Contents

Manufacturing Insight: Cnc Machined Part Price

Precision CNC Machined Part Pricing Starts with Transparency

Accurate and competitive pricing for CNC machined components remains a critical challenge in rapid prototyping and low-volume production. At Honyo Prototype, we eliminate quoting ambiguity through engineering-driven cost modeling and deep process expertise. Our vertical integration across multi-axis milling, turning, and Swiss machining ensures optimal resource allocation for every part, directly influencing cost efficiency without compromising on tolerances as tight as ±0.005mm or material versatility from aluminum 6061 to medical-grade PEEK.

Online Instant Quote: Real Pricing in 90 Seconds

Honyo’s proprietary Online Instant Quote platform delivers firm, no-obligation pricing within minutes—no sales calls or email delays. Simply upload your STEP or IGES file, specify material and quantity, and our system analyzes geometric complexity, machine time, and finishing requirements against live shop floor data. This transparency accelerates your design-for-manufacturability decisions and procurement workflow, turning RFQ uncertainty into actionable project timelines.

Engineered for reliability, validated by ISO 9001-certified processes, and backed by 15+ years in precision manufacturing, Honyo transforms CNC pricing from a barrier into a strategic advantage. Start your quote today and experience how technical rigor meets commercial clarity.

Technical Capabilities

CNC machined part pricing is influenced by several technical and operational factors, particularly when utilizing 3-axis, 4-axis, or 5-axis milling processes, CNC turning, and when tight tolerances are required. Key variables include machine complexity, setup time, cycle time, material type, and precision demands. Below is a detailed breakdown of how these factors impact cost across common engineering materials such as Aluminum, Steel, ABS, and Nylon.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance (±0.001″ or ±0.025 mm) |

|---|---|---|---|---|---|

| Base Complexity | Low | Medium | High | Low to Medium | High |

| Setup Time | Short | Moderate | Long | Short | Extended (alignment, inspection) |

| Machine Hourly Rate | $70–$90 | $90–$120 | $120–$180 | $60–$85 | Add $20–$50/hr for precision tooling |

| Cycle Time Influence | Low | Moderate | High (optimized tool paths) | Low | Increased (slower feeds/speeds) |

| Material: Aluminum (6061, 7075) | $80–$110 per hour | $110–$140 per hour | $140–$190 per hour | $70–$95 per hour | +15–25% cost increase |

| Material: Steel (1018, 4140) | $90–$130 per hour | $130–$160 per hour | $160–$210 per hour | $85–$110 per hour | +20–30% cost increase |

| Material: ABS (Thermoplastic) | $60–$80 per hour | $80–$100 per hour | $100–$130 per hour | $55–$75 per hour | +10–20% cost increase (chatter control) |

| Material: Nylon (PA6, PA66) | $65–$85 per hour | $85–$110 per hour | $110–$140 per hour | $60–$80 per hour | +15–25% cost increase (dimensional stability) |

| Tolerance Impact | Standard: ±0.005″ | ±0.003″ achievable | ±0.001″ with calibration | ±0.002″ typical | Requires CMM inspection (+$50–$150/setup) |

