Introduction: Navigating the Global Market for cnc machine nearby

As international B2B buyers navigate the complexities of sourcing a CNC machine nearby, they often encounter significant challenges, including finding reliable suppliers, understanding pricing structures, and evaluating machine specifications. This guide is designed to demystify the process of acquiring CNC machines, providing a comprehensive resource tailored to the unique needs of businesses in Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and Brazil.

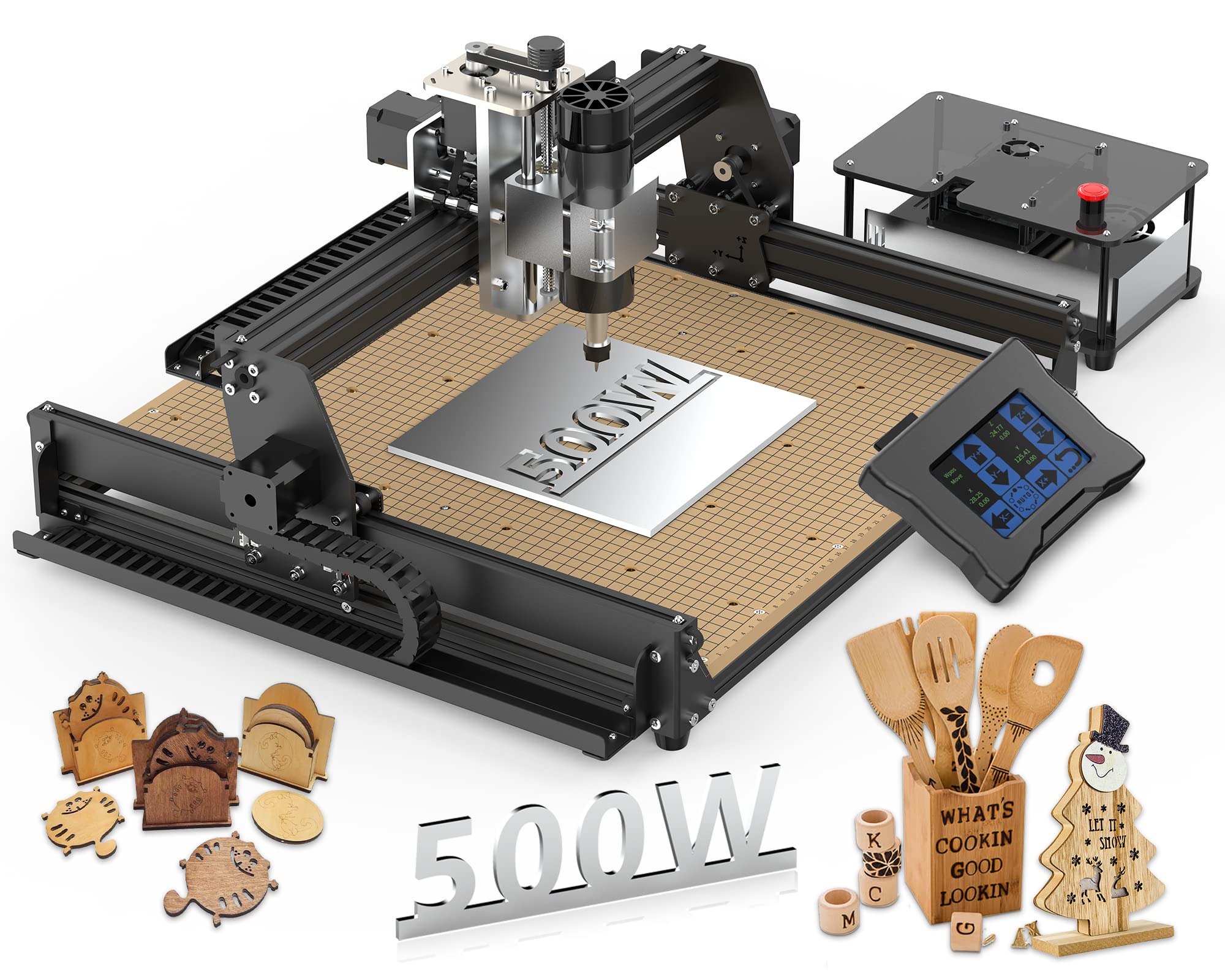

Within this guide, you will discover insights into various types of CNC machines, their applications across industries, and key factors to consider during the supplier vetting process. We delve into cost considerations, helping you make informed decisions that align with your budget and operational needs. Whether you’re a small business seeking a desktop CNC router for intricate designs or a larger enterprise in need of robust CNC milling capabilities, this guide equips you with the knowledge to navigate the global marketplace effectively.

By leveraging the insights provided here, you can enhance your purchasing strategy, mitigate risks, and ultimately drive better outcomes for your projects. Our aim is to empower you with the information necessary to select a CNC machine that not only meets your immediate requirements but also supports your long-term business goals.

