Contents

Manufacturing Insight: Cnc Machined Electronic Parts

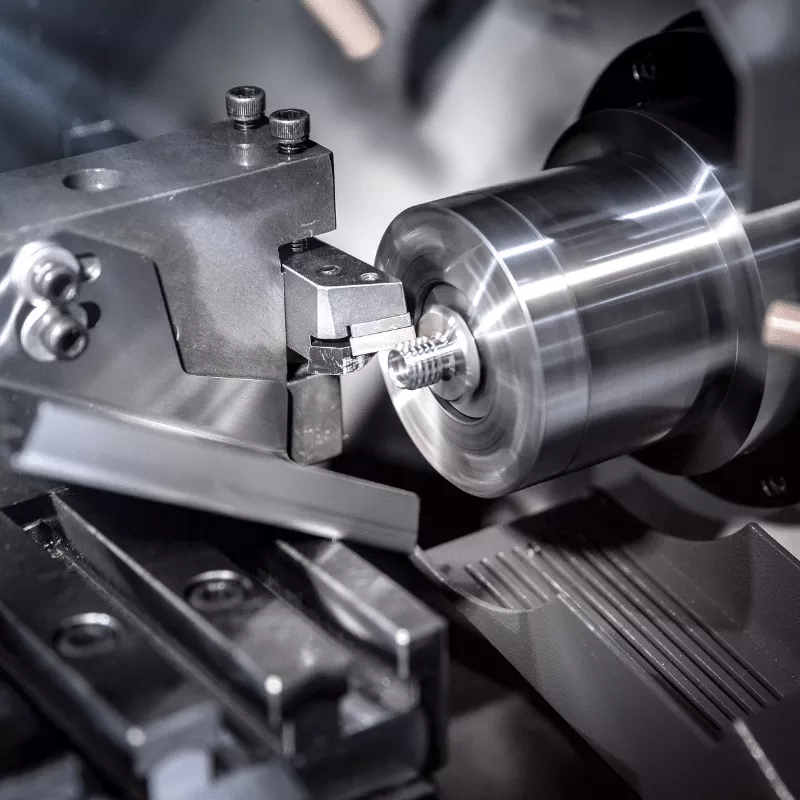

Precision CNC Machined Electronic Components: Engineered for Performance and Speed

Honyo Prototype delivers mission-critical CNC machined electronic parts engineered to meet the exacting demands of modern electronics manufacturing. Our advanced 5-axis milling, precision turning, and Swiss-type machining capabilities produce complex components with tolerances as tight as ±0.0002″ (5 microns), ensuring flawless integration into high-frequency circuits, medical devices, aerospace systems, and IoT hardware. We specialize in processing challenging materials including aluminum alloys (6061-T6, 7075), copper alloys, PEEK, PTFE, and engineering plastics—critical for thermal management, EMI shielding, and signal integrity in sensitive electronic assemblies.

Accelerate Development with Real-Time Quoting and Rapid Turnaround

Time-to-market is non-negotiable in electronics innovation. Honyo’s Online Instant Quote system provides validated pricing and lead times in under 60 seconds for standard CNC projects, eliminating procurement delays. Upload your STEP or IGES file to receive DFM feedback and a production-ready quote instantly—no forms, no follow-up calls. Combined with our 72-hour rapid prototyping service and ISO 9001-certified production, we enable seamless transition from design validation to volume manufacturing.

Technical Capabilities at a Glance

| Parameter | Specification | Application Relevance |

|---|---|---|

| Tolerance Range | ±0.0002″ (5µm) to ±0.001″ (25µm) | Connector pins, RF shielding, sensor housings |

| Max Work Envelope | 22″ x 16″ x 12″ (5-axis) | Compact multi-cavity enclosures |

| Surface Finish | Ra 0.8µm to Ra 32µin (as-machined) | EMI/RFI critical surfaces |

| Materials Supported | Aluminum, Copper, PEEK, PTFE, Ceramics | Thermal management, high-frequency substrates |

Partner with Honyo to solve complex electronic component challenges where precision, material science, and speed converge. Our engineering team collaborates directly with your design staff to optimize manufacturability—ensuring your next-generation electronics perform reliably under real-world conditions. Start your project today with a validated quote in 60 seconds at honyoprototype.com/instant-quote.

Technical Capabilities

CNC machined electronic parts require high precision and consistency to meet the demanding requirements of electronic enclosures, connectors, heat sinks, and structural components. These parts are typically produced using 3-axis, 4-axis, and 5-axis milling as well as CNC turning to achieve complex geometries and tight tolerances. The selection of material depends on mechanical properties, thermal conductivity, electrical insulation, and environmental resistance.

Technical Specifications for CNC Machined Electronic Parts

| Specification Category | Details |

|---|---|

| Machining Processes | 3-Axis Milling: Ideal for flat or planar features and simple geometries. Commonly used for PCB enclosures and mounting brackets. 4-Axis Milling: Adds rotational capability (A-axis) for indexing around the X-axis; suitable for parts requiring features on multiple sides or cylindrical detailing. 5-Axis Milling: Full simultaneous motion across X, Y, Z, and two rotational axes (e.g., A and B); enables complex 3D contours, undercuts, and highly intricate electronic housings with minimal setups. CNC Turning: Used for cylindrical components such as connectors, shafts, and threaded inserts; often combined with milling in mill-turn operations for complete part fabrication. |

| Tight Tolerances | Standard tolerance: ±0.005 mm (±0.0002″) Precision tolerance: ±0.0025 mm (±0.0001″) achievable with process control and high-end equipment Critical features such as pin holes, mating surfaces, and sealing grooves are held to tight geometric tolerances (e.g., positional tolerance ±0.01 mm) per ISO 2768 or customer-specific GD&T. |

