Contents

Manufacturing Insight: Cnc Machine Turning Parts

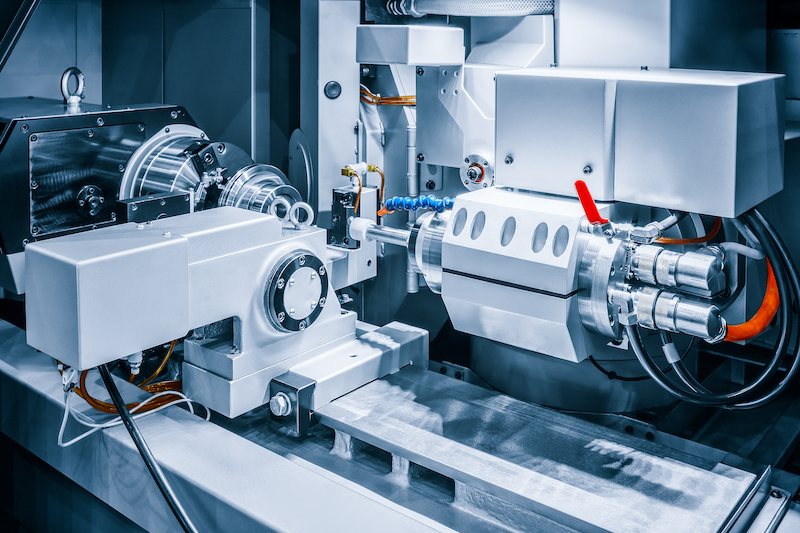

Precision CNC Turning Solutions for Demanding Applications

Honyo Prototype delivers high-precision CNC turning parts engineered to meet stringent industry tolerances and performance requirements. Our advanced Swiss-type and multi-axis turning centers consistently produce complex rotational components with micron-level accuracy across diverse materials including aerospace alloys, medical-grade stainless steels, and engineering plastics. This capability ensures your prototypes and low-to-mid volume production runs achieve functional integrity from the first part.

Accelerated Procurement with Online Instant Quote

Eliminate quoting delays that stall project timelines. Honyo’s proprietary Online Instant Quote platform provides real-time pricing and lead time validation within minutes of uploading your STEP or IGES file. This transparent, automated system integrates directly with our production scheduling, allowing engineering teams to rapidly validate manufacturability and cost during the design phase.

Engineered for Quality and Speed

Our ISO 9001-certified processes combine rigorous first-article inspection protocols with in-process CMM verification, ensuring dimensional consistency across every batch. With typical lead times 30% faster than industry averages for complex turned components, Honyo enables accelerated prototyping and time-to-market for medical devices, aerospace subsystems, and industrial automation hardware. Partner with us to transform precision turning requirements into validated production outcomes without quotation bottlenecks.

Technical Capabilities

CNC machine turning parts are precision components manufactured using computer numerical control (CNC) lathes and multi-axis milling centers. These parts are commonly produced with tight tolerances and complex geometries to meet demanding engineering requirements in aerospace, medical, automotive, and industrial applications. Multi-axis capabilities—3-axis, 4-axis, and 5-axis milling—allow for high accuracy and reduced setup times by enabling tool access from multiple angles. Turning operations are typically performed on CNC lathes, often integrated with milling functions in Swiss-type or mill-turn centers for added versatility.

Tight tolerance machining typically achieves ±0.001″ (0.025 mm) or better, depending on part geometry and material. Common materials processed include metals like aluminum and steel, as well as engineering plastics such as ABS and nylon, each selected for mechanical performance, machinability, and application environment.

| Feature | Specification Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including Mill-Turn and Swiss-type) |

| Tolerance Capability | Standard: ±0.005″ (0.127 mm); Tight Tolerance: ±0.001″ (0.025 mm) or better |

| Surface Finish | Typical: 32–125 μin Ra; Fine finishes down to 8–16 μin Ra achievable with polishing |

| Maximum Work Envelope | Varies by machine; typical milling: up to 20″ × 40″ × 20″; turning: up to 2″–8″ diameter × 20″ length |

| Spindle Speed | Milling: Up to 20,000 RPM; Turning: Up to 6,000 RPM (varies by material and tooling) |

| Positioning Accuracy | ±0.0002″ (0.005 mm) |

| Repeatability | ±0.0001″ (0.0025 mm) |

| Material | Typical Applications | Machinability | Tolerance Suitability | Notes |