Understanding cnc machine nearby Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Mills | Versatile, capable of high precision cutting | Aerospace, automotive, and industrial parts | Pros: High precision; Cons: Higher cost |

| CNC Lathes | Rotates material against a stationary cutting tool | Manufacturing cylindrical parts, shafts | Pros: Ideal for round shapes; Cons: Limited to specific shapes |

| 5-Axis CNC Machines | Allows movement on five axes for complex parts | Aerospace, medical devices, and automotive | Pros: Complex geometry; Cons: More expensive and requires skilled operators |

| CNC Routers | Uses a rotating bit to cut wood, plastic, and soft metals | Furniture, signage, and decorative items | Pros: Versatile for soft materials; Cons: Less effective on hard metals |

| Laser Cutters | Employs focused laser beams for cutting and engraving | Sign making, precision parts, and art | Pros: Clean cuts, minimal waste; Cons: Limited material types |

What Are CNC Mills and Their B2B Relevance?

CNC mills are among the most versatile types of CNC machines, characterized by their ability to perform various cutting operations with high precision. They are particularly suitable for manufacturing complex components in industries such as aerospace and automotive, where precision is paramount. B2B buyers should consider the machine’s capability to handle different materials and its adaptability to various production processes. While CNC mills can be a significant investment, their durability and precision often justify the cost over time.

How Do CNC Lathes Fit into Manufacturing?

CNC lathes are specialized machines designed to produce cylindrical parts by rotating the workpiece against a fixed cutting tool. This makes them ideal for manufacturing components like shafts and fittings, which are prevalent in automotive and industrial applications. When purchasing a CNC lathe, buyers should evaluate the machine’s speed, accuracy, and tooling options. Although they are more limited in shape versatility compared to mills, their efficiency in producing round shapes makes them a valuable asset in specific manufacturing processes.

Why Consider 5-Axis CNC Machines for Complex Designs?

5-axis CNC machines are designed for intricate cutting and shaping, allowing for movement along five different axes. This capability is essential for industries that require complex geometries, such as aerospace and medical devices. B2B buyers should assess the machine’s software compatibility and ease of operation, as these machines often require skilled operators. While the initial investment is higher, the ability to produce complex parts in a single setup can lead to significant time and cost savings.

What Are the Advantages of CNC Routers in Various Applications?

CNC routers utilize a rotating bit to cut materials like wood, plastic, and soft metals, making them an excellent choice for industries focused on furniture production, signage, and decorative items. Their versatility allows for intricate designs and quick production runs. Buyers should consider the machine’s cutting area and the types of materials it can handle. Although CNC routers are less effective on hard metals, their lower cost and ease of use make them an attractive option for many businesses.

How Do Laser Cutters Enhance Precision in Manufacturing?

Laser cutters use focused beams of light to cut or engrave materials, providing clean edges and minimal waste. They are widely used in sign making, precision parts production, and artistic applications. For B2B buyers, key considerations include the types of materials the machine can process and the thickness limits. While laser cutters excel in precision, they are often limited to specific materials, which can restrict their versatility in some manufacturing environments.

Key Industrial Applications of cnc machine nearby

| Industry/Sector | Specific Application of cnc machine nearby | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | High accuracy and reliability in critical parts | Certification for aerospace standards; local support |

| Automotive | Prototype and production parts | Faster turnaround for prototypes and mass production | Supplier’s experience with automotive designs |

| Electronics | PCB milling and engraving | Enhanced precision in electronic components | Compatibility with various PCB materials |

| Furniture & Woodworking | Custom furniture design and production | Unique, tailored designs and efficient production | Material versatility; ability to handle large sheets |

| Medical Devices | Custom surgical instruments | High precision and compliance with health standards | Certification for medical manufacturing; local regulations compliance |

How Are CNC Machines Used in the Aerospace Industry?

CNC machines in the aerospace sector are utilized for manufacturing precision components, such as airframe parts and engine components. These machines ensure high accuracy and reliability, which are critical for safety and performance in aviation. International buyers should consider suppliers with certifications that meet aerospace standards, as well as those who offer local support for maintenance and troubleshooting.

What Role Do CNC Machines Play in Automotive Manufacturing?

In the automotive industry, CNC machines are essential for both prototype development and mass production of parts. They enable manufacturers to quickly produce prototypes, reducing time-to-market for new vehicle models. Buyers should focus on suppliers with proven experience in automotive design and production, ensuring that they can meet the specific requirements of high-volume manufacturing.

How Are CNC Machines Applied in Electronics Production?

CNC machines are increasingly used in the electronics industry for PCB milling and engraving, allowing for the precise creation of circuit boards. This application enhances the accuracy of electronic components, which is vital for functionality and reliability. International buyers should ensure that the CNC machines they source can handle various PCB materials and are compatible with existing production processes.

In What Ways Do CNC Machines Benefit Furniture and Woodworking Industries?

In furniture and woodworking, CNC machines facilitate the design and production of custom furniture pieces. They allow for unique, tailored designs while improving production efficiency. Buyers in this sector should look for CNC machines that can work with various materials and handle large sheets, as this versatility is crucial for creating diverse furniture styles.

How Are CNC Machines Used in the Manufacturing of Medical Devices?

CNC machines are critical in the production of custom surgical instruments and other medical devices. These machines provide the high precision required to meet stringent health standards and regulations. International buyers must ensure that their suppliers are certified for medical manufacturing and compliant with local regulations to ensure the quality and safety of their products.

