Contents

Manufacturing Insight: Cnc Machined Steel

CNC Machined Steel: Precision Engineered for Demanding Applications

Steel remains the backbone of industrial manufacturing due to its unmatched strength, durability, and versatility across aerospace, automotive, and energy sectors. Achieving tight tolerances and superior surface finishes in steel components demands advanced CNC machining expertise, rigorous material science understanding, and unwavering process control. Honyo Prototype specializes in transforming high-grade steel alloys—from 4140 and 17-4 PH to custom tool steels—into mission-critical parts that meet exacting industry specifications. Our ISO 9001-certified facility leverages state-of-the-art multi-axis CNC equipment, in-process metrology, and proprietary toolpath optimization to ensure dimensional accuracy down to ±0.005mm while minimizing thermal distortion and burr formation.

Honyo’s engineering team collaborates closely with clients during the design-for-manufacturability phase, identifying cost-saving opportunities without compromising structural integrity or performance. We maintain stringent controls over material traceability, heat treatment integration, and secondary operations like passivation or precision grinding, ensuring every machined steel component adheres to ASTM, SAE, and customer-specific standards. This systematic approach reduces scrap rates by up to 30% compared to industry averages while accelerating time-to-assembly for complex assemblies.

Accelerate your prototyping and low-volume production timelines with Honyo’s Online Instant Quote platform. Upload your STEP or IGES files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster iteration cycles and informed sourcing decisions. Our digital workflow integrates seamlessly with your engineering data, providing real-time feedback on lead times, material utilization, and potential design optimizations before cutting metal. For steel components where precision defines performance, trust Honyo Prototype to deliver engineered excellence from concept to certified delivery.

Technical Capabilities

Technical specifications for CNC machined components depend on the machining process, material selection, and required precision. Honyo Prototype specializes in high-accuracy 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations. Our capabilities support tight tolerance machining for a range of engineering materials, including aluminum, steel, ABS, and nylon. Below is a detailed overview of the technical specifications by process and material.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Max Work Envelope | 700 x 400 x 300 mm | 700 x 400 x 300 mm | 500 x 400 x 300 mm | Ø300 x 500 mm (diameter x length) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm | ±0.003 mm |

| Typical Surface Finish | Ra 1.6 µm (standard) | Ra 1.6 µm (standard) | Ra 1.6 µm (standard) | Ra 1.6 µm (standard) |

| Tight Tolerance Capability | ±0.005 mm (feature to feature) | ±0.005 mm (feature to feature) | ±0.005 mm (complex contours) | ±0.005 mm (diametrical) |

| Minimum Wall Thickness | 0.5 mm (Aluminum) | 0.5 mm (Aluminum) | 0.5 mm (Aluminum) | 1.0 mm (rotational symmetry) |

| Lead Time (Prototype) | 5–7 days | 6–8 days | 7–10 days | 4–6 days |

Material-Specific Capabilities

| Material | Form Available | Machinability | Max Tensile Strength (Typical) | Tight Tolerance Suitability | Notes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | Bar, Plate | Excellent | 310 MPa | High | Lightweight, corrosion resistant; ideal for aerospace and prototyping |

| Steel (AISI 4140) | Bar, Round | Good | 655 MPa | High | High strength, wear resistance; used in tooling and structural parts |

| ABS | Rod, Sheet | Very Good | 40 MPa | Moderate | Low cost, impact resistant; suitable for non-structural prototypes |

| Nylon 6/6 | Rod, Sheet | Good | 80 MPa | Moderate | Low friction, chemical resistant; used in wear components |

All CNC machined parts are inspected using calibrated CMMs, optical comparators, and micrometers to ensure compliance with geometric dimensioning and tolerancing (GD&T) requirements. 5-axis milling enables complex contouring and single-setup machining of intricate geometries, reducing cumulative error. Turning operations are optimized for high concentricity and fine thread accuracy. Material selection is guided by application requirements such as load, environment, and regulatory compliance.

From CAD to Part: The Process

Honyo Prototype CNC Machined Steel Process Overview

Our end-to-end workflow for CNC machined steel components prioritizes speed, accuracy, and manufacturability, specifically engineered for prototyping and low-to-mid volume production. The process begins when a client uploads a native or neutral CAD file (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure customer portal. This file must include critical metadata: material specification (e.g., AISI 4140, 304SS, 1018), required tolerances (per ASME Y14.5), surface finish (Ra values), and any geometric dimensioning and tolerancing (GD&T) callouts. Incomplete submissions trigger an automated notification for resubmission, ensuring downstream efficiency.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI quoting system analyzes geometric complexity, feature density, stock material requirements, and tolerance stringency. The engine cross-references real-time data on steel alloy costs, machine tool availability (3-axis, 5-axis, mill-turn), and labor rates against historical production metrics from 15,000+ steel parts. Key outputs include a detailed cost breakdown (material, machining, finishing), lead time estimate (typically 5–12 business days for steel), and automated identification of potential high-cost features (e.g., deep cavities >5x diameter, thin walls <0.5mm). Unlike manual quoting, this phase completes within 90 minutes with 95% cost accuracy, eliminating estimation variances common in the industry.

