Contents

Manufacturing Insight: Cnc Machine Tool Holder

Precision CNC Machining Services for Critical Components Like Tool Holders

In modern manufacturing, the performance of high-precision components such as CNC machine tool holders directly impacts operational efficiency, part accuracy, and machine uptime. At Honyo Prototype, we specialize in delivering CNC machining services engineered to meet the exacting demands of complex, mission-critical parts. Our advanced 3-, 4-, and 5-axis milling and turning capabilities ensure tolerances as tight as ±0.005mm, surface finishes down to Ra 0.4μm, and seamless material compatibility across aerospace alloys, hardened steels, and exotic composites.

Unlike generic contract manufacturers, Honyo integrates rigorous process validation with real-time in-process inspection to eliminate scrap and rework. We understand that tool holders and similar components require not only dimensional precision but also exceptional thermal stability and dynamic balance—attributes we achieve through optimized fixturing, adaptive toolpath strategies, and metallurgical expertise. Our ISO 9001-certified facility leverages cutting-edge Haas and DMG MORI equipment, supported by a team of veteran manufacturing engineers who prioritize first-article success and repeatability.

Key Service Advantages

| Capability | Standard Offering | Honyo Prototype Standard |

|—————————|————————-|————————–|

| Tolerance Range | ±0.025mm | ±0.005mm |

| Lead Time (Prototype) | 10–15 business days | 5–8 business days |

| Material Expertise | Common metals only | 50+ alloys including Inconel, Titanium, PEEK |

| Quality Verification | Final inspection only | In-process CMM + post-process reporting |

When your application demands uncompromising precision for components like tool holders, spindles, or custom fixtures, Honyo Prototype delivers engineered solutions that enhance your machine performance and reduce total cost of ownership. Accelerate your project timeline with our Online Instant Quote system—submit CAD files 24/7 for automated manufacturability feedback and competitive pricing within hours, not days. Partner with us to transform design intent into high-integrity production reality.