3 Common User Pain Points for ‘cnc machine nearby’ & Their Solutions

Scenario 1: Difficulty in Locating Reliable CNC Machining Services Nearby

The Problem:

B2B buyers often struggle to find reliable CNC machining services in their vicinity, especially in regions where manufacturing resources are limited. The challenge is exacerbated in countries in Africa, South America, and the Middle East, where local suppliers may lack the necessary certifications, advanced technology, or the capacity to handle complex projects. This not only leads to delays in production timelines but also creates uncertainties regarding quality and service reliability.

The Solution:

To overcome this challenge, B2B buyers should utilize digital platforms that aggregate information on local CNC service providers. Websites like CNC Machines.com and Thumbtack allow users to filter results based on specific criteria, such as ratings, services offered, and proximity. Additionally, buyers should conduct thorough due diligence by reviewing testimonials and case studies from previous clients. Networking within local industry groups or trade associations can also provide valuable recommendations and insights into reputable service providers. By leveraging these resources, buyers can confidently select a CNC machining partner that meets their quality and reliability standards.

Scenario 2: Uncertainty About CNC Machine Specifications and Capabilities

The Problem:

Another common issue faced by B2B buyers is the uncertainty surrounding the specifications and capabilities of CNC machines available locally. This is particularly pertinent when buyers are unsure which machine would best suit their specific manufacturing needs, leading to potential misinvestments in equipment that may not deliver the expected results. The lack of clarity can result in wasted resources and missed production opportunities.

The Solution:

Buyers should engage in comprehensive research and consultation before making any purchasing decisions. This involves reaching out to manufacturers or suppliers for detailed specifications, performance data, and application examples of their CNC machines. Attending trade shows or industry expos can provide firsthand experience with various machines and direct interaction with manufacturers. Furthermore, utilizing simulation software can help buyers visualize how different CNC machines would perform in their specific manufacturing processes. By equipping themselves with this knowledge, buyers can make informed decisions that align with their production goals.

Scenario 3: Challenges in After-Sales Support and Maintenance

The Problem:

Once a CNC machine is purchased, B2B buyers often face challenges regarding after-sales support and maintenance, particularly in regions where suppliers may be less established. This can lead to significant downtime in operations, as buyers might struggle to obtain spare parts or technical support when issues arise. The lack of adequate after-sales service can severely impact a company’s production efficiency and profitability.

The Solution:

To mitigate this risk, buyers should prioritize vendors who offer robust after-sales support as part of their service agreements. It is essential to inquire about warranty terms, availability of spare parts, and the responsiveness of technical support teams before purchasing. Buyers can also consider partnering with local service providers who specialize in CNC maintenance and repair, ensuring that help is readily available when needed. Establishing a proactive maintenance schedule and training staff on basic troubleshooting can further enhance machine longevity and minimize downtime. By taking these steps, companies can ensure that they are not only investing in high-quality CNC machines but also securing the necessary support to maintain operational efficiency.

Strategic Material Selection Guide for cnc machine nearby

What Are the Key Materials Used in CNC Machining?

When selecting materials for CNC machining, it is crucial to understand the properties, advantages, and limitations of various materials to ensure optimal performance and suitability for specific applications. Below, we analyze four common materials used in CNC machining, focusing on their characteristics and implications for international B2B buyers.

How Does Aluminum Perform in CNC Machining?

Aluminum is a widely used material in CNC machining due to its favorable properties. It boasts excellent corrosion resistance, lightweight characteristics, and good thermal conductivity. These properties make aluminum ideal for applications in the automotive, aerospace, and consumer electronics industries.

Pros: Aluminum is relatively easy to machine, allowing for high precision and intricate designs. Its lightweight nature reduces shipping costs, which is beneficial for international buyers.

Cons: While aluminum is durable, it can be less resistant to wear compared to harder materials like steel. Its cost can also vary significantly based on alloy type.

Impact on Application: Aluminum is compatible with various media, including plastics and composites, making it versatile for different manufacturing needs.

Considerations for International Buyers: Compliance with standards such as ASTM B211 is essential for quality assurance. Buyers should also consider local availability and pricing fluctuations based on global aluminum markets.

What Are the Benefits of Using Steel in CNC Machining?

Steel is another popular material in CNC machining, known for its strength and durability. It has a high temperature and pressure rating, making it suitable for heavy-duty applications in industries like construction and manufacturing.

Pros: Steel’s robustness allows for the production of long-lasting components, and it can withstand harsh environments. It is also available in various grades, providing flexibility for specific applications.

Cons: Steel can be more challenging to machine than softer materials, leading to increased manufacturing complexity. Additionally, it is generally heavier, which can raise transportation costs.

Impact on Application: Steel is particularly suitable for applications requiring high strength and load-bearing capabilities, such as machinery parts and structural components.

Considerations for International Buyers: Compliance with standards like ASTM A36 or DIN 17100 is crucial for ensuring material quality. Buyers should also consider the implications of tariffs and trade agreements affecting steel imports.

Why Choose Plastics for CNC Machining Applications?

Plastics are increasingly popular in CNC machining due to their lightweight and corrosion-resistant properties. They are commonly used in consumer products, medical devices, and automotive components.

Pros: Plastics are easy to machine and can be produced in various colors and finishes, enhancing aesthetic appeal. They are also cost-effective, particularly for high-volume production runs.