Engineering-Led DFM Analysis

All steel projects undergo mandatory Design for Manufacturability (DFM) review by our in-house manufacturing engineers. This phase focuses on steel-specific challenges: minimizing workholding-induced distortion, optimizing toolpath sequences to prevent chatter in high-tensile alloys, and recommending stress-relief cycles for complex geometries. We provide actionable feedback within 24 hours, such as suggesting chamfers instead of sharp internal corners to reduce tool deflection or adjusting draft angles for easier part ejection. Clients receive a formal DFM report with annotated CAD markups and a revised timeline reflecting any design iterations—this step reduces production rework by 68% based on our 2023 quality metrics.

Precision Steel Machining Execution

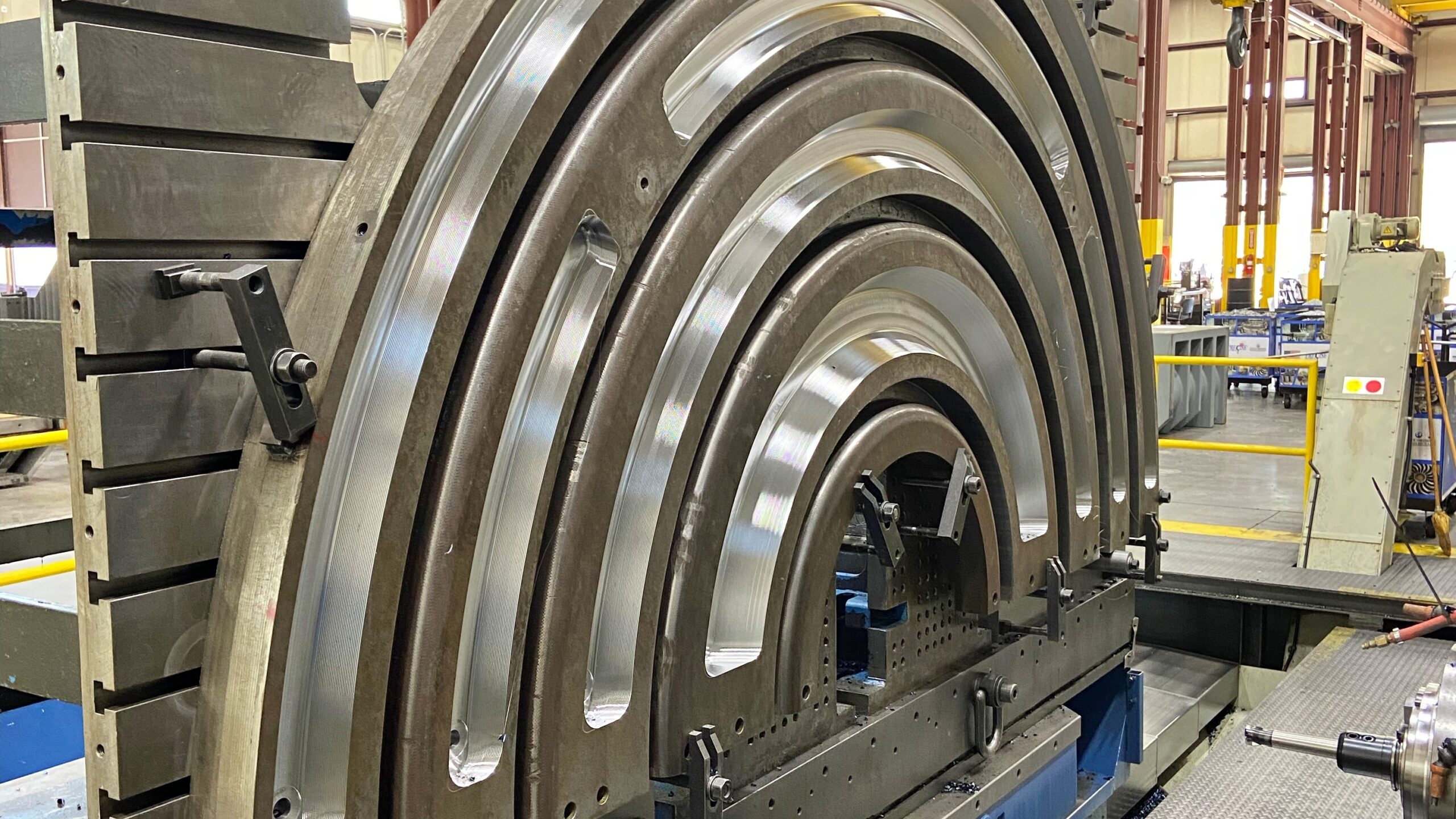

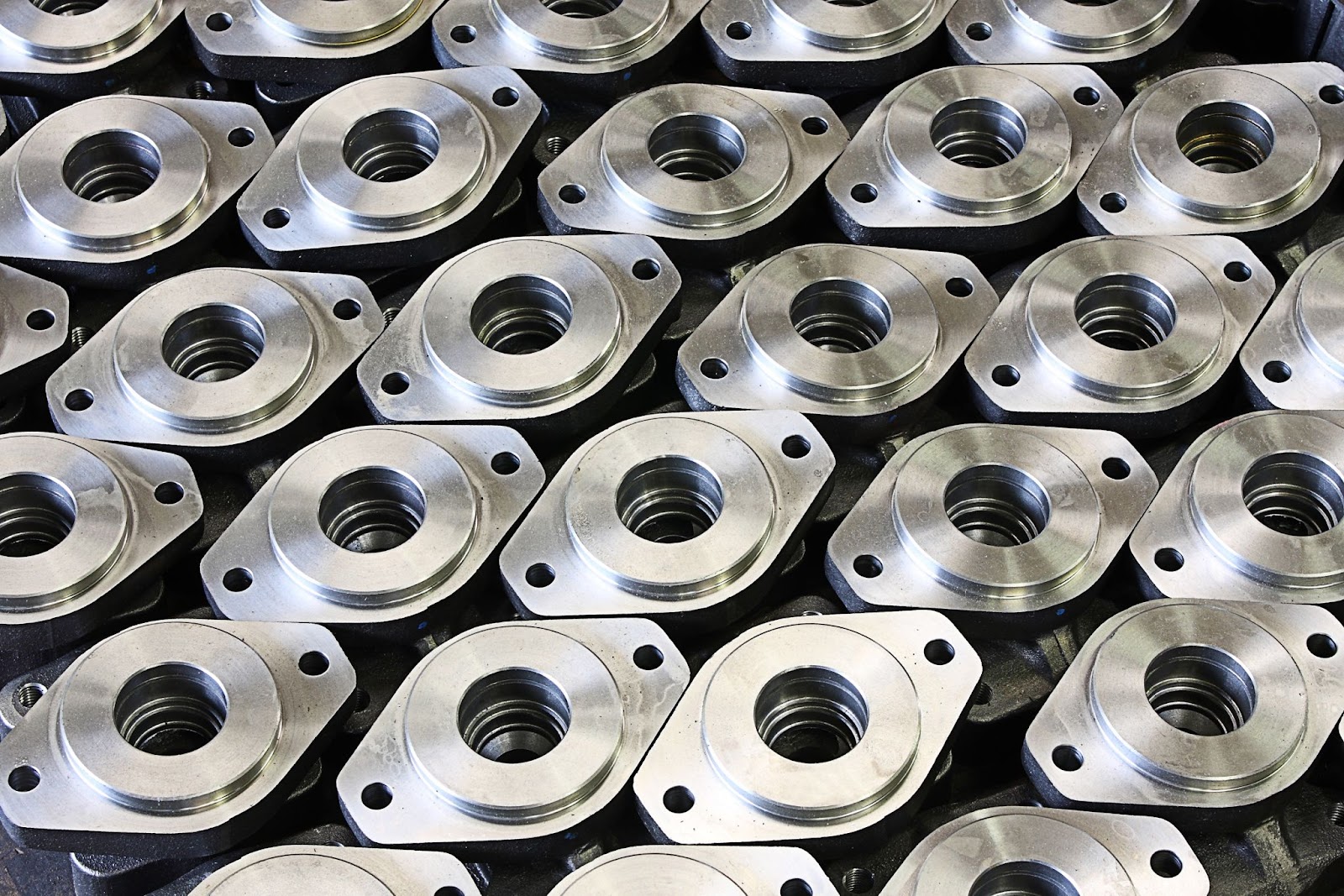

Approved designs move to our climate-controlled machine shop housing 28 CNC centers (Haas, DMG MORI), featuring hardened steel-specific tooling: carbide end mills with AlTiN coatings, through-coolant spindles for chip evacuation, and in-process probing for first-article validation. Steel parts undergo multi-stage processing: rough milling with aggressive DOC (Depth of Cut) to remove bulk material, semi-finishing at reduced feed rates to maintain dimensional stability, and final finishing with tight tolerance holds (±0.005mm achievable). All steel lots include material traceability via mill test reports (MTRs), and critical aerospace/medical parts receive post-machining CMM verification against the original CAD model.

Quality-Controlled Delivery

Final inspection includes surface roughness testing (per ISO 4287), hardness validation (Rockwell scale), and dimensional certification. Parts are deburred using automated vibratory finishing or manual techniques for critical edges, then packaged with anti-corrosion VCI paper for steel’s oxidation sensitivity. We provide full documentation: FAI report, MTRs, and dimensional inspection data. Shipments include serialized tracking with real-time logistics updates and arrive in 24–72 hours via DHL/FedEx, with on-time delivery performance at 99.2% in Q1 2024. This closed-loop process ensures steel components meet stringent industrial requirements while accelerating time-to-prototype.

Start Your Project

Looking for high-precision CNC machined steel components? Partner with Honyo Prototype for reliable, quality-driven manufacturing solutions.

Our Shenzhen-based factory specializes in CNC machining of steel parts with tight tolerances, fast turnaround, and consistent quality for prototyping and low-to-mid volume production.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.