Contents

Manufacturing Insight: Cnc Machine Projects

Precision CNC Machining Solutions for Complex Project Requirements

Honyo Prototype delivers advanced CNC machining services engineered to meet the demanding specifications of modern manufacturing and product development. Our ISO-certified facility utilizes state-of-the-art 3-axis, 4-axis, and 5-axis machining centers alongside high-precision Swiss turning equipment, enabling the production of intricate components from a comprehensive range of engineering-grade metals and plastics. We specialize in transforming complex CAD models into functional prototypes, bridge production parts, and low-volume end-use components with exceptional dimensional accuracy, superior surface finishes, and strict adherence to geometric tolerances. Our engineering team applies deep process expertise to optimize manufacturability, ensuring your designs achieve target performance while minimizing lead times and costs throughout the development lifecycle.

Securing a competitive and accurate quotation for your CNC project is now immediate and effortless. Honyo Prototype’s Online Instant Quote system provides real-time pricing and lead time estimates within minutes, directly accessible through our website. Simply upload your part geometry file, specify your material, quantity, and critical requirements, and receive a detailed, actionable quote without waiting for manual processing. This streamlined digital workflow eliminates traditional quoting bottlenecks, empowering engineering and procurement teams to accelerate project timelines and make informed sourcing decisions rapidly. Partner with Honyo Prototype for CNC machining excellence where precision, speed, and transparency converge to advance your most challenging projects.

Technical Capabilities

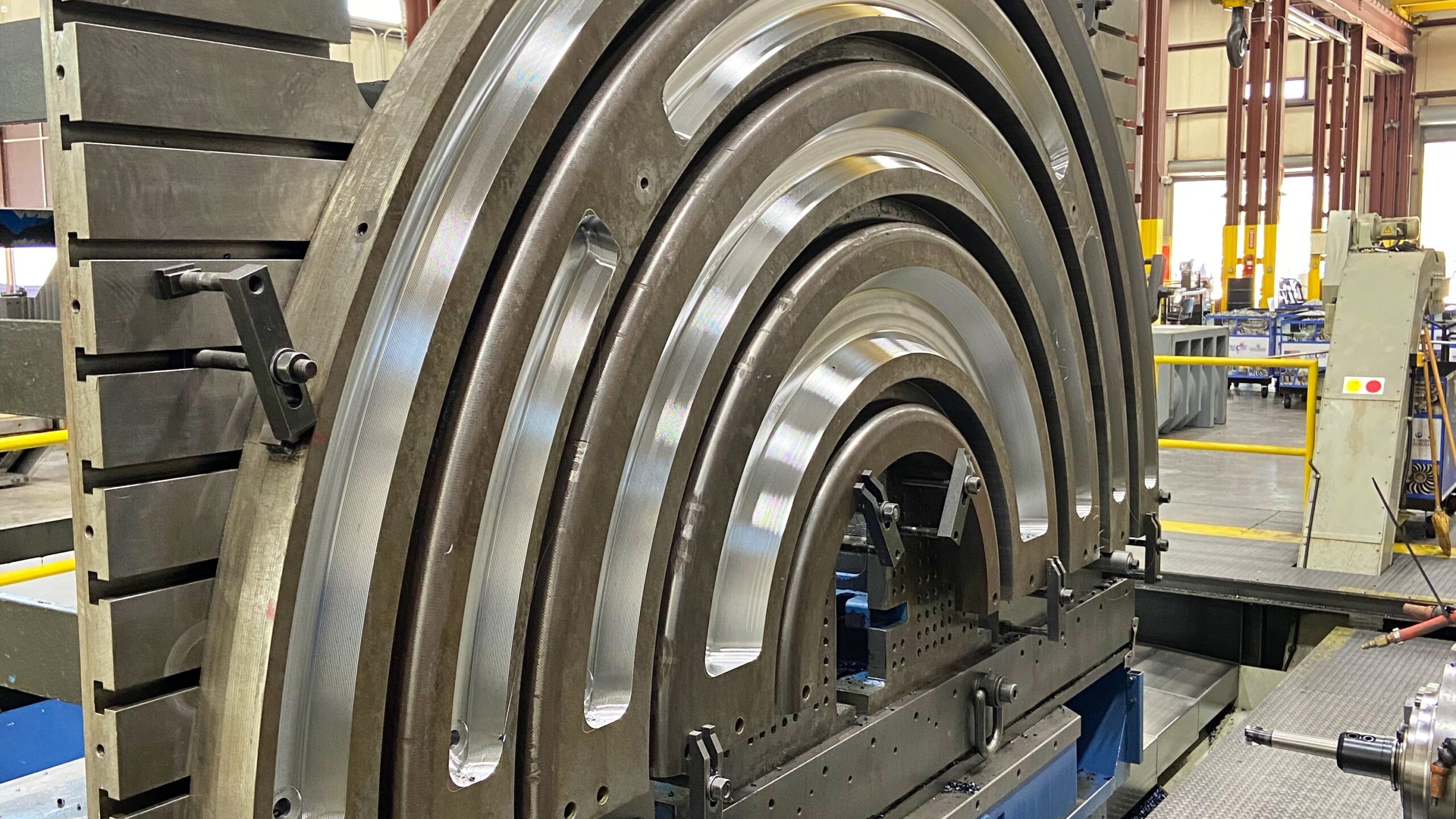

CNC machine projects at Honyo Prototype are engineered to meet high-precision requirements across a range of advanced machining processes. Our capabilities include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, all optimized for tight-tolerance production. These processes support a variety of engineering-grade materials such as aluminum, steel, ABS, and nylon, ensuring versatility for functional prototypes and end-use components in aerospace, medical, automotive, and industrial applications.