Cons: Plastics may not provide the same strength and durability as metals, making them less suitable for heavy-duty applications. They can also be sensitive to temperature changes, which may affect their performance.

Impact on Application: Plastics are compatible with a wide range of applications, including those requiring chemical resistance, making them ideal for industries like pharmaceuticals.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ISO 9001 for quality management. Additionally, understanding local regulations regarding plastic materials is essential to avoid legal issues.

How Do Composites Enhance CNC Machining Capabilities?

Composite materials, such as carbon fiber and fiberglass, offer unique advantages in CNC machining. They are known for their high strength-to-weight ratio and resistance to corrosion and fatigue.

Pros: Composites can be tailored to specific performance requirements, making them ideal for specialized applications in aerospace and automotive industries. They are lightweight, which can reduce transportation costs.

Cons: Machining composites can be more complex and may require specialized tools and techniques. They can also be more expensive than traditional materials.

Impact on Application: Composites are particularly effective in applications requiring lightweight and strong materials, such as in aerospace components.

Considerations for International Buyers: Compliance with standards like ASTM D3039 is important for ensuring the quality of composite materials. Buyers should also be aware of the supply chain complexities that may arise when sourcing composites internationally.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for cnc machine nearby | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, consumer electronics | Lightweight and corrosion-resistant | Less wear-resistant than steel | Medium |

| Steel | Machinery parts, structural components | High strength and durability | More challenging to machine | High |

| Plastics | Consumer products, medical devices | Cost-effective and easy to machine | Lower strength compared to metals | Low |

| Composites | Aerospace components, automotive parts | High strength-to-weight ratio | Complex machining requirements | High |

This guide provides valuable insights into material selection for CNC machining, helping international B2B buyers make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machine nearby

What Are the Main Stages of Manufacturing CNC Machines?

The manufacturing process for CNC machines involves several critical stages that ensure precision, efficiency, and quality. Each stage is essential in transforming raw materials into fully operational machines ready for the market.

Material Preparation: How Are Raw Materials Sourced and Processed?

The first step in manufacturing CNC machines is material preparation. Manufacturers typically source high-grade metals such as aluminum, steel, and cast iron, which are known for their durability and machinability. The materials undergo processes like cutting, shearing, and deburring to achieve the desired dimensions and surface quality. Advanced techniques such as laser cutting and water jet cutting may also be employed to ensure high precision.

Forming: What Techniques Are Used to Shape Components?

Once the materials are prepared, the next stage is forming, where components are shaped according to specifications. Techniques such as machining, forging, and casting are commonly used. CNC machining involves using computer-controlled tools to achieve high precision in shaping parts, which is crucial for components that require tight tolerances. This stage often utilizes multi-axis machining for complex geometries, enhancing the machine’s overall capability.

Assembly: How Are Components Integrated into Final Products?

After individual components are formed, they are assembled into complete machines. This stage requires skilled technicians who follow detailed assembly instructions to ensure that each part fits perfectly. The assembly process may include integrating electronic controls, motors, and other components necessary for the CNC machine’s operation. Quality checks are performed at various points during assembly to identify and rectify any issues early in the process.

Finishing: What Are the Final Touches Before Delivery?

The finishing stage involves final adjustments and treatments to enhance the machine’s performance and aesthetics. This includes processes such as painting, anodizing, and applying protective coatings. These treatments not only improve the machine’s appearance but also protect it from corrosion and wear. Final inspections are conducted to verify that the machine meets all specifications and quality standards before it is shipped to customers.

What Quality Assurance Practices Are Essential for CNC Machine Manufacturing?

Quality assurance (QA) is a vital aspect of CNC machine manufacturing, ensuring that products meet international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

CNC machine manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications are crucial for compliance and market acceptance. Buyers from Africa, South America, the Middle East, and Europe should verify that suppliers hold these certifications, as they reflect a commitment to quality and safety.

What Are the Key Quality Control Checkpoints in CNC Manufacturing?

Quality control in CNC manufacturing typically includes several checkpoints, including:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components as they arrive at the facility to ensure they meet specified quality standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor production quality. This includes checking machining tolerances and surface finishes at different stages.

-

Final Quality Control (FQC): Before a CNC machine is shipped, a comprehensive final inspection is conducted to ensure the machine meets all performance and safety criteria. This may involve testing the machine’s functionality and conducting performance tests.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures employed by CNC machine suppliers. Here are some effective strategies:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting audits is one of the most effective ways to assess a supplier’s quality management system. Buyers should request access to audit reports, which provide insights into the supplier’s compliance with relevant quality standards and practices. Regular audits help identify potential weaknesses in the manufacturing process, enabling buyers to make informed decisions.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services adds an extra layer of assurance. Independent inspectors can verify that manufacturing processes adhere to specified quality standards and that finished products meet contractual obligations. This is particularly important for international buyers who may not have the resources to conduct onsite inspections themselves.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must navigate various challenges when it comes to quality control in CNC machine procurement. Understanding regional differences in standards and practices is essential.

How Do Regional Standards Impact Quality Control?

Different regions may have varying standards and regulations affecting the manufacturing and testing of CNC machines. For instance, while ISO 9001 is widely recognized, specific industries may have additional requirements based on local regulations. Buyers should familiarize themselves with these regional standards to ensure compliance and avoid potential legal issues.

