Contents

Manufacturing Insight: Cnc Machines Net

Honyo Prototype: Precision CNC Machining Delivered at Prototype Speed

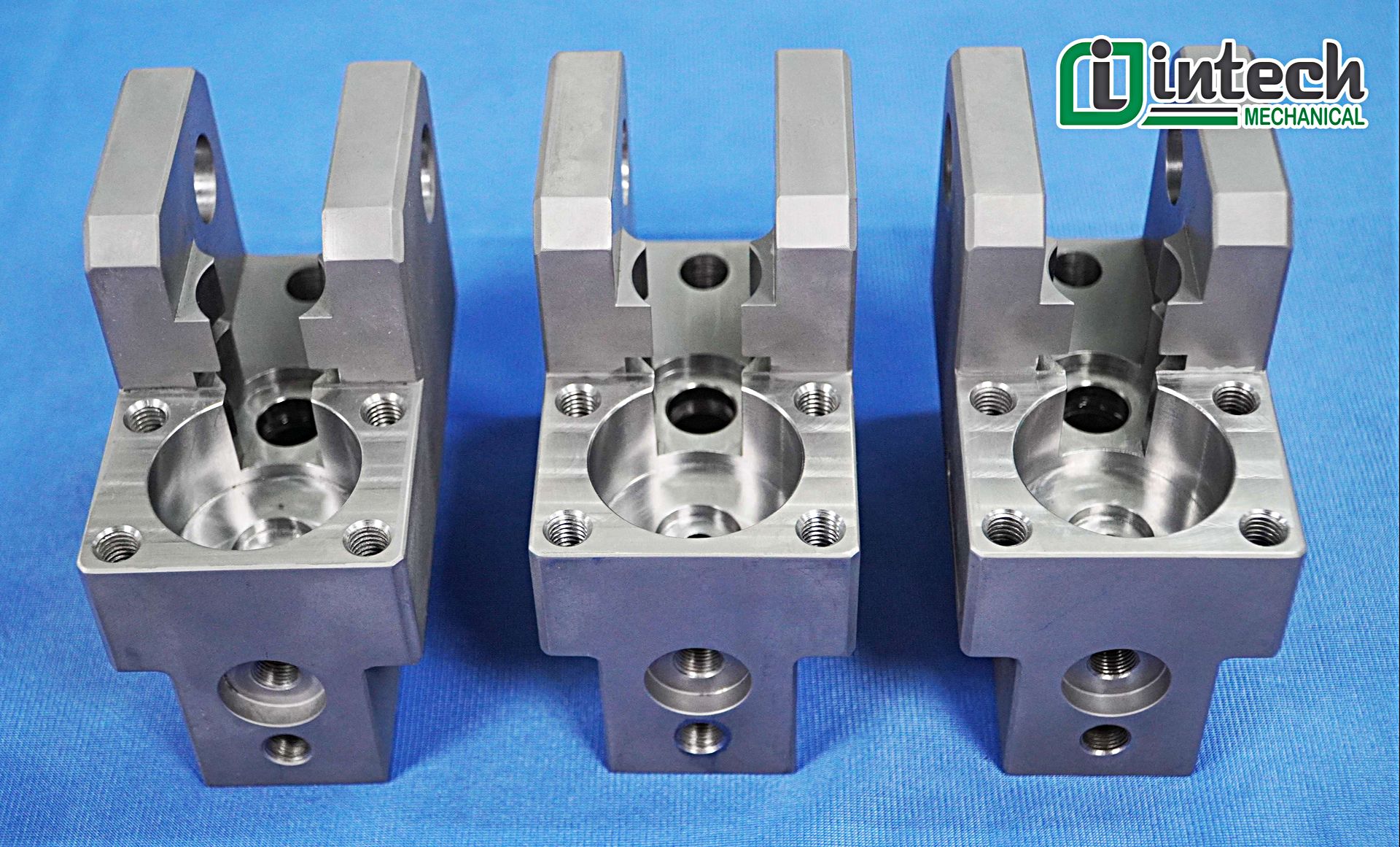

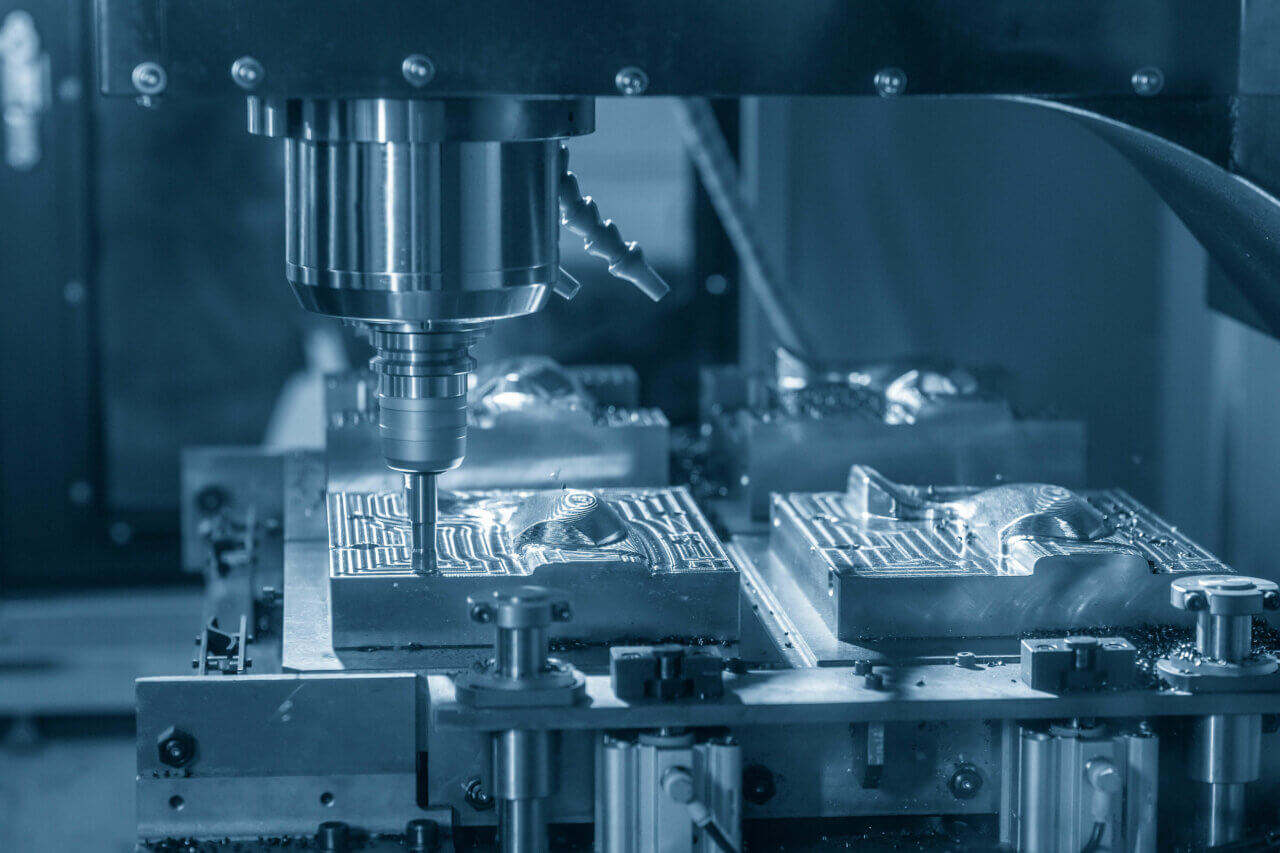

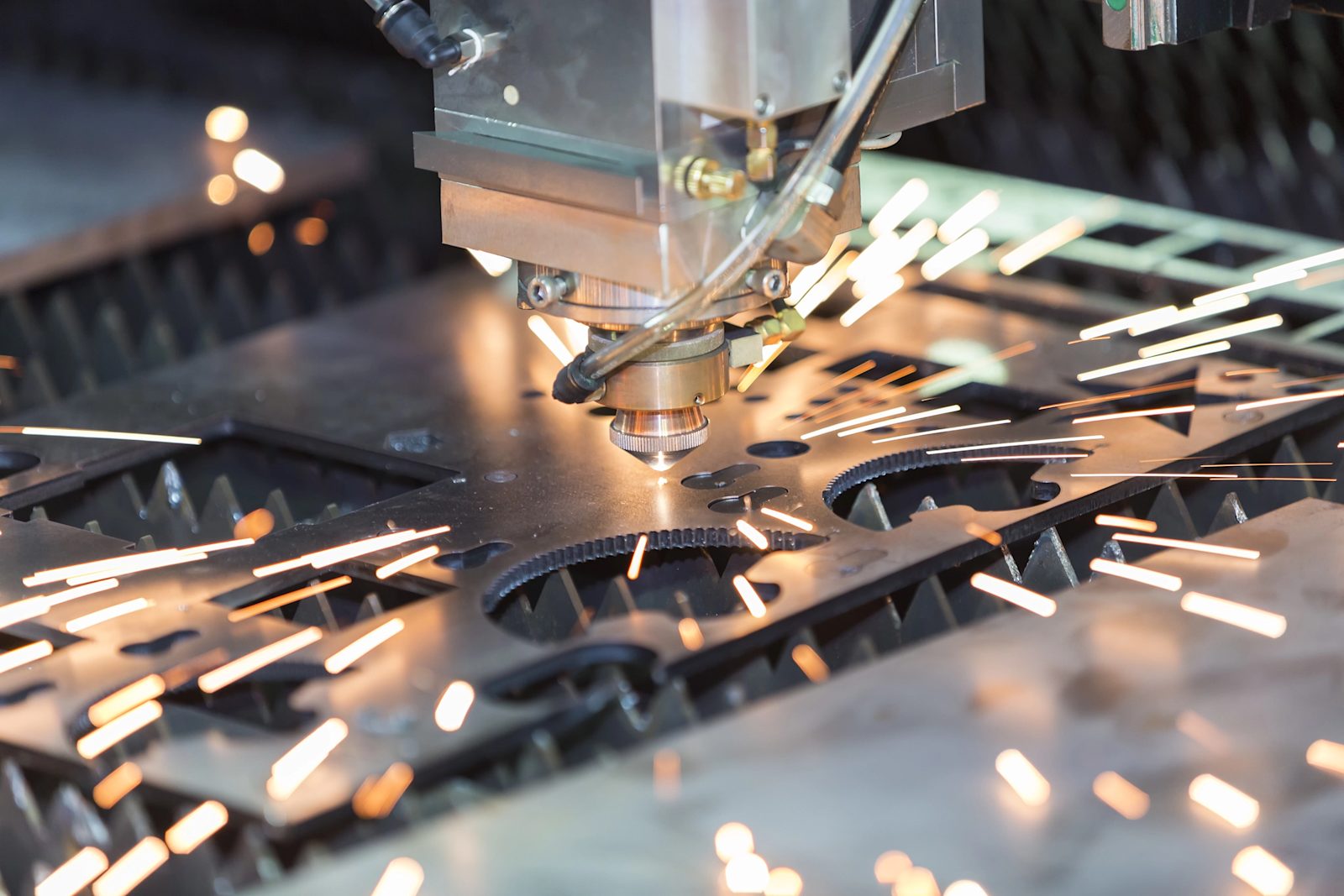

At Honyo Prototype, we understand the critical role rapid, high-precision CNC machining plays in accelerating your product development and low-volume production cycles. As your dedicated manufacturing partner, we leverage state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers to transform complex engineering designs into functional, production-intent components with exceptional accuracy and repeatability. Our focus is squarely on meeting the demanding requirements of engineers and procurement professionals who require parts faster without compromising on quality, utilizing materials ranging from aerospace-grade aluminum and stainless steel to engineering plastics and titanium.

Our comprehensive CNC machining services are engineered for efficiency, supporting tight tolerances down to ±0.0002 inches and complex geometries essential for demanding applications across aerospace, medical, robotics, and industrial equipment sectors. We integrate rigorous quality control processes, including in-process inspection and final CMM reporting, ensuring every component adheres to your exact specifications and industry standards. This commitment to precision manufacturing minimizes iteration cycles and reduces time-to-market for your critical projects.

Eliminate procurement delays and streamline your sourcing workflow with Honyo’s industry-leading Online Instant Quote system. Simply upload your CAD file directly to our platform, specify your material, quantity, and finish requirements, and receive a detailed, transparent cost estimate and lead time within seconds – not days. This powerful tool provides immediate budgetary clarity and project feasibility assessment, empowering your team to make faster, data-driven decisions. Experience the Honyo advantage: where advanced CNC capabilities meet unparalleled speed in quotation and delivery, dedicated to keeping your innovation moving forward. Request your instant quote today to see the difference precision manufacturing should make.

