Contents

Manufacturing Insight: Cnc Machine Tolerance

Precision Defined: Understanding CNC Machine Tolerance at Honyo Prototype

CNC machine tolerance represents the permissible deviation in a machined part’s dimensions, a critical parameter directly impacting functionality, assembly, and performance in demanding applications. At Honyo Prototype, we recognize that achieving consistent, industry-leading tolerances—from standard ±0.005″ down to ultra-precision ±0.0002″—is not merely a capability but a foundational commitment to engineering integrity. Our advanced 3-, 4-, and 5-axis CNC machining centers, coupled with rigorous in-process metrology and environmental controls, ensure dimensional stability across diverse materials including aluminum, stainless steel, titanium, and engineering plastics. This precision eliminates costly assembly failures and accelerates time-to-market for aerospace, medical, and industrial clients.

Tolerance adherence begins with meticulous process design. Honyo’s engineering team leverages decades of manufacturing expertise to optimize toolpaths, fixturing, and material selection, mitigating thermal drift and tool wear that compromise accuracy. Unlike generic shops, we implement real-time SPC (Statistical Process Control) monitoring during production, validating every critical feature against your blueprint. This proactive approach transforms tolerance from a theoretical specification into a guaranteed outcome, reducing scrap rates and ensuring first-article approval.

For engineering teams requiring rapid validation of manufacturability and cost, Honyo’s Online Instant Quote platform delivers actionable insights in minutes—not days. Simply upload your STEP or IGES file to receive a detailed tolerance analysis, material recommendations, and a transparent price breakdown aligned with your precision requirements. This seamless integration of technical rigor and digital efficiency allows you to iterate designs confidently, knowing Honyo’s CNC machining services bridge the gap between concept and certified production-ready components.

| Tolerance Capability | Typical Applications | Key Verification Method |

|---|---|---|

| ±0.005″ (0.127mm) | Enclosures, brackets, non-critical assemblies | CMM First Article Inspection |

| ±0.001″ (0.025mm) | Hydraulic components, consumer electronics | In-Process Probe + CMM |

| ±0.0005″ (0.013mm) | Optics mounts, sensor housings | Laser Interferometry |

| ±0.0002″ (0.005mm) | Aerospace actuators, medical implants | Environmental Chamber CMM |

Technical Capabilities

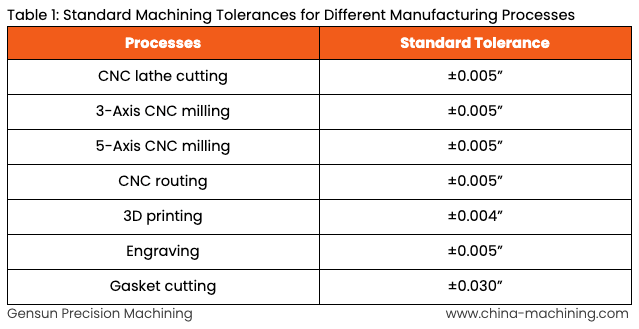

CNC machine tolerance refers to the allowable deviation in dimensions of a machined part, critical for achieving precision in manufacturing. Tolerances are influenced by machine capability, tooling, fixturing, material behavior, and process control. Honyo Prototype maintains tight tolerance standards across 3, 4, and 5-axis milling, as well as CNC turning operations. Below are typical achievable tolerances for common engineering materials under controlled conditions.

| Process | Axis Configuration | Typical Tolerance (General) | Tight Tolerance Capability | Material Considerations |

|---|---|---|---|---|

| 3-Axis CNC Milling | 3 | ±0.005 mm | ±0.002 mm | Aluminum: Excellent dimensional stability; minimal warpage. Steel: Higher rigidity but increased tool wear; thermal expansion controlled. ABS: Prone to warping; requires slow cooling and stress relief. Nylon: Hygroscopic; dimensions may shift post-machining without stabilization. |

| 4-Axis CNC Milling | 4 (3 + rotary A) | ±0.005 mm | ±0.003 mm | Aluminum: Ideal for complex indexing; high accuracy maintained. Steel: Suitable for multi-face features with minimal re-fixturing. ABS: Limited to low-stress geometries due to plastic deformation risk. Nylon: Requires sharp tooling and low cutting forces to avoid deflection. |

| 5-Axis CNC Milling | 5 (X, Y, Z, A, B/C) | ±0.005 mm | ±0.002 mm | Aluminum: Optimal for complex contours and aerospace components. Steel: Used in high-precision molds and tooling with tight geometric controls. ABS: Machined for prototypes requiring high detail; post-processing critical. Nylon: Best for functional prototypes with tight fit requirements after moisture conditioning. |

| CNC Turning | 2 (X, Z) + rotary | ±0.005 mm | ±0.001 mm (diameter) | Aluminum: High-speed turning with excellent surface finish. Steel: Capable of micron-level diameter control with fine finishing passes. ABS: Limited to low-RPM cutting; edge chipping possible. Nylon: Requires honed cutting edges; parts may require post-bore adjustment due to creep. |

Note: Tight tolerances (±0.001–0.003 mm) require process validation, thermal stabilization, high-precision tooling (e.g., PCD or carbide with sub-micron coatings), and in-process metrology. Material condition (e.g., annealed vs. hardened steel, dry vs. conditioned nylon) significantly affects final dimensional accuracy. Honyo Prototype employs environmental controls and CMM verification to ensure compliance with tight tolerance specifications across all materials and machine platforms.

