Contents

Manufacturing Insight: Cnc Machine Quality Control

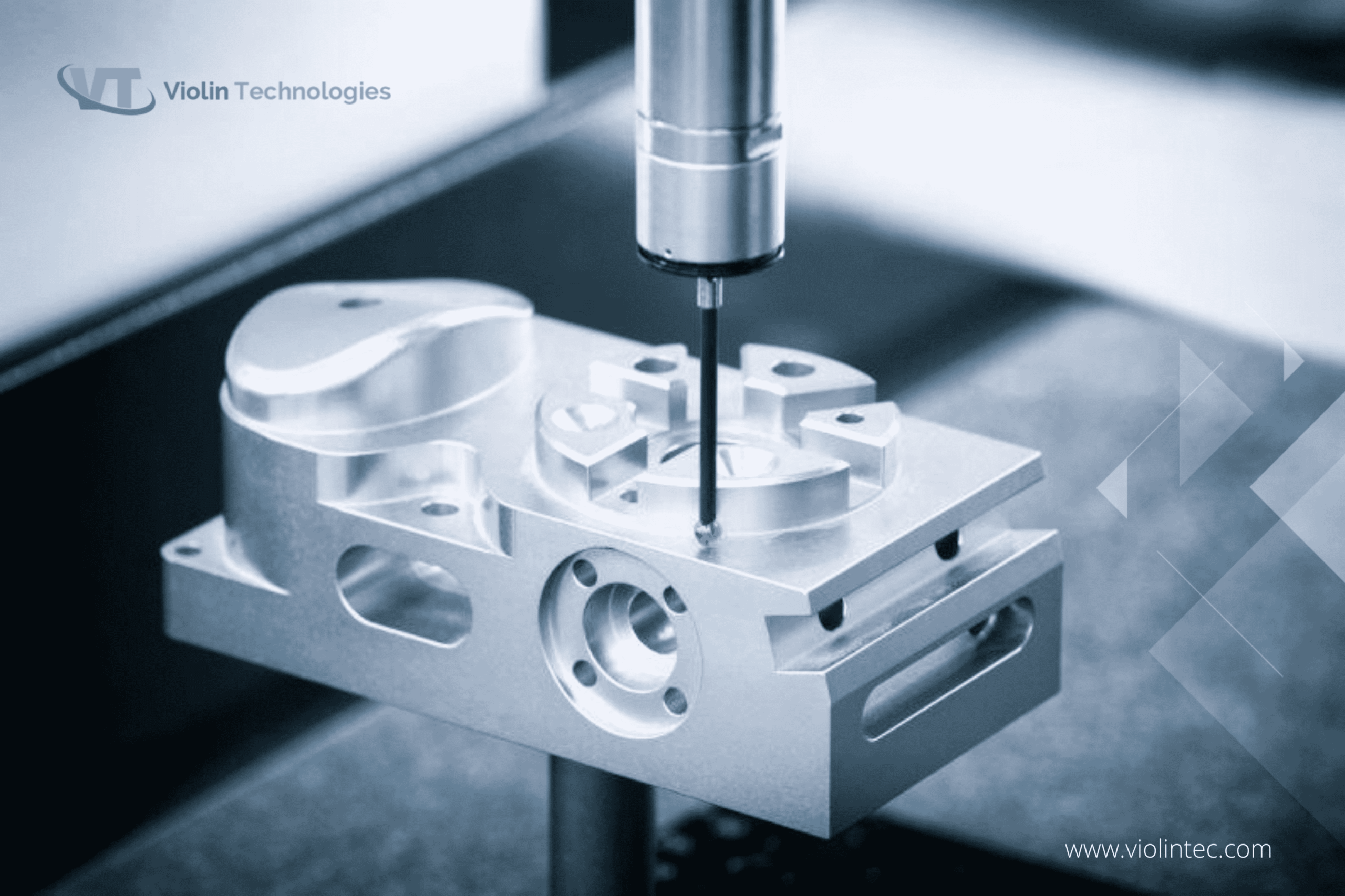

CNC Machine Quality Control

Precision manufacturing demands rigorous quality control at every stage of CNC machining to ensure components meet exacting specifications and performance requirements. At Honyo Prototype, our integrated quality management system is engineered to eliminate variability and defects before they impact your production timeline. We deploy advanced metrology tools—including CMMs, optical comparators, and in-process probing—alongside statistical process control (SPC) methodologies to validate tolerances as tight as ±0.0002″ across complex geometries. This systematic approach guarantees repeatability and compliance with ISO 9001 standards, directly translating to reduced scrap rates and accelerated time-to-market for your critical parts.