Technical Capabilities

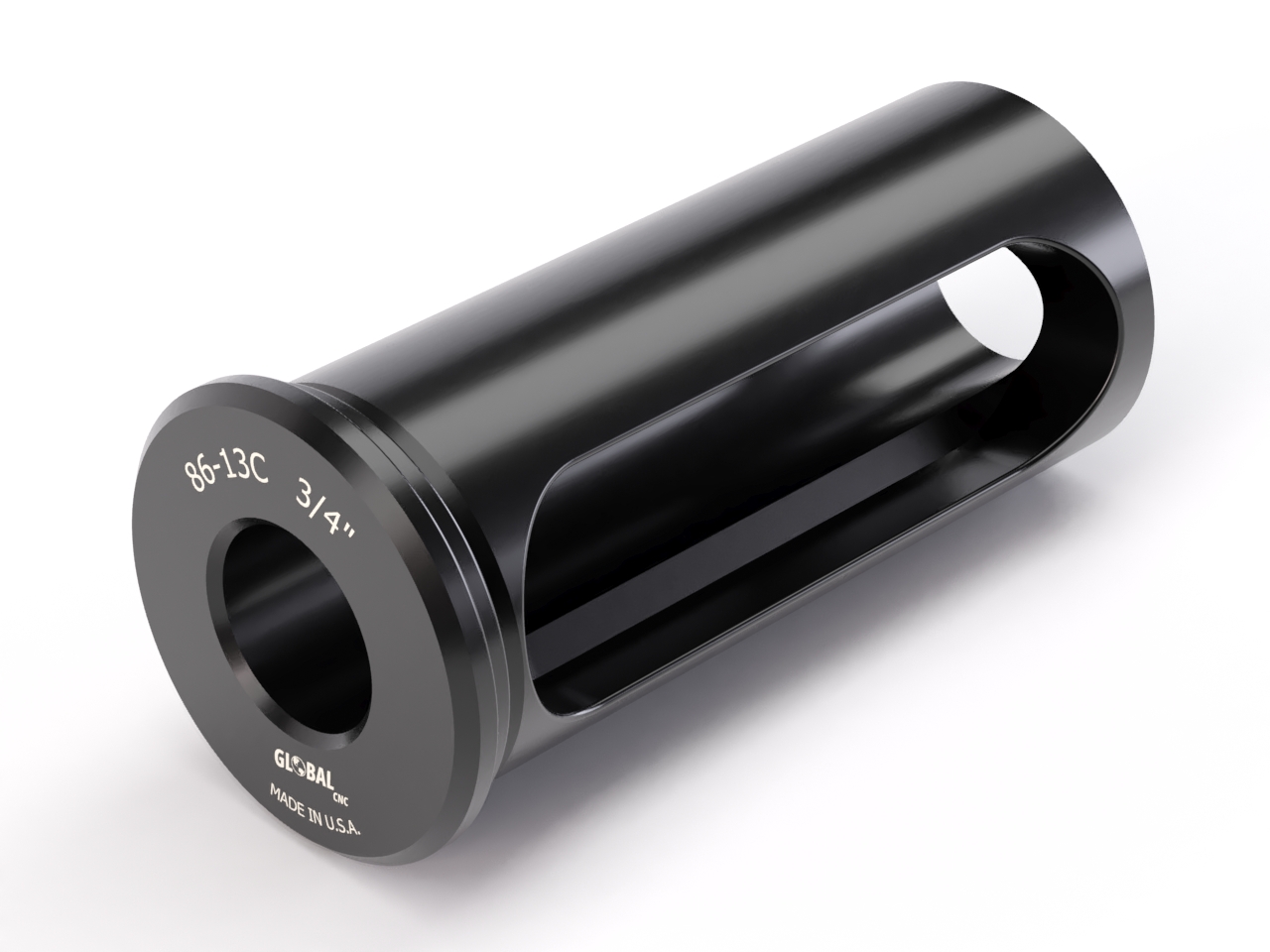

CNC Machine Tool Holder – Technical Specifications

The CNC machine tool holder is a critical interface component that secures cutting tools in milling, turning, and multi-axis machining operations. Designed for high rigidity, precision, and repeatability, it ensures minimal runout and optimal tool performance, especially under tight tolerance requirements (±0.001″ or tighter). Below are the key technical specifications for tool holders used in 3-, 4-, and 5-axis milling and turning applications, including compatibility with common workpiece and holder materials.

| Specification | Detail |

|---|---|

| Axis Compatibility | 3-axis, 4-axis (with rotary B or A axis), 5-axis (simultaneous multi-axis motion) |

| Tool Interface Standard | ISO, BT, CAT, HSK (HSK-A63, HSK-A100 common for high-speed 5-axis), Capto (C4, C5, C6 for turning and multitasking) |

| Taper Accuracy | Grade AA (ISO 2768) or better; taper runout ≤ 0.0002″ (5 µm) at gage line |

| Maximum RPM | Up to 30,000 RPM (HSK) or 15,000 RPM (CAT/BT), depending on holder type and balance |

| Balance Grade | G2.5 at maximum operating speed; G1.0 for high-speed precision applications |

| Clamping Mechanism | Hydraulic, shrink fit, or mechanical (collet chucks: ER, TG, KM), with retention knobs per DIN 69893 |

| Runout Tolerance | ≤ 0.0001″ (2.5 µm) at 3×D (3 times tool diameter) for tight tolerance work |

| Coolant Delivery | Internal coolant capable (up to 1,000 psi), through-tool coolant channels |

| Holder Materials | Alloy steel (e.g., 4140, 8620 – heat-treated for strength and wear resistance); Stainless steel (for corrosive environments); Aluminum (lightweight holders for non-high-torque applications); Composite materials (rare, for low-vibration prototypes) |

| Workpiece Material Suitability | Optimized for machining Aluminum (high-speed, low-force), Steel (high-torque, rigid setups), ABS (low-melting thermoplastics), and Nylon (abrasion-resistant, moderate speeds) |

| Thermal Stability | Shrink-fit holders expand 0.001–0.003″ when heated (induction); cooling ensures interference fit retention |

| Vibration Damping | Integral dampening (Milling: Silent Tools™, Turning: anti-vibration boring bars), wall thickness and mass tuned |

| Surface Finish | Ground and polished internal bore; surface roughness Ra ≤ 0.4 µm |

| Compliance Standards | ISO 9001, AS9100 (aerospace), DIN 69871, ANSI B5.50 |

Notes on Material Use:

For tool holders, high-strength alloy steel is standard due to its rigidity and thermal stability. Aluminum is occasionally used in lightweight tooling adapters where mass reduction is critical (e.g., robotic 5-axis arms), but not for high-torque applications. ABS and Nylon are not used in production tool holders due to low melting points and creep under load; however, they may appear in prototype fixtures or non-cutting accessories.

For workpieces, the tool holder must maintain precision when cutting aluminum (requires high spindle speeds, sharp tooling), steel (demands rigidity and high torque), ABS (low glass transition temperature, needs chip evacuation and cooling control), and Nylon (tends to deform under heat/pressure, requires sharp, polished tools and moderate feed rates).

