Contents

Manufacturing Insight: Cnc Machine Size

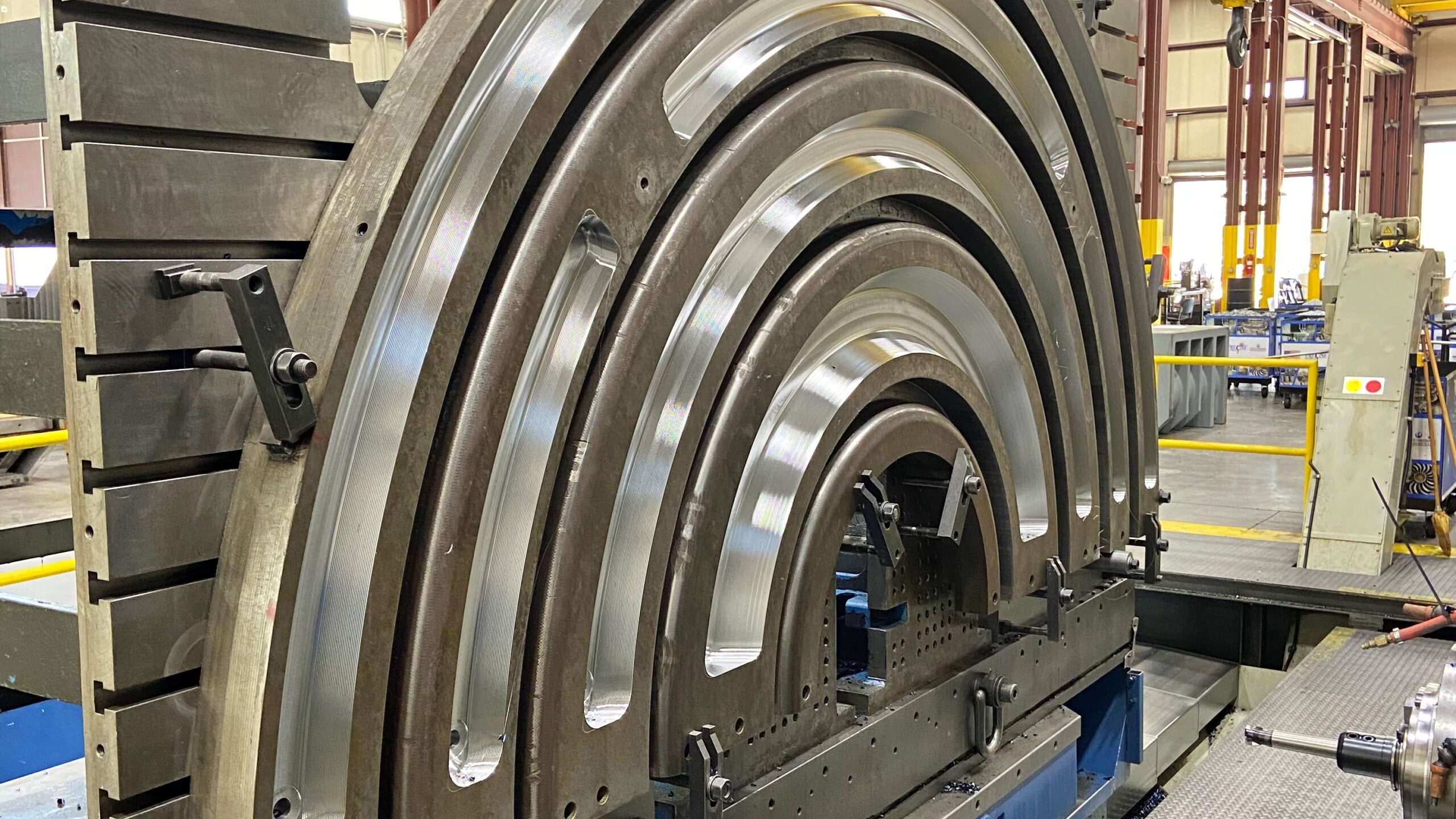

Precision Machining Capabilities Defined by Scale

At Honyo Prototype, our CNC machining services are engineered to accommodate the full spectrum of part complexity and dimensional requirements. The strategic selection of appropriate CNC machine size is critical to achieving optimal precision, throughput, and cost-efficiency for your project. We maintain a rigorously calibrated fleet spanning compact 3-axis mills to large-format 5-axis machining centers, ensuring your components—whether miniature aerospace fittings or structural enclosures—are produced within exacting tolerances without compromise. Our facility supports work envelopes from micro-machining scales up to 1000mm x 600mm x 500mm travel, eliminating dimensional constraints that bottleneck traditional prototyping and low-volume production.

