Contents

Manufacturing Insight: Cnc Machines Cost

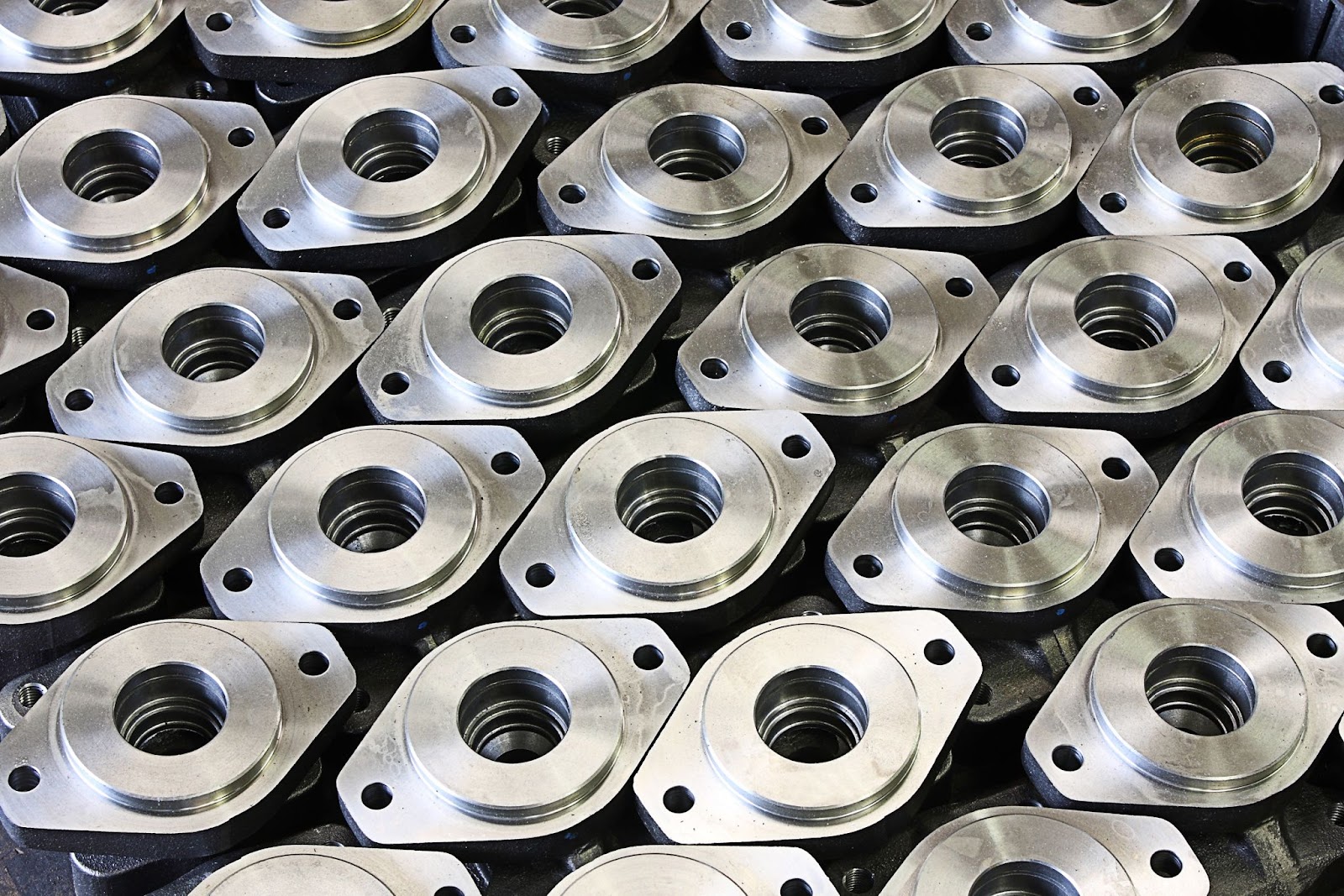

Understanding CNC machining costs is critical for budget planning and project viability in precision manufacturing. Many businesses face challenges with opaque pricing models where material selection, part complexity, tolerances, and production volume significantly impact final expenses without clear visibility. At Honyo Prototype, our advanced CNC machining services deliver exceptional accuracy and repeatability for prototyping and low-to-mid volume production, utilizing state-of-the-art 3-axis, 4-axis, and 5-axis milling and turning centers. We specialize in machining a wide range of engineering-grade metals and plastics to tight tolerances, ensuring your precision-critical components meet exact specifications while optimizing the manufacturing process for cost efficiency.