What Are the Common Testing Methods Used to Ensure Quality?

Common testing methods in CNC manufacturing include functional testing, dimensional accuracy checks, and performance evaluations. These tests ensure that the machine operates as intended and meets the specifications set forth in the design phase. Buyers should inquire about the specific tests performed on the machines they are considering for purchase, as this information is vital for assessing quality.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Critical for B2B Buyers?

For B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices of CNC machines is crucial. This knowledge empowers buyers to make informed decisions, select reliable suppliers, and ultimately enhance their operational efficiency and product quality. By prioritizing quality in their procurement processes, businesses can ensure that they invest in machines that deliver consistent performance and long-term value.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machine nearby’

In the realm of manufacturing, sourcing a CNC machine nearby can significantly enhance operational efficiency and reduce logistical challenges. This practical guide serves as a step-by-step checklist for B2B buyers looking to procure CNC machines effectively, ensuring a seamless purchasing process.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline the technical specifications of the CNC machine you require. Consider factors such as the type of materials you’ll be working with, the complexity of parts to be machined, and the required precision. This clarity will help you narrow down your options and communicate effectively with potential suppliers.

Step 2: Research Local Suppliers

Identifying suppliers in your vicinity can save time and reduce shipping costs. Utilize online platforms and local directories to compile a list of CNC machine vendors. Look for suppliers who have a strong local presence and positive reviews from previous customers to ensure reliability and support.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider the following:

– Certifications: Ensure they hold relevant certifications (ISO, CE) that validate their manufacturing processes.

– Reputation: Look for testimonials or reviews that speak to their customer service and product quality.

Step 4: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to understand the market rate for the CNC machines that meet your specifications. When comparing prices, consider not only the initial cost but also potential maintenance fees, warranty terms, and the availability of spare parts. This comprehensive view will help you make an informed decision.

Step 5: Check for After-Sales Support and Training

A CNC machine is a significant investment, and ongoing support is crucial for its effective operation. Inquire about the after-sales services offered by suppliers, such as:

– Training Programs: Ensure that the supplier provides adequate training for your team to operate the machine effectively.

– Technical Support: Confirm the availability of technical support for troubleshooting and maintenance.

Step 6: Inspect the Machine Before Purchase

If possible, arrange to inspect the CNC machine in person or via a virtual tour. This step allows you to verify the machine’s condition, features, and overall quality. Look for signs of wear and ensure that all promised specifications are met.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and confirmed the machine’s specifications and condition, it’s time to finalize the purchase agreement. Review the terms carefully, ensuring that all aspects—price, delivery schedules, warranty, and support—are clearly outlined. This will protect your investment and establish clear expectations.

By following this structured checklist, B2B buyers can efficiently navigate the sourcing process for CNC machines, ensuring they make informed decisions that align with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for cnc machine nearby Sourcing

What Are the Key Cost Components for Sourcing CNC Machines Nearby?

When considering the cost structure for sourcing CNC machines, several critical components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

- Materials: The type of materials used directly impacts the final cost. High-quality materials, such as advanced alloys or composite materials, typically command higher prices but can lead to superior machine performance and longevity.

- Labor: Skilled labor is essential for CNC machine assembly and setup. Regions with higher labor costs may see increased overall pricing.

- Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

- Tooling: Specialized tooling can significantly affect pricing, especially for machines designed for specific tasks or industries.

- Quality Control: Comprehensive QC processes ensure reliability and performance, but they also add to the cost. Machines with certifications (e.g., ISO) often have higher price tags due to stringent QC standards.

- Logistics: Transportation costs, particularly for international shipments, can vary widely based on location, shipping methods, and any tariffs or duties.

- Margin: Supplier margins can vary significantly based on market demand, competition, and brand reputation.

How Do Price Influencers Affect CNC Machine Costs?

Several factors influence the final pricing of CNC machines:

- Volume/MOQ: Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their operational needs.

- Specifications and Customization: Custom machines tailored to specific applications can increase costs. Buyers should balance their needs for customization with budget constraints.

- Material Quality and Certifications: Machines made from premium materials and possessing industry-standard certifications may have higher upfront costs but offer better durability and reliability.

- Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers often command higher prices due to their proven track record and support services.

- Incoterms: Understanding the terms of delivery, such as FOB (Free on Board) or CIF (Cost Insurance and Freight), is crucial as it impacts the total landed cost of the machine.

What Are the Best Practices for Negotiating CNC Machine Prices?

To achieve cost-efficient sourcing of CNC machines, buyers should consider the following tips:

- Conduct Market Research: Understanding the prevailing market rates for CNC machines can empower buyers during negotiations. Utilizing platforms that provide historical pricing data can be beneficial.

- Assess Total Cost of Ownership (TCO): When evaluating CNC machines, consider not just the purchase price but the entire lifecycle costs, including maintenance, energy consumption, and potential downtime.

- Leverage Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and ensure competitive pricing.

- Explore Financing Options: Some suppliers may offer financing plans or leasing options, which can alleviate upfront costs and improve cash flow.

- Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and priority access to new technologies or updates.

