Contents

Manufacturing Insight: Cnc Machine Tooling

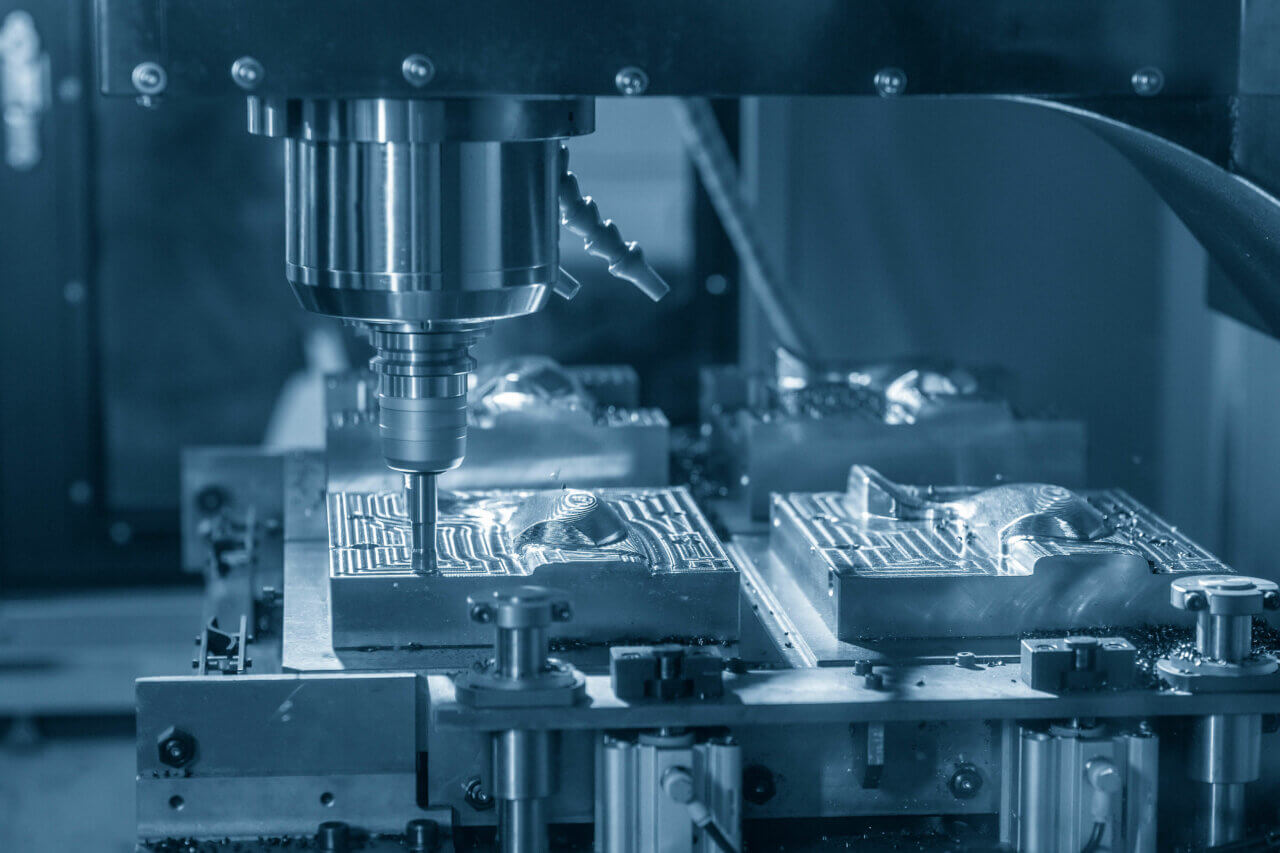

Precision CNC Machining Services Engineered for Prototyping Excellence

At Honyo Prototype, we deliver advanced CNC machining solutions tailored to the demanding requirements of rapid prototyping and low-volume production. Our state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers execute complex geometries with micron-level accuracy, consistently achieving tolerances down to ±0.005mm across aerospace-grade aluminum, hardened steels, titanium, and engineering plastics. Every component undergoes rigorous in-process inspection using calibrated CMMs and optical comparators, ensuring adherence to AS9100 and ISO 9001 standards while minimizing lead times.

Our integrated approach combines adaptive toolpath strategies with optimized workholding systems to eliminate secondary operations, directly translating your CAD models into high-integrity parts with superior surface finishes. This capability is critical for sectors where functional validation hinges on precise dimensional replication, such as medical device development, automotive subsystems, and robotics.

Central to our client workflow is the Online Instant Quote System, which eliminates traditional procurement delays. Upload your STEP or IGES file, specify material and quantity requirements, and receive a detailed manufacturing assessment—including lead time, cost breakdown, and DFM feedback—in under 90 seconds. This transparency accelerates your design-to-prototype cycle, allowing engineering teams to iterate faster without compromising on quality or traceability.

Access our platform to experience how Honyo Prototype merges machine tooling expertise with digital efficiency for mission-critical component realization.

