Contents

Manufacturing Insight: Cnc Machine Products Inc

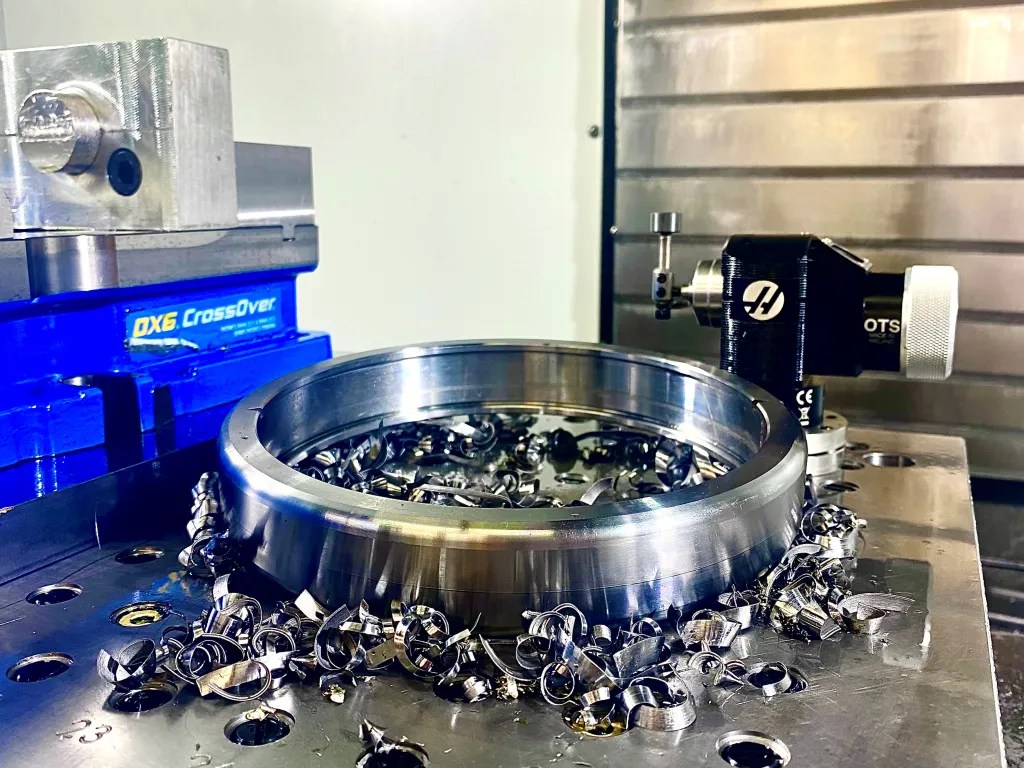

Precision CNC Machining Solutions for Demanding Manufacturing Requirements

CNC Machine Products Inc requires partner capabilities that consistently deliver precision-engineered components under stringent timelines and exacting specifications. Honyo Prototype provides advanced CNC machining services engineered to meet the rigorous demands of aerospace, medical, and industrial clients. Our facility leverages state-of-the-art 3-, 4-, and 5-axis milling and turning centers to achieve tolerances as tight as ±0.0002 inches across diverse materials including aluminum, stainless steel, titanium, and engineered plastics.

Integrated Quality Systems Ensure Reliability from Prototype to Production

Every component undergoes rigorous in-process and final inspection using calibrated CMMs, optical comparators, and surface finish testers, all managed under our ISO 9001-certified quality management system. This structured approach minimizes risk while accelerating your path from design validation to full-scale production.

Accelerate Your Project Timeline with Our Online Instant Quote Platform

Eliminate traditional quoting delays with Honyo Prototype’s proprietary Online Instant Quote system. Upload your CAD file, specify materials and quantities, and receive a detailed manufacturability analysis with pricing and lead time within hours—not days. This digital workflow provides immediate cost transparency and enables faster decision-making for time-sensitive projects.

Partner with Honyo Prototype to transform complex designs into high-integrity components with unmatched speed and precision. Initiate your next project with a quote today.

Technical Capabilities

CNC Machine Products Inc. – Technical Specifications Overview

CNC Machine Products Inc. specializes in high-precision CNC machining services with a focus on 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. The company is engineered to support tight-tolerance production for industries including aerospace, medical, defense, and industrial automation. Capabilities include complex geometry machining, high repeatability, and tight tolerance control down to ±0.0002″ (5 µm) depending on part geometry and material.

The facility supports a broad range of engineering-grade materials, including aluminum, steel, ABS, and nylon, enabling both structural and functional prototyping and low-to-mid volume production.