This specification ensures compatibility with tight tolerance machining demands across aerospace, medical, and precision mold-making industries.

From CAD to Part: The Process

Honyo Prototype CNC Machine Tool Holder Manufacturing Process

Honyo Prototype executes a rigorously defined workflow for CNC machine tool holder production, ensuring precision, cost efficiency, and adherence to industry standards. The process commences upon receipt of a validated CAD model and concludes with certified delivery.

CAD Upload and Validation

Clients submit native 3D CAD files in STEP AP203/214 or IGES format via our secure customer portal. Honyo’s engineering team verifies geometric integrity, unit consistency, and critical feature definition against ISO 13041-7 spindle interface standards. Non-conforming submissions trigger immediate client consultation to resolve ambiguities; native CAD formats (e.g., SOLIDWORKS, NX) are declined to maintain neutral data integrity and IP protection protocols.

AI-Powered Quoting Engine

Validated CAD geometry undergoes automated analysis through Honyo’s proprietary AI quoting system. This engine calculates material utilization (factoring ISO 13399-compliant holder classifications), machine time based on 5-axis milling/grinding complexity, and secondary operations (e.g., precision grinding, balancing). Quotes include parametric cost drivers: material grade (e.g., AISI 8620 vs. X39CrMo17-1), tolerance bands (IT5-IT7 per ISO 286), and surface finish requirements (Ra ≤ 0.4 µm). Output is a time-stamped, auditable quote with ±8% cost accuracy, excluding non-recurring engineering for first-article validation.

Engineering DFM Review

All quotes undergo mandatory Design for Manufacturability (DFM) assessment by senior manufacturing engineers. This phase identifies geometric conflicts with high-speed machining constraints (e.g., taper runout exceeding DIN 69893 CAT40 Class A limits of 0.0002″ TIR). Key DFM checkpoints include:

| DFM Parameter | Industry Standard | Honyo Enhanced Check |

|---|---|---|

| Taper Angle Tolerance | ±0.0005″ (ISO 26623) | ±0.0002″ via interferometric scan |

| Balance Grade | G2.5 @ 25,000 RPM | G1.0 @ 30,000 RPM (ISO 1940-1) |

| Flange Face Runout | 0.0004″ TIR | 0.00015″ TIR (laser calibration) |

Engineers collaborate directly with clients to resolve conflicts, such as modifying relief grooves that induce chatter at >20,000 RPM or optimizing coolant channel geometry for thermal stability. DFM sign-off requires documented client approval.

Precision Production Execution

Approved designs enter a controlled production cell. Tool holders are manufactured using hardened/pre-hardened alloy steels (e.g., 42CrMo4) on Makino a61nx 5-axis machining centers with Renishaw probes for in-process verification. Critical stages include:

Pre-machining heat treatment to 58-62 HRC followed by stress-relieving. Precision grinding of taper interfaces using Marposs gauging systems to achieve ≤0.00015″ TIR runout. High-speed balancing per ISO 1940-1 with Schenck balancers, certified to G0.4 at operational RPM. All components undergo 100% post-process metrology via Zeiss CONTURA CMMs, validating conformance to ASME B5.50.

Certified Delivery and Traceability

Completed tool holders are packaged with serialized traceability tags linking to digital quality records. Each shipment includes:

ISO/IEC 17025-accredited calibration reports for taper geometry and balance

Material test certificates (EN 10204 3.1)

First-article inspection reports (FAIR) per PPAP Level 3

Dynamic performance data (measured runout at 10k/20k/30k RPM)

Delivery occurs via tracked logistics with climate-controlled packaging, typically within 12-15 business days from DFM approval. Honyo maintains full lot traceability for 10 years, supporting audit requirements for aerospace and medical clients.

This integrated process ensures tool holders meet stringent OEM spindle compatibility requirements while minimizing time-to-assembly for end-users. Honyo’s closed-loop feedback system continuously refines AI quoting accuracy and DFM rule sets based on production metrology data.

Start Your Project

Need a reliable CNC machine tool holder for your precision manufacturing operations? Honyo Prototype offers high-performance tool holders engineered for accuracy, durability, and seamless integration in demanding CNC environments. Built to exacting standards, our tool holders ensure optimal tool grip, minimal runout, and extended tool life—critical for maintaining tight tolerances in aerospace, automotive, and medical part production.

All products are manufactured at our Shenzhen facility, where advanced metrology and strict quality control guarantee consistent performance. Whether you’re setting up a new machining center or optimizing existing workflows, our engineering team is ready to support your requirements.

Contact Susan Leo for technical specifications, pricing, or bulk order inquiries.

Email: [email protected]

Factory location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.