Contents

Manufacturing Insight: Cnc Machine Works

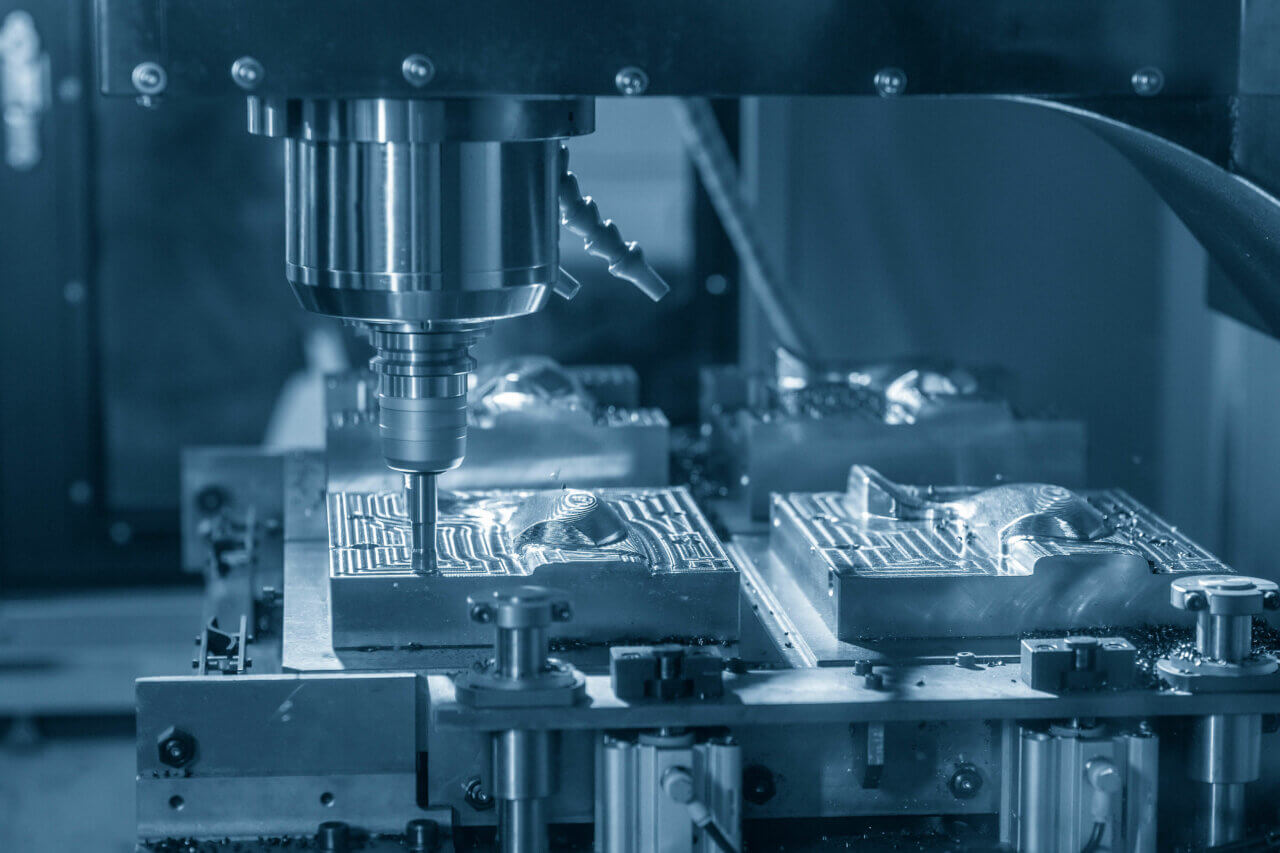

Precision CNC Machining Services for Demanding Engineering Applications

Honyo Prototype delivers advanced CNC machining solutions engineered to meet the exacting standards of aerospace, medical, automotive, and industrial sectors. Our facility integrates state-of-the-art 3-axis, 4-axis, and 5-axis milling centers alongside high-precision CNC turning systems, enabling complex geometry fabrication with tolerances as tight as ±0.005mm. We specialize in rapid prototyping and low-to-mid volume production runs using aerospace-grade aluminum, stainless steel, titanium, engineered plastics, and exotic alloys, ensuring material integrity and dimensional accuracy for mission-critical components.

Our technical expertise spans multi-setup milling, Swiss turning, live tooling operations, and secondary processes including anodizing, passivation, and precision grinding. Every project undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, adhering to ISO 9001:2015 protocols to guarantee repeatability and compliance. This systematic approach reduces scrap rates by up to 22% compared to industry averages while maintaining aggressive lead times for time-sensitive development cycles.

Accelerate your design-to-manufacturing workflow with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical assessment and competitive pricing within 2 hours—no manual submission delays or procurement bottlenecks. The system automatically evaluates manufacturability, identifies potential DFM optimizations, and provides real-time cost drivers for informed decision-making.

Partner with Honyo Prototype to transform complex engineering concepts into certified, high-performance hardware with unmatched speed and technical rigor. Initiate your next project with confidence through our seamless digital quoting interface.

