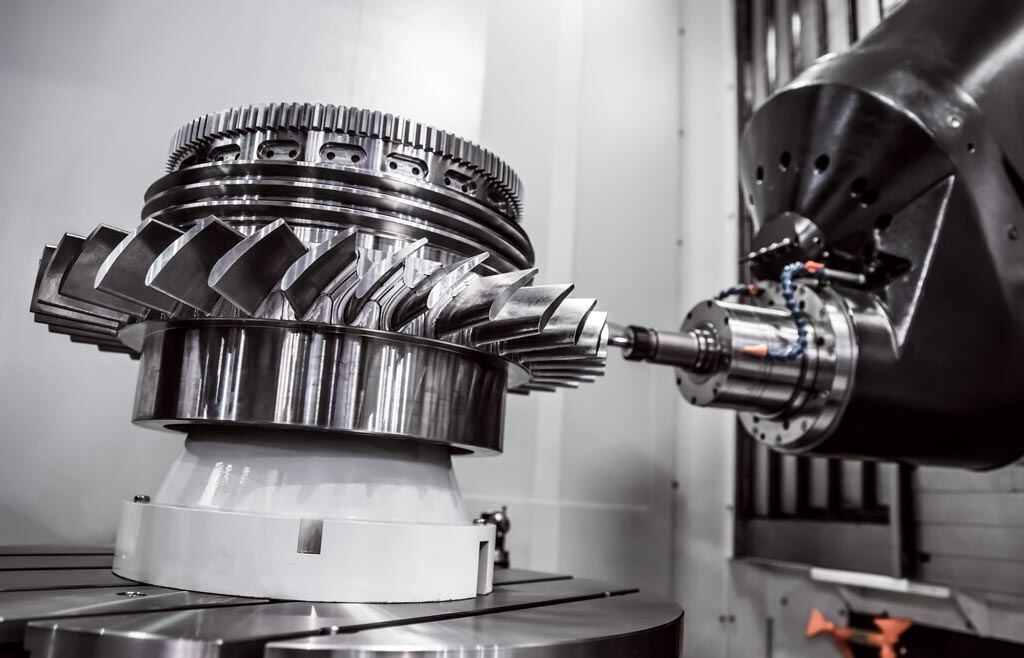

Precision CNC Machining Solutions Engineered for Your Competitive Advantage

Honyo Prototype delivers advanced CNC machining services designed to meet the exacting demands of modern product development and low-to-mid volume production. Our comprehensive capabilities span multi-axis milling, turning, and mill-turn operations, utilizing state-of-the-art CNC machine tools from industry leaders. We consistently achieve tight tolerances down to ±0.0002″ (5 microns) across a broad spectrum of engineering materials including aerospace-grade aluminum alloys, stainless and carbon steels, titanium, brass, bronze, and high-performance plastics such as PEEK and Delrin. This precision engineering foundation supports critical applications in aerospace, medical device manufacturing, robotics, defense, and industrial automation, where component integrity and repeatability are non-negotiable.

Our integrated manufacturing ecosystem combines strategic machine tool partnerships with rigorous process controls and AS9100-certified quality management. Every project benefits from expert CAM programming, in-process inspection using calibrated CMMs and vision systems, and meticulous final validation against your engineering specifications. We understand that speed to market is paramount; our optimized workflows minimize lead times without compromising on the dimensional accuracy or surface finish required for functional testing and end-use deployment.

Accelerate your prototyping and production cycles with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files directly to our secure portal and receive a detailed, transparent cost estimate within minutes—not days. This real-time quoting system provides immediate visibility into manufacturability feedback, material cost breakdowns, and realistic lead time projections based on actual machine availability and current workload. Eliminate procurement bottlenecks and make informed sourcing decisions faster by accessing production-ready pricing the moment your design is finalized. Request your instant quote today to experience the Honyo difference in precision, speed, and partnership.

