Contents

Manufacturing Insight: Cnc Machine Shop Houston

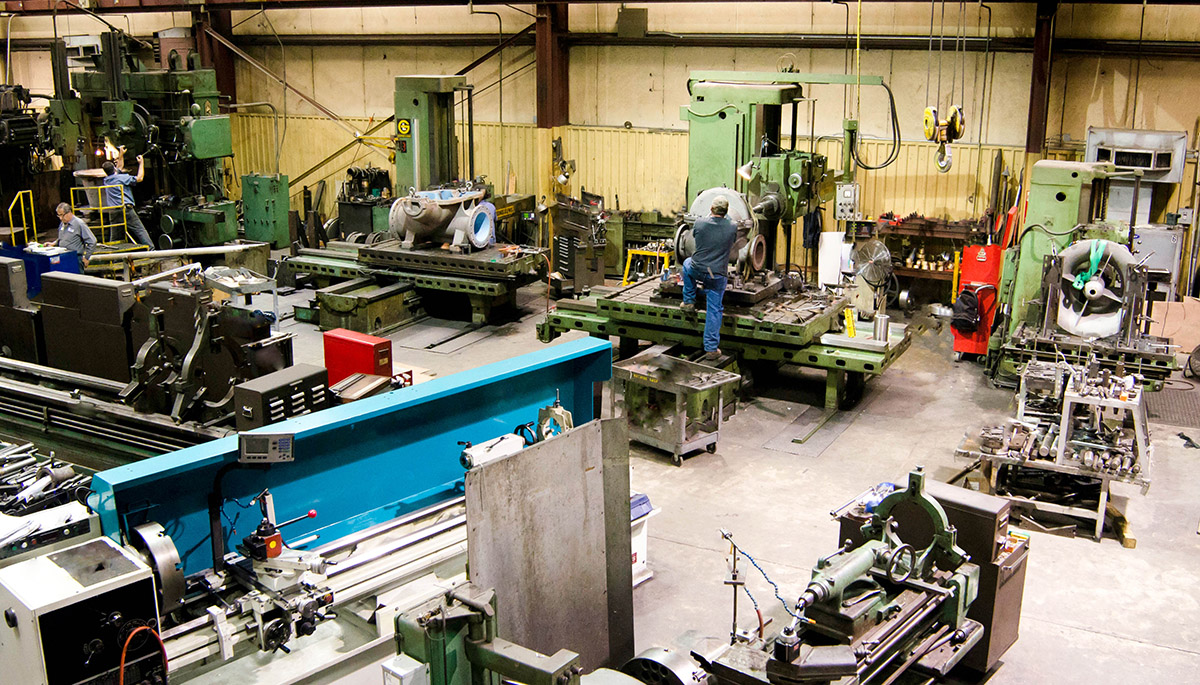

Precision CNC Manufacturing for Houston Industry

Honyo Prototype delivers advanced CNC machining services engineered for Houston’s demanding industrial landscape. As a full-service machine shop specializing in rapid prototyping and low-to-mid volume production, we leverage state-of-the-art 3-, 4-, and 5-axis milling centers alongside precision turning capabilities to produce complex components with tolerances down to ±0.0002″. Our facility supports aerospace, energy, medical, and industrial clients with certified material traceability, rigorous in-process inspection, and finishes meeting ISO 2768-mK standards.

What sets Honyo apart is our commitment to accelerating your development timeline. Traditional RFQ processes create critical delays, but our Online Instant Quote system eliminates this bottleneck. Upload your STEP or IGES file, specify materials and quantities, and receive a detailed manufacturing assessment with lead time and pricing in under 60 seconds—no manual intervention required. This empowers Houston-based engineering teams to iterate faster and respond to urgent production needs without administrative friction.

Speed Comparison: Traditional vs. Honyo Workflow

| Process Stage | Industry Average | Honyo Prototype |

|---|---|---|

| Quote Turnaround | 24–72 hours | < 60 seconds |

| First Article Lead | 10–15 business days | 5–8 business days |

| Material Sourcing | Client-coordinated | In-house inventory + JIT procurement |

We understand Houston manufacturers require more than machining—they need a responsive engineering partner. Honyo combines technical precision with digital efficiency to ensure your projects move from design to delivery faster. Start your next project with a validated quote today at honyoprototype.com.