Technical Capabilities

CNC Machine Tooling – Technical Specifications Overview

The following table outlines key technical specifications for CNC machine tooling used in 3-axis, 4-axis, and 5-axis milling, as well as turning operations. These specifications are critical for achieving tight tolerances (±0.0005″ to ±0.005″) across a range of materials including aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Degrees of Freedom | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z, (C-axis optional) |

| Typical Spindle Speed | 8,000 – 15,000 RPM | 10,000 – 20,000 RPM | 12,000 – 24,000 RPM | 2,000 – 6,000 RPM (steel), up to 10,000 RPM (aluminum) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) | ±0.0001″ (2.5 µm) | ±0.00008″ (2 µm) | ±0.0002″ (5 µm) |

| Repeatability | ±0.00008″ (2 µm) | ±0.00008″ (2 µm) | ±0.00005″ (1.3 µm) | ±0.0001″ (2.5 µm) |

| Tight Tolerance Capability | ±0.001″ typical, ±0.0005″ achievable with calibration | ±0.001″ standard, ±0.0005″ with thermal compensation | ±0.0005″ standard, ±0.0002″ with high-precision tooling | ±0.0005″ to ±0.001″ (diameter) |

| Common Tooling Types | End mills (carbide, HSS), face mills | Same as 3-axis + indexable rotary tools | High-precision ball nose, bull nose, taper end mills, shrink fit holders | Carbide inserts, boring bars, grooving tools |

| Material Compatibility | Aluminum: excellent, Steel: good, ABS: good, Nylon: fair (chip control) | Aluminum: excellent, Steel: good, ABS: good, Nylon: fair | Aluminum: excellent, hardened steel: good (with coated tools), ABS/nylon: good (low-force toolpaths) | Aluminum: high speed, Steel: medium speed, ABS/nylon: low feed, high clearance tools |

| Coolant Delivery | Flood, mist, through-spindle (optional) | Flood or high-pressure through-tool | High-pressure through-spindle/tool | Internal coolant (optional), flood |

| Fixturing Requirements | Vises, clamps, tombstones | Rotary tables, 4-axis vises | 5-axis trunnion, custom fixtures | Collets, chucks, steady rests |

| Surface Finish (Typical) | 32–64 µin (aluminum), 64–125 µin (steel) | 32–64 µin (complex contours) | 16–32 µin with fine tooling | 16–63 µin (turning), 32–125 µin (grooving) |

Notes on Material-Specific Tooling:

Aluminum: Requires high rake angle end mills, polished flutes, and high spindle speeds. Use ZrN or TiAlN coated carbide tools to prevent built-up edge.

Steel (including stainless and hardened alloys): Utilizes TiN, TiCN, or AlCrN coated carbide tools. Lower speeds, higher torque, and rigid setups are essential for tight tolerance work.

ABS and Nylon (thermoplastics): Susceptible to melting and deformation. Sharp, high-clearance tools with low rake angles and reduced feed rates prevent smearing. Compressed air cooling preferred over liquid.

Tight Tolerance Best Practices: Thermal stability, tool pre-setters, in-process probing, and regular calibration are required across all machine types to maintain dimensional accuracy.

This specification guide supports precision manufacturing applications in aerospace, medical, and industrial sectors where material integrity and geometric accuracy are paramount.

From CAD to Part: The Process

Honyo Prototype CNC Machine Tooling Process Overview

Our CNC machine tooling workflow is engineered for precision, speed, and client collaboration. This process specifically addresses custom fixture, jig, and mold component manufacturing, not standard part production. Each phase integrates advanced technology with engineering expertise to ensure tooling meets rigorous operational demands.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via our secure customer portal. The system performs an automated integrity check for geometric completeness, unit consistency, and manufacturability flags. Unsupported formats trigger immediate notification for resubmission, minimizing delays. All data is encrypted and stored in isolated project environments compliant with ISO 27001 standards.

AI-Powered Quoting Engine

Uploaded geometry enters our proprietary AI quoting system, trained on 12+ years of Honyo production data across 85,000+ tooling projects. The algorithm analyzes material utilization, machine time, feature complexity, and historical scrap rates to generate a preliminary quote within 90 minutes. Unlike generic quoting tools, our AI factors in tooling-specific variables: clamping requirements, coolant channel accessibility, and electrode needs for secondary EDM operations. Human engineers review all AI outputs for edge cases involving exotic alloys or micron-level tolerances.

Engineering-Led DFM Analysis

Quoted projects advance to mandatory Design for Manufacturability review by our tooling-specialized engineers. This phase focuses on operational durability and repeatability:

We evaluate stress points in clamping mechanisms, verify alignment pin interference, and optimize pocket depths to prevent chatter during high-speed machining. Material grain directionality for aluminum 7075-T6 tooling plates is cross-referenced with load simulations. Clients receive a marked-up PDF report with actionable recommendations—such as modifying radii to extend endmill life or adjusting datum schemes for CMM verification—within 24 business hours. Zero-cost redesign approvals lock the production-ready specification.