What Should International Buyers Consider in Pricing Nuances?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of several pricing nuances:

- Currency Fluctuations: Exchange rates can significantly affect the final cost. It’s advisable to lock in prices or negotiate in a stable currency when possible.

- Import Duties and Taxes: Understanding local regulations regarding import duties can help in budgeting accurately for the total cost of acquisition.

- Cultural Factors: Different regions may have unique negotiation styles and expectations. Familiarity with local customs can enhance communication and foster better deals.

Disclaimer on Indicative Prices

The prices mentioned in various sources can vary significantly based on the machine specifications, supplier location, and market demand. As such, it is essential for buyers to perform due diligence and obtain tailored quotes to ensure accurate budgeting for their CNC machine sourcing needs.

Alternatives Analysis: Comparing cnc machine nearby With Other Solutions

Exploring Alternatives to CNC Machines Nearby

In the rapidly evolving manufacturing landscape, businesses often seek alternatives to traditional CNC machines to enhance efficiency and reduce costs. Understanding the various options available allows B2B buyers to make informed decisions tailored to their specific operational needs. This analysis compares ‘CNC machine nearby’ with two viable alternatives: 3D Printing and Manual Machining.

| Comparison Aspect | Cnc Machine Nearby | 3D Printing | Manual Machining |

|---|---|---|---|

| Performance | High precision and repeatability | Excellent for complex geometries; limited by material strength | Variable precision; depends on operator skill |

| Cost | Initial investment is high; ongoing operational costs | Lower material costs; equipment can be expensive | Generally lower initial investment; labor costs can be high |

| Ease of Implementation | Requires skilled operators; setup can be complex | User-friendly for design changes; requires knowledge of CAD | Simple setup; requires skilled labor for precision |

| Maintenance | Regular maintenance needed; parts can be costly | Low maintenance; occasional nozzle replacements | Frequent maintenance; dependent on machine age and use |

| Best Use Case | Mass production of high-tolerance parts | Prototyping and small-batch production | Custom, one-off parts and repairs |

In-Depth Analysis of Alternatives

3D Printing: Is It the Future of Manufacturing?

3D printing has gained traction as an alternative to CNC machining due to its ability to create complex geometries that are often difficult to achieve with traditional methods. The technology allows for rapid prototyping and can significantly reduce material waste, making it cost-effective for small production runs. However, the mechanical properties of 3D printed parts can be inferior to those produced by CNC machines, limiting their use in high-stress applications. Additionally, while the initial setup costs may be lower than CNC machines, high-quality 3D printers can still require a significant investment.

Manual Machining: The Traditional Approach

Manual machining remains a viable alternative for businesses that require custom, one-off parts. This method allows for flexibility and adaptability, particularly in low-volume production environments. While manual machining can be less expensive to start, it heavily relies on the skill of the machinist, which can lead to variability in quality. Maintenance can also be more frequent and labor-intensive compared to CNC machines, especially as equipment ages. Manual machining is best suited for specialized projects where precision is less critical, or rapid changes to design are needed.

Choosing the Right Solution for Your Business Needs

When selecting the right solution, B2B buyers must consider their specific operational requirements, budget constraints, and production volumes. CNC machines excel in high-volume production with consistent quality, making them ideal for industries that demand precision. On the other hand, 3D printing offers flexibility and innovation for prototyping and small batches, while manual machining provides a cost-effective solution for custom projects. By analyzing these alternatives, businesses can make strategic decisions that align with their production goals and market demands, ultimately enhancing their competitive edge.

Essential Technical Properties and Trade Terminology for cnc machine nearby

When considering the acquisition of CNC machines, understanding the essential technical properties and trade terminology is crucial for making informed B2B decisions. This knowledge not only aids in selecting the right equipment but also enhances communication with suppliers and partners. Below are key specifications and industry terms relevant to CNC machines.

What Are the Key Technical Properties of CNC Machines?

1. Material Grade

Material grade refers to the type and quality of materials used in the construction of CNC machines, impacting durability and performance. Common materials include aluminum, steel, and various composites. For B2B buyers, selecting machines made from high-grade materials ensures longevity and resistance to wear, crucial for maintaining operational efficiency.

2. Tolerance

Tolerance indicates the permissible limit of variation in a machine’s dimensions. It is a critical specification that affects the precision of the machining process. In industries such as aerospace or automotive, where exact specifications are vital, understanding tolerance levels ensures that the CNC machine can meet stringent production standards, thereby reducing waste and enhancing product quality.

3. Axis Configuration

CNC machines can have various axis configurations, including 3-axis, 4-axis, and 5-axis systems. The number of axes determines the complexity of the machining operations that can be performed. For B2B buyers, selecting the appropriate axis configuration is essential for meeting specific manufacturing needs, such as intricate designs or multi-dimensional parts.

4. Spindle Speed

Spindle speed refers to the rotation speed of the spindle, typically measured in revolutions per minute (RPM). Higher spindle speeds can lead to faster machining processes and better surface finishes. For businesses aiming for efficiency, understanding spindle speed helps in selecting machines that optimize production timelines while maintaining quality.

5. Feed Rate

Feed rate indicates how quickly the cutting tool moves through the material, usually measured in inches per minute (IPM). This property directly affects machining time and overall productivity. B2B buyers should consider the feed rate when evaluating CNC machines, as it plays a significant role in balancing speed and precision.