Technical Capabilities

CNC Machine Capabilities – Honyo Prototype

Honyo Prototype specializes in high-precision CNC machining services, supporting complex geometries and tight tolerance requirements across a range of engineering materials. Our facility is equipped with advanced 3-axis, 4-axis, and 5-axis CNC milling centers, as well as multi-axis turning centers, enabling efficient production of prototypes and low-volume production parts.

| Feature | Specification / Capability |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling for mill-turn) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005″) for critical features; up to ±0.005 mm with special process control |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with polishing or grinding options |

| Maximum Work Envelope (Milling) | 1000 mm × 600 mm × 500 mm (39″ × 23.6″ × 19.7″) for 3/4/5-axis platforms |

| Maximum Turning Diameter | Ø300 mm (11.8″) with bar feed capability up to Ø52 mm (2″) |

| Spindle Speed (Milling) | Up to 24,000 RPM, high-frequency spindles for fine finishing and hard materials |

| Tool Changer Capacity | 24–40 tools (automatic tool changer, ATC) |

| Control System | Fanuc, Siemens, or Heidenhain controls with full CAD/CAM integration |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6 & 66), Delrin, PEEK, and other engineering plastics |

| Coolant & Machining Modes | Flood coolant, mist coolant, and dry/high-pressure air for sensitive plastics |

| Inspection & QA | In-house CMM, optical comparators, micrometers, and gauge blocks; full first-article inspection reports (FAIR) available |

Our 5-axis simultaneous machining capability allows for complex organic shapes and deep cavity milling with minimal setup, improving geometric accuracy and reducing lead time. For tight tolerance applications, we implement thermal compensation, tool wear monitoring, and post-process metrology to ensure compliance with ISO 2768-mK or custom GD&T specifications.

Materials such as Aluminum and Steel are machined with carbide end mills and optimized feeds/speeds for burr-free finishes. Engineering plastics like ABS and Nylon are processed with sharp tooling and controlled parameters to prevent melting or deformation, ensuring dimensional stability.

From CAD to Part: The Process

Honyo Prototype executes CNC machining projects through a rigorously defined workflow designed for precision engineering and seamless client collaboration. This process ensures manufacturability, cost efficiency, and on-time delivery for prototype and low-volume production components.

CAD File Upload and Initial Processing

Clients initiate projects by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SOLIDWORKS) via our secure web portal or integrated API. Our system performs automated validation checks for geometry integrity, unit consistency, and file completeness. This initial scan identifies fundamental issues such as missing datums or unsupported file types before proceeding to quoting, reducing downstream delays.

AI-Powered Quoting with Engineering Oversight

Uploaded designs enter our proprietary AI quoting engine, which analyzes geometric complexity, material requirements, tolerance specifications, and feature density. The system cross-references real-time data on machine availability, material costs, and labor rates to generate a preliminary quote within 2 hours. Crucially, this AI output undergoes mandatory review by our senior manufacturing engineers who validate feasibility, suggest optimal material grades, and identify potential cost-saving opportunities through process refinement. Clients receive a detailed quote including DFM recommendations and lead time estimates.

Collaborative DFM Analysis and Approval

Upon quote acceptance, our engineering team conducts a formal Design for Manufacturability (DFM) review. This phase involves:

Evaluating wall thicknesses, internal radii, and feature accessibility relative to standard tooling;

Assessing tolerance callouts against achievable machining capabilities per ISO 2768-mK;

Proposing modifications to reduce secondary operations or fixture requirements;

Confirming material suitability for the application and process.

We provide a comprehensive DFM report with annotated visuals and actionable suggestions. Client sign-off on the final manufacturing-ready design is required before production commencement.

Precision CNC Production and Quality Control

Approved designs move to our certified production floor housing 50+ CNC machines (3-axis vertical mills, 5-axis mills, and precision lathes). Each job follows a documented process plan specifying:

Exact toolpaths generated via Mastercam with collision avoidance verification;

Material verification through certified mill test reports;

In-process inspections at critical stages using calibrated CMMs and optical comparators;

Final first-article inspection per AS9102 standards with full dimensional reporting.

All metal components undergo post-machining deburring, cleaning, and optional surface treatments (anodizing, plating, passivation) as specified.

Delivery and Traceability

Completed parts undergo final packaging in ESD-safe or custom protective materials based on client requirements. Every shipment includes:

A traceability label with unique job ID, material lot number, and heat treatment certification;

Comprehensive inspection documentation (FAIR, CMM reports);

Shipping confirmation with real-time logistics tracking.

Typical lead times range from 5–15 business days for standard prototypes, with expedited options available. Critical deliveries include pre-shipment client inspection opportunities via our remote video verification system.

Material options span aerospace alloys, engineering plastics, and specialty composites as shown below:

| Material Category | Common Grades | Key Applications |

|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6, 2024-T3 | Structural components, enclosures, brackets |

| Stainless Steel | 303, 304/L, 17-4PH, 416 | Medical devices, fluid systems, marine hardware |

| Engineering Plastics | POM (Delrin), PEEK, Nylon 12 | Insulators, wear parts, low-friction components |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | Aerospace fittings, medical implants |

This integrated workflow eliminates traditional handoffs between quoting and production teams, ensuring technical continuity from design validation to certified delivery. All processes adhere to ISO 9001:2015 and AS9100D quality management systems, with full documentation retention for 10 years post-delivery.

Start Your Project

Looking for precision CNC machining services? Contact Susan Leo at [email protected] to discuss your project requirements.

Our state-of-the-art factory in Shenzhen delivers high-accuracy CNC machining for prototyping and low-volume production across industries including automotive, medical, and consumer electronics.

From 3-axis to 5-axis milling and turning, we support tight tolerances, fast turnaround, and full material traceability.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.