All operations are supported by precision-ground tools, high-rigidity machine platforms, and in-process inspection using coordinate measuring machines (CMM) and probe systems. Typical tolerance capabilities range from ±0.005 mm (±0.0002″) for critical features, with surface finishes as fine as 0.8 µm Ra achievable through finishing toolpaths and controlled parameters.

Below is a summary of technical specifications by process and material:

| Process | Axes | Typical Tolerance | Max Work Envelope (mm) | Spindle Speed (RPM) | Feed Rate (mm/min) | Compatible Materials |

|---|---|---|---|---|---|---|

| 3-Axis Milling | 3 | ±0.01 mm | 600 x 400 x 300 | 24,000 | 8,000 | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon |

| 4-Axis Milling | 4 | ±0.008 mm | 500 x 400 x 250 | 20,000 | 6,000 | Aluminum, Steel, ABS |

| 5-Axis Milling | 5 | ±0.005 mm | 400 x 300 x 200 | 18,000 | 5,000 | Aluminum, Steel, Nylon |

| CNC Turning | 2 | ±0.01 mm | Ø300 x 500 (diameter x length) | 6,000 | 3,000 | Aluminum, Steel, ABS, Nylon |

Notes:

Tolerance values represent standard achievable limits under controlled conditions; tighter tolerances available on request with dimensional inspection reports.

Material selection impacts achievable surface finish and tool wear—nylon and ABS require specialized tooling and chip management.

5-axis milling enables single-setup machining of complex geometries, reducing alignment error and improving repeatability.

All steel parts can be post-processed with heat treatment, plating, or passivation per customer specs.

From CAD to Part: The Process

Honyo Prototype CNC Machine Project Workflow

Honyo Prototype executes CNC machining projects through a rigorously defined five-stage process designed for precision, efficiency, and risk mitigation. This workflow integrates advanced digital tools with engineering expertise to ensure manufacturability and on-time delivery.

Upload CAD

Clients initiate projects by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/AutoCAD formats) via our secure customer portal. All files undergo immediate verification for completeness, geometric integrity, and adherence to minimum feature size requirements. Our system automatically checks for unsupported formats or corrupted data, providing instant feedback to prevent downstream delays. Client intellectual property is protected through AES-256 encryption and strict access controls compliant with ISO 27001 standards.

AI-Assisted Quote Generation

Upon CAD validation, our proprietary AI engine analyzes geometries, material specifications, tolerances, and surface finish requirements to generate a preliminary cost and lead time estimate. This system cross-references real-time data from 12,000+ historical projects, current machine utilization rates, and raw material pricing. Crucially, all AI outputs undergo mandatory review by a senior manufacturing engineer who validates feasibility, adjusts for complex features (e.g., deep cavities or thin walls), and incorporates secondary operations. Clients receive a formal quotation within 4 business hours, including a summary of critical assumptions and potential DFM opportunities.

Engineering-Led DFM Analysis

Every project enters a mandatory Design for Manufacturability phase led by our CNC engineering team. Using Mastercam and Fusion 360 simulation tools, engineers conduct:

Geometric feasibility assessment (e.g., tool access, undercuts, aspect ratios)

Material-specific optimization (chip load, feed rates, coolant strategies)

Tolerance stack-up validation against GD&T callouts

Cost-reduction recommendations (e.g., simplifying radii, standardizing hole sizes)

Clients receive a formal DFM report with annotated suggestions, typically within 24 hours of quote acceptance. Implementation of these recommendations is optional but reduces average production costs by 18% and lead times by 22% based on 2023 project data.