Honyo’s CNC machining services leverage this quality-first philosophy across milling, turning, and multi-axis operations, supporting materials from aerospace-grade alloys to medical polymers. Our engineers collaborate with clients to embed quality checkpoints into the manufacturing workflow, ensuring dimensional accuracy and surface integrity without compromising throughput. This commitment to excellence is further streamlined through our Online Instant Quote platform, which provides transparent, real-time pricing and lead times while factoring in stringent quality protocols from the initial design review. Clients gain immediate visibility into how Honyo’s quality-controlled processes deliver reliability and cost efficiency, turning prototypes and production runs into trusted extensions of your supply chain.

Technical Capabilities

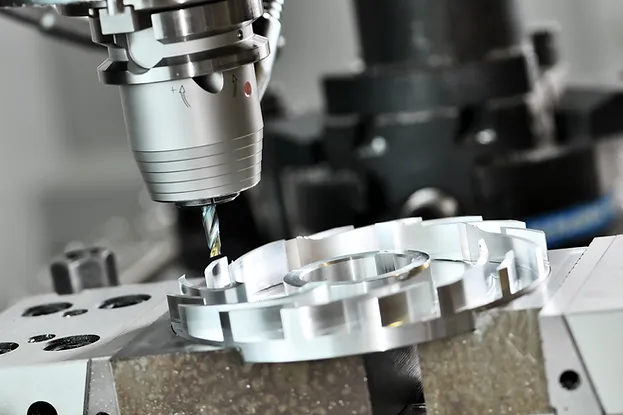

CNC machine quality control involves a comprehensive set of technical specifications and procedural checks to ensure precision, repeatability, and compliance with tight tolerance requirements across 3-axis, 4-axis, and 5-axis milling, as well as CNC turning operations. These controls are critical when working with a variety of materials such as aluminum, steel, ABS, and nylon, each presenting unique challenges in dimensional stability, surface finish, and tool interaction.

The following table outlines key quality control parameters and specifications relevant to high-precision CNC machining:

| Parameter | Specification / Tolerance | Applicable Processes | Material Considerations |

|---|---|---|---|

| Positional Accuracy | ±0.005 mm (±0.0002 in) | 3/4/5-Axis Milling, Turning | Critical for multi-axis alignment; steel and aluminum require thermal compensation |

| Repeatability | ±0.002 mm (±0.0001 in) | All CNC processes | Verified via gauge R&R studies; essential for batch consistency in nylon and ABS |

| Linear Axis Tolerance (Per ISO 230-2) | < 0.010 mm over 300 mm travel | 3/4/5-Axis Milling | Verified using laser interferometry; steel machining demands higher rigidity |

| Angular Tolerance (5-Axis) | ±1 arc minute | 5-Axis Milling | Achieved via rotary table calibration; critical for complex aluminum aerospace parts |

| Surface Roughness (Ra) | 0.8 µm (32 µin) typical, down to 0.4 µm (16 µin) with finishing | Milling, Turning | Steel and aluminum achieve better finishes than ABS and nylon; post-process polishing may be required |

| Dimensional Tolerance (General) | ±0.025 mm (±0.001 in) | All processes | Tight tolerance parts in steel require tool wear monitoring |

| Tight Tolerance Capability | ±0.005 mm to ±0.0125 mm (±0.0002–0.0005 in) | Precision Milling & Turning | Achieved with in-process probing, thermal stabilization, and high-precision tooling |

| Tool Runout | < 0.003 mm (0.0001 in) at spindle nose | All processes | Minimized using high-quality collet systems; critical for fine features in aluminum and ABS |

| In-Process Metrology | Probing systems (touch-trigger or laser) | 3/4/5-Axis Milling, Turning | Used for part alignment, tool setting, and dimensional verification; especially useful for nylon due to potential moisture absorption |

| Spindle Thermal Stability | < 0.005 mm thermal growth over 8-hour shift | Milling, Turning | Managed via spindle chillers; essential when switching between steel and aluminum |

| Material-Specific Fixturing | Low-pressure clamping for plastics, rigid vises for metals | All processes | Prevents deformation in ABS and nylon; ensures stability in high-force steel cutting |

| First Article Inspection (FAI) | AS9102 or ISO 17025 compliant reports | All processes | Includes CMM reports, cross-sectional views, and material certifications |

| Coordinate Measuring Machine (CMM) Accuracy | ±(1.5 + L/600) µm | Post-process verification | Used for validation of complex geometries in 5-axis aluminum components |

Quality control protocols are enforced throughout the machining cycle, including pre-machining material inspection, real-time tool wear monitoring, post-process metrology, and environmental control (temperature and humidity) to minimize drift—particularly critical when machining hygroscopic materials like nylon or thermally conductive aluminum. For steel components requiring tight tolerances, slow cutting passes and rigid setups are combined with periodic in-machine probing to maintain accuracy.