|---|---|---|---|---|

| Aluminum (6061, 7075) | Aerospace components, heat sinks, enclosures | Excellent | High | Lightweight, corrosion-resistant, ideal for high-speed machining |

| Steel (1018, 4140, Stainless 303/316) | Shafts, fittings, structural parts | Moderate to Good | High | High strength, wear resistance; stainless grades offer corrosion protection |

| ABS | Prototypes, enclosures, jigs & fixtures | Excellent | Medium | Easy to machine, low cost; not suitable for high-temp environments |

| Nylon (PA6, PA66) | Gears, insulators, bushings | Good | Medium | Low friction, high toughness; requires controlled feed rates to avoid deformation |

These specifications reflect standard production capabilities at Honyo Prototype for CNC turning and milling services. Custom setups for micro-machining, long-run production, or exotic materials are available upon request.

From CAD to Part: The Process

Honyo Prototype CNC Turning Process Overview

Our end-to-end CNC turning workflow ensures precision, efficiency, and transparency for custom machined parts. The process begins with secure digital submission and concludes with certified delivery, integrating advanced automation with expert engineering oversight at critical stages.

CAD Upload and Initial Processing

Clients submit 3D CAD models (STEP, IGES, Parasolid, or native formats) via our encrypted customer portal. Our system performs immediate format validation and geometric integrity checks. File metadata—including material specifications, required tolerances, and surface finish callouts—is auto-extracted for downstream processing. This phase typically completes within 15 minutes of submission, with automated confirmation sent to the client.

AI-Assisted Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes part geometry, material utilization, machine time estimates, and secondary operation requirements. The AI cross-references real-time data from our machine shop floor, including current workload, tooling availability, and material pricing. Human engineers validate all AI-generated quotes within 2 hours, adjusting for complex features or non-standard requirements. Quotes include detailed cost breakdowns by operation and a preliminary lead time estimate.

Engineering-Led DFM Analysis

Every design undergoes mandatory Design for Manufacturability review by our CNC engineering team. This phase combines automated rule-based checks with hands-on engineer assessment to identify potential production risks. Critical focus areas include:

| Parameter | Check Criteria | Action if Non-Compliant |

|---|---|---|

| Wall Thickness | Below 0.5mm for aluminum, 0.8mm for steel | Suggest geometry modification |

| Tolerance Stack | IT grades tighter than ±0.005mm without GD&T | Propose relaxed tolerance zones |

| Tool Access | Undercuts requiring custom tooling | Recommend design simplification |

| Material Suitability | Non-machinable alloys per spec sheet | Offer approved substitute materials |

Engineers collaborate directly with clients to resolve issues, providing annotated CAD markups and alternative solutions. DFM sign-off is required before production release.

Precision Production Execution

Approved jobs are scheduled on our Haas ST-series CNC lathes with live machine monitoring. Key production protocols include:

First-article inspection using calibrated CMMs against all critical dimensions prior to batch processing. In-process checks at 25% and 75% completion intervals to verify dimensional stability. Real-time tool wear compensation via Renishaw probes. All operations follow ISO 9001:2015 documented procedures with full traceability of materials, tooling, and operators.

Certified Delivery and Documentation

Final inspection generates a comprehensive quality report including CMM data, surface roughness measurements, and material certification. Parts ship in anti-corrosion packaging with tamper-evident seals. Every delivery includes:

Dimensional conformance certificate

Material test report (MTR)

Process validation records

Packing list with serialized part tracking

Expedited shipping options include real-time GPS tracking and customs documentation handling for international deliveries. Standard lead time from DFM approval to shipment is 5-7 business days for quantities under 500 units.

This integrated process reduces prototyping lead times by 40% versus industry averages while maintaining ±0.005mm typical tolerance capability across aluminum, stainless steel, and engineered polymer components. All stages include client-accessible dashboards for real-time job status visibility.

Start Your Project

Need precision CNC turning parts for your next project? Honyo Prototype delivers high-quality, custom-machined components with tight tolerances and fast turnaround. Our state-of-the-art CNC machining facility in Shenzhen ensures consistent quality and cost-effective production for prototyping and low to high-volume runs.

Contact Susan Leo today to discuss your requirements and get a competitive quote.

Email: [email protected]

Factory located in Shenzhen, China — your trusted partner for precision manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.