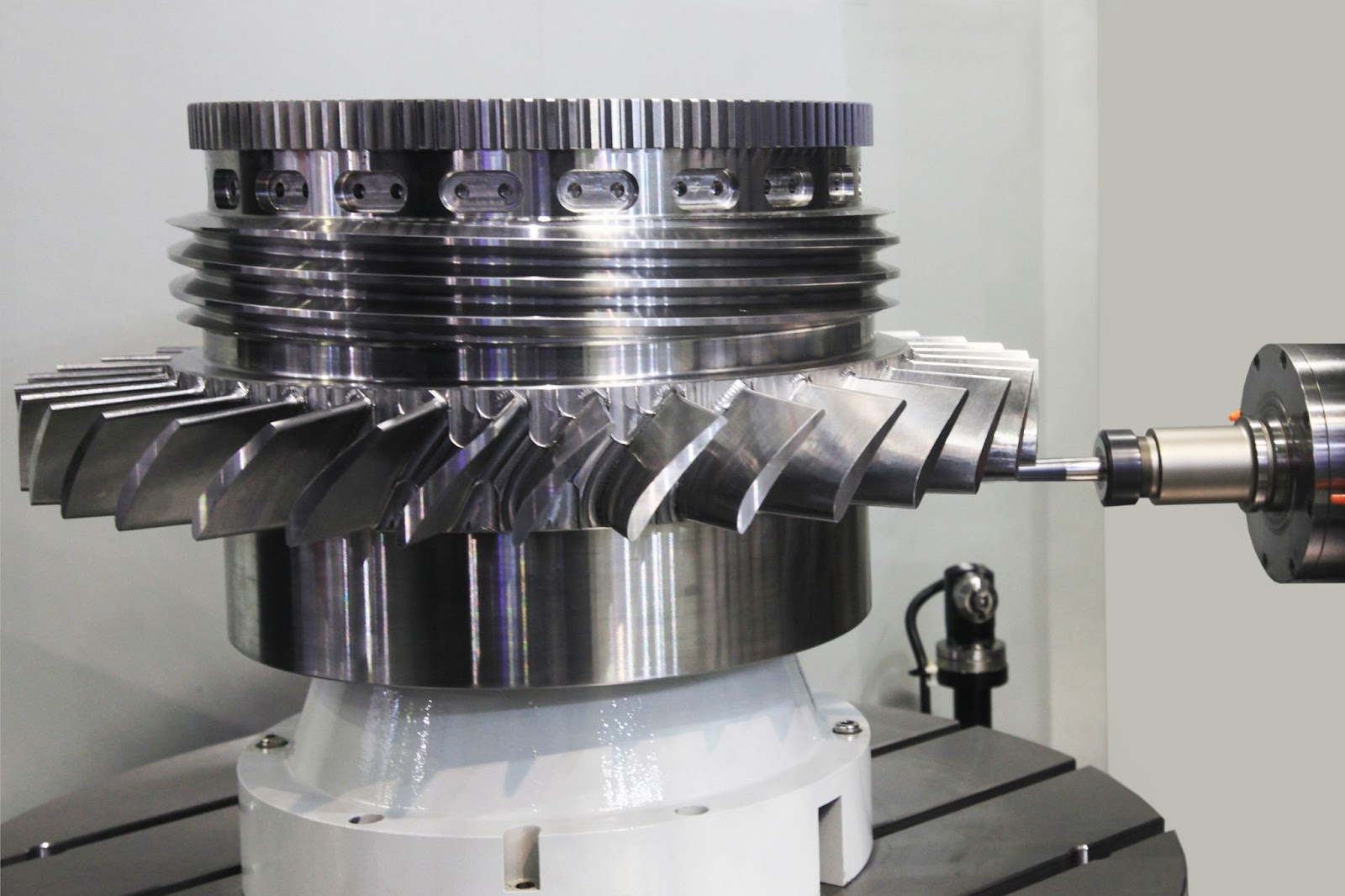

| Typical Applications | Brackets, housings | Indexing features | Aerospace, complex contours | Shafts, bushings | Medical, aerospace, precision gears |

Notes:

5-axis milling reduces need for multiple setups, lowering labor but increasing machine cost.

Tight tolerances require high-precision tooling, environmental control, and post-process inspection, significantly increasing unit cost.

Non-metallic materials like ABS and Nylon are less expensive to machine than metals but require careful fixturing and speed control to avoid deformation.

Steel incurs higher tool wear and slower cutting speeds, increasing machining time and cost compared to aluminum.

Prototyping or low-volume production amplifies setup cost per unit; high volume improves cost efficiency.

From CAD to Part: The Process

Honyo Prototype CNC Machined Part Pricing Process Overview

Honyo Prototype delivers rapid, transparent pricing for CNC machined parts through an integrated digital workflow. Our process eliminates traditional quoting delays while ensuring manufacturability and cost efficiency. Below is a detailed explanation of each phase, emphasizing technical execution and value drivers.