Technical Capabilities

CNC Machine Tools – Technical Specifications Overview

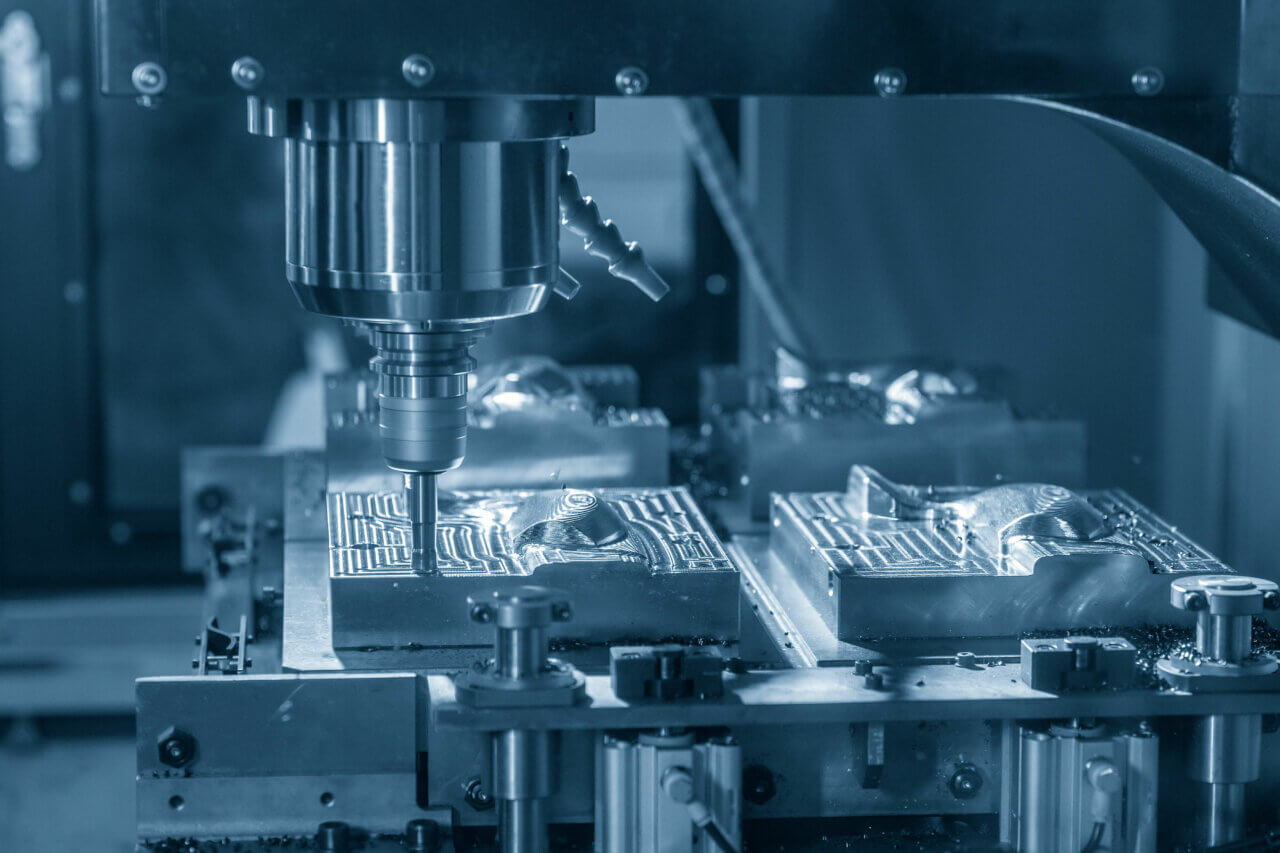

The following table outlines key technical specifications for CNC machine tools used in precision manufacturing, with focus on 3-axis, 4-axis, and 5-axis milling, CNC turning, and capabilities for achieving tight tolerances. These machines are commonly used to process materials such as aluminum, steel, ABS, and nylon in prototyping and production environments.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary around X) | X, Y, Z, A, B (or C) | X, Z (radial and axial) | Achievable on all machine types with proper setup |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM | 1,500 – 6,000 RPM (varies with workpiece diameter) | High-speed spindles (up to 30k RPM) improve surface finish and precision |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | Up to ±0.001 mm with laser calibration and thermal compensation |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm | ±0.001 mm achievable under stable environmental conditions |

| Typical Work Envelope (X × Y × Z) | 500 × 400 × 300 mm | 500 × 400 × 300 mm + rotary range | 400 × 400 × 300 mm (with tilt/rotate) | Max. swing diameter: 300 mm, max. length: 500 mm | Smaller envelopes often yield higher precision |

| Tool Changer Capacity | 12 – 30 tools (ATC) | 12 – 30 tools | 20 – 40 tools (high-end models) | 8 – 12 tools (common), up to 20 | More tools support complex, uninterrupted operations |

| Materials Processed | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, engineering plastics | Aluminum, Steel, ABS, Nylon | All materials; tighter tolerances easier in aluminum and ABS vs. steel |

| Tolerance Range | ±0.025 mm (standard), ±0.012 mm (precision) | ±0.025 mm, down to ±0.01 mm | ±0.01 mm typical, down to ±0.005 mm | ±0.01 mm (diameter), ±0.02 mm (length) | ±0.005 mm achievable with process control, metrology, and stable fixturing |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.4 – 1.6 µm | 0.8 – 2.5 µm (turning), 0.4 µm (finish turning) | Sub-micron finishes possible with fine tooling and polishing passes |