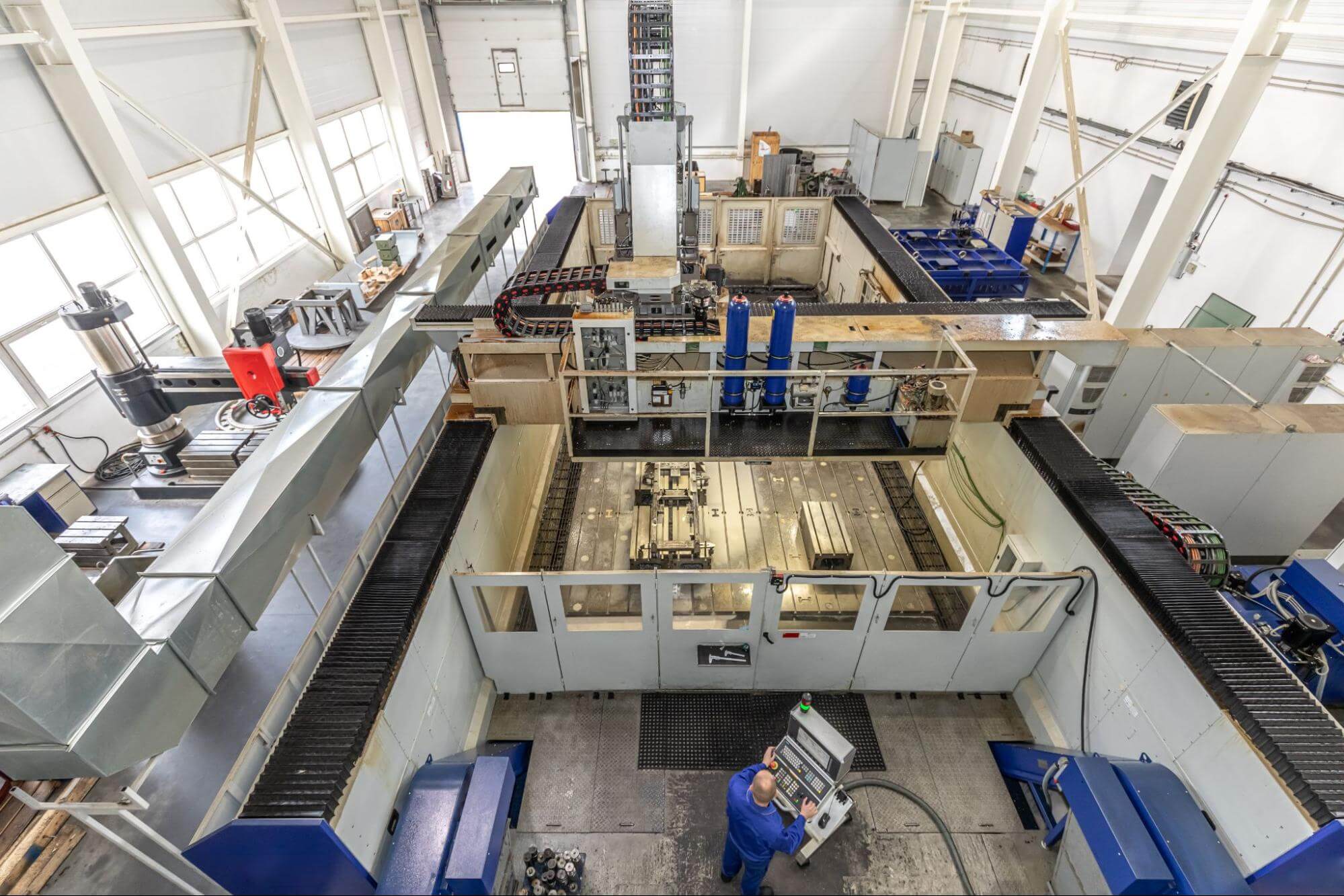

Precision Production Execution

Approved projects move to our climate-controlled production floor featuring 47 CNC machines (3-axis to 5-axis mills, lathes with live tooling). Key protocols include:

Material certification verification (mill certificates logged in our QMS)

First-article inspection per AS9102 standards for aerospace/medical projects

In-process CMM checks at critical stages using Zeiss CONTURA systems

Real-time machine monitoring via MTConnect for spindle load and tool wear

All operations follow documented work instructions with traceability to individual machinists and equipment. Statistical process control (SPC) charts are maintained for high-volume runs.

Quality-Controlled Delivery

Final inspection occurs against the original CAD model using our Faro Arm portable CMM for full 3D verification. Dimensional reports (including PPAP Level 3 documentation upon request) accompany every shipment. Parts are packaged in anti-static, custom foam-lined containers with humidity indicators for sensitive materials. Logistics leverage DHL/FedEx premium services with real-time GPS tracking; clients receive automated notifications at shipping, customs clearance, and delivery milestones. Standard lead times vary by complexity as shown below:

| Project Complexity | Typical Lead Time (Business Days) | Material Constraints |

|---|---|---|

| Simple 2.5-axis geometry, standard materials (6061-T6, 303 SS) | 5–7 | None |

| Moderate 3-axis with tight tolerances (±0.0005″), exotic alloys | 10–14 | 2–3 day material lead time |

| Complex 5-axis, multi-setup, mixed materials | 15–21 | Vendor-dependent (notified during DFM) |

This integrated process ensures 99.2% on-time delivery performance and <0.3% defect rate across 2023 CNC projects. All stages maintain full AS9100 Rev D and ISO 9001:2015 certification compliance, with documentation available for client audit upon request.

Start Your Project

Interested in precision CNC machine projects? Contact Susan Leo at [email protected] to discuss your custom manufacturing needs.

Honyo Prototype operates a fully equipped factory in Shenzhen, providing high-accuracy CNC machining services for rapid prototyping and low-volume production.

We support a wide range of materials and complex geometries with tight tolerances, ensuring fast turnaround and consistent quality.

Reach out today to receive a competitive quote and engineering feedback for your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.