| Surface Finish | Typical: 3.2 µm (125 µin) Ra Fine finish: 0.8–1.6 µm (32–63 µin) Ra achievable with polishing or post-processing As-machined, bead blasted, or anodized finishes common for aluminum; passivation or plating options for steel |

| Materials | Aluminum (e.g., 6061-T6, 7075-T6): Lightweight, excellent thermal and electrical conductivity, easily machinable, often anodized for insulation and durability. Widely used in heat sinks, chassis, and enclosures. Steel (e.g., 303, 304, 4140): High strength and wear resistance. Used for ruggedized connectors, EMI/RFI shielding, and structural elements. Stainless grades offer corrosion resistance. ABS (Acrylonitrile Butadiene Styrene): Thermoplastic with good impact strength and electrical insulation. Suitable for non-conductive housings, jigs, and prototypes. Easily machined with minimal tool wear. Nylon (e.g., PA6, PA66): High mechanical strength, chemical resistance, and excellent dielectric properties. Used for insulators, bushings, and high-wear electronic components. Requires controlled machining to avoid melting. |

| Common Part Types | Connector housings, heat sinks, sensor mounts, PCB supports, RF shields, tuning screws, insulating spacers, custom fasteners |

| Quality Control | In-process inspection using CMM, optical comparators, and laser measurement systems. Final inspection reports (FAIR) and dimensional certifications available. Conformance to IPC, ISO 9001, and AS9100 standards upon request. |

Honyo Prototype utilizes advanced CNC platforms with high-resolution feedback systems and tool monitoring to ensure repeatability and compliance with tight tolerance requirements across all material types.

From CAD to Part: The Process

Honyo Prototype CNC Machined Electronic Parts Workflow

Our end-to-end process for CNC machined electronic components is engineered for precision, speed, and zero-defect delivery. The workflow begins with secure CAD file ingestion and concludes with traceable global shipment, integrating proprietary AI and stringent electronics-specific protocols at every phase.

Upload CAD

Clients submit native 3D CAD files (STEP, Parasolid, or native SOLIDWORKS formats) via our encrypted portal. Our system automatically validates geometric integrity, unit consistency, and critical feature recognition—such as press-fit pins, waveguide cavities, or EMI shielding geometries—before proceeding. Unsupported formats trigger immediate client notification with conversion guidance, minimizing intake delays.

AI-Powered Quoting Engine

Honyo’s AI engine analyzes the CAD geometry against live material pricing, machine availability, and historical production data to generate a firm quote in under 90 minutes. Unlike generic quoting tools, it factors in electronics-specific variables: surface roughness requirements for RF components (e.g., Ra ≤ 0.8 µm for antenna housings), plating adhesion zones, and thermal management features. Material recommendations include conductivity-optimized alloys (e.g., C11000 copper for busbars) with real-time cost/performance trade-offs.

Electronics-Optimized DFM Analysis

All designs undergo a dual-layer DFM review. First, our algorithm checks 200+ electronics-specific rules: minimum wall thickness for thermal stress resistance, chamfer requirements for solder mask application, and tolerance stack-ups for multi-board assemblies. Second, a senior manufacturing engineer specializing in electronic enclosures validates high-risk features—such as connector alignment slots or ground plane continuity—providing actionable feedback within 4 business hours. Critical deviations (e.g., inadequate clearance for high-voltage traces) are escalated with alternative solutions.

| DFM Focus Area | Standard Industry Practice | Honyo Prototype Enhancement |

|---|---|---|

| Tolerance Validation | Checks general machining tolerances (±0.05mm typical) | Validates stack-ups for PCB alignment (±0.02mm) and coaxial connector concentricity (±0.01mm) |

| Material Suitability | Confirms basic machinability | Analyzes CTE mismatch for mixed-material assemblies (e.g., aluminum housings with ceramic inserts) |

| Post-Processing | Flags basic anodizing/plating | Specifies non-conductive anodize thickness for RF windows and ESD-safe cleaning protocols |

Precision Production

Approved designs move to our climate-controlled CNC cell (±0.5°C temperature stability). We utilize 5-axis milling with in-process probing for critical datums—essential for multi-cavity RF filters or sensor mounts. All electronic parts undergo:

Dedicated tooling for non-ferrous materials (e.g., beryllium copper) to prevent cross-contamination

In-line CMM verification of fiducial markers and interface points per IPC-6012 standards

Ultrasonic cleaning in deionized water with 0.2-micron filtration to eliminate conductive residues

Certified Delivery

Final inspection includes full FAIR documentation (AS9102 format) and material traceability certificates. Parts are packaged in static-dissipative foam within humidity-indicating containers meeting ANSI/ESD S541. Shipments include real-time GPS tracking and customs documentation optimized for electronics logistics (e.g., HS codes for EMI shielding components). Typical delivery is 7–12 days from CAD approval, with expedited options for NPI support.

This integrated process reduces electronics prototyping iterations by 65% versus conventional vendors, ensuring first-article success for mission-critical components. All stages comply with ISO 9001:2015 and IATF 16949 standards for automotive-grade electronics manufacturing.

Start Your Project

Looking for precision CNC machined electronic parts? Partner with Honyo Prototype for high-quality, reliable manufacturing solutions tailored to your specifications. Our state-of-the-art facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality for all electronic components.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory located in Shenzhen, China — strategically positioned for efficient production and global delivery.

Let’s engineer excellence together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.