From CAD to Part: The Process

Honyo Prototype CNC Machine Tolerance Process Overview

Our end-to-end CNC machining workflow rigorously manages dimensional tolerances from initial design to final shipment. This ensures parts meet functional requirements while optimizing manufacturability and cost. Tolerance control is embedded at every phase, not treated as a final inspection checkpoint.

Upload CAD

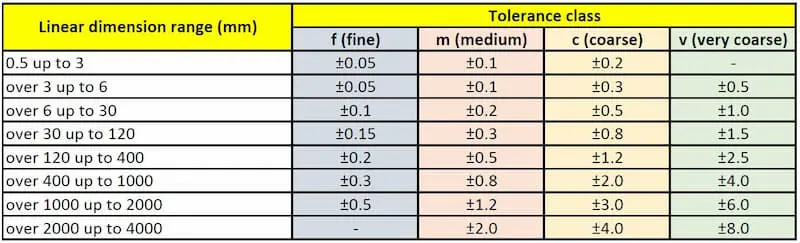

Clients submit native CAD files (STEP, IGES, Parasolid) containing geometric dimensioning and tolerancing (GD&T) specifications. Our system automatically parses critical features, nominal dimensions, and declared tolerances (e.g., ±0.05 mm, ISO 2768-m). We verify file integrity and flag missing tolerance callouts immediately, preventing downstream ambiguities. All dimensional requirements are digitally captured for traceability.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD geometry alongside declared tolerances to generate an instant, accurate quote. The system cross-references tolerance demands against machine capabilities, material properties, and feature complexity. Tighter tolerances (e.g., ±0.005 mm) trigger cost adjustments reflecting required process controls, specialized tooling, or secondary operations. The quote explicitly states achievable tolerance ranges per feature, avoiding unrealistic client expectations.

DFM Analysis with Tolerance Validation

Engineers perform a detailed Design for Manufacturability review focused on tolerance feasibility. We assess:

Whether specified tolerances align with standard machine capabilities (e.g., 3-axis vs. 5-axis milling)

Risk of tolerance stack-up in multi-feature components

Material behavior under cutting forces that may affect dimensional stability

Necessity of custom fixtures or process adjustments for critical features

Clients receive a formal DFM report with tolerance-specific recommendations, such as relaxing non-critical dimensions or suggesting alternative GD&T schemes to reduce cost without compromising function. Over 90% of tolerance-related issues are resolved here.

Production Execution with In-Process Verification

Tolerance management drives production protocols. For features requiring tight control:

Dedicated tooling and fixturing minimize deflection

Machine calibration is verified pre-run using laser interferometers

In-process CMM checks occur at defined intervals (e.g., 1st article, mid-lot) against the original CAD model

Statistical Process Control (SPC) charts monitor critical dimensions in real-time

All measurements are documented digitally, with deviations triggering immediate process correction. High-precision work adheres to our internal tolerance standards exceeding ISO 2768.

Delivery with Comprehensive Certification

Final inspection validates all tolerances using calibrated CMMs, optical comparators, or custom gauges. Clients receive:

A dimensional report showing actual measurements vs. nominal/tolerance limits for all critical features

Material certification and process documentation

As-built CAD model with inspection data overlay (optional)

This package provides full traceability, confirming adherence to both client specifications and Honyo’s quality management system (ISO 9001:2015 certified).

Standard Tolerance Capabilities Reference

| Tolerance Class | Typical Range | Common Applications |

|—————-|—————|———————|

| Standard Machining | ±0.05 mm (±0.002″) | Non-critical brackets, housings |

| Precision Machining | ±0.0125 mm (±0.0005″) | Hydraulic components, mating surfaces |

| High Precision | ±0.005 mm (±0.0002″) | Aerospace actuators, medical implants |

| Micromachining | ±0.001 mm (±0.00004″) | Optics, semiconductor tooling |

This structured approach ensures tolerances are proactively managed, not merely inspected. By integrating tolerance analysis from quotation through delivery, Honyo Prototype delivers parts that fit and function as intended, reducing assembly delays and field failures for our clients.

Start Your Project

Achieve precision in every component with our advanced CNC machining services. At Honyo Prototype, we specialize in tight-tolerance CNC manufacturing to meet the most demanding engineering specifications.

Our state-of-the-art facility in Shenzhen ensures high repeatability, superior quality, and fast turnaround times for prototyping and low-volume production.

For technical inquiries or project quotations, contact Susan Leo at [email protected]. Let’s engineer excellence together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.