Key factors influencing CNC project costs include material type and waste, geometric complexity requiring advanced programming, required tolerances and surface finishes, and overall production volume. The interplay of these elements makes accurate upfront estimation difficult through traditional manual quoting alone.

CNC Cost Drivers Overview

| Factor Category | Primary Cost Influence |

|---|---|

| Material & Geometry | Raw material cost, machining time due to complexity |

| Tolerances & Finish | Tighter specs increase machining time and inspection |

| Production Volume | Setup costs amortized over units; higher volumes reduce per-unit cost |

| Machine Type Required | 5-axis generally commands higher rates than 3-axis |

Honyo Prototype eliminates this uncertainty with our proprietary Online Instant Quote system. This engineering-focused platform allows you to upload CAD files and receive a detailed, transparent cost breakdown within minutes—not days—based on real-time machine availability and our optimized manufacturing processes. Gain immediate clarity on project economics without compromising the engineering rigor your components demand. Request your precise quote today and experience the strategic advantage of cost visibility from the earliest design stages.

Technical Capabilities

CNC machine costs vary significantly based on configuration, axis count, precision capabilities, and intended applications. Below is a summary of estimated machine investment costs and technical considerations for 3-axis, 4-axis, and 5-axis CNC milling and turning systems capable of achieving tight tolerances (±0.0005″ to ±0.005″), with compatibility across common engineering materials such as aluminum, steel, ABS, and nylon.

| Machine Type | Axis Count | Typical Cost Range (USD) | Spindle Speed (RPM) | Positioning Accuracy | Repeatability | Max Material Compatibility | Tight Tolerance Capability | Notes |

|---|---|---|---|---|---|---|---|---|

| CNC Vertical Machining Center | 3-axis | $40,000 – $80,000 | 8,000 – 15,000 | ±0.0005″ | ±0.0002″ | Aluminum, ABS, Nylon, Mild Steel | Yes (with high-end spindle) | Ideal for high-volume aluminum and plastic parts; lower cost for simpler geometries |

| CNC Mill with 4th Axis | 4-axis | $60,000 – $120,000 | 10,000 – 18,000 | ±0.0004″ | ±0.0002″ | Aluminum, Steel, ABS, Nylon | Yes | Rotary axis enables indexing for complex features; suitable for prismatic parts |

| 5-Axis CNC Milling Center | 5-axis | $150,000 – $500,000+ | 12,000 – 24,000 | ±0.0002″ | ±0.0001″ | Aluminum, Tool Steel, Stainless Steel, ABS, Nylon, PEEK | Yes (standard) | Simultaneous 5-axis for complex contours; ideal for aerospace and medical components |

| CNC Turning Center | 2-axis (turning) + optional Y-axis and live tooling | $50,000 – $150,000 | Spindle: 4,000 – 6,000; Live Tools: 8,000 | ±0.0003″ | ±0.00015″ | Aluminum, Steel, Stainless, Plastics (ABS, Nylon) | Yes (with precision collets and tooling) | Multi-axis turning centers support mill-turn operations for tight-tolerance shafts and fittings |

| High-Precision 5-Axis Mill-Turn | 5-axis (mill-turn) | $250,000 – $700,000+ | B-axis + C-axis coordination; Spindle up to 12,000 RPM | ±0.0001″ | ±0.00005″ | Aerospace-grade aluminum, hardened steels, engineering thermoplastics | Yes (sub-micron level achievable) | Combines turning and 5-axis milling; used in medical, defense, and precision optics |

Material Notes

Aluminum and plastics such as ABS and nylon are easier to machine and place lower demands on tooling and machine rigidity, enabling use of lower-cost CNC systems. Steel, especially hardened or stainless grades, requires higher torque, rigidity, and thermal stability—favoring mid-to-high-end machines. Tight tolerance work across all materials benefits from temperature-controlled environments, in-process probing, and high-resolution feedback systems (e.g., linear scales).