Technical Capabilities

Honyo Prototype offers precision CNC machining services in Houston with advanced 3-axis, 4-axis, and 5-axis milling capabilities, complemented by high-accuracy CNC turning. Our facility is equipped to handle demanding applications requiring tight tolerances down to ±0.0002″ (5 µm), supporting a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon. Ideal for aerospace, medical, and industrial clients, our machines deliver repeatable precision, superior surface finishes, and complex geometry machining.

| Feature | Specification |

|---|---|

| Milling Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling Centers |

| Turning Capabilities | CNC Swiss and Turning Centers with live tooling |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Typical Tolerance Range | ±0.0002″ to ±0.0005″ (5–12 µm) |

| Maximum Work Envelope (Milling) | 40″ × 24″ × 20″ (X×Y×Z) |

| Maximum Work Envelope (Turning) | Ø1.5″ × 6″ bar feed (Swiss), Ø6″ × 24″ (turning) |

| Materials – Metals | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Tool Steel, Carbon Steel |

| Materials – Plastics | ABS, Nylon (6 & 6/6), Delrin (POM), PEEK, Polycarbonate |

| Surface Finishes | As-machined, Deburred, Smoothed, Polished (up to 8 µin Ra) |

| CNC Control Systems | Fanuc, Siemens, and Heidenhain |

| In-Process Inspection | On-machine probing, CMM verification, First Article Inspection (FAI) |

| Industries Served | Aerospace, Medical, Oil & Gas, Industrial Equipment, R&D |

Our Houston CNC machine shop maintains ISO-compliant processes and supports rapid prototyping through low- to mid-volume production runs. All parts undergo rigorous quality control to ensure dimensional accuracy and material integrity across both metallic and engineering plastic substrates.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven CNC machining workflow at our Houston facility designed for engineering precision and rapid turnaround. This integrated process eliminates traditional quoting delays while ensuring manufacturability from the initial design phase.

CAD File Upload and System Integration

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid, SolidWorks) via our secure customer portal. The system automatically validates file integrity and extracts critical geometric data including part dimensions, tolerances, and feature complexity. Houston-based engineering teams immediately gain visibility into the project within our centralized manufacturing execution system.

AI-Powered Quoting Engine

Our proprietary AI engine processes the CAD geometry alongside real-time operational parameters from Houston’s machine shop floor. It calculates precise machining time by simulating toolpaths, accounting for material removal rates, spindle utilization, and machine-specific capabilities across our Haas, DMG MORI, and Makino equipment. Material costs, fixture requirements, and secondary operations are dynamically priced using current supplier data and shop rate structures. Quotes include detailed cost breakdowns and are typically generated within 2 hours for standard parts.

Engineer-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by Houston-based manufacturing engineers before production release. The AI output serves as the baseline, but human expertise identifies critical optimizations:

| DFM Parameter | Typical Improvement Area | Impact on Production |

|---|---|---|

| Wall Thickness | Adjusting for chatter reduction | 30% faster cycle times |

| Internal Radii | Standardizing to tooling availability | Eliminates custom tool costs |

| Tolerance Stackups | Relaxing non-critical GD&T callouts | Reduces scrap by 15-25% |

| Feature Orientation | Optimizing for 3+2 axis setups | Cuts secondary operations by 50% |

Engineers collaborate directly with clients via secure portal comments or scheduled technical calls to resolve conflicts, providing annotated CAD markups and alternative solutions within 24 hours.

Precision Production Execution

Approved designs move to Houston’s climate-controlled production floor where:

CNC programs undergo virtual verification in NCSIMUL prior to machine loading

Raw materials from certified domestic suppliers are quarantined for batch traceability

In-process inspections occur at critical stages using Faro arms and Zeiss CMMs

All machining parameters are logged in real-time to our quality database

Secondary operations (tapping, deburring, heat treating coordination) follow integrated workflow

Certified Delivery and Documentation

Completed parts undergo final dimensional validation against original CAD models. Houston shipments include:

First article inspection reports (FAIR) with full GD&T verification

Material test reports (MTRs) from original mill certificates

Process validation documentation for AS9100-compliant projects

Tracking with real-time GPS visibility for time-sensitive deliveries

Optional packaging configurations for cleanroom or automotive applications

This closed-loop process reduces traditional prototyping lead times by 40-60% while maintaining strict adherence to ISO 9001:2015 and ITAR requirements. The Houston facility’s strategic location enables same-day shipping across the Gulf Coast industrial corridor, with typical production cycles ranging from 3-10 business days depending on part complexity and material availability. Clients maintain full visibility through our customer portal with real-time production status updates from order placement through delivery confirmation.

Start Your Project

Looking for precision CNC machining services in Houston? Partner with Honyo Prototype for high-quality, on-time manufacturing solutions.

Contact Susan Leo today at [email protected] to discuss your project requirements.

While our advanced production facility is located in Shenzhen, we provide seamless support and fast turnaround for clients across North America.

Let’s build precision together—reach out now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.