From CAD to Part: The Process

Honyo Prototype CNC Machining Quality Control Process Overview

Honyo Prototype implements a closed-loop quality control system integrated at every stage of our CNC machining workflow, ensuring dimensional accuracy, material integrity, and compliance with client specifications. This process begins at CAD upload and extends through final delivery, with rigorous checkpoints designed to prevent defects rather than merely detect them. Below is a technical breakdown of quality control activities within each phase.

CAD Upload Phase Quality Control

Upon CAD file receipt, our system performs automated geometric validation to verify file integrity and manufacturability. This includes checking for non-manifold edges, unit consistency, and minimum feature size compliance against our CNC capabilities. Files failing validation trigger immediate client notification with specific error diagnostics, preventing downstream quoting inaccuracies. All accepted CAD models undergo version control logging to ensure traceability throughout production.

AI Quote Phase Quality Control

During AI-driven quoting, our proprietary algorithm cross-references the validated CAD geometry against Honyo’s machine capability database, material stock tolerances, and historical process data. Critical checks include tolerance feasibility analysis (e.g., confirming ±0.005mm features are achievable on specified equipment), surface finish validation per ISO 21920-1, and material suitability verification against ASTM/AMS standards. The AI flags potential risks such as thin-wall instability or non-optimal tool access, generating a preliminary DFM report before formal quotation.

DFM Phase Quality Control

Our engineering team conducts a manual DFM review augmented by simulation software, overriding AI suggestions where necessary. Key quality interventions include:

Tolerance stack analysis using Monte Carlo simulation to predict assembly fit issues

Material removal rate optimization to prevent thermal distortion in high-precision features

Fixture design validation via FEA to ensure part stability during machining

Surface finish mapping to critical functional zones per client drawings

Clients receive annotated 3D PDFs highlighting suggested modifications with GD&T rationale. Only after client sign-off on the DFM report does production commence, locking all quality parameters.

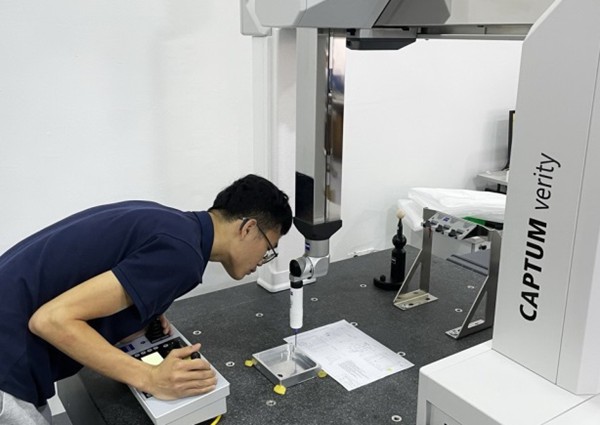

Production Phase Quality Control

In-process quality control employs a tiered inspection strategy aligned with AS9102 aerospace standards:

| Inspection Type | Timing | Method/Equipment | Purpose |

|---|---|---|---|

| First Article | Post-setup, pre-batch | CMM with 0.5μm accuracy, optical comparator | Validates program execution against CAD |

| In-Process | Critical feature completion | Hard gaging, laser micrometers | Monitors tool wear effects on tolerances |

| Final Dimensional | Pre-shipment | 5-axis CMM, surface profilometer | Full GD&T verification per drawing |

| Material Certification | Pre-machining | Mill test reports, PMI spectroscopy | Confirms alloy composition & heat treat |

All measurements feed into our SPC dashboard, with real-time alerts for process drift beyond ±1.33 Cpk thresholds. Non-conforming parts trigger root cause analysis using 5-Why methodology before rework authorization.

Delivery Phase Quality Control

Final quality documentation includes:

AS9102-compliant FAI package with ballooned drawings

Material traceability certificates with heat/lot numbers

CMM reports in ISO 10303-21 STEP format for client validation

Process capability indices (Cp/Cpk) for critical features

Parts undergo final visual inspection per MIL-STD-1312 for surface defects prior to vacuum-sealed packaging. Delivery includes digital access to our quality portal for lifetime part history tracking, enabling rapid issue resolution if field anomalies occur.

This integrated approach reduces client risk by embedding quality into each workflow phase, resulting in a 99.2% first-pass yield rate across Honyo’s CNC production floor. Our system ensures every delivered component meets the exact functional requirements defined in the original CAD model, with full auditability from design intent to end-use application.

Start Your Project

Ensure precision and consistency in your manufacturing process with our advanced CNC machine quality control services at Honyo Prototype. Located in Shenzhen, our state-of-the-art facility leverages industry-leading inspection protocols and metrology equipment to guarantee every component meets strict tolerance and quality standards.

For detailed inquiries or to request a quote, contact Susan Leo at [email protected]. Our engineering team is ready to support your project with technical expertise and fast turnaround.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.