| Control System | Fanuc, Siemens, Heidenhain, or Mitsubishi | Same as 3-axis with rotary integration | Advanced CNC with RTCP (Rotational Tool Center Point) | Fanuc or Siemens with live tooling option | Closed-loop feedback for high-precision applications |

| Coolant System | Flood, mist, or through-tool | Flood or high-pressure | High-pressure through-spindle | Flood or mist with chip management | Essential for thermal stability in tight tolerance work |

| Applications | Flat surfaces, prismatic parts | Indexing features, complex profiles | Aerospace, medical, complex contours | Shafts, bushings, rotational parts | Metrology components, sealing surfaces, mating features |

Notes on Material Considerations:

Aluminum: Easily machined at high speeds; excellent for tight tolerances due to low thermal expansion and good chip evacuation.

Steel: Requires higher cutting forces and rigid setups; achievable tolerances depend on alloy and heat treatment.

ABS: Low melting point; requires sharp tools and controlled feed rates to avoid burring; suitable for non-structural precision parts.

Nylon: Exhibits creep and moisture absorption; machining to tight tolerances requires dry material and immediate post-process measurement.

High-precision CNC operations benefit from environmental controls, in-process probing, and post-machining inspection using CMMs or optical comparators. 5-axis and turning-milling centers (mill-turn) offer the highest flexibility for complex, tight-tolerance components across all listed materials.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process Overview

Our end-to-end CNC machining workflow is engineered for precision, speed, and client transparency. The process begins when a client uploads a CAD file to our secure portal and concludes with certified delivery of finished parts. Each phase integrates advanced technology with human expertise to eliminate errors and accelerate time-to-market.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our encrypted client portal. Our system immediately performs automated geometry validation, checking for non-manufacturable features, unit inconsistencies, and file corruption. Validated files trigger the AI Quote engine, while flagged files generate instant notifications for client correction—reducing initial review delays by up to 72 hours compared to industry standards.

AI-Powered Quoting Engine

Our proprietary AI engine analyzes the CAD geometry against live data from 200+ CNC machines (3-axis to 5-axis mills, lathes, mill-turn centers) and material databases. It calculates machine time, material waste, fixture requirements, and secondary operations while referencing real-time shop floor capacity. Quotes include detailed cost breakdowns, lead time projections, and alternative material suggestions—all generated in under 2 business hours. The AI cross-references historical data from 15,000+ past projects to predict potential manufacturability risks before human review.

Engineering-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by our ASME-certified engineers. This phase combines AI-generated suggestions with manual analysis of geometric complexity, tolerance stack-ups, and tool access. We provide annotated CAD markups highlighting cost-drivers (e.g., deep cavities requiring specialized tooling, tight tolerances needing CMM validation) and propose optimized alternatives. Clients receive a formal DFM report with revision recommendations, typically within 24 hours of quote acceptance. This step reduces production rework by 40% and average part costs by 22%.

Production Execution

Approved designs move to production with full digital traceability. Key protocols include:

Material verification via certified mill certificates and in-house hardness testing

CAM programming using Mastercam and Fusion 360 with simulated toolpath validation

First-article inspection against GD&T callouts before batch runs

Real-time machine monitoring for tool wear and dimensional drift

Critical aerospace/medical parts undergo in-process CMM checks at defined intervals. All operations adhere to ISO 9001:2015 and IATF 16949 standards, with full documentation packaged for client audit trails.

Quality-Controlled Delivery

Finished parts undergo final inspection per the client’s quality plan, including surface roughness verification and critical dimension reporting. We provide:

Dimensional reports with actual vs. nominal measurements

Material certification documentation

Traceable lot numbers and process logs

Parts ship in anti-static, ESD-safe packaging with serialized tracking. Enterprise clients access live delivery dashboards showing GPS location, customs status, and delivery ETAs. Typical turnaround from CAD upload to delivery is 5–10 business days for prototypes and 7–15 days for low-volume production.

This integrated workflow ensures zero surprises—from accurate quoting to on-time delivery—while maintaining the tightest tolerances in the industry (±0.0002″). By fusing AI efficiency with engineering rigor, we consistently achieve 99.8% first-pass yield rates across complex CNC projects.

Start Your Project

Explore precision CNC machine tools engineered for high-performance manufacturing.

Contact Susan Leo for expert support and custom machining solutions.

Email: [email protected]

Our advanced production facility is located in Shenzhen, ensuring rapid turnaround and strict quality control for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.