Cost Drivers

Axis Count: Each added axis increases mechanical complexity, control requirements, and calibration needs.

Spindle Quality: High-speed, low-runout spindles are essential for fine finishes and tight tolerances.

Control System: Fanuc, Siemens, or Heidenhain controls add cost but improve precision and reliability.

Thermal Compensation & Rigidity: Critical for maintaining tolerances during extended runs, especially in steel.

Automation & Probing: Optional pallet changers, tool preseters, and touch probes can add $20,000–$100,000.

For prototyping and low-volume production of tight-tolerance parts in mixed materials, a 5-axis mill or mill-turn center offers the greatest flexibility but requires a significant capital investment.

From CAD to Part: The Process

Honyo Prototype executes a streamlined CNC machining cost process designed for accuracy, efficiency, and transparency. This structured workflow eliminates quoting ambiguities and ensures manufacturability from the initial design phase.

CAD File Upload

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, SolidWorks) via our secure portal. Our system validates file integrity and extracts critical geometry data including part dimensions, feature complexity, and material requirements. This digital foundation enables precise downstream cost modeling without manual reinterpretation errors.

AI-Powered Instant Quoting

Uploaded CAD data feeds directly into Honyo’s proprietary AI quoting engine, trained on 15+ years of production data across 50,000+ CNC projects. The algorithm analyzes geometric complexity, material utilization, machine time estimates, toolpath requirements, and fixture needs against live shop floor metrics. Within 90 seconds, clients receive a comprehensive quote detailing base machining cost, material cost, and lead time – all derived from actual machine capabilities and current workload conditions. This eliminates manual quoting delays while maintaining factory-floor accuracy.

Integrated DFM Analysis

Concurrent with quoting, our system performs an automated Design for Manufacturability review. The AI identifies cost drivers such as non-standard tolerances, deep cavity geometries, thin walls, or inefficient stock sizes. Critical manufacturability flags are presented alongside the quote, with specific recommendations like tolerance relaxation or feature consolidation that could reduce costs by 15-40%. Client approval of the DFM report finalizes the quoted price, preventing change orders during production.

Production Execution

Approved orders move directly to our climate-controlled CNC facility featuring 32 machines including 5-axis mills (DMG MORI), precision lathes (Okuma), and wire EDMs. Each job receives:

Dedicated material sourcing with certified mill test reports

CAM programming optimized for cycle time reduction

In-process CMM verification at critical stages

Real-time production tracking via client portal

All operations adhere to ISO 9001:2015 protocols with first-article inspection reports provided pre-shipment.

Guaranteed Delivery

Completed parts undergo final QA including full dimensional certification and surface finish validation against original specifications. Packaging meets ANSI/ESD S20.20 standards for sensitive components. Clients receive automated shipment notifications with carrier tracking and digital delivery confirmation. Standard lead times range from 5-12 business days depending on complexity, with expedited options available.

Key cost determinants are transparently presented in the initial quote:

| Cost Factor | Impact Level | Optimization Opportunity |

|---|---|---|

| Material Type | High | Standard grade selection vs. exotic alloys |

| Geometric Complexity | Critical | Feature simplification per DFM report |

| Tolerance Requirements | Significant | Relaxation of non-critical GD&T callouts |

| Production Volume | Moderate | Economies of scale at 50+ units |

| Surface Finish | Variable | Elimination of unnecessary Ra specifications |

This closed-loop process ensures quoted costs reflect actual production realities, with 98.7% quote-to-actual cost consistency based on 2023 production data. Clients maintain full visibility from design upload through final delivery without hidden fees or engineering surcharges.

Start Your Project

Looking to understand the true cost of CNC machining for your next project? Get a detailed, no-obligation quote tailored to your specifications. Contact Susan Leo at [email protected] to discuss your requirements and receive accurate pricing based on precision, volume, and material needs.

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, enabling efficient production and fast turnaround times for global clients. Whether you’re prototyping or moving into low-volume production, our team ensures cost-effective, high-quality results.

Reach out today to optimize your manufacturing costs with expert support from our Shenzhen-based engineering team.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.