Seamless Integration from Design to Manufacture

Honyo’s technical team leverages this scalable infrastructure to dynamically match your part geometry, material, and volume needs to the ideal machine platform. This capability minimizes fixturing complexity, reduces setup time, and ensures thermal stability across extended operations—directly translating to faster time-to-part and reduced non-recurring costs. Crucially, our process begins with immediate accessibility: the Online Instant Quote system allows engineers to upload CAD files and receive detailed manufacturability feedback alongside competitive pricing within hours, not days. This transparency empowers rapid iteration and informed decision-making at the earliest design stages.

Operational Excellence Through Strategic Sizing

Understanding that machine size directly impacts surface finish, feature resolution, and production economics, Honyo prioritizes technical alignment over one-size-fits-all approaches. By integrating our broad equipment range with real-time quoting technology, we deliver a responsive, data-driven pathway from concept to certified component—accelerating your development cycle while maintaining uncompromised quality standards for mission-critical applications.

Technical Capabilities

CNC machine size specifications are critical when selecting equipment for precision machining of components requiring tight tolerances across various materials such as aluminum, steel, ABS, and nylon. The physical footprint, work envelope, and axis travel determine the maximum part size and complexity that can be accommodated. Below is a technical summary of typical CNC machine size parameters for 3-axis, 4-axis, and 5-axis milling machines, as well as CNC turning centers, designed for high-accuracy applications.

| Machine Type | Axis Travel (X × Y × Z) | Work Envelope (mm) | Max Part Size (mm) | Spindle Speed (RPM) | Positioning Accuracy (± mm) | Repeatability (± mm) | Typical Materials Handled | Notes |

|---|---|---|---|---|---|---|---|---|

| 3-Axis CNC Mill | 500 × 400 × 300 | 500 × 400 × 300 | 500 × 400 × 300 | 8,000 – 15,000 | 0.005 | 0.003 | Aluminum, Steel, ABS, Nylon | Ideal for prismatic parts; tight tolerance ±0.01 mm achievable with proper fixturing and tooling |

| 4-Axis CNC Mill | 600 × 500 × 400 | 600 × 500 × 400 | 600 × 500 × 400 | 10,000 – 18,000 | 0.004 | 0.002 | Aluminum, Steel, ABS | Rotary axis (A or B) enables indexing; suitable for complex contours and undercuts |

| 5-Axis CNC Mill | 750 × 650 × 550 | 750 × 650 × 550 | 750 × 650 × 550 | 12,000 – 24,000 | 0.003 | 0.0015 | Aluminum, Steel, ABS, Nylon | Full simultaneous 5-axis motion; ideal for aerospace and medical parts with ±0.005 mm tolerance |

| CNC Turning Center | Max. Swing: 400 mm, Z: 500 mm, X: 200 mm | Ø400 × 500 | Ø380 × 480 | 4,000 – 6,000 (main spindle) | 0.005 | 0.003 | Aluminum, Steel, Nylon | Capable of tight-tolerance shafts, bushings; often paired with live tooling for mill-turn operations |

| 5-Axis Mill-Turn Center | B-axis + C-axis rotation, X/Y/Z: 300 × 250 × 400 | Ø250 × 400 rotary work zone | Ø230 × 380 | 12,000 – 15,000 (mill), 5,000 (turn) | 0.003 | 0.0015 | Aluminum, Steel, ABS | Combines turning and multi-axis milling; excellent for complex, high-precision components |

Notes on Material Considerations:

Aluminum and steel are commonly machined on all machine types listed, with steel requiring higher torque and rigidity. ABS and nylon, being engineering plastics, are typically processed on 3- and 4-axis mills with reduced cutting forces and optimized toolpaths to prevent melting or deformation. Tight tolerance work (±0.01 mm or better) demands thermal stability, high-precision ball screws or linear motors, and rigid machine structures—features standard in mid-to-high-end 5-axis and mill-turn platforms.