CAD Upload and Initial Processing

Customers upload native CAD files (STEP, IPT, SLDPRT, or Parasolid formats) via our secure client portal. Our system automatically parses geometric data, material specifications, and critical tolerances. All files undergo immediate encryption and IP protection protocols compliant with ISO 27001 standards. Non-native formats trigger a validation alert to prevent interpretation errors, ensuring dimensional accuracy from the first step.

AI-Powered Instant Quoting

Proprietary AI algorithms analyze the CAD geometry to generate a preliminary quote within 90 seconds. The system calculates baseline costs using real-time shop floor data: machine hourly rates, material waste factors, toolpath complexity metrics, and setup time coefficients. Material costs are dynamically sourced from our vendor network with live pricing feeds. Critical tolerances (e.g., ±0.005mm vs. ±0.1mm) automatically adjust machining time multipliers. The output includes a base price range, lead time estimate, and material cost breakdown.

Key Cost Drivers in AI Quotation

| Factor | Impact Mechanism | Example Adjustment |

|———————–|————————————————–|———————————-|

| Material Type | Raw material cost + machinability index | 6061-T6 aluminum vs. Inconel 718 |

| Geometric Complexity | Toolpath length + feature count multiplier | 3x complex pockets vs. flat part |

| Tolerance Stringency | Required passes + metrology time coefficient | ±0.01mm adds 15% to base cost |

| Quantity | Setup amortization curve | 100 parts reduces unit cost by 40% |

Engineer-Validated DFM Analysis

All AI quotes undergo mandatory review by Honyo’s manufacturing engineering team. We perform rigorous Design for Manufacturability (DFM) assessment within 2 business hours, identifying:

Unmachinable features requiring design modification

Suboptimal wall thicknesses causing vibration or deflection

Over-specified tolerances increasing cost without functional benefit

Material waste reduction opportunities via nesting optimization

Clients receive a formal DFM report with annotated CAD suggestions. Revised quotes reflect manufacturability improvements, typically reducing costs by 18–35% while maintaining part functionality. This phase includes direct engineer-to-engineer consultation for critical applications.

Production Execution

Approved orders trigger our integrated production system. Parts are assigned to optimal machines based on:

Machine capability matrices (e.g., 5-axis vs. mill-turn)

Current shop floor load balancing

Material-specific tooling availability

Real-time tracking provides customers with machine start times, in-process inspection data, and first-article validation reports. All critical dimensions undergo CMM verification against GD&T callouts, with full inspection documentation delivered with the shipment.

Delivery and Logistics

Completed parts undergo final QA sign-off per AS9102 standards before packaging. We offer multiple delivery options:

Standard global shipping (5–7 business days post-approval)

Expedited air freight (2–3 days with priority scheduling)

Consolidated shipments for multi-part programs

Every shipment includes traceable material certs, FAI reports, and a digital twin of the as-machined part for validation against original CAD.

Process Advantages for Clients

This workflow reduces traditional CNC quoting cycles from 3–5 days to under 4 hours while preventing costly redesign iterations. The AI-to-engineer handoff ensures quotes reflect real-world production constraints, not theoretical pricing. Clients consistently achieve 22% lower total project costs through our DFM-driven optimization, with 99.2% on-time delivery performance over the past 18 months. We maintain transparency at every stage through our client portal, where users can track order status, review DFM annotations, and access historical cost analytics.

Start Your Project

Get an instant quote for precision CNC machined parts from Honyo Prototype. Our state-of-the-art manufacturing facility in Shenzhen delivers high-quality, tight-tolerance components with fast turnaround times.

Contact Susan Leo directly for pricing and project support.

Email: [email protected]

We specialize in low-volume production, rapid prototyping, and custom machining for industries including automotive, medical, and consumer electronics. From 3-axis to 5-axis CNC milling and turning, our team ensures your parts meet exact specifications with consistent quality.

Request your free quote today and experience reliable, cost-effective manufacturing from China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.