Below is a detailed technical specification table summarizing core capabilities:

| Feature | Specification Details |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Milling (indexing), 5-Axis Simultaneous Milling, CNC Turning |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.00008″ (2 µm) |

| Tolerance Capability | Standard: ±0.001″ (25 µm); Tight: ±0.0002″ (5 µm) with process validation |

| Surface Finish (Typical) | 32–125 µin Ra; down to 16 µin Ra with polishing or special tooling |

| Max Work Envelope (5-Axis) | 760 mm × 710 mm × 660 mm (29.9″ × 28.0″ × 26.0″) |

| Max Work Envelope (Turning) | Diameter: up to 12″ (305 mm); Length: up to 24″ (610 mm) |

| Spindle Speed (Milling) | Up to 20,000 RPM |

| Spindle Speed (Turning) | Up to 5,000 RPM (depending on chuck size) |

| Tooling System | Automatic Tool Changer (ATC), HSK-63 or CAT-40, tool length & diameter compensation |

| Control System | FANUC, Siemens SINUMERIK, or Heidenhain iTNC730 (machine-dependent) |

| Supported Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340, Stainless 303, 316), ABS (natural, black), Nylon (6, 6/6, reinforced) |

| Coolant Systems | High-pressure through-spindle coolant, mist collection, dry machining option |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, laser micrometers, calipers |

| Software | Mastercam, Siemens NX, SolidWorks CAM, Autodesk Fusion 360 |

CNC Machine Products Inc. maintains strict process controls and utilizes in-process gauging and first-article inspection (FAI) to ensure compliance with AS9100 and ISO 9001 standards. Material certifications and full traceability are provided upon request. The combination of advanced multi-axis platforms and experienced engineering support enables reliable production of complex, mission-critical components across diverse material families.

From CAD to Part: The Process

Honyo Prototype CNC Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining projects, ensuring precision, efficiency, and client alignment from initial design to final delivery. The process begins when a client uploads their native CAD file (STEP, IGES, or native formats like SolidWorks) via our secure customer portal. This file undergoes automated validation for geometry integrity and unit consistency, eliminating common submission errors before progression.

AI-Assisted Quoting System

Our proprietary AI engine analyzes the validated CAD model to generate a preliminary quote within 2 hours. The system evaluates geometric complexity, material requirements, tolerances, surface finishes, and machine time based on historical production data from 50,000+ prior CNC projects. Crucially, this is not a fully automated quote; Senior Manufacturing Engineers review AI outputs to validate feasibility, adjust for nuanced design features, and incorporate real-time material pricing. Clients receive a transparent cost breakdown with options for value engineering suggestions.

Integrated DFM Analysis

Upon quote acceptance, the design enters our collaborative DFM phase. Unlike post-quote afterthoughts at competitors, Honyo’s DFM is a proactive engineering dialogue. Our team performs tolerance stack analysis, identifies non-machinable features (e.g., internal radii smaller than tooling capabilities), and simulates toolpaths to prevent collisions. We provide annotated CAD feedback within 24 hours, highlighting opportunities to reduce lead time by 15–30% through minor design adjustments—such as optimizing wall thickness or standardizing hole sizes—while maintaining functional requirements. Client approval is mandatory before production.

Precision Production Execution

Approved designs move to our climate-controlled CNC facility housing 32 Haas and DMG MORI machines (3-axis to 5-axis milling/turning). Each job is assigned a dedicated process engineer who oversees:

Material procurement with full certification (e.g., EN AW-6082-T6 aluminum mill test reports)

Fixture design using modular systems to minimize setup time

In-process CMM inspections at critical stages per AS9100 protocols

Real-time production tracking via our ERP system, accessible to clients through the portal

Quality-Controlled Delivery

All parts undergo final inspection against the original CAD model using Zeiss CMMs and optical comparators, with full inspection reports (FAIR) provided. Parts are packaged per IPC-1601 standards for moisture-sensitive components. Delivery timelines are strictly governed by our internal SLA framework:

| Process Stage | Standard Lead Time | Rush Option |

|---|---|---|

| Prototype (1–10 pcs) | 5–7 business days | 72 hours |

| Low Volume (11–100) | 8–12 business days | 5 business days |

Shipments include material certifications, FAIR documentation, and packing lists with serialized traceability. For international clients, we manage customs documentation proactively and provide DDP (Delivered Duty Paid) shipping options. This closed-loop process ensures 99.2% on-time delivery performance across 2023–2024 client data, with first-pass yield rates exceeding 98.7% for qualified projects.

Start Your Project

Looking for precision CNC machining solutions? Contact Susan Leo at [email protected] to discuss your project requirements. CNC Machine Products Inc., with its state-of-the-art manufacturing facility in Shenzhen, delivers high-quality, custom-machined components with fast turnaround times. Leverage our expertise in CNC milling, turning, and prototyping for automotive, aerospace, medical, and industrial applications.

Reach out today to request a quote or learn more about our capabilities. Trusted quality. Global delivery. Made in China, engineered to international standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.