What Are Common Trade Terms Related to CNC Machines?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is important for B2B buyers as it helps in identifying quality suppliers and ensuring that components meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is crucial for B2B transactions as it helps buyers gauge production capabilities and manage inventory costs effectively, ensuring that they do not overstock or understock essential materials.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products or services. For B2B buyers, utilizing RFQs streamlines the procurement process, allowing for better budget management and supplier comparison.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is vital for B2B buyers involved in global sourcing, as they clarify shipping, insurance, and tariffs, thus minimizing risks associated with international trade.

5. CAD (Computer-Aided Design)

CAD refers to software used for creating precision drawings or technical illustrations. This term is significant for B2B buyers in CNC machining, as it influences design accuracy and facilitates better communication between engineers and machinists.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can enhance their decision-making process, ensuring they select the most suitable CNC machines for their operational needs. Understanding these aspects not only aids in procurement but also fosters better relationships with suppliers and partners in the CNC machining landscape.

Navigating Market Dynamics and Sourcing Trends in the cnc machine nearby Sector

What Are the Current Market Dynamics and Key Trends in the CNC Machine Sector?

The CNC machine sector is experiencing robust growth, driven by advancements in automation, precision engineering, and the increasing demand for customized manufacturing solutions. Global supply chains have evolved to become more interconnected, enabling international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to access a broader range of CNC technologies. Key trends include the adoption of Industry 4.0 principles, which leverage IoT and data analytics to enhance machine efficiency and minimize downtime. Additionally, the rise of desktop CNC machines is democratizing access to advanced manufacturing capabilities, allowing small businesses and hobbyists to engage in CNC machining without significant capital investment.

Emerging technologies such as additive manufacturing and hybrid CNC systems are also gaining traction, further diversifying the market. For international buyers, understanding regional market dynamics is crucial. For instance, buyers in Brazil may prioritize cost-effective solutions due to budget constraints, while European buyers may seek high-precision machines with robust support networks. The demand for CNC machines that can handle a variety of materials, from metals to composites, is increasing, reflecting the growing complexity of manufacturing processes across various industries.

How Does Sustainability and Ethical Sourcing Impact the CNC Machine Industry?

Sustainability is becoming a critical consideration in the CNC machine sector, impacting sourcing decisions and operational practices. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to adopt more sustainable practices. International B2B buyers are increasingly looking for suppliers who prioritize eco-friendly materials and energy-efficient machines. This trend is particularly pronounced in Europe, where regulatory frameworks encourage green manufacturing practices.

Ethical sourcing is equally important, as companies are held accountable for their supply chains. This includes ensuring that raw materials are sourced responsibly and that labor practices adhere to ethical standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential criteria for suppliers. Buyers can enhance their brand reputation and customer loyalty by partnering with manufacturers who demonstrate a commitment to sustainability through their production processes and sourcing strategies.

What Is the Brief Evolution of CNC Machines and Their Impact on B2B?

CNC machines have evolved significantly since their inception in the 1940s and 1950s, transitioning from large, complex systems primarily used in industrial settings to versatile, user-friendly machines accessible to small businesses and individual users. Initially, CNC technology was limited to high-end applications; however, advancements in computer technology and software have made CNC machining more affordable and efficient.

Today, CNC machines are integral to various industries, including aerospace, automotive, and woodworking, enabling manufacturers to produce high-quality, intricate components with minimal human intervention. The evolution of CNC technology has not only improved precision and repeatability but has also reduced lead times and waste, making it an attractive option for B2B buyers looking to optimize their production processes. This continuous innovation within the CNC sector is set to shape the future of manufacturing, providing opportunities for international buyers to leverage advanced technologies for competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machine nearby

-

1. How do I choose the right CNC machine for my business needs?

Selecting the appropriate CNC machine involves assessing your specific production requirements, including the materials you will be working with and the complexity of your projects. Start by determining the type of CNC machine that best fits your needs, such as CNC routers for wood or CNC mills for metal. Consider factors like machine size, precision, and speed. It’s also essential to evaluate the machine’s compatibility with your existing workflow and software. Engaging with suppliers for demonstrations or recommendations can further assist in making an informed choice. -

2. What are the key features to look for in a CNC machine?

When sourcing a CNC machine, focus on critical features such as precision, build quality, and ease of use. Look for machines with advanced controls, high spindle speeds, and robust construction to ensure durability. Additionally, consider the availability of support and training from the manufacturer, which can significantly impact your operational efficiency. Features like automatic tool changers and integrated software can enhance productivity, making them important considerations in your selection process. -

3. How can I ensure the quality of CNC machines I purchase?

To ensure the quality of CNC machines, conduct thorough supplier vetting by reviewing their certifications, customer testimonials, and past projects. Request samples or demonstrations of the machines to evaluate their performance firsthand. Additionally, inquire about the manufacturing process and materials used in production. Establishing a relationship with reputable suppliers who offer warranties and post-purchase support can also provide peace of mind regarding machine quality and reliability. -

4. What are the common payment terms for purchasing CNC machines?

Payment terms for CNC machine purchases can vary widely depending on the supplier and the machine’s cost. Common arrangements include full upfront payments, deposits followed by balance payments upon delivery, or installment plans. For international buyers, it is advisable to use secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms in the contract, including any penalties for late payments, to avoid misunderstandings. -