From CAD to Part: The Process

Honyo Prototype employs a structured CNC machining workflow designed to optimize precision, efficiency, and client transparency. The process is not defined by “CNC machine size” as a standalone metric but integrates machine capacity selection as a critical technical decision within broader production planning. Below is the accurate sequence with technical context:

CAD Upload and Initial Assessment

Clients submit native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs an immediate geometry validation check, flagging unsupported formats or corrupted files. This phase confirms basic manufacturability and extracts key dimensional parameters, including bounding box volume, feature complexity, and material requirements—essential data for subsequent machine allocation.

AI-Powered Instant Quoting

Our proprietary AI engine analyzes the CAD geometry alongside client specifications (material, tolerances, finish, quantity). It cross-references this against Honyo’s real-time machine park capacity, historical cycle time databases, and material waste algorithms. The output is a technically validated quote within minutes, including explicit confirmation of compatible machine types (e.g., “3-axis VMC under 500mm travel” or “5-axis mill-turn with B-axis”). This step prevents quoting for parts exceeding our equipment limits.

Engineering-Driven DFM Analysis

Quoted projects undergo rigorous Design for Manufacturability review by our applications engineering team. We assess:

Feature accessibility relative to standard machine travel ranges

Minimum tool diameter requirements versus cavity depths

Workholding feasibility within machine pallet systems

Potential need for secondary operations due to size constraints

Clients receive actionable feedback with geometric suggestions (e.g., “Increase radius to 0.8mm for 6mm end mill access”) before order confirmation. This phase ensures the design aligns with our CNC capabilities, eliminating size-related production failures.

Production Planning and Machine Allocation

Upon DFM approval, our production team assigns the optimal machine based on:

Part envelope dimensions versus machine working volume

Required axes (3-axis, 4-axis, 5-axis) for geometric complexity

Spindle power and torque profiles matching material removal rates

Fixture compatibility with machine pallet systems

This is not a generic “size” assignment but a technical matching process using our machine specifications database. For example:

| Machine Type | Max Travel (X/Y/Z) | Max Part Weight | Typical Use Case |

|---|---|---|---|

| 3-Axis Vertical Mill | 510 x 510 x 510 mm | 300 kg | Flat plates, simple brackets |

| 5-Axis Mill-Turn | 400 x 300 x 300 mm | 150 kg | Complex impellers, medical components |

| Large-Format Mill | 1000 x 600 x 600 mm | 1000 kg | Automotive fixtures, structural parts |

Production Execution

Machining occurs on the pre-allocated CNC system with real-time process monitoring. We enforce strict adherence to the DFM-agreed parameters, including in-process inspections for critical dimensions. Machine capacity constraints (e.g., maximum tool length, spindle RPM limits) are actively managed by our CNC programmers to maintain tolerances.

Quality Verification and Delivery

All parts undergo CMM or optical inspection against the original CAD model, with reports detailing dimensional compliance. Only after passing our AQL 1.0 quality standard are parts packaged per client specifications and shipped with full traceability documentation. This closed-loop process ensures the initial machine capacity assessment directly enables on-time, defect-free delivery.

This workflow systematically addresses equipment limitations at each stage, transforming “CNC machine size” from a potential risk factor into a controlled variable through technical validation and engineering oversight.

Start Your Project

For detailed specifications on our CNC machine capabilities and available machine sizes, contact Susan Leo directly at [email protected]. Our manufacturing facility is located in Shenzhen, China, where we maintain a full range of CNC equipment to support prototyping and low-volume production across industries. Let us know your project requirements, and we’ll ensure the right machine and capacity are allocated for precision, speed, and scalability.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.