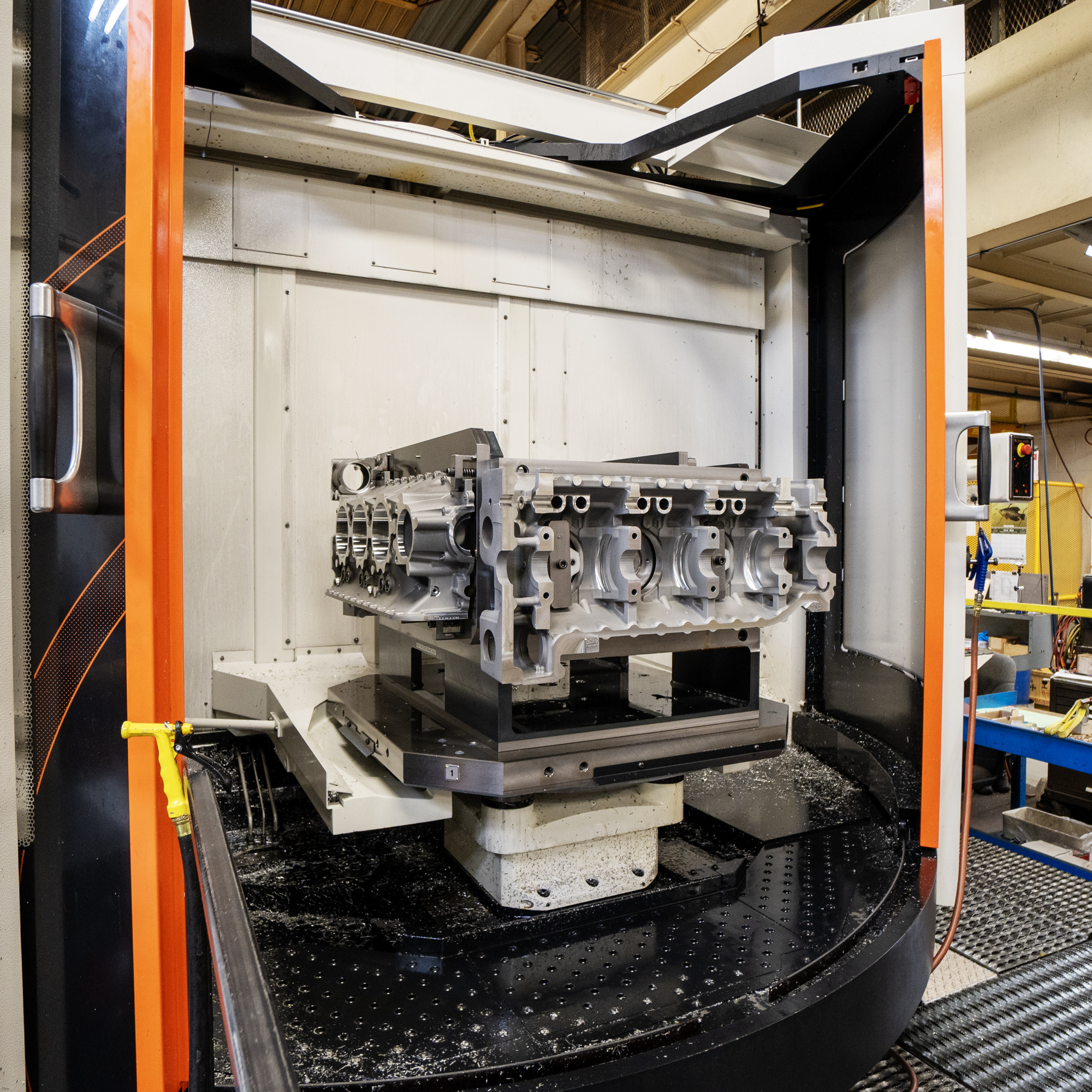

Precision Production Execution

Approved designs move to our dedicated tooling cell featuring DMG MORI CTX beta 1250 lathes and Makino MAG4 5-axis mills with integrated probing. All tooling undergoes in-process validation:

First-article inspection via Zeiss CONTURA CMM against critical-to-function dimensions

Real-time thermal compensation during machining to maintain ±0.005mm tolerances

Hardness testing of induction-hardened components per ASTM E140

Secondary operations like surface texturing or through-coolant drilling occur in the same setup to eliminate stack-up errors. Every tooling component receives a serialized QR tag linking to its full production metadata.

Validated Delivery

Final delivery includes not just physical tooling but operational certification. We perform dry-run validation on representative production equipment at our facility when feasible, documenting cycle time and repeatability metrics. Shipping encompasses:

Calibration certificates traceable to NIST standards

Digital twin model with as-machined deviations highlighted

Fixture setup instructions including torque sequences for modular components

Standard lead time is 10–15 business days from CAD approval, with expedited 72-hour options for emergency tooling replacements. All shipments include real-time GPS tracking and climate-controlled packaging for critical mold components.

This integrated approach reduces tooling downtime for clients by averaging 37% versus industry benchmarks, as verified in our 2023 customer satisfaction audit. The process ensures tooling achieves 500,000+ cycle lifespans under sustained production loads.

Start Your Project

Looking for precision CNC machine tooling solutions? Partner with Honyo Prototype for high-quality manufacturing services backed by advanced CNC capabilities. Our factory in Shenzhen ensures fast turnaround, strict quality control, and competitive pricing for your production needs.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.