5. What is the minimum order quantity (MOQ) for CNC machines?

The minimum order quantity (MOQ) for CNC machines can vary based on the supplier and the specific machine type. Many suppliers may have an MOQ of one machine, especially for standard models. However, custom machines or specialized configurations may require larger orders to justify production costs. Always discuss MOQs upfront with your supplier, as they may offer flexibility depending on your business needs and long-term partnership potential. -

6. How do I handle logistics and shipping for CNC machines?

Logistics and shipping for CNC machines require careful planning due to their size and complexity. Coordinate with your supplier to understand the shipping methods available and the associated costs. Ensure that all customs documentation is in order for international shipments to avoid delays. It may be beneficial to partner with a logistics provider experienced in handling heavy machinery to facilitate smooth transportation and delivery. Additionally, plan for installation and setup at your facility, accounting for any specialized equipment or expertise required. -

7. Can I customize CNC machines to fit my specific requirements?

Yes, many CNC machine suppliers offer customization options to tailor machines to your specific requirements. Customizations can include modifications to size, features, and software compatibility to align with your production processes. When discussing customization with suppliers, clearly outline your needs and expectations. Be prepared for potential additional costs and longer lead times, as custom machines often require more detailed engineering and testing. -

8. What are the best practices for maintaining CNC machines?

Regular maintenance of CNC machines is crucial to ensure longevity and optimal performance. Establish a maintenance schedule that includes routine cleaning, lubrication, and inspection of critical components. Train your staff on proper operating procedures to minimize wear and tear. Additionally, keep accurate records of maintenance activities and any repairs performed. Collaborating with the manufacturer for support and guidance on maintenance best practices can also enhance machine reliability and efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Machine Nearby Manufacturers & Suppliers List

1. Thumbtack – Top CNC Machinists

Domain: thumbtack.com

Registered: 1998 (27 years)

Introduction: Top 10 CNC Machinists near you with ratings and reviews. 1. Hoglund Design LLC – 5.0 rating, 1 hire, contact for price. 2. RLT Visualization Studio-3D Rendering Service – 5.0 rating, 58 hires, contact for price. 3. Caldreams design – 4.7 rating, $40 on-site estimate. 4. Shiraz 3d studio – 5.0 rating, free on-site estimate. 5. FrameViz architectural visualization – services include architectural 3D…

2. Rockler – CNC Machines

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: This company, Rockler – CNC Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Carbide 3D – Nomad 3 CNC Mill

Domain: shop.carbide3d.com

Registered: 2013 (12 years)

Introduction: CNC Machines – Carbide 3D offers a range of high-quality desktop CNC machines and CNC routers designed for hobbyists, professionals, woodworkers, and small businesses. Key products include: 1. Nomad 3 – Desktop CNC Mill priced at $2,800.00 2. Shapeoko 4 CNC Router starting from $1,800.00 3. Shapeoko Pro CNC Router priced at $2,400.00 4. Shapeoko 5 Pro CNC Router priced at $3,250.00 5. Shapeoko HDM…

4. CNC Machines – Used CNC Equipment

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: CNC Machines: Sell & Buy Used CNC Machines & Equipment. Over 10,000 CNC machines for sale. Popular CNC types include CNC Mill, CNC Lathe, 5 Axis Mill/Turn, Swiss, Boring Mill, 3D Printer, Laser, Waterjet, and Router. Newest Listings: HAAS VF2SSYT 2016 Vertical Mach Center (30″x20″x20″), DOOSAN LYNX 2100LMSB 2020 CNC Lathe (Chuck 8″, Bar 2″), HAAS ST15 2018 CNC Lathe (Chuck 8.3″, Bar 2.5″), HAAS VF…

5. SMART Machine Tool – Key Products

Domain: smartmachinetool.com

Registered: 2018 (7 years)

Introduction: This company, SMART Machine Tool – Key Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Openbuilds – LEAD CNC Machine 1515

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Openbuilds – LEAD CNC Machine 1515, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Genmitsu – PROVerXL 4030 CNC Router Machine

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Genmitsu – PROVerXL 4030 CNC Router Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cnc machine nearby

In navigating the landscape of CNC machines, strategic sourcing emerges as a critical lever for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By focusing on local suppliers, companies can benefit from reduced lead times, lower shipping costs, and enhanced service support. Identifying reliable vendors that offer high-quality machines, such as those from established manufacturers, allows businesses to leverage technological advancements and ensure a competitive edge.

Furthermore, the importance of engaging with suppliers who provide comprehensive after-sales support—including warranties, training, and software—cannot be overstated. These elements are vital for maximizing operational efficiency and minimizing downtime. As the demand for precision manufacturing continues to rise globally, the ability to strategically source CNC machines will play a pivotal role in driving innovation and productivity.

Looking ahead, B2B buyers are encouraged to actively seek partnerships with local manufacturers and service providers. By embracing a proactive sourcing strategy, businesses can not only enhance their manufacturing capabilities but also contribute to the growth of local economies. Take the next step in your sourcing journey—explore the robust opportunities that CNC machines nearby can provide for your operations.