Technical Capabilities

CNC Machines Net provides high-precision computer numerical control (CNC) machining solutions designed for demanding industrial applications. The systems specialize in 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, with an emphasis on tight-tolerance production for prototyping and low-to-mid volume manufacturing. These machines support a wide range of engineering materials including aluminum, steel, ABS, and nylon, ensuring versatility across aerospace, automotive, medical, and industrial sectors.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z (with optional C-axis) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.003 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.002 mm | ±0.001 mm |

| Spindle Speed (RPM) | Up to 15,000 | Up to 15,000 | Up to 18,000 | Up to 6,000 |

| Tool Changer | Optional (ATC available) | Optional (ATC available) | Standard (16–30 tool pockets) | Optional (bar feeders) |

| Max Work Envelope (mm) | 760 x 460 x 460 | 760 x 460 x 460 + 360° A-axis | 600 x 500 x 400 | Ø300 x 500 length |

| Tolerance Capability | ±0.01 mm (standard) | ±0.01 mm | ±0.005 mm (tight tolerance) | ±0.005 mm (diameter) |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.4 – 1.6 µm |

| Supported Materials | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Coolant System | Flood, mist, or air cooling | Flood or mist cooling | High-pressure flood cooling | Flood cooling standard |

| Control System | Fanuc, Siemens, or Heidenhain | Fanuc, Siemens, or Heidenhain | Heidenhain or Siemens | Fanuc or Mitsubishi |

| Typical Applications | Flat parts, housings, plates | Indexing complex features | Aerospace components, molds | Shafts, pins, bushings |

Material compatibility is rigorously maintained across all platforms. Aluminum (6061, 7075) and steel (1018, 4140, stainless) are processed with optimized feeds and speeds to maintain dimensional stability and surface integrity. Engineering thermoplastics such as ABS and nylon are machined with specialized tooling and reduced thermal input to prevent deformation. All machines are calibrated for thermal compensation and vibration damping to ensure tight tolerance consistency across production runs.

From CAD to Part: The Process

Honyo Prototype’s CNC machining workflow integrates advanced digital tools with rigorous engineering oversight to ensure precision, speed, and cost efficiency for prototype and low-volume production. Our five-stage process begins with CAD file upload and concludes with certified delivery, systematically de-risking each phase while maintaining tight tolerances and material integrity.

Upon receiving a client’s CAD file (STEP, IGES, or native formats), our proprietary AI quoting engine performs an immediate preliminary analysis of geometric complexity, material selection, and basic manufacturability. This generates a preliminary cost and timeline estimate within 15 minutes. Crucially, this AI output is not a final quote but a foundation for human engineering review. A dedicated Manufacturing Engineer validates the AI assessment, cross-referencing real-time machine availability, tooling constraints, and secondary operation requirements to issue a binding quotation with guaranteed lead times.

The Design for Manufacturability (DFM) phase is where Honyo adds significant value through iterative collaboration. Our engineers conduct a comprehensive tolerance stack-up analysis, identifying potential issues such as thin walls below 0.5mm, undercuts requiring specialized tooling, or surface finish conflicts. Unlike automated DFM checkers, we provide actionable redesign suggestions via secure client portal comments—often resolving 70% of issues before production begins. Critical DFM parameters we validate include:

| Parameter | Standard Capability | Precision Capability | Risk Mitigation Action |

|---|---|---|---|

| Minimum Feature Size | 0.8mm | 0.3mm (with micro-milling) | Suggest geometry consolidation |

| Positional Tolerance | ±0.05mm | ±0.01mm | Recommend datum alignment strategy |

| Surface Roughness | Ra 3.2μm | Ra 0.8μm | Specify toolpath optimization |

| Max Work Envelope | 1000x600x500mm | 500x400x300mm (high-precision) | Propose part segmentation |

Production leverages our network of 47 HAAS and DMG MORI CNC centers, each equipped with Renishaw probes for in-process verification. Every run begins with first-article inspection against the original CAD model using CMM or optical scanning. We implement dynamic toolpath adjustments based on real-time vibration monitoring to prevent chatter marks on critical surfaces. For multi-axis work, we enforce strict work-holding protocols to eliminate repositioning errors—documented in our internal production logs accessible to clients.

Delivery encompasses more than physical shipment. Each order includes a full quality dossier: CMM inspection reports traceable to NIST standards, material certs with lot numbers, and a final DFM closure report confirming all flagged items were resolved. Parts ship in custom anti-static packaging with environmental monitoring tags for sensitive applications. Our logistics team coordinates customs documentation for global clients, maintaining a 98.7% on-time delivery rate for international shipments. This closed-loop process—where DFM insights feed continuous improvement into quoting algorithms—reduces average CNC prototyping lead time to 72 hours while achieving 99.2% first-pass yield rates across aluminum, steel, and engineering plastics.

Start Your Project

Interested in high-precision CNC machining services? Contact Susan Leo at [email protected] to discuss your next project.

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, providing advanced CNC machining solutions for industries worldwide. From rapid prototyping to low-volume production, our capabilities ensure fast turnaround, tight tolerances, and consistent quality.

Reach out today to request a quote or learn more about how our CNC machines can support your engineering and manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.